Key Highlights:

- The Emergency Stop Signal, indicated by crossing arms, instructs forklift operators to stop immediately, preventing accidents.

- Training on emergency stop signals is lacking, with few operators receiving comprehensive instruction, highlighting a need for specialised training programmes.

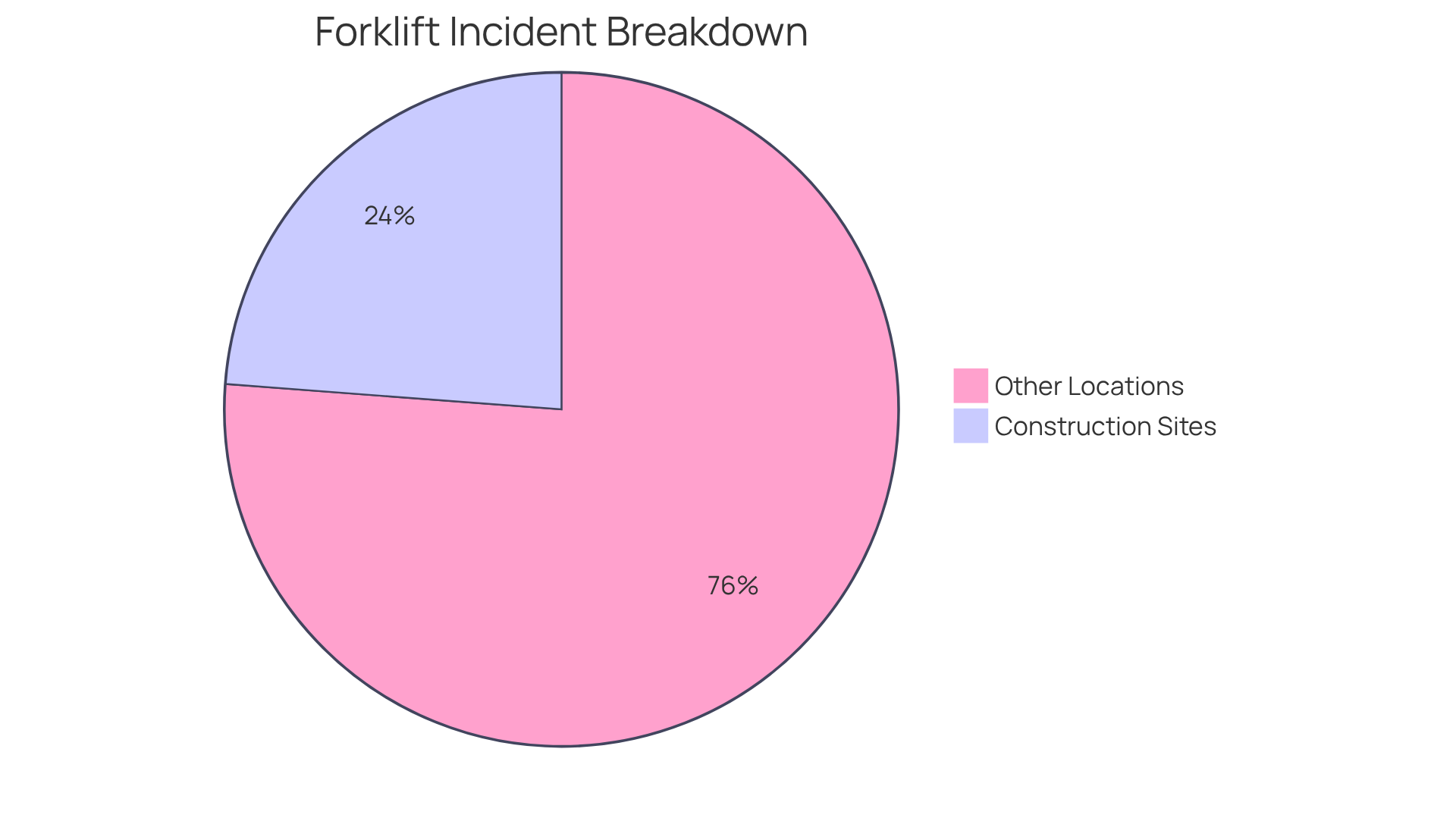

- Approximately 23.8% of lift truck incidents occur on construction sites, underscoring the importance of emergency stop training.

- The Dog Everything Signal, indicated by clasping hands, directs operators to halt movements, fostering a culture of safety in busy environments.

- About 55% of construction workers feel they need more safety training, indicating a gap in effective communication and safety practises.

- The Raise Tines Signal ensures safe elevation of loads, with proper execution reducing the risk of incidents related to cargo stability.

- Lift truck overturning accounts for 25% of incidents, emphasising the importance of correct height management.

- The Lower Tines Signal directs operators to lower tines safely, with proper positioning critical to prevent serious accidents.

- Around 20% of lift truck incidents involve pedestrians, highlighting the need for careful load handling.

- The Tilt Mast Forward Signal is crucial for secure load placement, with improper mast positioning leading to many accidents.

- Training can reduce forklift accidents by up to 70%, emphasising the need for ongoing education.

- The Tilt Mast Back Signal secures cargo stability during transport, with OSHA mandating pre-shift inspections for safety.

- The Move Tines Left or Right Signal helps manage weight distribution, crucial for preventing tip-overs.

- The Raise/Lower Slowly Signal directs gradual height adjustments, enhancing load handling safety and operational efficiency.

- The Honk the Horn Signal alerts others to the forklift's presence, significantly reducing accident risks.

- The forklift hand signals chart standardises communication, reducing accident risk by up to 30% in workplaces that implement it.

Introduction

Effective communication stands as a cornerstone in the dynamic realm of forklift operations, where even a single miscommunication can result in severe accidents. This article explores the essential hand signals that every forklift operator must master to bolster workplace safety and efficiency. By examining the importance of signals such as the Emergency Stop and Dog Everything, readers will discover how these straightforward gestures can significantly mitigate the risk of incidents on job sites.

What are the consequences when these vital signals are neglected? Organizations must ensure their teams receive the necessary training to avert costly mistakes. By prioritizing effective communication and proper training, companies can foster a safer work environment, ultimately enhancing productivity and reducing liability.

Emergency Stop Signal

The Emergency Stop Signal, indicated by crossing both arms in front of the chest, serves as a vital directive for forklift operators, instructing them to halt all operations immediately. This alert is essential for preventing incidents in hazardous situations, safeguarding both the operator and nearby personnel. In construction environments, where the risk of accidents is heightened, the effectiveness of this alert is evident in real-world scenarios where quick recognition has prevented potential injuries.

Experts emphasize that comprehensive training in emergency stop signals is crucial. However, data reveals that only a small percentage of lift truck operators receive thorough instruction in this area. To enhance safety, organizations must implement specialized training programs that focus on recognizing and responding to emergency stop cues. This ensures operators can act swiftly and decisively during critical moments.

Moreover, with approximately 23.8% of lift truck incidents occurring on construction sites, the importance of this alert cannot be overstated. Investing in training can significantly mitigate the risk of accidents, as proper education can reduce forklift incidents by up to 70%. By prioritizing training and awareness, companies can foster a safer work environment and protect their workforce.

Dog Everything Signal

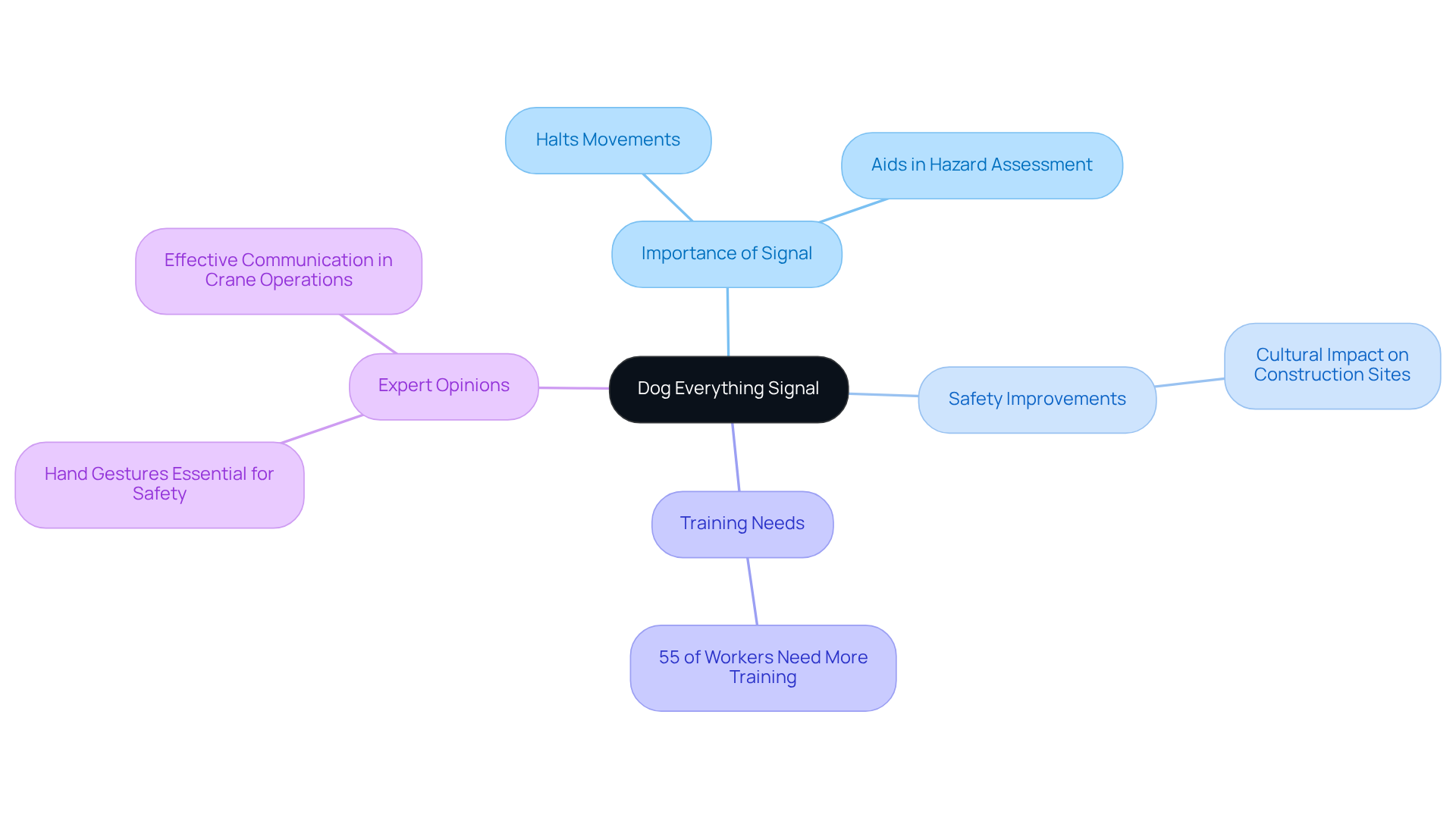

The Dog Everything Signal, indicated by clasping both hands in front of the body, is a vital command for operators to halt all movements. This alert is crucial in bustling work environments, where unexpected situations can emerge, enabling teams to effectively assess potential hazards. By adopting this signal, construction sites can see significant safety improvements, fostering a culture of caution and awareness.

Notably, around 55% of construction workers feel they require additional safety training, underscoring the persistent need for effective communication and safety practices. Experts from Eagle West Crane & Rigging assert that hand gestures, detailed in the forklift hand signals chart, are essential for safe operations, stating, 'Hand gestures form an essential component of safe crane operations.'

Prioritizing the Dog Everything Signal empowers construction teams to cultivate a safer work environment, ultimately minimizing the risk of incidents and injuries.

Raise Tines Signal

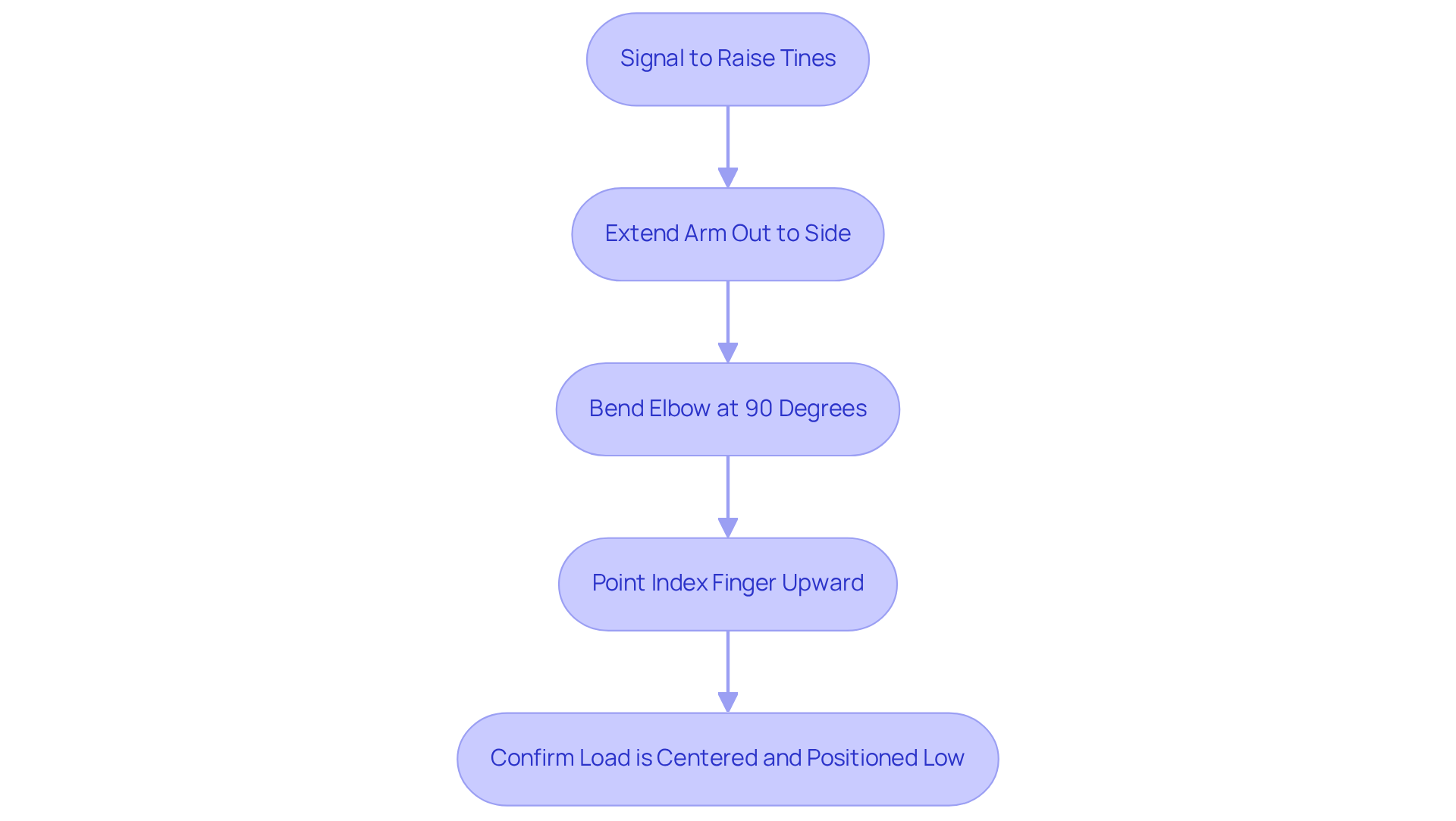

To signal the operator to raise the tines, use the forklift hand signals chart by extending one arm out to the side, bending the elbow at a 90-degree angle with the index finger pointing upward. This signal is crucial for safely elevating items to the desired height, ensuring that the weight remains stable before any movement. Notably, lift truck overturning accounts for 25% of all lift truck incidents, highlighting the importance of effective height management for cargo.

According to the forklift hand signals chart, best practices for utilizing the Raise Tines Signal include confirming that the load is centered and positioned low, which helps sustain the vehicle's center of gravity - an essential factor in preventing tip-overs. Real-world examples demonstrate that adhering to this signal can significantly reduce the risk of incidents. As noted by CertifyMe: "While lift truck accidents can never be entirely eradicated, most incidents are avoidable through strict compliance with safety standards and continuous training." This statement underscores the critical nature of raising tines safely in construction environments, where the stakes are high and proper lifting techniques can make all the difference in maintaining a safe worksite.

Lower Tines Signal

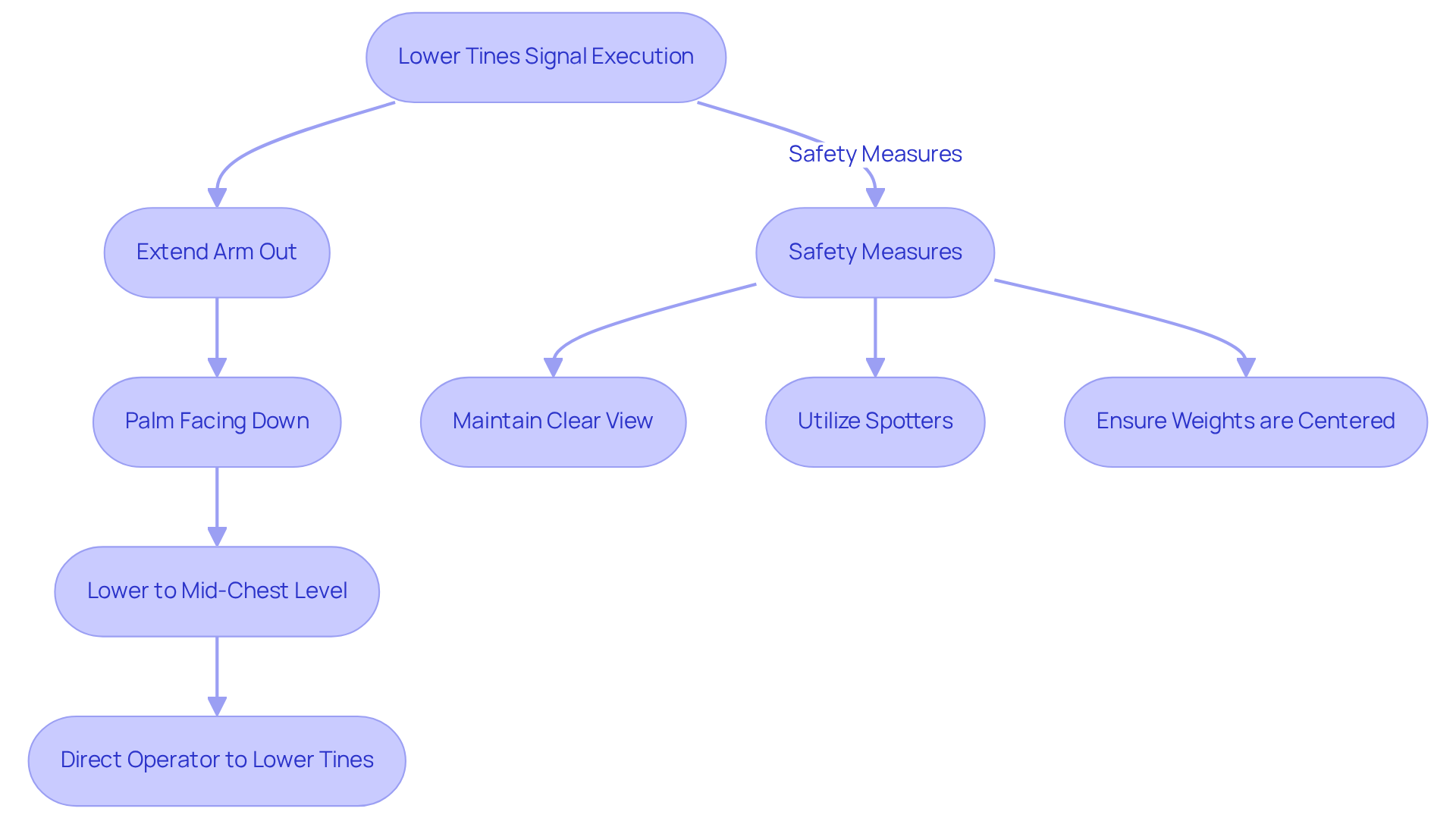

The Lower Tines Signal is essential for ensuring safe operations of utility vehicles. This signal is executed by extending one arm out to the side, palm facing down, and lowering it to mid-chest level. It directs the operator to lower the tines with care, ensuring that the weight is positioned safely and accurately. Proper cargo positioning is critical; mishandling can lead to serious incidents, with approximately 20% of lift truck incidents involving pedestrians, contributing to 36% of lift truck-related fatalities. Furthermore, forklift accidents result in 8,000 to 9,000 injuries serious enough to require days away from work (DAFW), underscoring the broader implications of these incidents on workplace safety.

To effectively reduce risks, operators should:

- Maintain a clear view of the area.

- Utilize spotters when visibility is limited.

- Ensure that weights are centered and secured to prevent shifting.

Construction safety expert Luis Batongbakal emphasizes that accurate load placement not only protects workers but also enhances overall site safety, significantly reducing the risk of injuries and fatalities. Additionally, regular vehicle maintenance is crucial to prevent breakdowns and safety issues, as neglecting maintenance is a common cause of accidents.

By adhering to the Lower Tines Signal and following the forklift hand signals chart along with these best practices, operators can significantly mitigate the risks associated with forklift operations. Prioritizing safety not only protects workers but also fosters a culture of reliability and quality in the workplace.

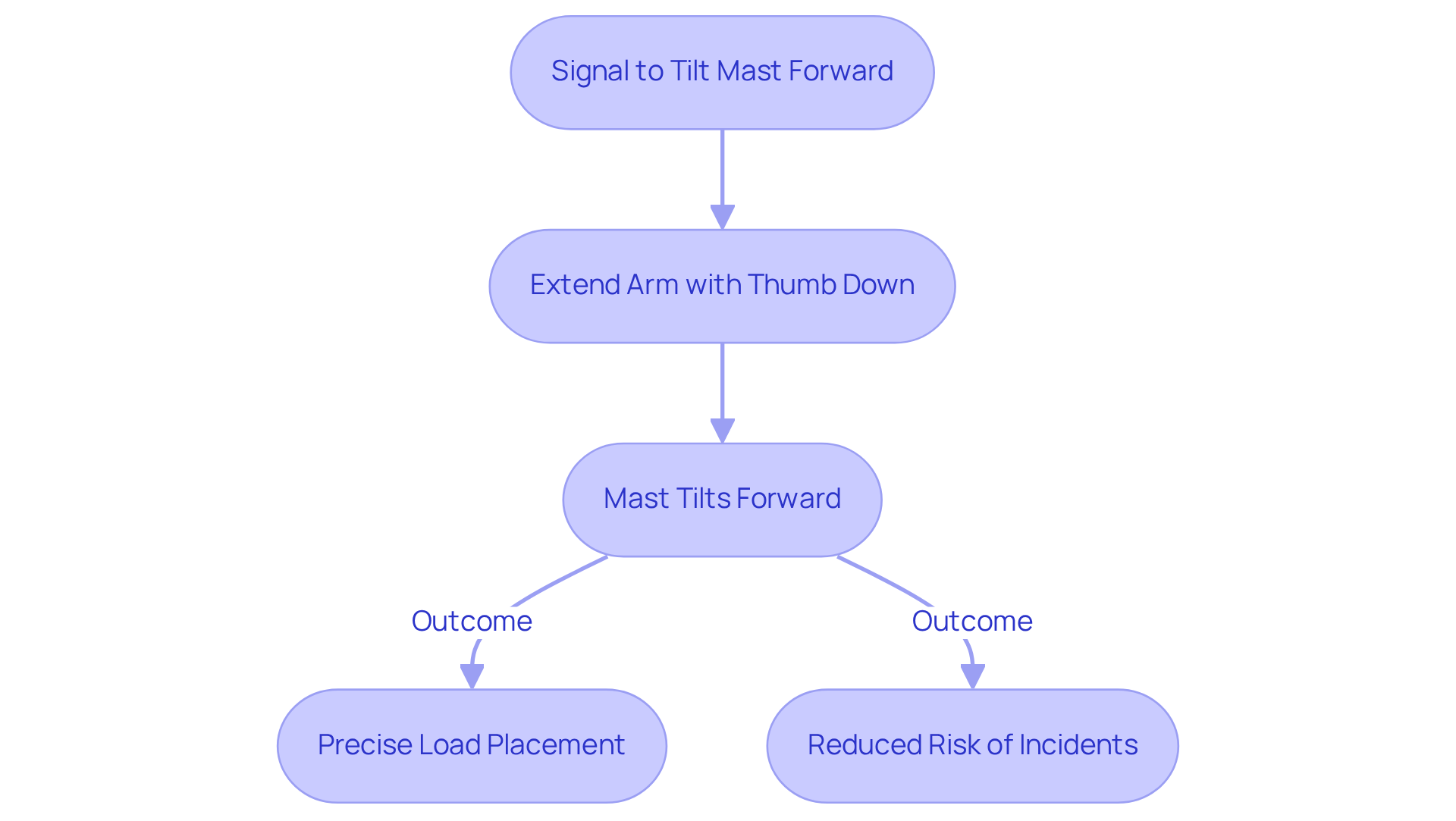

Tilt Mast Forward Signal

To signal the operator to tilt the mast forward, extend one arm out to the side with the thumb pointing down. This clear indication is vital when the operator needs to bring the mast closer to the ground, allowing for precise and secure placement of the load. Incorrect mast placement can lead to serious incidents; research indicates that nearly 20% of lift truck mishaps involve pedestrians, often due to insufficient operator training and poor cargo handling.

Precise load positioning is essential. For instance, effectively utilizing the tilt mast forward indicator can prevent loads from tipping or falling, a common cause of workplace injuries. Real-world examples demonstrate that operators who consistently use this signal report fewer load-related incidents, underscoring the importance of effective communication and adherence to safety protocols in lifting operations.

Moreover, proper training can reduce forklift accidents by up to 70%. This statistic highlights the critical need for ongoing education and safety meetings to reinforce these best practices. By prioritizing training and communication, we can significantly enhance safety in the workplace.

Tilt Mast Back Signal

The Tilt Mast Back Signal plays a vital role in ensuring weight stability during transport. By extending one arm out to the side with the thumb pointing up, the operator is instructed to tilt the mast backward. This simple yet effective action secures the cargo against the backrest, significantly lowering the risk of accidents that can arise from improper mast tilt. In fact, improper mast positioning is a leading cause of forklift-related incidents, contributing to thousands of injuries each year. For instance, in 2021, there were 7,290 injuries linked to lift truck operations, and this number was even higher in 2018, reaching 7,940. Such statistics underscore the critical need for effective communication and strict adherence to the forklift hand signals chart for safety protocols.

Safety experts emphasize that 'securing cargo correctly not only enhances stability but also protects operators and pedestrians.' Furthermore, OSHA mandates pre-shift inspections to ensure that forklifts are safe to operate, which is essential for maintaining load stability and overall operational safety. By effectively utilizing the Tilt Mast Back Signal, operators can ensure safer transport of materials, thereby minimizing the potential for accidents and enhancing operational efficiency.

In summary, the importance of the Tilt Mast Back Signal cannot be overstated. The forklift hand signals chart is a key component in the safe operation of forklifts, and understanding its proper use is crucial for anyone involved in lift truck operations. Prioritizing safety not only protects individuals but also contributes to a more efficient workplace.

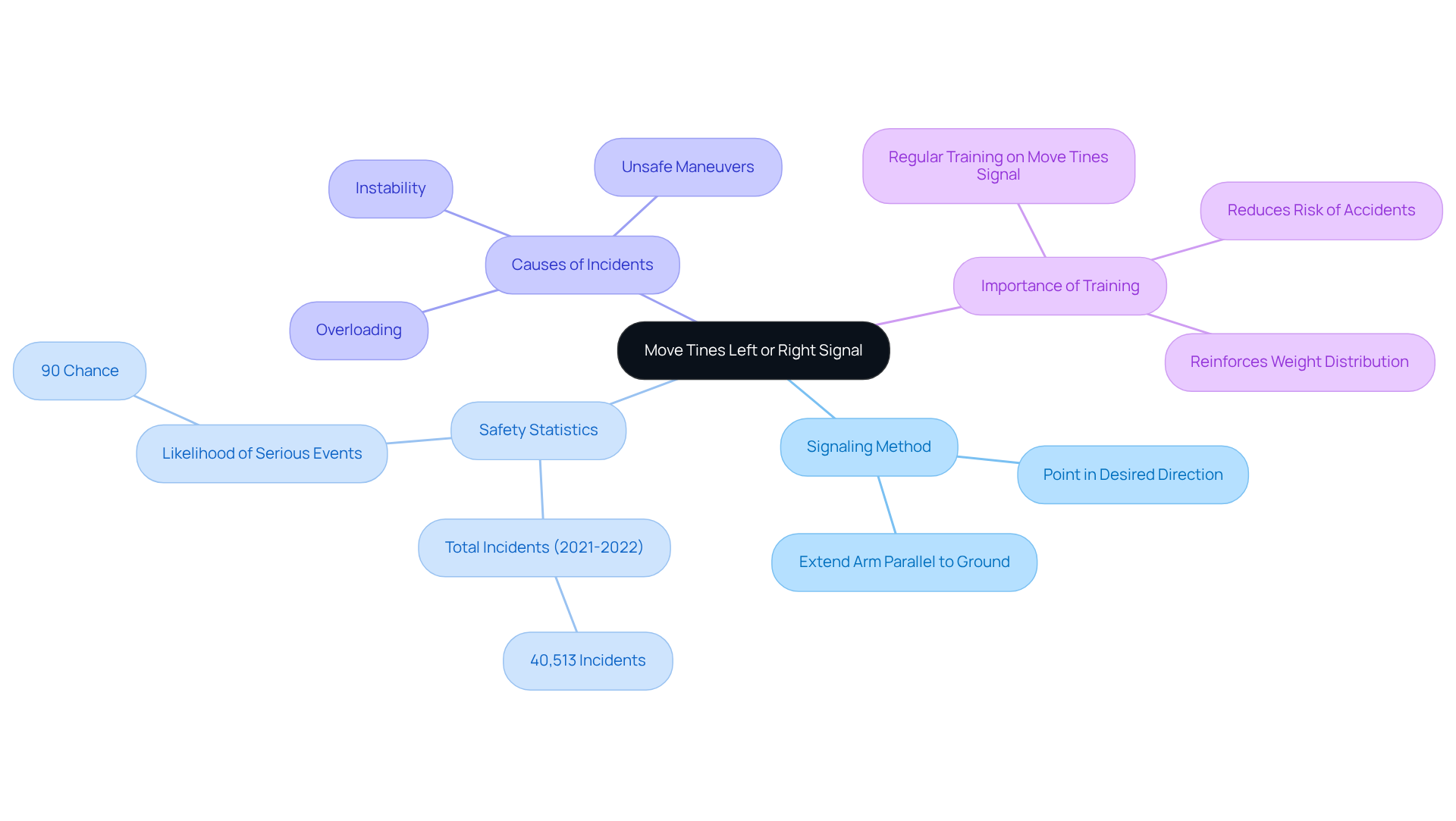

Move Tines Left or Right Signal

To effectively signal the operator to move the tines left or right, extend one arm out to the side, parallel to the ground, and point in the desired direction. This crucial signal modifies the tines' position, ensuring that weights are balanced and managed safely. In fact, statistics reveal that there were 40,513 incidents related to lift trucks reported in 2021-2022, with these vehicles having a staggering 90% likelihood of being involved in a serious event during their service life. For instance, a recorded incident involved a warehouse employee who was trapped by a toppled lifting vehicle after attempting a sharp turn on an uneven dock, underscoring the dangers associated with unsteady cargo.

Tip-overs caused by instability, overloading, or unsafe maneuvers rank highest among severe forklift incidents, highlighting the critical need for operators to prioritize weight distribution. Regular training on the Move Tines Signal, based on the forklift hand signals chart, is essential, as it reinforces the importance of maintaining balanced weight, ultimately reducing the risk of accidents and enhancing workplace safety. Successful safety management demands commitment from leadership and active engagement from operators, making it imperative for organizations to cultivate a robust culture of safety.

Raise/Lower Slowly Signal

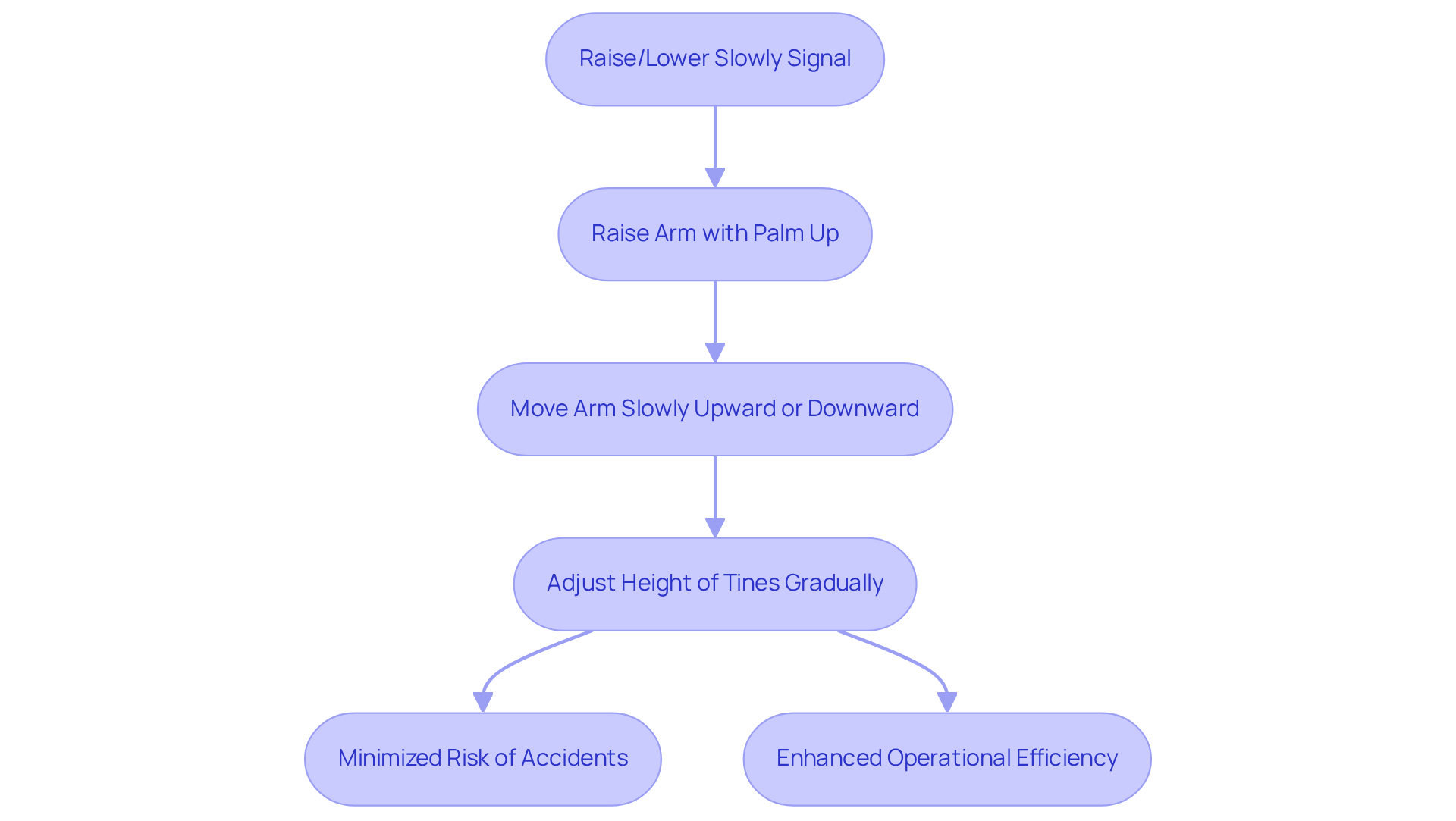

Raise/Lower Slowly Signal: Precision in Action

The Raise/Lower Slowly Signal is a crucial indicator in equipment operation, signaled by raising one arm with the palm facing up and moving it in a deliberate, slow upward or downward motion. This clear indication directs the operator to adjust the height of the tines gradually, ensuring that loads are handled with utmost care and precision.

By utilizing this signal, operators can effectively manage the height of their equipment, minimizing the risk of accidents and ensuring safety on the job site. The gradual adjustment not only protects the integrity of the load but also enhances overall operational efficiency. In addition, this practice fosters a culture of safety and reliability, which is paramount in the equipment rental industry.

Incorporating the Raise/Lower Slowly Signal into your operations is a step towards achieving excellence in equipment handling. It reflects a commitment to quality and safety that resonates with our clients. For those looking to elevate their operational standards, adopting this signal is a straightforward yet impactful decision.

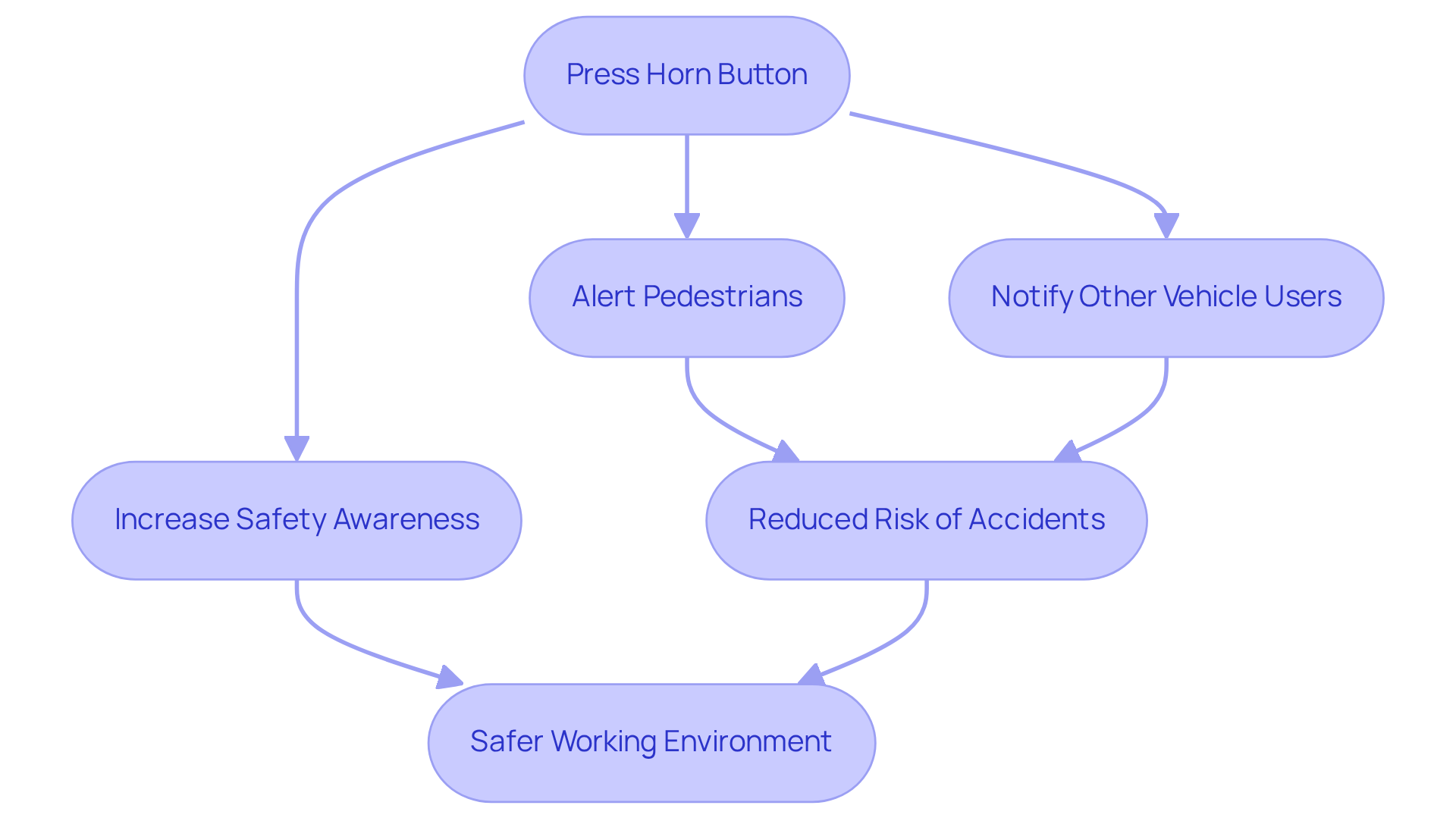

Honk the Horn Signal

The Honk the Horn Signal serves a crucial role in enhancing safety on the job site. By simply pressing the horn button on the lifting truck, operators can effectively alert pedestrians and other users of the vehicle's presence. This is especially important when approaching corners, intersections, or blind spots, where visibility may be limited.

Regular use of the horn not only promotes awareness but also significantly reduces the risk of accidents. When everyone is informed of the forklift's movements, it fosters a safer working environment for all. In addition, this simple action can prevent costly damages and injuries, making it an essential practice in any operation involving lifting trucks.

Investing in reliable equipment like our lifting trucks ensures that safety features, such as the Honk the Horn Signal, are always at your fingertips. Don't compromise on safety - choose equipment that prioritizes the well-being of your team. Contact us today to learn more about our range of lifting trucks and how they can enhance your operational safety.

Importance of Forklift Hand Signals

The forklift hand signals chart plays a crucial role in ensuring clear communication between operators and ground personnel, especially in noisy environments where verbal communication can fall short. The forklift hand signals chart provides standardized signals that create a universal language all team members can understand, significantly reducing the risk of accidents. In fact, research indicates that workplaces that implement hand gestures see a remarkable decrease in incidents, with some studies showing a reduction of up to 30% in accidents when these gestures are properly utilized.

Training in these hand signals, as outlined in a forklift hand signals chart, is essential for promoting safety and efficiency on job sites, ultimately leading to successful project outcomes. As Kina Repp wisely noted, 'You are your last line of defense in safety,' underscoring the vital role each team member plays in cultivating a safety culture through effective communication. By adopting a forklift hand signals chart and reinforcing its use through comprehensive training, teams can improve their cohesion and effectiveness, thus boosting overall productivity on job sites.

Conclusion

Effective communication through forklift hand signals is crucial for ensuring safety in busy work environments. These signals play a vital role in preventing accidents and fostering a culture of safety among operators and ground personnel. By understanding and utilizing the essential forklift hand signals chart, teams can significantly enhance their operational efficiency while minimizing the risk of incidents.

Key signals such as the Emergency Stop, Dog Everything, and Raise Tines are explored in detail. Each signal is defined and contextualized within real-world scenarios, underscoring their importance in maintaining safety standards. Comprehensive training in these signals is essential; proper education can lead to substantial reductions in accidents, thereby protecting workers and enhancing overall site safety.

Prioritizing forklift hand signals goes beyond mere compliance; it reflects a commitment to creating a safe and efficient workplace. Organizations should invest in training programs that reinforce these essential signals, ensuring that every team member is equipped to contribute to a safer environment. By fostering a culture of communication and safety, companies can protect their workforce and improve productivity. Implementing these hand signals is a vital step towards operational excellence.

Frequently Asked Questions

What is the Emergency Stop Signal and its purpose?

The Emergency Stop Signal, indicated by crossing both arms in front of the chest, instructs forklift operators to halt all operations immediately. It is essential for preventing incidents in hazardous situations and safeguarding both the operator and nearby personnel.

Why is training in emergency stop signals important?

Comprehensive training in emergency stop signals is crucial because it enables operators to recognize and respond effectively to emergency cues, ensuring swift and decisive action during critical moments.

What percentage of lift truck incidents occur on construction sites?

Approximately 23.8% of lift truck incidents occur on construction sites, highlighting the importance of emergency stop signals in these environments.

How can training impact the risk of forklift incidents?

Proper education and training can reduce forklift incidents by up to 70%, significantly mitigating the risk of accidents and fostering a safer work environment.

What is the Dog Everything Signal and when is it used?

The Dog Everything Signal, indicated by clasping both hands in front of the body, is a command for operators to halt all movements. It is crucial in busy work environments to assess potential hazards effectively.

What percentage of construction workers feel they need additional safety training?

Around 55% of construction workers feel they require additional safety training, indicating a persistent need for effective communication and safety practices.

What does the Raise Tines Signal indicate?

The Raise Tines Signal, indicated by extending one arm out to the side with the index finger pointing upward, signals the operator to safely elevate items to the desired height.

Why is effective height management important in forklift operations?

Effective height management is important because lift truck overturning accounts for 25% of all lift truck incidents. Ensuring the load is centered and positioned low helps maintain the vehicle's center of gravity, preventing tip-overs.

What can be done to minimize lift truck accidents?

Adhering to safety standards and continuous training can significantly reduce lift truck accidents, as most incidents are avoidable with strict compliance to best practices.