Key Highlights:

- Trench boxes are essential for preventing cave-ins during excavation, significantly reducing the risk of injuries and fatalities.

- Excavation work has a fatality rate 112% higher than general construction, with collapses being the leading cause of these fatalities.

- Implementing trench boxes ensures compliance with OSHA regulations for excavations deeper than five feet.

- Trench boxes stabilise trench walls against lateral soil pressure, enhancing worker safety and minimising project delays.

- User-friendly design of trench boxes allows for rapid installation, leading to labour cost savings of up to 20%.

- Excavation supports can reduce installation time to under 2%, compared to traditional methods requiring significantly more time.

- Utilising trench boxes fosters a culture of safety and reliability in construction practises.

- Investing in durable trench boxes reduces long-term costs through lower replacement frequency and insurance premiums.

- High-quality trench boxes retain resale value, making them a financially smart investment for project managers.

- EZ Equipment Rental offers a range of reliable trench boxes that enhance safety and operational efficiency on job sites.

Introduction

Trench boxes stand as essential tools in the construction industry, significantly boosting safety and operational efficiency on job sites. These structures provide crucial protection against cave-ins, safeguarding workers and enabling project managers to comply with stringent OSHA regulations. But how can the strategic use of trench boxes not only reduce risks but also lead to substantial cost savings and improved project timelines?

This article explores ten key benefits of trench boxes, offering insights that can revolutionize how project managers approach excavation safety and efficiency. By understanding these advantages, you can make informed decisions that enhance both safety and productivity on your job sites.

Enhance Safety with Trench Boxes

Trench boxes are vital safety structures that create a secure working environment by preventing cave-ins during excavation. These protective barriers allow workers to operate confidently within the excavation, free from the constant fear of soil collapse. The significance of excavation supports is underscored by alarming statistics: digging work has a fatality rate that is 112% higher than general construction, with collapses being the leading cause of these fatalities. By implementing protective enclosures, managers can drastically reduce the risk of injuries and fatalities, ensuring compliance with OSHA regulations that mandate safety systems for excavations deeper than five feet.

Safety experts emphasize the necessity of excavation supports, particularly in unstable soil conditions. For example, vibrations from nearby traffic can compromise soil integrity, heightening the risk of collapses. Trench boxes not only provide robust containment but also enhance efficiency by minimizing excavation delays caused by collapses. Real-world examples illustrate their effectiveness; in numerous construction projects, excavation shields have successfully prevented collapses, safeguarding workers and maintaining project timelines.

Incorporating protective enclosures into risk management strategies fosters a culture of safety on the job site, reflecting a commitment to worker protection and regulatory compliance. As the construction industry continues to evolve, staying informed about the latest safety guidelines and best practices related to excavation supports is crucial for project managers aiming to enhance safety and efficiency in their operations.

Prevent Collapses with Structural Support

Trench boxes play a crucial role in providing structural support during excavation. They effectively stabilize the trench box walls, significantly reducing the risk of collapses. These trench boxes are designed to withstand lateral soil pressure, ensuring that excavations remain secure for workers, safeguarding personnel and preventing costly delays that can arise from accidents or the need for rework.

Civil engineers emphasize that when a trench box is utilized effectively, it can transform safety standards at construction sites. This not only enhances the overall efficiency of project execution but also fosters a culture of reliability and quality in construction practices. By investing in robust trench boxes, you’re not just protecting your team; you’re also ensuring that your projects stay on track and within budget.

Don’t compromise on safety. Choose trench boxes that adhere to the highest standards of engineering excellence. Contact us today to learn more about our range of reliable equipment and how it can elevate your construction projects.

Achieve Operational Efficiency on the Jobsite

Boosting operational efficiency on job sites is crucially supported by trench boxes. Their user-friendly design allows for rapid installation, enabling crews to focus on excavation tasks rather than risk management. This efficiency not only accelerates task completion but also leads to significant labor cost reductions. For instance, projects utilizing excavation enclosures have reported labor cost savings of up to 20%, as teams can work more effectively with fewer hours spent on setup and safety measures.

Project leaders have noted that employing excavation supports can save valuable time, facilitating quicker task completion and better financial management. Furthermore, OSHA mandates protective systems for excavations deeper than 5 feet, underscoring the vital safety function that these enclosures serve in preventing potentially fatal collapses. As one manager aptly stated, "Utilizing excavation supports not only ensures our team’s safety but also enables us to finish tasks punctually and within budget."

By investing in excavation enclosures, contractors can achieve a more streamlined workflow, ultimately enhancing overall project success. Don't miss out on the opportunity to improve your operations-consider using a trench box for your next project and experience the benefits firsthand.

Ensure Compliance with OSHA Regulations

Excavation systems are essential for meeting OSHA regulations, which mandate safety measures for excavations deeper than five feet. By implementing excavation enclosures, managers can ensure compliance with these regulations, significantly reducing the risk of penalties and legal repercussions. In fact, trenching violations accounted for 9% of penalties in construction in 2023, underscoring the financial stakes of non-compliance. This proactive strategy not only safeguards workers but also bolsters the initiative's reputation and credibility within the industry.

For instance, projects that have effectively utilized a trench box have successfully avoided costly fines associated with trench regulation violations. Furthermore, with trenching and excavation fatalities surging by 160% in 2022, adhering to these regulations fosters a culture of safety on-site, ultimately benefiting both the workforce and the overall success of the project. As OSHA emphasizes, the use of a trench box for trench protection is vital for maintaining a secure working environment and complying with OSHA regulations.

To enhance safety and compliance, managers should regularly evaluate excavation protocols and ensure that protective structures are utilized in all applicable situations. This commitment to safety not only protects employees but also enhances operational efficiency and project outcomes.

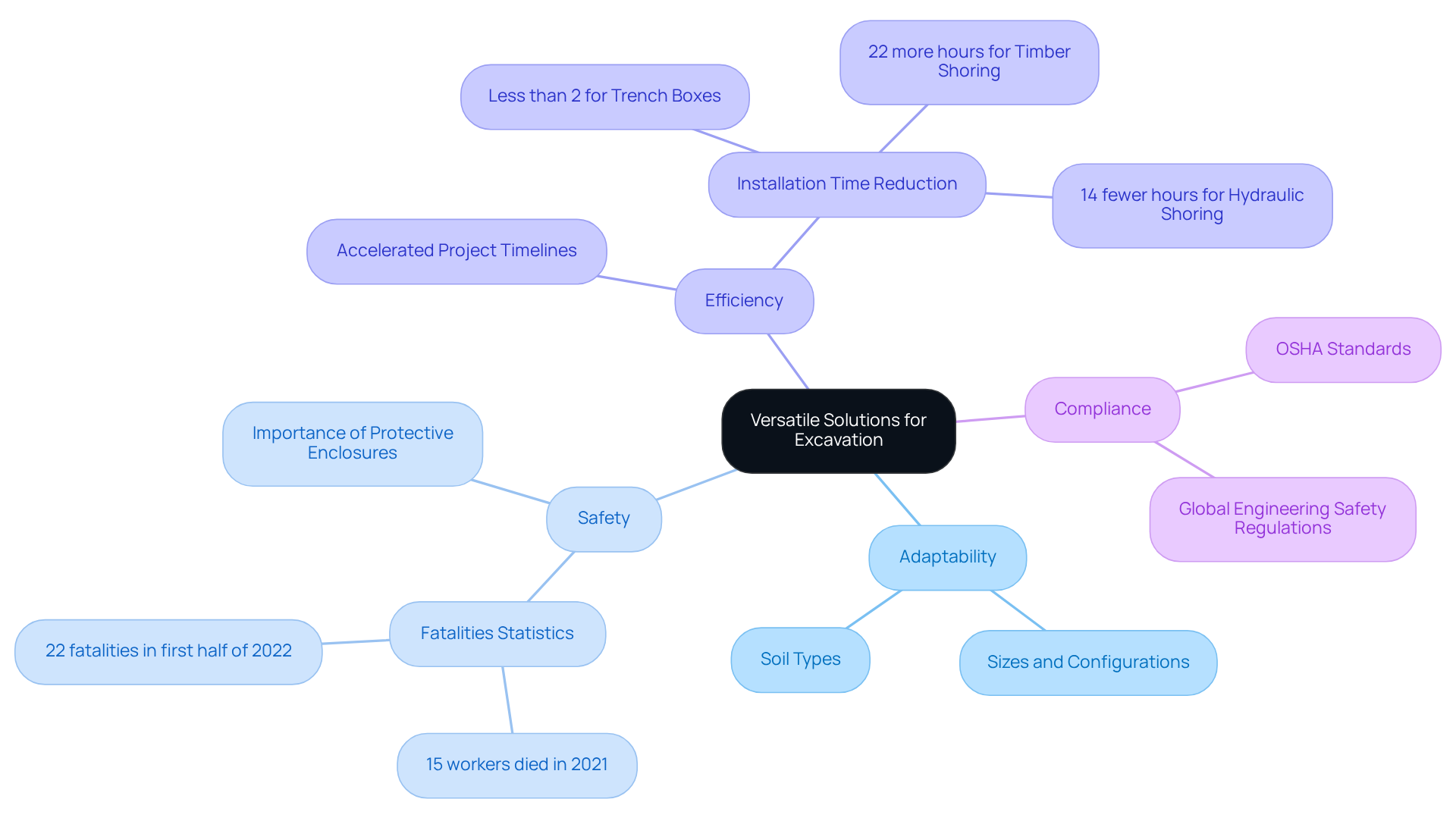

Utilize Versatile Solutions for Various Conditions

Trench boxes are available in a variety of sizes and configurations, making them perfect for diverse excavation conditions. Their innovative design allows for modifications that accommodate unstable soil or varying excavation depths. This adaptability ensures project managers can effectively address challenges while prioritizing safety and efficiency.

For instance, adjustable excavation supports can be tailored to meet the specific requirements of different soil types, such as clay or sandy ground, which significantly impacts excavation stability. Statistics reveal that excavation supports can reduce installation time to under 2%, compared to traditional methods like timber shoring, which require an additional 22% in hours. This remarkable efficiency not only accelerates project timelines but also minimizes the risk of accidents. In fact, 15 workers tragically lost their lives in trenching and excavation work throughout 2021, with 22 fatalities reported in the first half of 2022.

By utilizing excavation shields, project managers can ensure compliance with safety regulations while enhancing operational effectiveness. As Doug Parker, Assistant Secretary for Occupational Safety and Health, states, "Every one of these tragedies could have been prevented had employers complied with OSHA standards." This underscores the critical role of protective enclosures in safeguarding workers and preventing fatalities.

Don't compromise on safety - choose trench boxes that provide reliability and quality. Engage with us today to learn more about how our equipment can enhance your excavation projects.

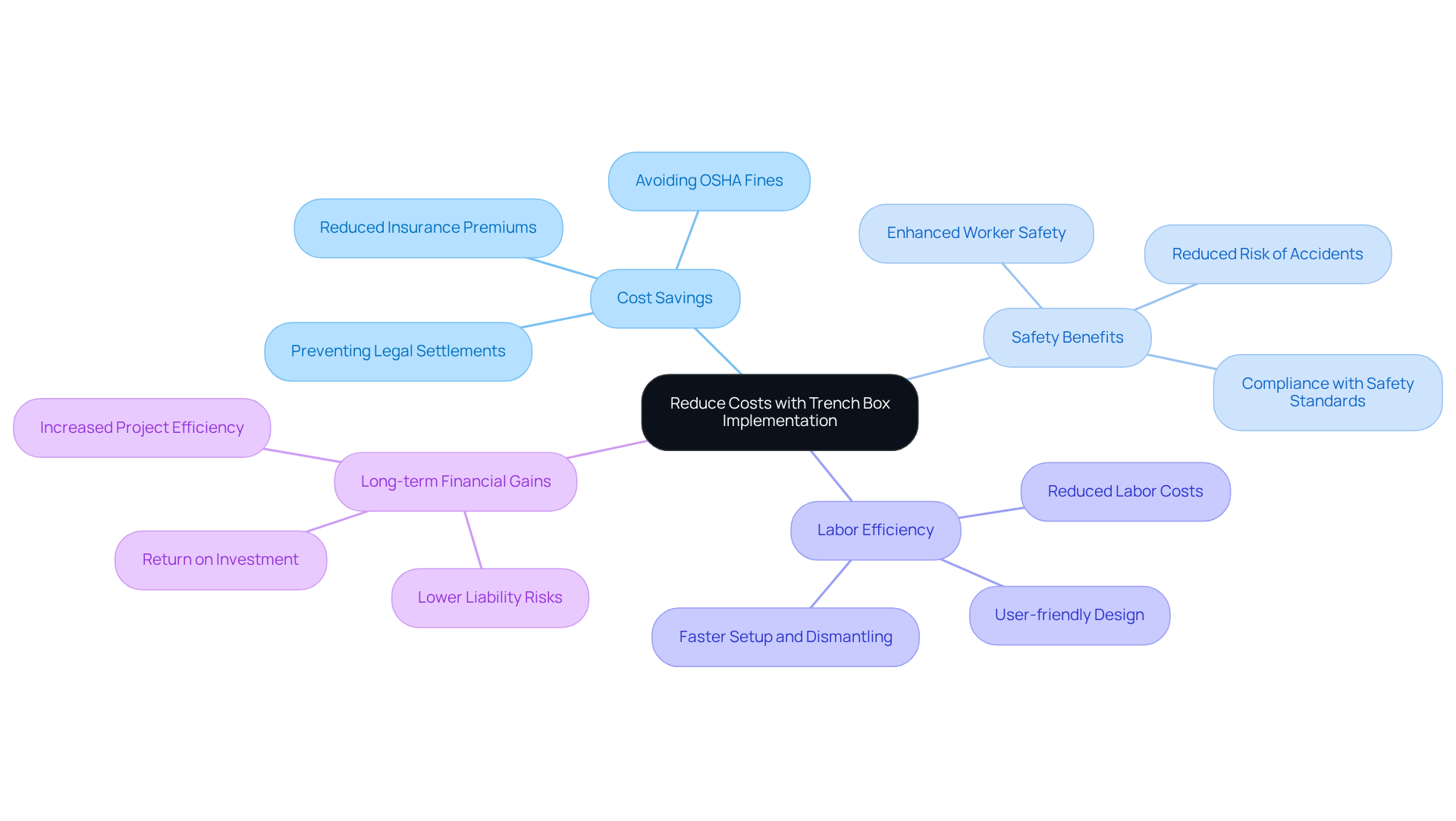

Reduce Costs with Trench Box Implementation

Maximize Your Savings with Excavation Enclosures

Excavation enclosures are not just a safety measure; they are a strategic investment that can lead to significant cost reductions. By minimizing the likelihood of incidents and related setbacks, these enclosures protect your project timeline and budget. Furthermore, their user-friendly design means fewer workers are required to manage safety concerns, effectively lowering labor costs.

Over time, investing in a trench box pays off through reduced insurance premiums and decreased liability risks. This means that not only do you save money upfront, but you also enjoy long-term financial benefits. Don’t overlook the value of safety; it’s an investment in your peace of mind and your bottom line.

In addition, the reliability of excavation enclosures is backed by numerous case studies and testimonials from satisfied customers. They consistently report enhanced safety and efficiency on their job sites, reinforcing the quality of these systems. Join the ranks of successful projects that prioritize safety and efficiency.

Take action today by exploring our range of excavation enclosures. Equip your team with the tools they need to succeed while safeguarding your investment. Contact us now to learn more about how our solutions can benefit your next project!

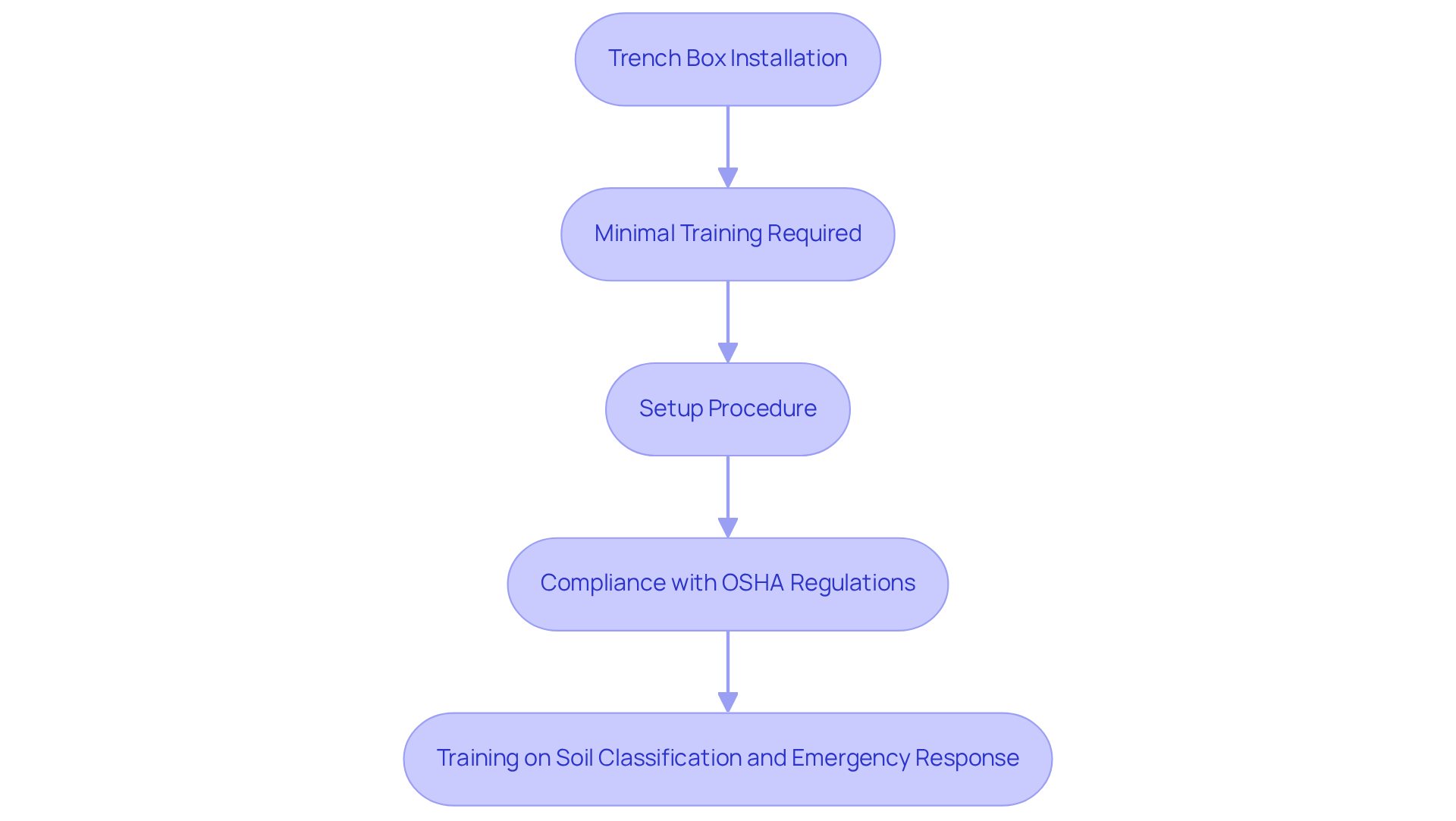

Simplify Installation and Usage

Trench boxes are designed to allow crews to set them up with minimal training, ensuring rapid and straightforward installation. This intuitive design enables workers to concentrate on their tasks rather than grappling with complicated protective gear. Such ease of use not only boosts security but also significantly enhances overall project efficiency.

Moreover, excavation enclosures must comply with OSHA safety regulations for specific excavation depths and soil categories, ensuring both compliance and worker safety. Training requirements for using trench boxes are crucial, as OSHA mandates that workers receive instruction on installation, soil classification, and emergency response protocols. Experts emphasize that adequate training is essential for ensuring that workers can effectively position, secure, and inspect trench boxes, thereby minimizing risks associated with excavation work.

As one trainer noted, "Understanding the setup procedure is vital for maintaining a safe work environment." With the right training, teams can confidently utilize excavation supports, ensuring adherence to safety regulations while boosting productivity on the job site. Don't compromise on safety - invest in proper training and equipment today!

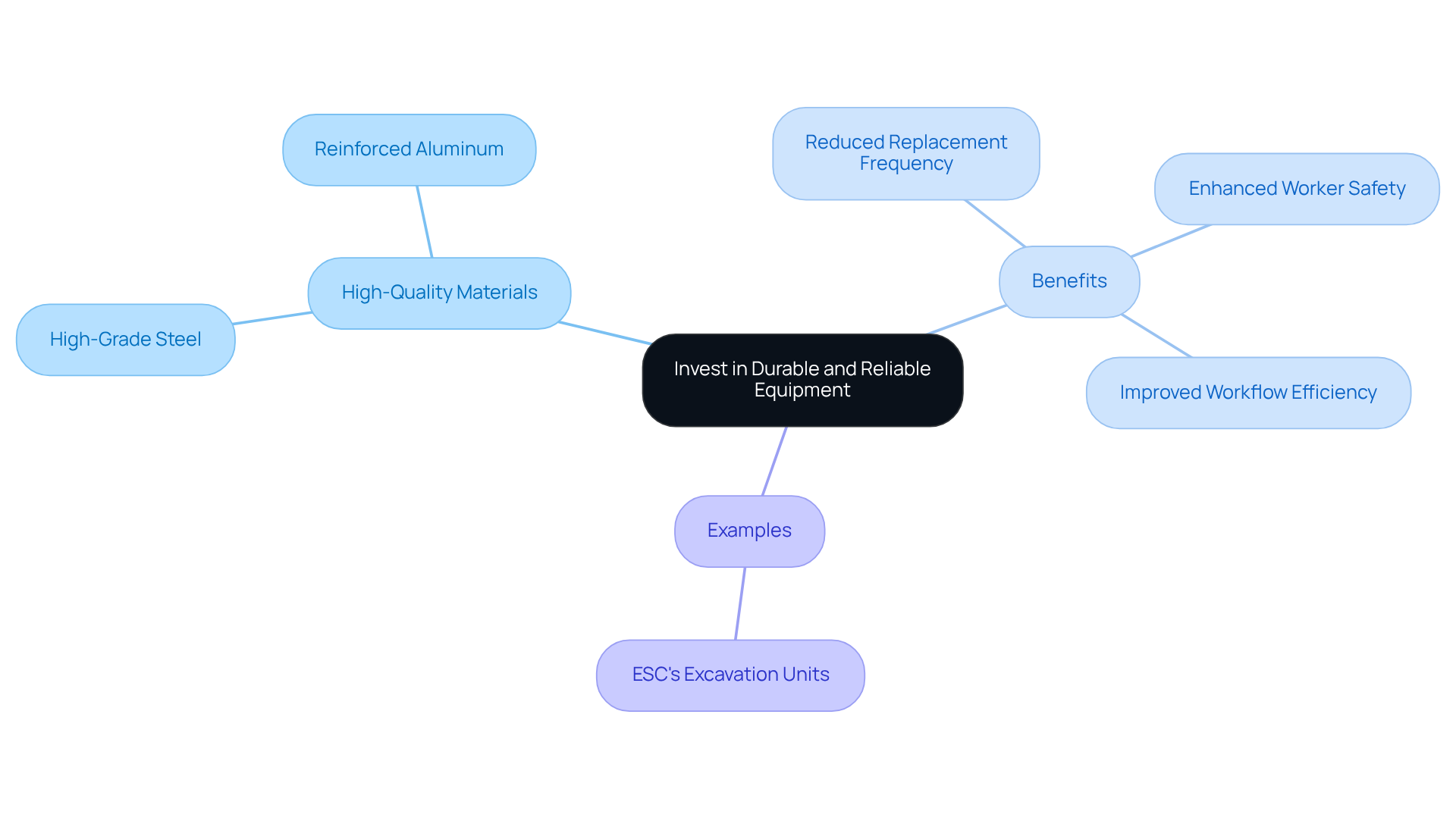

Invest in Durable and Reliable Equipment

Investing in high-quality protective structures is crucial for tackling the challenges faced on construction sites. Materials like high-grade steel and reinforced aluminum are designed for exceptional durability, significantly cutting down on replacement frequency.

For instance, ESC's excavation units, rated for depths up to 40 feet, are built to withstand lateral pressures and harsh conditions, ensuring long-term reliability. This durability not only boosts worker safety but also reduces disruptions on the job site, fostering a more efficient workflow.

By utilizing robust excavation supports, project managers can expect fewer delays and a smoother operational process, ultimately contributing to the success of their projects.

Maximize Resale Value of Equipment

Trench containers, especially those crafted from premium materials, stand out for their impressive ability to retain resale value. As construction equipment ages, a robust resale value can significantly offset initial investment costs. Project managers can capitalize on this by selecting excavation containers that are not only well-maintained but also highly sought after in the rental market.

Equipment appraisers frequently note that excavation containers, thanks to their durable design and essential role in safety, experience slower depreciation rates compared to other construction tools. This positions them as a smart investment for managers looking to maximize their equipment's financial return over time.

By adhering to proper maintenance practices and staying updated on market trends, managers can ensure their excavation containers remain valuable assets throughout their lifecycle. In addition, the demand for reliable equipment in the rental market underscores the importance of choosing high-quality trench boxes. Furthermore, investing in such equipment not only enhances project efficiency but also contributes to long-term financial stability.

Don't miss out on the opportunity to secure your investment - explore our range of excavation containers today!

Source Reliable Trench Boxes from EZ Equipment Rental

EZ Equipment Rental provides a diverse range of premium excavation containers that meet stringent industry standards for reliability and durability. By choosing excavation enclosures from a trusted supplier like EZ Equipment Rental, managers can secure dependable equipment that significantly enhances safety and operational efficiency on job sites. Our commitment to customer satisfaction is evident in the positive feedback from managers who recognize the advantages of leasing trench boxes. Many have noted that using these reliable systems not only mitigates risks associated with cave-ins but also speeds up project timelines.

With an extensive inventory of well-maintained machinery and a strong emphasis on quality, EZ Equipment Rental is the top choice for all trench box requirements in the Dallas-Fort Worth area. We ensure that every project is equipped with the best tools for success. In addition, our customers have shared their experiences, highlighting how our equipment has transformed their operations. For example, one manager reported a significant reduction in downtime thanks to the reliability of our trench box.

Don’t settle for less when it comes to your excavation needs. Choose EZ Equipment Rental for equipment that you can trust. Contact us today to learn more about our offerings and how we can support your next project!

Conclusion

Trench boxes are indispensable tools for project managers, significantly boosting safety, compliance, and operational efficiency in construction environments. By implementing these protective structures, managers can establish a secure worksite that minimizes accident risks and ensures adherence to safety regulations. The significance of trench boxes is immense; their role in preventing cave-ins and facilitating safe excavation practices directly influences worker safety and project success.

Key benefits of trench boxes include:

- Their ability to provide robust structural support

- Streamlining installation processes

- Adapting to various soil conditions

Furthermore, trench boxes lead to substantial cost savings by reducing labor hours and minimizing the likelihood of costly accidents. With the constant need for compliance with OSHA regulations, utilizing trench boxes not only protects workers but also safeguards the project's integrity and reputation.

In conclusion, strategically using trench boxes is a vital investment for project managers looking to enhance safety and efficiency on job sites. By prioritizing these protective systems, managers can cultivate a culture of safety, ensuring their teams operate effectively and within budget. Embracing trench boxes as a standard practice not only mitigates risks but also positions projects for long-term success and sustainability in the competitive construction landscape.

Frequently Asked Questions

What are trench boxes and why are they important?

Trench boxes are safety structures used during excavation to prevent cave-ins, creating a secure working environment for workers. They are crucial because excavation work has a significantly higher fatality rate compared to general construction, with collapses being the leading cause of these fatalities.

How do trench boxes enhance safety for workers?

Trench boxes provide robust containment that stabilizes trench walls and minimizes the risk of soil collapse. This allows workers to operate without the fear of cave-ins, ensuring compliance with OSHA regulations that require safety systems for excavations deeper than five feet.

What are the consequences of not using trench boxes?

Without trench boxes, the risk of collapses increases, which can lead to serious injuries or fatalities. Additionally, accidents can cause costly delays and rework, impacting project timelines and budgets.

How do trench boxes contribute to operational efficiency?

Trench boxes facilitate rapid installation, allowing crews to focus on excavation tasks rather than risk management. This efficiency can lead to significant labor cost reductions, with some projects reporting savings of up to 20% due to reduced setup and safety measure time.

What role do trench boxes play in risk management strategies?

Incorporating trench boxes into risk management fosters a culture of safety on job sites, reflecting a commitment to worker protection and compliance with safety regulations. They help ensure that projects stay on track and within budget.

What should project managers consider when selecting trench boxes?

Project managers should choose trench boxes that adhere to the highest standards of engineering excellence to ensure safety and reliability on job sites. Investing in quality trench boxes can enhance project execution and protect workers effectively.