Key Highlights:

- Forklift dumpsters must be made from high-quality materials to withstand heavy use in construction environments.

- Dependable equipment is crucial; failures can lead to significant costs, with incidents exceeding $200,000.

- Selecting dumpsters that meet industry standards enhances safety and operational efficiency.

- Customization options for forklift dumpsters include varying capacities, specialised dumping mechanisms, and enhanced protective features.

- Self-dumping containers improve waste disposal efficiency, allowing operators to unload materials without dismounting, saving up to 30% time.

- Pin designs offer stability while pin-less designs provide ease of use and quicker maintenance, enhancing productivity.

- Heavy-duty steel is preferred for durability in construction, outperforming aluminium in high-stakes projects.

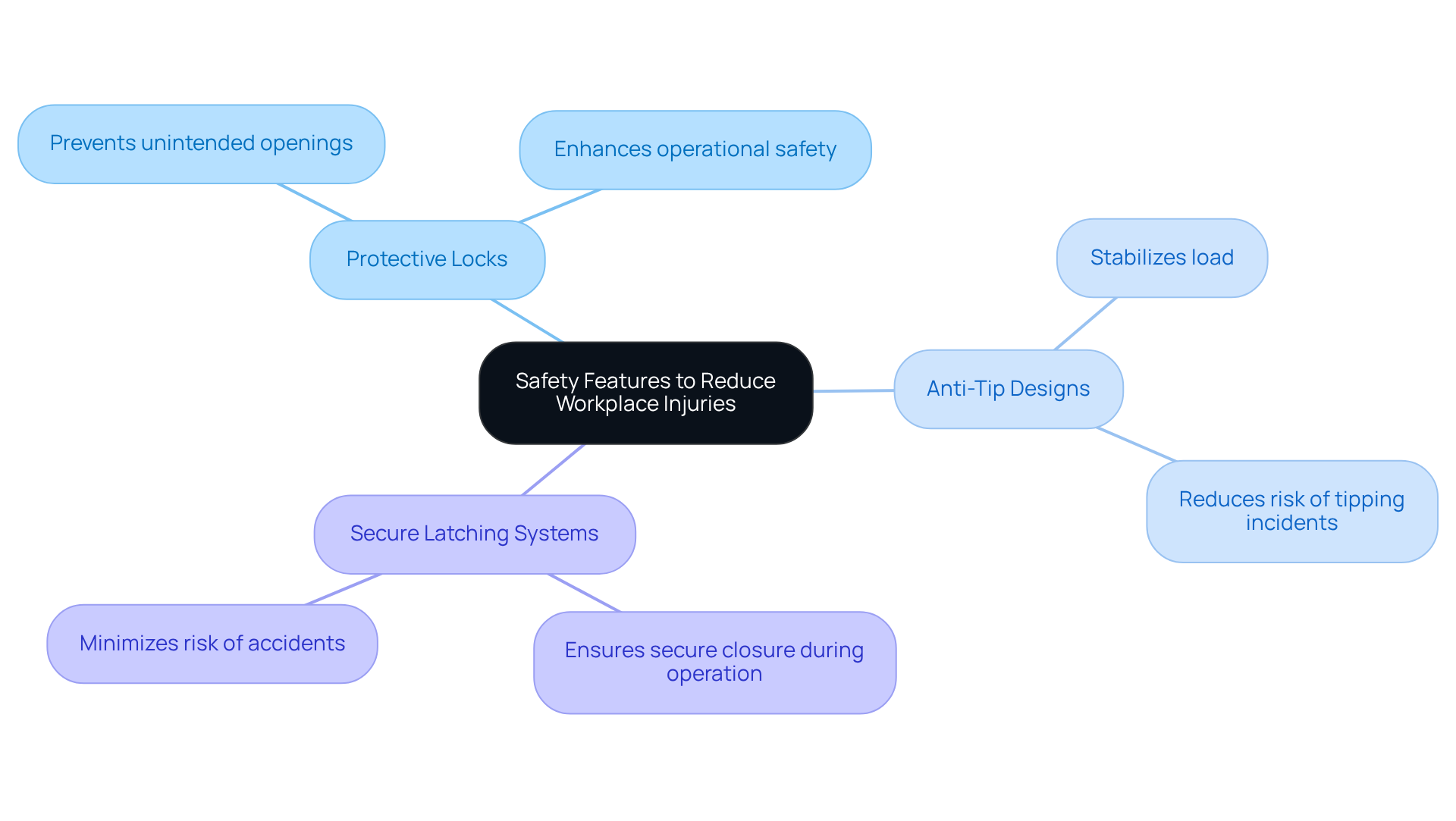

- Safety features such as protective locks and anti-tip designs are essential for reducing workplace injuries.

- Choosing reliable dumpsters from reputable manufacturers with strong warranties is vital for maintaining efficiency.

- Self-dumping hoppers are increasingly used in construction, manufacturing, and waste management, enhancing safety and productivity.

Introduction

The construction industry is continually evolving, necessitating innovative solutions that enhance efficiency and safety on job sites. Forklift dumpsters have become essential tools for project managers, providing a variety of features that streamline material handling and mitigate operational risks. With numerous options available, determining the best forklift dumpster for specific project needs can be challenging. This article explores ten critical features that define high-quality forklift dumpsters, guiding project managers in making informed decisions that significantly impact productivity and safety in their operations.

Quality and Reliability in Forklift Dumpsters

To withstand the rigors of heavy use in construction environments, forklift dumpsters must be constructed from high-quality materials. At EZ Equipment Rental, we understand that dependability is crucial; equipment failures can lead to significant delays and increased costs. For example, a major incident involving equipment can surpass $200,000 in total expenses, highlighting the importance of reliable tools.

When selecting dumpsters, prioritize those that have undergone rigorous testing and meet industry standards, ensuring they can handle the demands of your specific project. Investing in high-quality equipment not only enhances safety but also streamlines operations, ultimately facilitating timely task completion.

Furthermore, it's important to recognize that 70% of forklift incidents could have been prevented with better protective measures, highlighting the necessity of selecting high-quality forklift dumpsters from a trusted supplier like EZ Equipment Rental.

Customization for Material Handling Needs

Forklift dumpster options can be customized in size, shape, and features to meet specific project requirements. Options for customization include:

- Varying capacities

- Specialized dumping mechanisms

- Enhanced protective features such as reinforced edges and locking systems

This adaptability ensures that the forklift dumpster integrates seamlessly into your workflow, significantly improving efficiency and security on site.

Recent trends show a rising demand for tailored handling solutions, driven by the need for operational precision and safety in construction environments. Project managers have noted that forklift dumpsters not only facilitate better resource handling but also reduce labor costs and enhance overall productivity. For instance, customizable dump hoppers designed for roofing tasks utilize lightweight materials for easy transport and maneuverability, allowing for effective waste management at heights.

Moreover, EZ Equipment Rental in Dallas provides a diverse fleet of specialized forklifts, including electric and rough terrain options, ensuring you have the right equipment tailored to your needs. As the industry evolves, the integration of intelligent technology and ergonomic designs in tailored dumpsters-such as automated lifting systems and user-friendly controls-is becoming increasingly common, further streamlining handling processes.

Pin vs. Pin-less Design in Forklift Dumpsters

When considering forklift dumpsters, choosing between pin and pin-less designs can significantly influence operational efficiency. Pin designs are recognized for their stability and security during operation, making them a dependable option for heavy-duty tasks. In contrast, pin-less designs excel in ease of use and quicker maintenance, which is essential in fast-paced environments. For managers, selecting the right forklift dumpster design should be based on the operational environment and usage frequency.

Pin-less dumpsters, for example, facilitate rapid loading and unloading, thereby reducing downtime and enhancing productivity. Research indicates that these designs can boost operational efficiency by up to 30%, making them particularly appealing for frequent use. Industry experts highlight that the simplicity of pin-less designs not only streamlines operations but also minimizes the risk of injury, contributing to a safer work environment. Ultimately, understanding the specific demands of your tasks will guide you in choosing the most effective dumpster design for your handling needs.

Heavy-Duty Fabrication and Steel for Durability

Forklift dumpster units made from heavy-duty steel are designed to withstand the challenges of demanding construction environments and heavy loads. Selecting dumpsters with reinforced seams and robust construction is crucial for ensuring reliability. In 2026, durability standards for construction equipment highlight the need for materials that can endure extreme conditions, with steel being the preferred choice due to its exceptional strength and resilience. For instance, steel dumpsters have demonstrated lower failure rates under heavy loads compared to aluminum alternatives, making them ideal for high-stakes projects.

Industry professionals consistently emphasize that durability is essential. As Zig Ziglar aptly stated, 'You don't build a business. You build people, and people build the business.' This commitment to durability not only enhances operational efficiency but also promotes safety on job sites, ultimately contributing to the success of construction projects. Furthermore, the global dumping container market is projected to grow significantly, driven by the increasing demand for effective handling solutions, underscoring the importance of investing in robust equipment.

How Self-Dumping Hoppers Enhance Productivity

Self-dumping containers revolutionize the waste disposal process by allowing operators to unload materials directly into a forklift dumpster, significantly enhancing operational efficiency. This automation reduces the time spent on waste management tasks, enabling teams to focus on their core responsibilities. In construction settings, utilizing self-dumping containers can lead to time savings of up to 30%, as workers no longer need to dismount their equipment to manage waste. This efficiency is vital, particularly in large-scale projects where every minute is crucial.

Moreover, self-dumping containers are designed with features such as:

- Robust construction

- Easy connection to a forklift dumpster

- Safety systems that prevent accidental dumping

The integration of smart technology in these containers allows for real-time tracking of load weights and usage cycles, further optimizing disposal processes. Managers have noted that streamlined disposal techniques not only reduce labor costs but also enhance safety on job sites by lowering the risk of injuries associated with manual handling. With the self-dumping hopper market expected to grow at a CAGR of 5.8% from 2026 to 2033, the demand for these innovative solutions in construction and waste management is anticipated to increase, underscoring their essential role in modern material handling systems.

Guaranteed Reliability in Forklift Dumpsters

Choosing forklift dumpsters from reputable manufacturers that offer strong warranties is crucial for maintaining efficiency. Reliable equipment significantly lowers the chances of breakdowns, which can disrupt schedules and increase costs. For example, contractors have reported completing tasks ahead of schedule thanks to the uninterrupted service provided by dependable equipment. A single excavator or loader that remains idle for just half a day can result in thousands of dollars lost in labor and missed production.

Investing in high-quality dumpsters not only boosts operational efficiency but also leads to considerable cost savings by reducing downtime and preventing unexpected repair expenses. As highlighted by industry leaders like Hillview Equipment:

- "Contractors who operate reliable machines with solid service support experience fewer interruptions and more consistent production."

A robust warranty is essential; it serves as a safeguard against unforeseen issues, ensuring that equipment remains operational and efficient throughout its lifecycle. Furthermore, many warranties are transferable to new owners, enhancing the forklift's value. Ultimately, selecting reliable forklift dumpsters is a strategic choice that can greatly affect the success of construction projects.

Top Industries Using Self-Dumping Hoppers

Self-dumping containers play a crucial role in construction, manufacturing, waste management, and recycling industries, significantly enhancing material handling processes. By allowing operators to empty contents without direct contact, these containers improve workplace safety and efficiency. Companies utilizing self-dumping containers have reported notable productivity increases, with teams saving valuable time previously spent on waste management. For instance, if a team dedicates over 15 minutes daily to waste management, transitioning to self-dumping containers can yield immediate time and cost benefits.

Case studies indicate that organizations employing self-dumping containers experience reduced labor costs and heightened output. In construction settings, these containers are strategically placed next to waste-generating workstations, facilitating a single handling of waste material. This arrangement minimizes the time employees invest in waste removal, enabling them to concentrate on more productive tasks.

Industry leaders underscore the advantages of self-dumping containers. Justin Oberholtzer, CEO of Creekside Manufacturing, noted that these containers allow teams to manage waste only once, freeing up time for revenue-generating activities. The integration of self-dumping containers not only streamlines operations but also enhances safety by reducing the risks associated with manual loading and unloading.

As the self-dumping hopper market continues to expand, projected to achieve a compound annual growth rate of 5.3% from 2026 to 2033, the demand for these efficient material handling solutions is anticipated to rise. Their versatility and customization options render them suitable for various job sites, further solidifying their position as an essential tool in the construction and manufacturing sectors.

Safety Features to Reduce Workplace Injuries

When selecting forklift dumpster models, it is essential to prioritize features such as:

- Protective locks

- Anti-tip designs

- Secure latching systems

These advanced features play a crucial role in preventing accidents and ensuring that operators can perform their tasks safely and efficiently. For instance, secure locks help prevent unintended openings during operation, while anti-tip designs stabilize the load, significantly reducing the risk of tipping incidents. Protection experts indicate that implementing such features can lead to a notable reduction in workplace injuries. Comprehensive protection programs that incorporate these design elements have demonstrated a decrease in accident rates within material handling environments.

In 2021, there were 7,290 injuries involving forklifts, underscoring the urgent need for enhanced protection measures. By investing in dumpsters equipped with these protective enhancements, project managers can foster a more secure work environment, ultimately improving operational efficiency and employee morale.

As the Occupational Safety & Health Administration (OSHA) states, 'If companies implemented more stringent training policies, the Occupational Safety & Health Administration (OSHA) estimates that about 70% of forklift accidents in the US could be prevented.' This highlights the importance of prioritizing protective features in forklift dumpster designs.

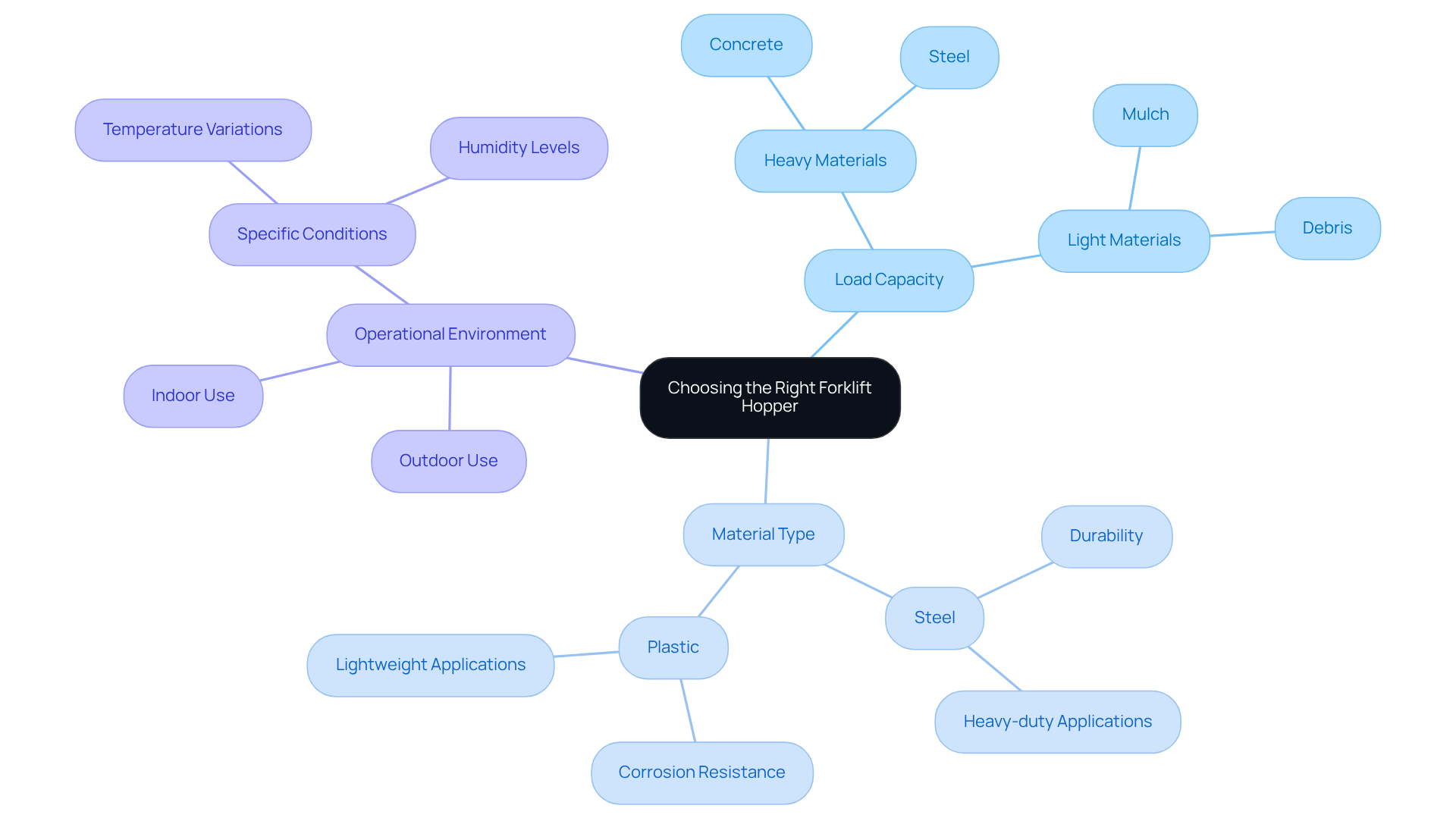

Choosing the Right Forklift Hopper for Your Needs

When selecting a forklift dumpster, it's essential to consider several key factors, including load capacity, material type, and the operational environment. Load capacity is critical; containers must handle the weight of the goods being transported without compromising safety or efficiency. For instance, containers designed for heavy construction materials like concrete require a higher load capacity than those used for lighter items such as mulch or debris.

The type of material also significantly influences container selection. Different materials, such as steel or plastic, offer varying levels of durability and corrosion resistance, impacting the container's lifespan and efficiency in specific environments. Steel containers are often preferred for heavy-duty applications due to their robustness, while plastic bins may be suitable for lighter, less abrasive materials.

Recent trends indicate a growing use of specialized containers tailored for specific materials, enhancing resource handling efficiency. Successful projects demonstrate that customized container solutions can markedly improve workflow and reduce downtime. For example, a construction company that implemented tailored containers for various material types reported a 30% increase in operational efficiency.

As a leading provider of quality forklift rentals in the Dallas-Fort Worth area, EZ Equipment Rental offers a diverse fleet of well-maintained forklifts, including specialized forklift dumpsters, ensuring clients find the ideal fit for their specific needs. Industry experts stress the importance of these considerations. One professional noted, "Selecting the appropriate container is not just about capacity; it's about aligning the container with the specific requirements of the task." This perspective underscores the necessity for managers to thoroughly assess their specific needs, ensuring that the chosen container effectively supports their operational objectives.

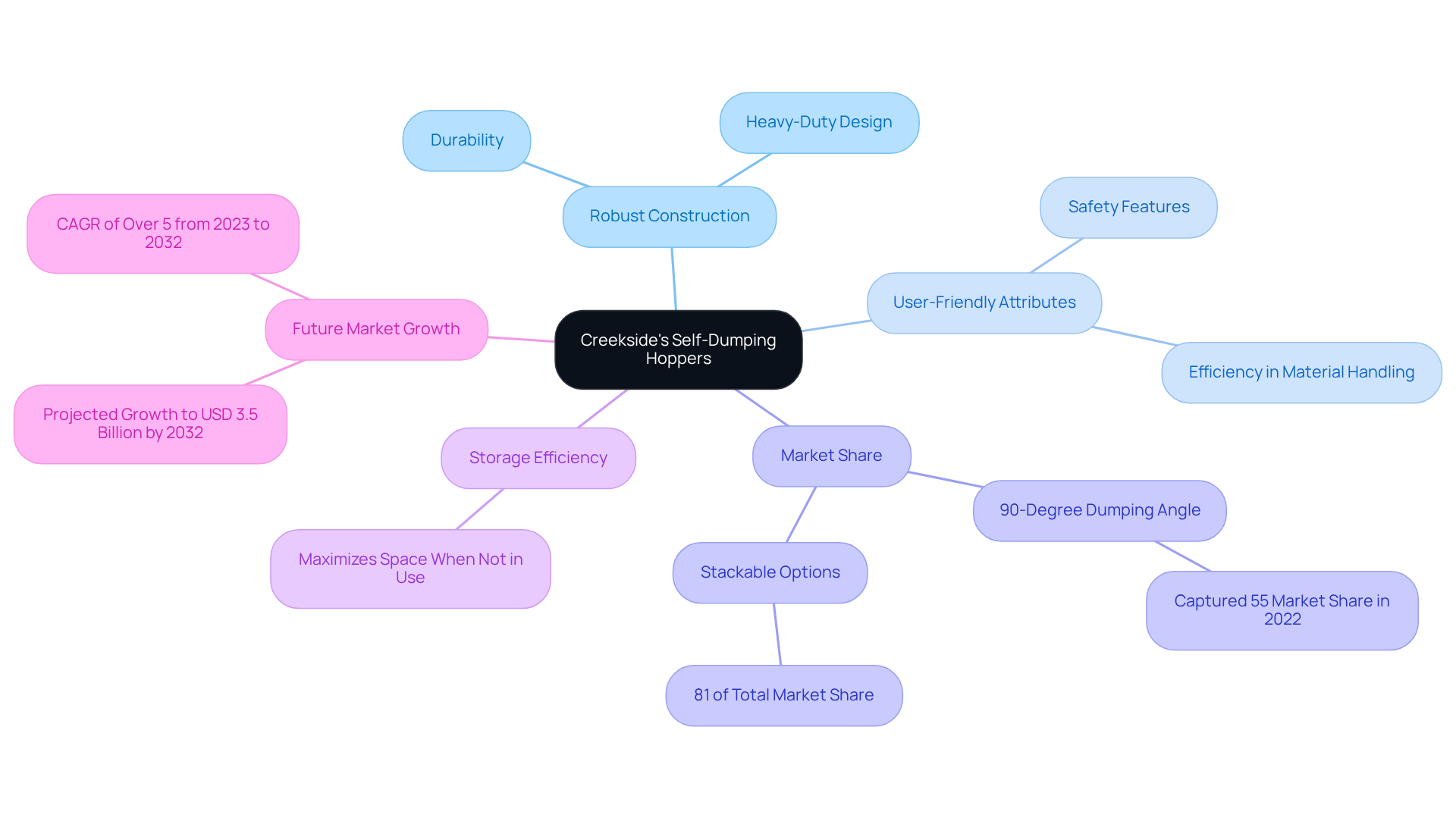

Why Creekside's Self-Dumping Hoppers Are the Best Choice

Creekside's self-dumping containers stand out due to their robust construction and innovative design, specifically crafted to meet the rigorous demands of project managers. These containers feature user-friendly attributes that prioritize safety and efficiency, making them a top choice for enhancing operational workflows and minimizing workplace injuries.

Project managers frequently express high satisfaction levels, highlighting the durability and reliability of Creekside's containers as pivotal in their decision-making process. The 90-degree dumping angle, which captured approximately 55% of the market share in 2022, streamlines material handling, while the stackable options maximize storage efficiency when not in use.

Furthermore, the incorporation of advanced manufacturing technologies is expected to propel the self-dumping containers market to USD 3.5 billion by 2032, ensuring that Creekside's products remain aligned with industry standards and provide a competitive advantage. As a result, project managers increasingly opt for Creekside's forklift dumpster solutions, recognizing the performance and security benefits they offer.

Industry experts emphasize that these features not only boost operational efficiency but also significantly enhance workplace safety, solidifying Creekside's position as a leader in the self-dumping hopper market.

Conclusion

Selecting the right forklift dumpster is a crucial decision for project managers focused on enhancing operational efficiency and safety on construction sites. Prioritizing quality, customization, and reliable designs ensures that the selected equipment meets the unique demands of various projects. High-quality materials and advanced safety features not only minimize the risk of accidents but also streamline waste management processes, leading to significant time and cost savings.

Key features such as:

- Durability

- Customization options

- Choice between pin and pin-less designs

are critical in maximizing productivity. The benefits of self-dumping hoppers further illustrate how innovative solutions can improve material handling, making operations smoother and more efficient. By investing in dependable and tailored forklift dumpsters, project managers can reduce risks associated with equipment failures and enhance overall workflow on job sites.

In summary, the significance of selecting the right forklift dumpster cannot be overstated. As the industry evolves, embracing high-quality, customizable, and safe equipment will be essential for maintaining a competitive edge and ensuring successful project outcomes. Project managers should prioritize these features in their equipment selection process, fostering a safer and more productive work environment.

Frequently Asked Questions

What materials are forklift dumpsters made from, and why is quality important?

Forklift dumpsters must be constructed from high-quality materials to withstand heavy use in construction environments. Quality is crucial because equipment failures can lead to significant delays and increased costs, sometimes exceeding $200,000 in total expenses.

How can I ensure that a forklift dumpster meets my project requirements?

When selecting dumpsters, prioritize those that have undergone rigorous testing and meet industry standards. This ensures they can handle the demands of your specific project.

What percentage of forklift incidents could be prevented with better protective measures?

Research indicates that 70% of forklift incidents could have been prevented with better protective measures, underscoring the importance of selecting high-quality forklifts from trusted suppliers.

Can forklift dumpsters be customized for specific needs?

Yes, forklift dumpsters can be customized in size, shape, and features to meet specific project requirements, including varying capacities, specialized dumping mechanisms, and enhanced protective features.

What are the benefits of customizing forklift dumpsters?

Customizing forklift dumpsters improves efficiency and security on site, facilitates better resource handling, reduces labor costs, and enhances overall productivity.

What types of forklifts does EZ Equipment Rental offer?

EZ Equipment Rental provides a diverse fleet of specialized forklifts, including electric and rough terrain options, tailored to meet various material handling needs.

What is the difference between pin and pin-less designs in forklift dumpsters?

Pin designs are known for their stability and security during operation, making them suitable for heavy-duty tasks. Pin-less designs excel in ease of use and quicker maintenance, which is beneficial in fast-paced environments.

How do pin-less designs improve operational efficiency?

Pin-less dumpsters facilitate rapid loading and unloading, reducing downtime and enhancing productivity. Research shows that these designs can boost operational efficiency by up to 30%.

What factors should I consider when choosing a forklift dumpster design?

When choosing a forklift dumpster design, consider the operational environment, usage frequency, and specific demands of your tasks to select the most effective option for your handling needs.

List of Sources

- Quality and Reliability in Forklift Dumpsters

- 9 Surprising Forklift Statistics - Forklift Certifcation (https://forkliftcertification.com/9-surprising-forklift-statistics?srsltid=AfmBOorYuRMibQHOC3-8OuRaTb2qLCUzyPsrXHgVwzUNlCULcVUkQDJR)

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- Get Motivated with 20 Classic Quotes About Construction (https://planhub.com/resources/get-motivated-with-20-classic-quotes-about-construction)

- 119 Construction Quotes that Hit the Nail on the Head | BigRentz (https://bigrentz.com/blog/construction-quotes?srsltid=AfmBOopYat8FOUNcyfq-gFIqIyEFGjBJ6Dt-itDLnvDikswlO8_0NpjA)

- Customization for Material Handling Needs

- Dumping Hopper Market Size, Share and Analysis | Trends – 2032 (https://skyquestt.com/report/dumping-hopper-market)

- Self-Dumping Hopper Market Size, Growth & Forecast Analysis by 2032 (https://straitsresearch.com/report/self-dumping-hopper-market)

- Dumping Hopper Market to Reach $4.25 Billion by 2035, Growing at 6.7% CAGR | Fact.MR Report (https://globenewswire.com/news-release/2025/02/18/3027717/0/en/Dumping-Hopper-Market-to-Reach-4-25-Billion-by-2035-Growing-at-6-7-CAGR-Fact-MR-Report.html)

- Dumping Hopper Market Size, Share & Forecast - 2035 (https://factmr.com/report/dumping-hopper-market)

- The Importance of Investing in a Customizable Dumping Hopper (https://boxhaul.com/customizing-dump-hoppers)

- Pin vs. Pin-less Design in Forklift Dumpsters

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- Dumping Hopper Market Size, Share & Forecast - 2035 (https://factmr.com/report/dumping-hopper-market)

- 6 Things to Consider When Picking The Best Forklift Dumpster - Creekside Manufacturing (https://creeksidemanufacturing.com/blog/6-things-to-consider-when-picking-the-best-forklift-dumpster)

- The Features That Make The Best Forklift Dumpsters Stand Out - Creekside Manufacturing (https://creeksidemanufacturing.com/blog/best-forklift-dumpster)

- Heavy-Duty Fabrication and Steel for Durability

- 15 of the Most Inspiring Quotes about Construction - Digital Builder (https://autodesk.com/blogs/construction/inspiring-construction-quotes)

- The Advantages of Steel Dump Bodies: Cost, Durability, and Heavy-Duty Jobs - Evolution Welding Fabrication (https://evolutionweldings.com/the-advantages-of-steel-dump-bodies-cost-durability-and-heavy-duty-jobs)

- 40 Construction Quotes to Motivate Your Team (https://projectmanager.com/blog/construction-quotes)

- Dumping Hopper Market Size, Share and Analysis | Trends – 2032 (https://skyquestt.com/report/dumping-hopper-market)

- Get Motivated with 20 Classic Quotes About Construction (https://planhub.com/resources/get-motivated-with-20-classic-quotes-about-construction)

- How Self-Dumping Hoppers Enhance Productivity

- Self-Dumping Hopper Market Size, Growth & Forecast Analysis by 2032 (https://straitsresearch.com/report/self-dumping-hopper-market)

- Self Dumping Hopper Market Analysis 2026, Market Size, Share, Growth, CAGR, Forecast, Trends, Revenue, Industry Experts, Consultation, Online/Offline Surveys, Syndicate Reports (https://cognitivemarketresearch.com/self-dumping-hopper-market-report)

- Dumping Hopper Market Size, Share and Analysis | Trends – 2032 (https://skyquestt.com/report/dumping-hopper-market)

- Dumping Hopper Market Size & Share | Growth Forecasts 2032 (https://gminsights.com/industry-analysis/dumping-hopper-market)

- Navigating Self-Dumping Hopper Market Growth: 5.3% CAGR and Key Trends by 2033 (https://linkedin.com/pulse/navigating-self-dumping-hopper-market-growth-53-cagr-liphe)

- Guaranteed Reliability in Forklift Dumpsters

- How Smart Equipment Choices Keep Construction Projects on Schedule | Contractors Hot Line (https://contractorshotline.com/article/how-smart-equipment-choices-keep-construction-projects-on-schedule)

- Forklift Warranties Explained: What to Look For Before You Buy (https://forkliftselect.com/blogs/news/forklift-warranties-explained-what-to-look-for-before-you-buy)

- Worldwide Heavy Equipment Warranty Report: (https://warrantyweek.com/archive/ww20251127.html)

- The Key to Reliable Construction Equipment (https://southweststeelprocessing.com/news/the-key-to-reliable-construction-equipment)

- Forklift Warranties: What Is and Isn’t Included (https://lillyforklifts.com/blog/what-is-and-isnt-included-in-forklift-warranty)

- Top Industries Using Self-Dumping Hoppers

- Self-Dumping Hopper Market Size, Growth & Forecast Analysis by 2032 (https://straitsresearch.com/report/self-dumping-hopper-market)

- Self Dumping Hopper Market Analysis 2026, Market Size, Share, Growth, CAGR, Forecast, Trends, Revenue, Industry Experts, Consultation, Online/Offline Surveys, Syndicate Reports (https://cognitivemarketresearch.com/self-dumping-hopper-market-report)

- Navigating Self-Dumping Hopper Market Growth: 5.3% CAGR and Key Trends by 2033 (https://linkedin.com/pulse/navigating-self-dumping-hopper-market-growth-53-cagr-liphe)

- Exploring the Dynamics of Self-dumping Hoppers: Key Insights and Trends for 2033 (https://linkedin.com/pulse/exploring-dynamics-self-dumping-hoppers-key-insights-np0ef)

- The Benefits of Using a Self-Dumping Hopper - Creekside Manufacturing (https://creeksidemanufacturing.com/blog/the-benefits-of-using-a-self-dumping-hopper)

- Safety Features to Reduce Workplace Injuries

- National Forklift Safety Day Statistics │ MHEDA (https://mheda.org/journal/national-forklift-safety-day-statistics)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Work Safety: Forklifts - Injury Facts (https://injuryfacts.nsc.org/work/safety-topics/forklifts)

- 25 Inspiring Workplace Safety Quotes for Safer Workspaces (https://yodeck.com/use-cases/workplace-safety-quotes)

- Top 100 Inspirational Workplace Safety Quotes (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- Choosing the Right Forklift Hopper for Your Needs

- 100 Leadership Quotes About Employee Engagement | Azim Khamisa (https://azimkhamisa.com/leadership-quotes-employee-engagement)

- 100 Best Quotes On Leadership (https://forbes.com/sites/kevinkruse/2012/10/16/quotes-on-leadership)

- Words to Live & Work By: The C-Suite's Favorite Leadership Quotes (https://shrm.org/executive-network/insights/words-to-live-work-c-suites-favorite-leadership-quotes)

- 35 Leadership Quotes to Inspire You (https://businessnewsdaily.com/7481-leadership-quotes.html)

- Why Creekside's Self-Dumping Hoppers Are the Best Choice

- Dumping Hopper Market Size & Share | Growth Forecasts 2032 (https://gminsights.com/industry-analysis/dumping-hopper-market)

- U.S Self-Dumping Hopper Market Size, Trends, Share to 2023 (https://straitsresearch.com/report/us-self-dumping-hopper-market)

- Dumping Hopper Market to Reach $4.25 Billion by 2035, Growing at 6.7% CAGR | Fact.MR Report (https://globenewswire.com/news-release/2025/02/18/3027717/0/en/Dumping-Hopper-Market-to-Reach-4-25-Billion-by-2035-Growing-at-6-7-CAGR-Fact-MR-Report.html)

- Navigating Self-Dumping Hopper Market Growth: 5.3% CAGR and Key Trends by 2033 (https://linkedin.com/pulse/navigating-self-dumping-hopper-market-growth-53-cagr-liphe)

- Self-Dumping Hopper Market Size, Growth & Forecast Analysis by 2032 (https://straitsresearch.com/report/self-dumping-hopper-market)