Key Highlights:

- Trench compactors compress soil in narrow ditches, enhancing soil stability and preventing subsidence.

- High-frequency vibrations rearrange soil particles, reducing air pockets and increasing density for better support of structures.

- Effective soil densification is crucial for the success of construction projects, especially for retaining walls and subsurface utilities.

- Trench compactors accelerate project timelines by minimising the number of passes needed to achieve optimal soil density.

- Using trench compactors can reduce labour costs by up to 20%, making them a valuable investment for construction teams.

- These machines are versatile, suitable for various applications including utility installation, road construction, and landscaping.

- Modern trench compactors improve job site safety by ensuring adequate soil compaction and allowing for remote operation.

- User-friendly features and intuitive controls enhance efficiency and reduce operator fatigue.

- Durability and reliability of trench compactors reduce maintenance costs and increase long-term project efficiency.

- Trench compactors promote environmental sustainability by minimising soil disturbance and reducing construction waste.

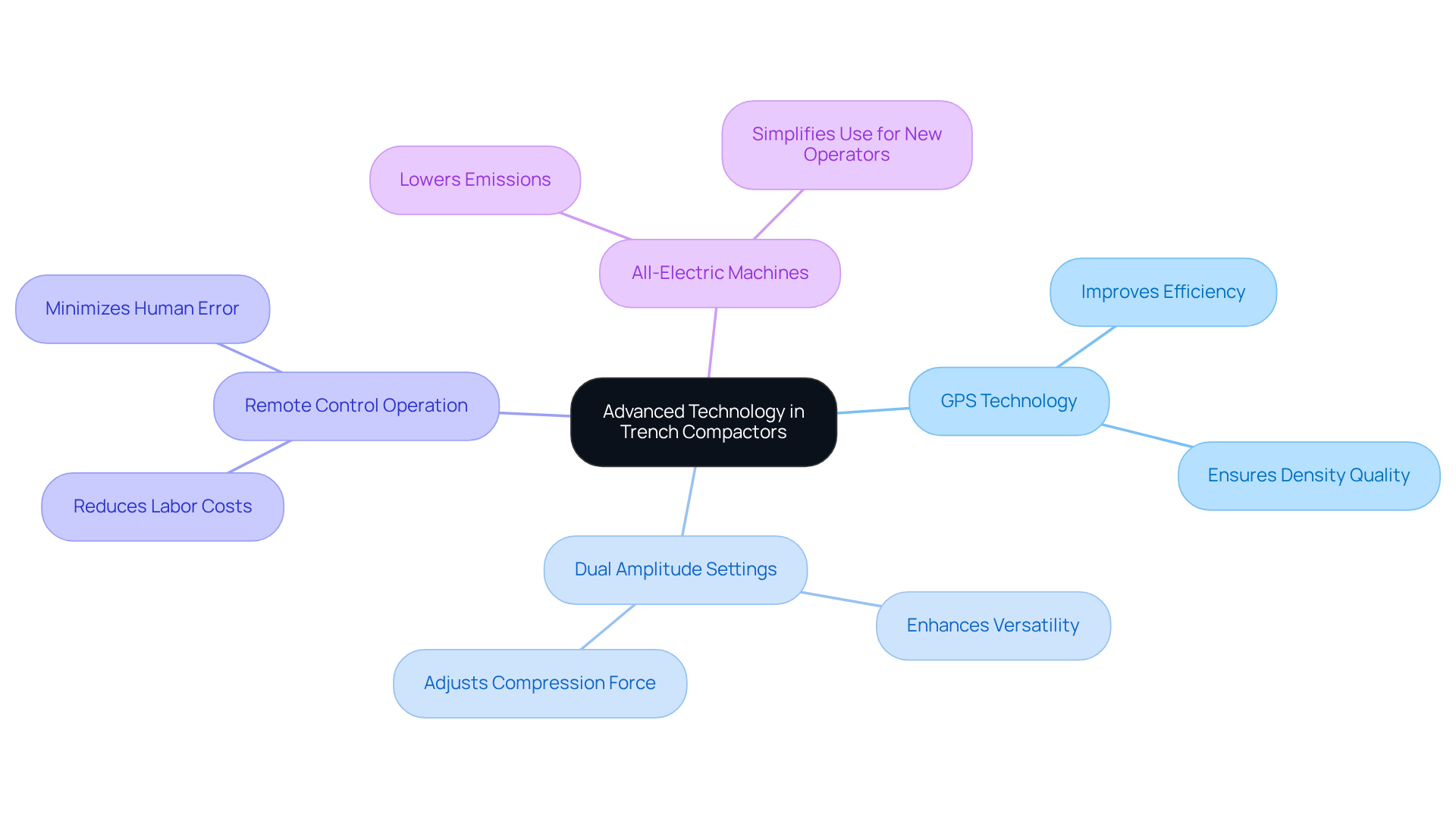

- Advanced technology in trench compactors, such as GPS and dual amplitude settings, enhances performance and usability.

- Rental options for trench compactors provide contractors with access to well-maintained equipment and expert guidance.

Introduction

Trench compactors are transforming the construction landscape, providing a unique combination of efficiency and versatility that is difficult to ignore. These robust machines not only improve soil stability but also enhance operations across a range of projects, from utility installations to road construction. As the need for dependable and effective compaction solutions increases, contractors must consider how to utilize trench compactors to boost productivity, reduce costs, and ensure safety on the job site. This article explores the significant advantages of trench compactors, demonstrating how they can elevate construction outcomes and contribute to project success.

Improve Soil Stability with Trench Compactors

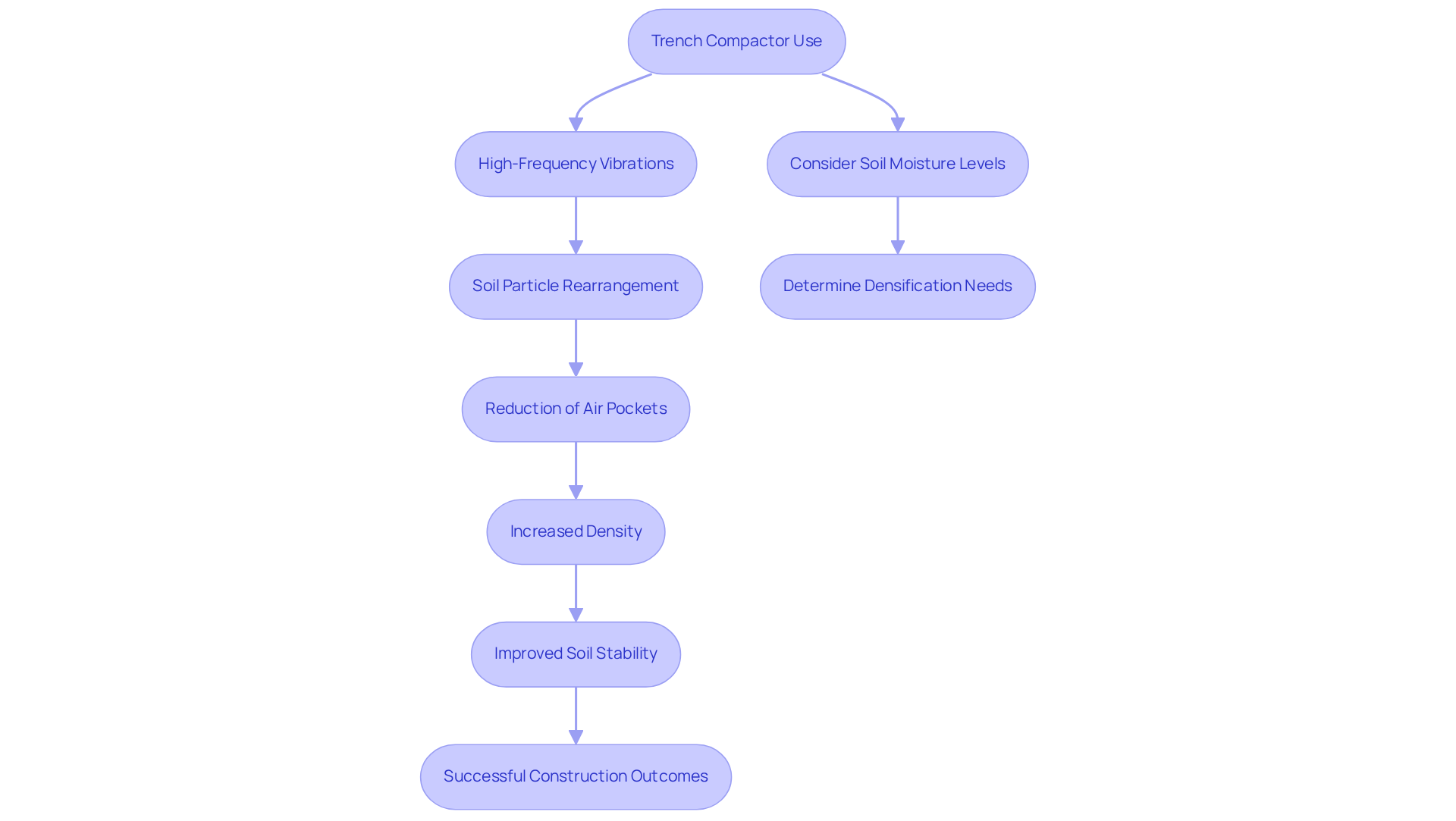

Trench compactors are essential tools designed to effectively compress soil in narrow ditches, significantly enhancing soil stability. By employing high-frequency vibrations, these machines rearrange soil particles, reducing air pockets and increasing density. This densification process is crucial for preventing subsidence, ensuring that the ground can adequately support structures, pipes, or cables installed within the trench compactor area. Achieving the right density minimizes the risk of settling, which can lead to costly repairs and project delays.

Civil engineers emphasize that effective soil densification directly correlates with the success rates of construction projects, as it establishes a robust foundation for subsequent tasks. For instance, in projects involving retaining walls or subsurface utilities, the use of a trench compactor has proven its capability to enhance soil stability, thereby improving overall outcomes. By utilizing advanced soil consolidation methods, contractors can ensure that their projects are completed on time while adhering to necessary safety and durability standards.

Moreover, understanding soil moisture levels is vital for determining the appropriate degree of densification needed, as it significantly influences the overall effectiveness of the process. With the soil compaction machines market projected to reach USD 11.8 billion by 2035, the importance of reliable trench compactors as excavation compacting devices is more pronounced than ever. As civil engineer Mike Woof notes, "With manufacturers eager to comply with new regulations and enhance performance for customers, a variety of new soil compression machines are now entering the market." This highlights the competitive landscape and ongoing technological advancements that can further improve the efficiency of trench machines.

Accelerate Compaction Processes Using Trench Compactors

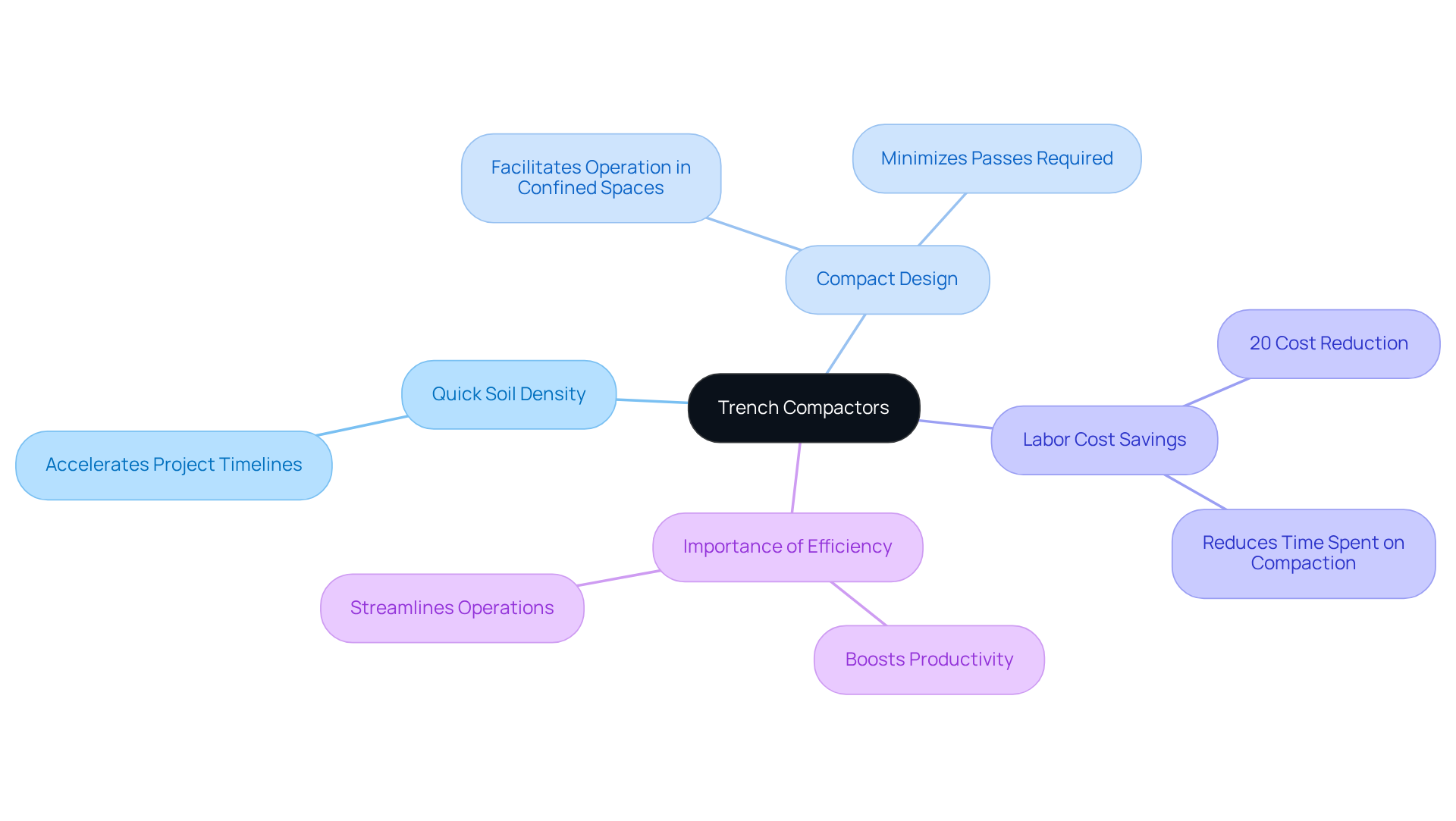

Trench compactors are designed to provide quick and efficient soil density, which enables contractors to significantly accelerate project timelines. Their compact design facilitates operation in confined spaces, minimizing the number of passes required to achieve optimal soil density. This enhanced efficiency not only expedites the overall timeline but also leads to substantial labor cost savings. By reducing the time spent on compaction, a trench compactor serves as a valuable investment for construction teams aiming to boost productivity and streamline operations.

As construction managers often highlight, completing tasks swiftly without sacrificing quality is essential in today’s competitive environment. For instance, Jeremy Renner noted that overcoming challenges in construction often requires innovative solutions, and soil compacting machines exemplify this by allowing for faster task completion. Furthermore, research indicates that using a trench compactor can reduce labor costs by as much as 20%, highlighting its importance in modern construction projects.

Utilize Trench Compactors for Diverse Construction Applications

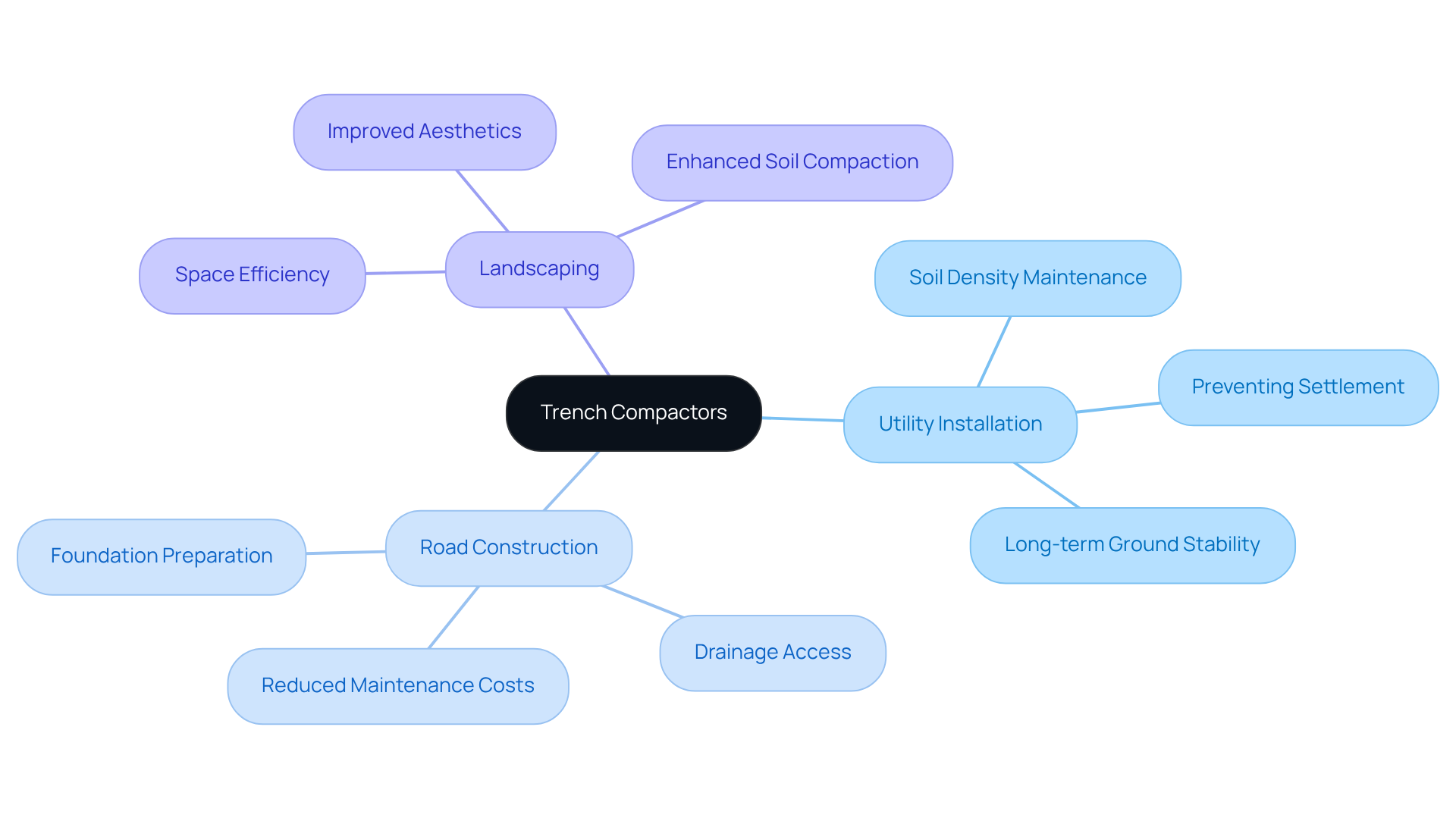

Trench compactors play a crucial role in the construction industry, recognized for their versatility in various applications such as utility installation, road construction, and landscaping. Their design allows for efficient soil compression in confined spaces, making them indispensable where traditional equipment falls short. For instance, in utility projects, excavation rollers are vital for maintaining optimal soil density around pipelines, which is essential to prevent future settling that could compromise utility services. Adequate soil compression significantly reduces the risk of pavement cracking, sinkholes, and structural damage, common issues in areas with insufficient compaction.

Recent projects have highlighted the effectiveness of soil compacting machines in utility installations, with a growing number of construction efforts utilizing these devices to meet stringent soil density requirements. Excavation rollers, in particular, are increasingly employed in the installation of sewer and water mains, gas lines, and electrical utilities, ensuring long-term ground stability and minimizing the need for costly repairs.

The design of modern soil compacting machines, including those with padfoot drums and standard extensions, enhances their performance in cohesive soils, enabling deeper penetration and improved compaction. This feature is especially advantageous in urban settings where space is limited and safety is a priority. Furthermore, the introduction of remote-controlled excavation compacting machines has revolutionized safety protocols, allowing operators to work from outside the excavation site, thereby mitigating risks associated with deep digging.

In summary, soil compacting devices are not just machines; they are integral components of successful construction projects, ensuring that infrastructure is built on a solid foundation.

Achieve Cost Savings with Trench Compactors

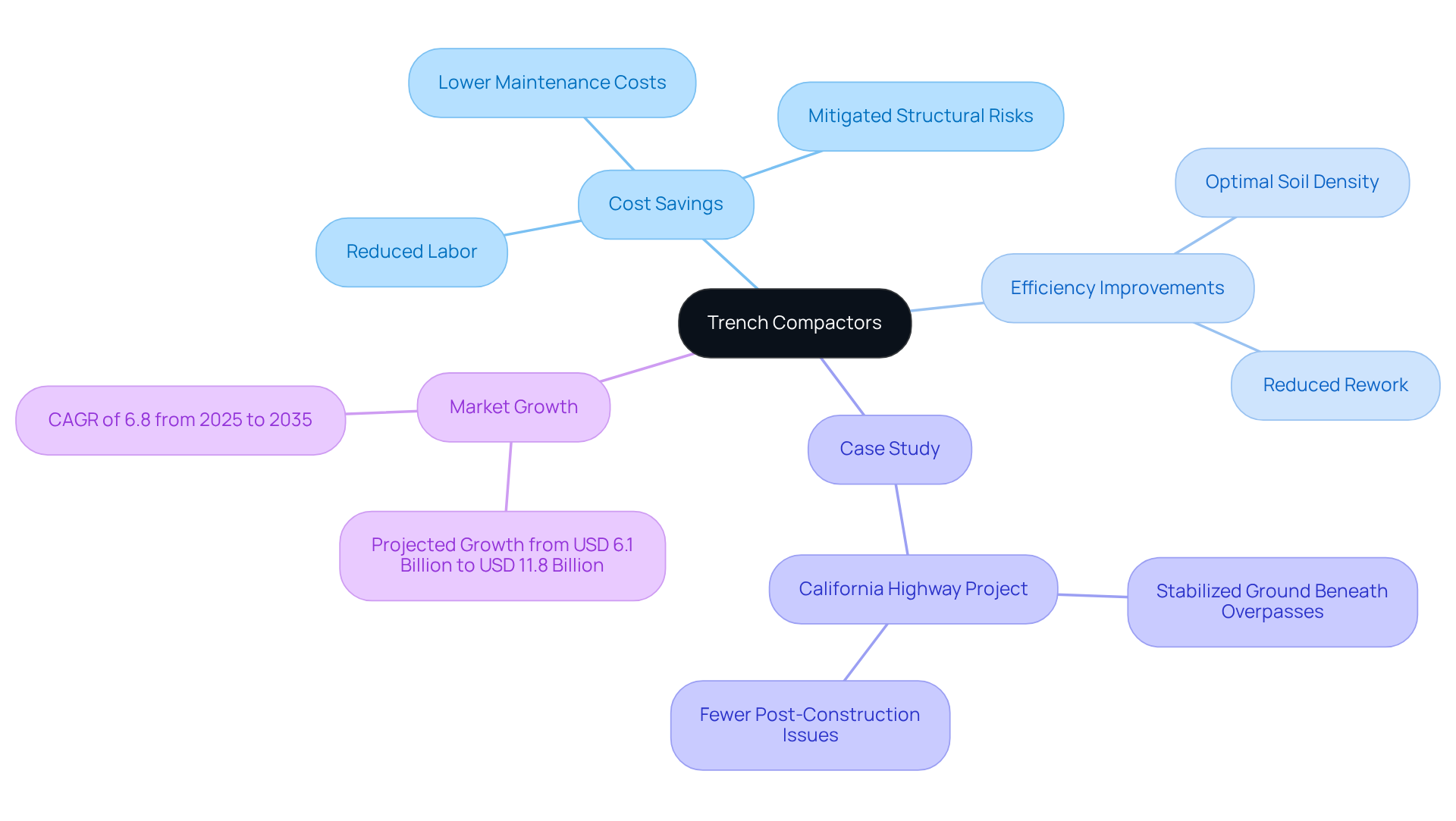

Investing in trench compactors offers substantial long-term financial benefits. The trench compactor improves efficiency by significantly decreasing the need for extra labor and reducing the risk of costly rework due to insufficient soil compaction.

For instance, a recent highway project in California utilized a trench compactor as soil compacting equipment to stabilize the ground beneath new overpasses, resulting in fewer post-construction issues and lower maintenance costs. By ensuring optimal soil density, excavation rollers mitigate the risk of future structural problems, which can lead to expensive repairs.

Financial analysts note that the initial investment in trench compactors is frequently recouped through increased productivity and diminished long-term expenses. With the global soil compaction equipment market projected to grow from USD 6.1 billion in 2025 to USD 11.8 billion by 2035, the demand for effective ground stabilization solutions emphasizes the significance of trench compactors in construction projects.

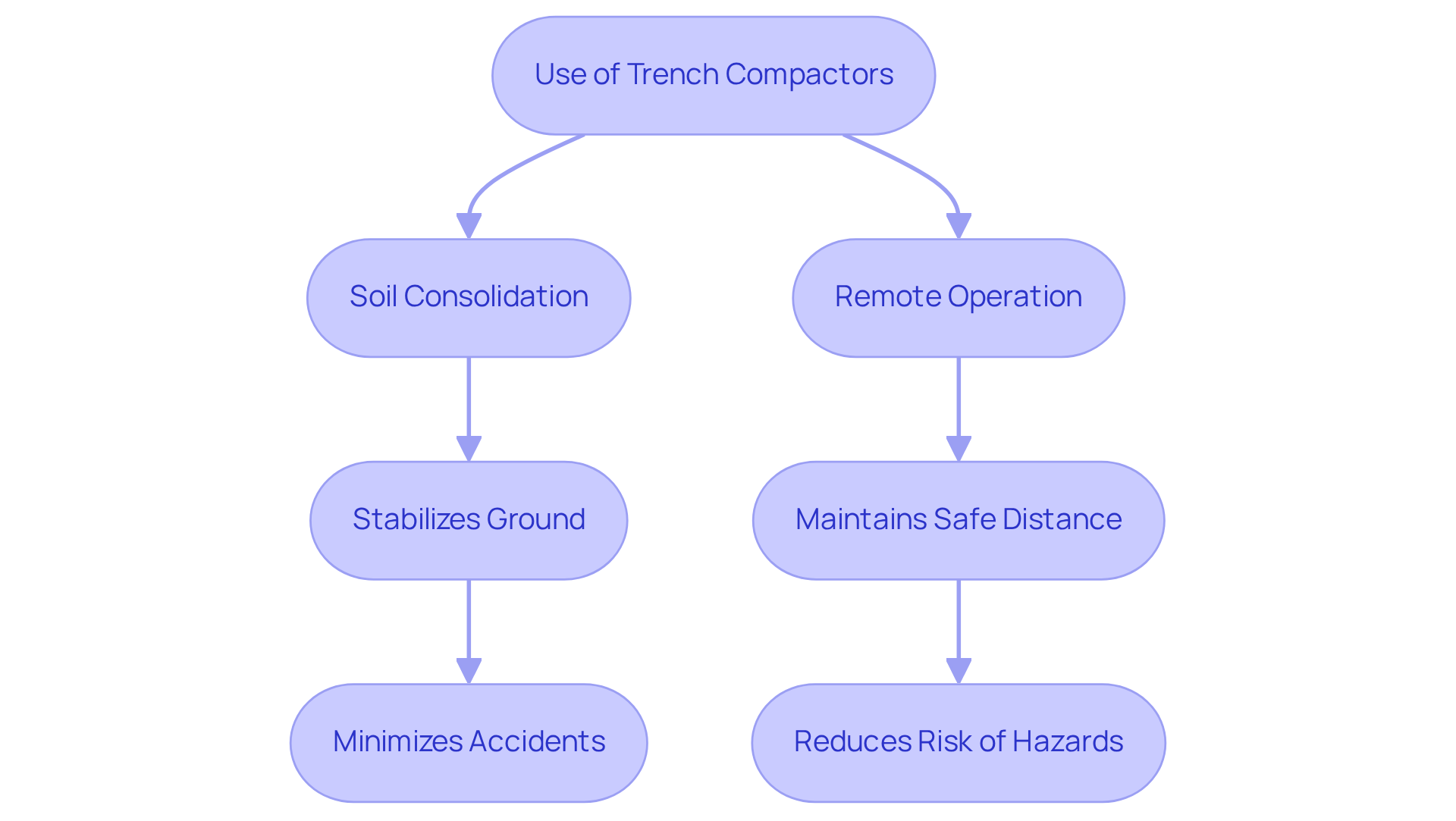

Enhance Job Site Safety with Trench Compactors

Excavation compactors are essential for enhancing job site safety by ensuring that excavations are adequately compacted, which significantly reduces the risk of collapses. Their innovative design often facilitates remote operation, allowing operators to maintain a safe distance from potential hazards. Properly compacted soil not only stabilizes the ground but also minimizes the likelihood of accidents related to unstable conditions, thereby fostering a safer working environment for all personnel involved in the project. Safety officers emphasize that efficient consolidation is crucial; as one noted, "Proper consolidation is our primary safeguard against excavation collapses."

Moreover, with an estimated 14,000 fatalities resulting from job-related incidents in the year prior to the implementation of the OSH Act, the importance of adhering to the latest safety guidelines for excavation machines cannot be overstated. These standards ensure that all operations meet rigorous guidelines designed to protect workers. By emphasizing soil consolidation, construction teams can significantly enhance job site safety metrics, ultimately leading to a more secure and efficient work environment. As a reminder, "Safety is everyone’s responsibility," highlighting the collective commitment to maintaining a safe job site.

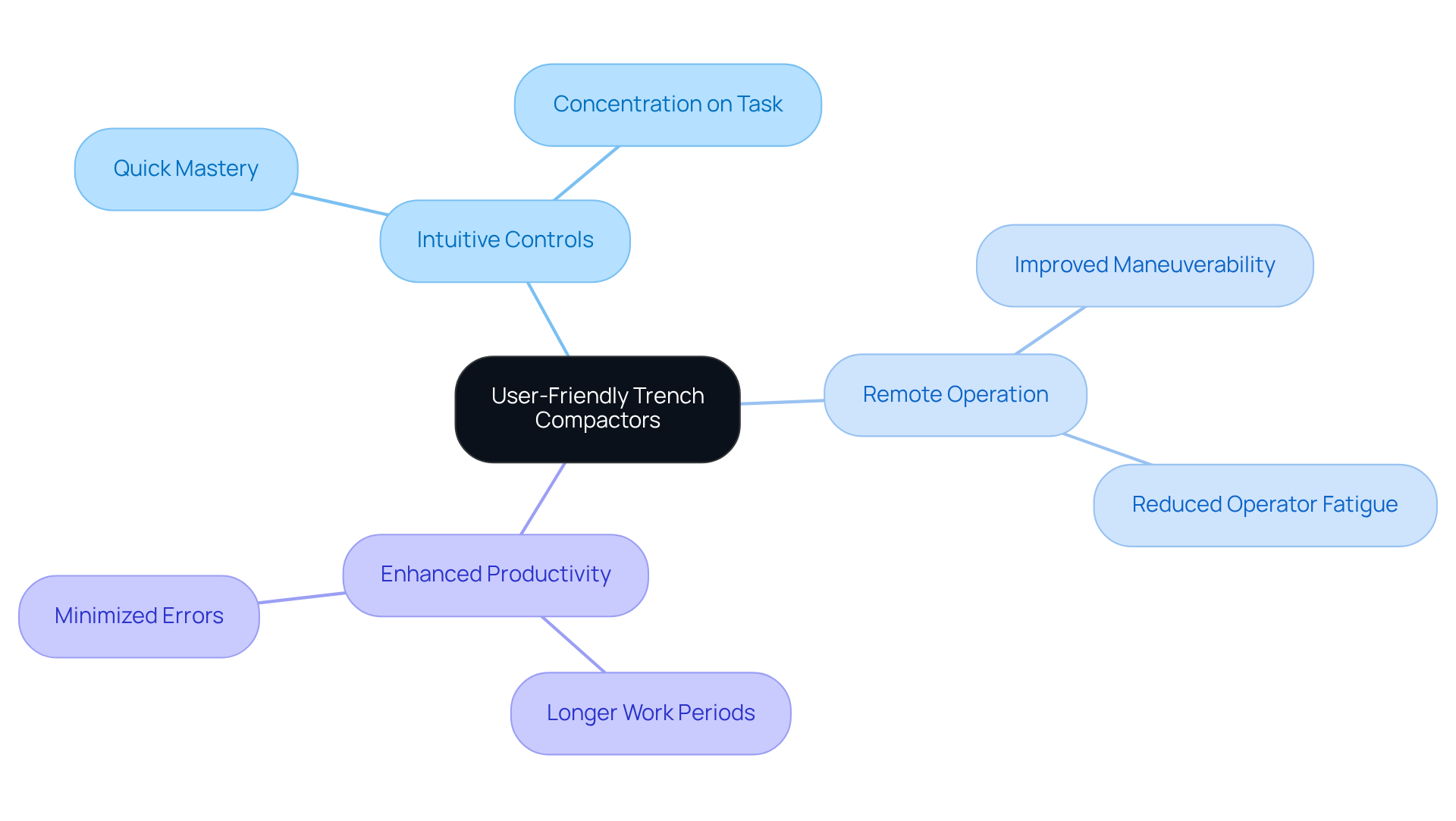

Simplify Operations with User-Friendly Trench Compactors

Modern trench compactors come equipped with user-friendly features that effectively streamline operations. Many models come equipped with intuitive controls, allowing operators to quickly master the equipment, which enhances overall efficiency on the job site. Operators have noted that the straightforward design of the controls enables them to concentrate on the task at hand rather than struggling with the machinery.

Furthermore, advancements such as remote control operation of the trench compactor improve maneuverability and reduce operator fatigue, allowing for longer work periods without discomfort. This ease of use not only boosts productivity but also minimizes the likelihood of operator error, leading to superior outcomes when using a trench compactor.

As one operator remarked, 'The new controls make it so much easier to get the job done right the first time.' These innovations ultimately contribute to the success of their projects.

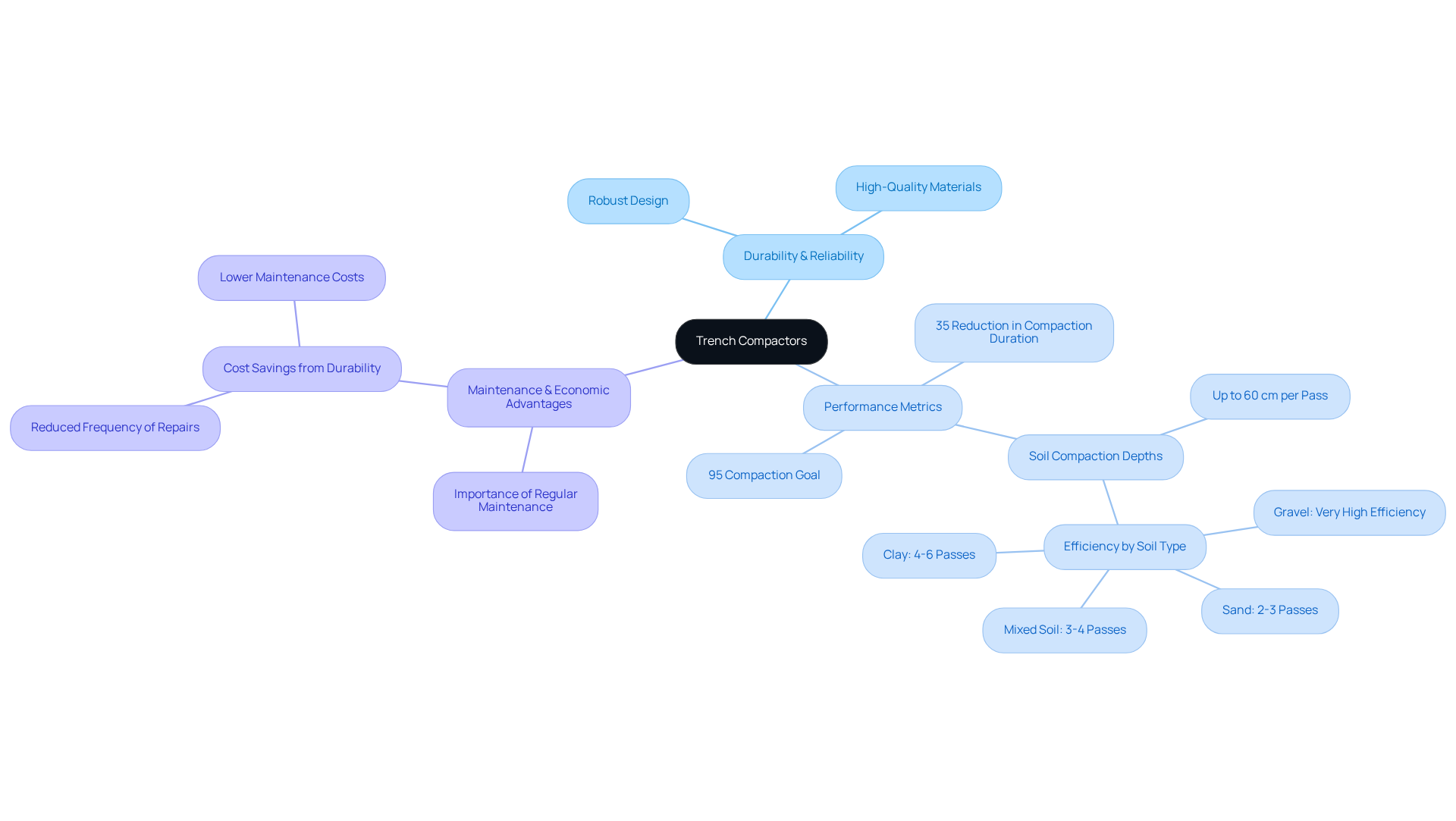

Ensure Durability and Reliability with Trench Compactors

Trench compactors are designed to withstand the demanding conditions of construction sites, ensuring reliable performance over time. Their robust design, constructed from high-quality materials, enables effective operation even in the most challenging environments. For instance, a local water supply initiative in Southeast Asia utilized reversible plate compressing devices (RPCs) for excavation compaction over a distance of 15 km, achieving a compaction goal of 95% Standard Proctor Density in just 2-3 passes. This approach significantly reduced compaction duration by 35% compared to manual tamping.

To enhance their longevity and efficiency, regular maintenance is crucial. This practice not only boosts reliability but also minimizes downtime, making earth-moving machines a prudent investment for contractors. When evaluating maintenance costs, trench compactors often demonstrate greater economic advantages than other equipment, as their durability decreases the frequency of repairs and replacements, ultimately resulting in substantial cost savings over time. Industry experts note that the effective use of RPCs can lead to significant improvements in project efficiency and long-term stability.

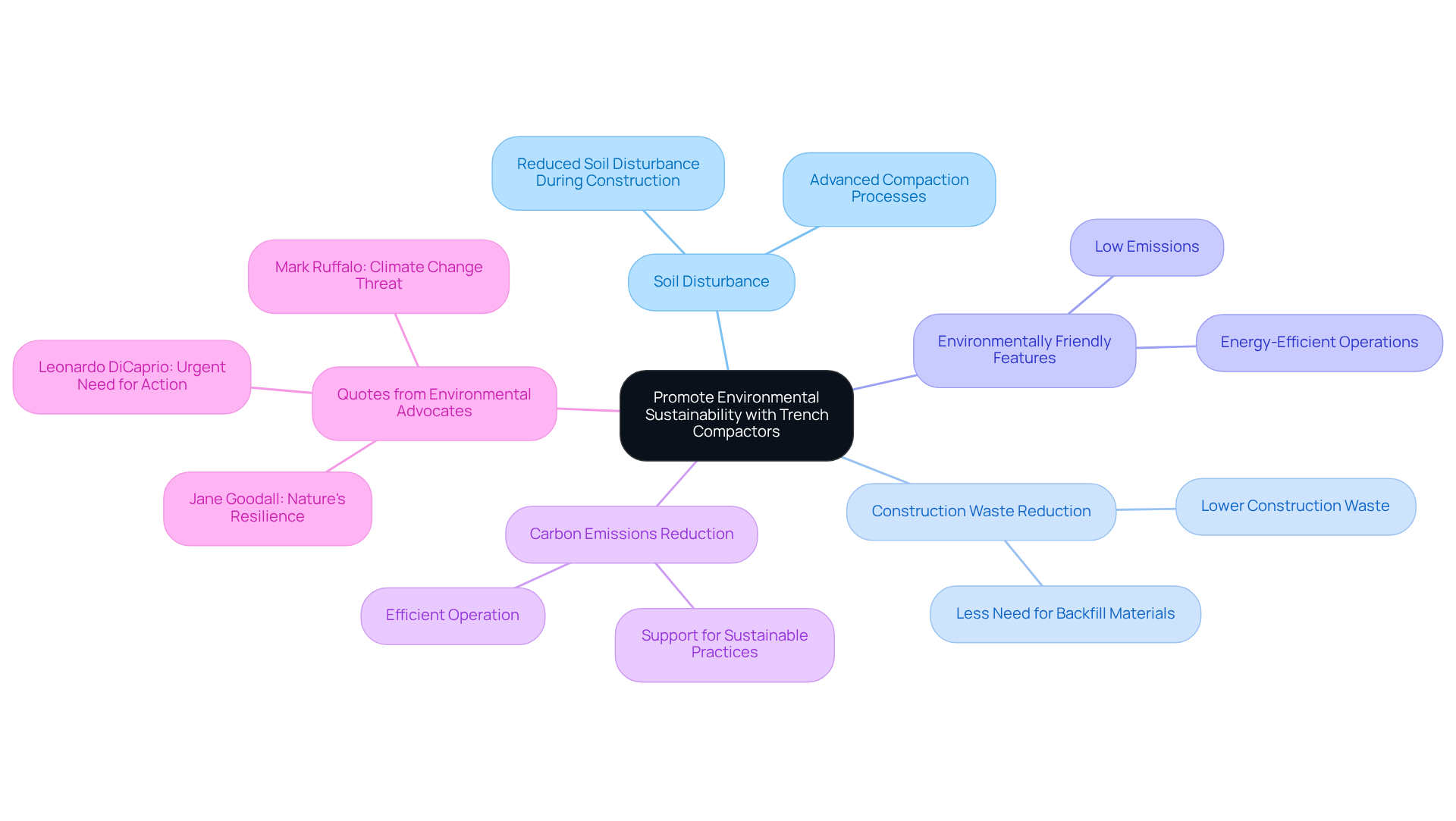

Promote Environmental Sustainability with Trench Compactors

Trench compactors are essential for enhancing environmental sustainability by significantly reducing soil disturbance during construction activities. Their advanced compaction processes ensure that soil is densely packed, which reduces the need for excessive backfill materials and effectively lowers construction waste. Additionally, many modern trench compactors are equipped with environmentally friendly features, such as low emissions and energy-efficient operations, which align with the industry's growing commitment to sustainable practices. This transition not only contributes to reduced carbon footprints but also supports construction methods that prioritize the health of our planet.

As environmental advocates like Jane Goodall emphasize, 'nature is resilient and can support life again if given time and help.' This reinforces the notion that every effort counts in combating climate change. Furthermore, the use of trench compactors can lead to significant reductions in carbon emissions, as they are designed to operate efficiently, thereby promoting a more sustainable construction sector.

Leverage Advanced Technology in Trench Compactors

Modern trench compactors now incorporate advanced technology that significantly boosts their performance and usability. The integration of GPS technology allows for precise monitoring of density quality, ensuring contractors achieve optimal results consistently. This innovation has been shown to enhance efficiency by up to 15%, as real-time feedback helps prevent over-compaction, which can lead to material failure.

Moreover, dual amplitude settings enable operators to adjust the compression force according to different soil types, improving performance across various applications. For example, forward plate compactors are well-suited for granular soils and asphalt, while reversible models offer enhanced maneuverability in tight spaces, making them versatile tools on job sites.

Remote control operation further streamlines the densification process, allowing operators to manage equipment from a distance. This capability reduces labor costs and minimizes the risk of human error. Additionally, the shift towards all-electric compression machines is gaining momentum, significantly lowering emissions and operating expenses while simplifying use for new operators. As James Thornton, CEO of Thornton Equipment, highlights, selecting the right trench compactor can considerably shorten timelines and improve surface quality, making these innovations essential for modern construction practices.

The growing demand for innovative compaction solutions is driven by urbanization and infrastructure initiatives, underscoring the importance of staying current with the latest technology.

Access Comprehensive Support and Rental Options for Trench Compactors

Contractors can significantly enhance their work efficiency with the extensive support and flexible rental options available for soil machines at EZ Equipment Rental. We set ourselves apart by offering a diverse selection of well-maintained trench compactors tailored to meet various project requirements, along with expert guidance to help contractors choose the most suitable equipment. This assistance not only facilitates effective project management but also helps minimize costs and maximize productivity.

With our high customer satisfaction ratings, contractors can rely on us to provide the necessary support for a seamless rental experience. Our competitive pricing and extensive inventory ensure that contractors can access the equipment they need without straining their budgets. For example, effective management strategies, such as barcode tracking systems, have been shown to reduce losses and guarantee that contractors have the tools they require when they need them.

Moreover, considering that the construction industry contributes nearly 40% of global emissions, utilizing efficient equipment is essential for sustainable practices. As Mike Disser from RMC Consults LLC points out, rising costs require rental companies to communicate effectively with customers to maintain satisfaction. By leveraging these resources, contractors can concentrate on their core tasks while EZ Equipment Rental manages the complexities of equipment rental.

Conclusion

Trench compactors are essential tools that significantly enhance construction projects by improving soil stability, accelerating compaction processes, and ensuring job site safety. Their effectiveness in densifying soil leads to a solid foundation, which reduces the risk of costly repairs and project delays. As the construction industry evolves, the versatility and efficiency of trench compactors make them indispensable for various applications, including utility installations and road construction.

This article has highlighted several key benefits of trench compactors, such as their role in achieving cost savings, promoting environmental sustainability, and integrating advanced technology. The compact design and user-friendly features of modern trench compactors streamline operations while enhancing operator safety and comfort. Furthermore, the growing demand for these machines underscores their importance in meeting the rigorous standards of today’s construction landscape.

Embracing the advantages of trench compactors is crucial for contractors seeking to improve project outcomes and sustainability. By investing in these advanced machines and leveraging their capabilities, construction teams can enhance their efficiency and contribute to a safer, more environmentally friendly industry. As the market for soil compaction equipment continues to expand, staying informed about the latest innovations will empower contractors to make informed choices for their projects.

Frequently Asked Questions

What is the primary function of trench compactors?

Trench compactors are designed to compress soil in narrow ditches, enhancing soil stability by reducing air pockets and increasing density through high-frequency vibrations.

Why is soil densification important in construction projects?

Effective soil densification prevents subsidence, ensuring that the ground can adequately support structures, pipes, or cables, thereby minimizing the risk of settling that can lead to costly repairs and project delays.

How do trench compactors impact project timelines?

Trench compactors provide quick and efficient soil density, allowing contractors to accelerate project timelines and reduce labor costs by minimizing the time spent on compaction.

In what construction applications are trench compactors particularly useful?

Trench compactors are versatile and used in various applications, including utility installation, road construction, and landscaping, where efficient soil compression in confined spaces is required.

What are some benefits of using trench compactors in utility projects?

They help maintain optimal soil density around pipelines, reducing the risk of future settling that could compromise utility services and preventing issues like pavement cracking and sinkholes.

How do modern trench compactors enhance performance in cohesive soils?

Modern trench compactors feature designs such as padfoot drums and standard extensions that allow for deeper penetration and improved compaction, making them effective in urban settings with limited space.

What advancements have been made in trench compactor technology?

The introduction of remote-controlled excavation compacting machines has improved safety protocols, allowing operators to work from outside the excavation site, thereby reducing risks associated with deep digging.

What is the projected market growth for soil compaction machines?

The soil compaction machines market is projected to reach USD 11.8 billion by 2035, indicating the growing importance of trench compactors in the construction industry.

List of Sources

- Improve Soil Stability with Trench Compactors

- Zekkos' Favorite Terzaghi's sayings (https://geoengineer.org/education/karl-terzaghi/quotes)

- Soil compaction advances from key firms (https://globalhighways.com/wh2/products/soil-compaction-advances-key-firms)

- Soil Compaction Machines Market Share and Statistics - 2035 (https://factmr.com/report/1978/soil-compaction-machines-market)

- Ultimate Guide to Trench Compaction and Backfilling Methods for Landscape Professionals (https://tomahawk-power.com/blogs/articles/trench-compaction-backfilling-methods?srsltid=AfmBOoq50QHxud5JkYuNHQv8MWLKz2mkFpjIRXqi8lvjWMz9yi0rOsBz)

- Accelerate Compaction Processes Using Trench Compactors

- Get Motivated with 20 Classic Quotes About Construction (https://planhub.com/resources/get-motivated-with-20-classic-quotes-about-construction)

- 10 Construction Quotes to Inspire Your Project (https://horstconstruction.com/10-wise-construction-quotes-to-inspire-your-next-project-2)

- 40 Construction Quotes to Motivate Your Team (https://projectmanager.com/blog/construction-quotes)

- Top 10 Construction Quotes to Inspire Your Next Project (https://estimators.us/construction-quotes-to-inspire-your-next-project)

- 9 Inspiring Quotes About Construction (https://constructconnect.com/blog/9-inspiring-construction-quotes)

- Utilize Trench Compactors for Diverse Construction Applications

- Trench Roller / Compactors - Bobcat Company (https://bobcat.com/na/en/equipment/light-compaction/trench-rollers)

- What is Trench Compactor? Uses, How It Works & Top Companies (2025) (https://linkedin.com/pulse/what-trench-compactor-uses-how-works-top-companies-2025-s4b8c)

- Trench Compactor (https://bladesdirect.net/blogs/diamond-blade-1/trench-compactor?srsltid=AfmBOoomuFGWKBXUnV-esaTnyyE2uUXfCacb4AQn4fSKhwtyCNl1mUKQ)

- Achieve Cost Savings with Trench Compactors

- Soil Compaction Machines Market Share and Statistics - 2035 (https://factmr.com/report/1978/soil-compaction-machines-market)

- United States Trench Compactor Market Market Revenue, Future Scope & CAGR 2026-2033 (https://linkedin.com/pulse/united-states-trench-compactor-market-revenue-lhlzf)

- How Proper Compaction Reduces Long-Term Maintenance Costs in Construction (https://nationaldispatching.com/how-proper-compaction-reduces-long-term-maintenance-costs)

- Enhance Job Site Safety with Trench Compactors

- Safety Quotes: Motivation to Improve Work Safety Culture (https://osha.com/blog/work-safety-quotes)

- Powerful Safety Quotes to Strengthen Your Workplace Culture (https://getmojo.ai/blog/safety-quotes-to-strengthen-your-workplace-culture)

- 40+ Inspiring Safety Quotes for Work to Strengthen Your Safety Culture and Motivate Your Team (https://flowdit.com/workplace-safety-quotes)

- Contact Us | Outside US & Canada | Damotech (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- Top 20 Safety Quotes To Improve Your Safety Culture (https://blog.safetyculture.com/industry-trends/top-20-safety-quotes-improve-safety-culture)

- Simplify Operations with User-Friendly Trench Compactors

- Get Motivated with 20 Classic Quotes About Construction (https://planhub.com/resources/get-motivated-with-20-classic-quotes-about-construction)

- 10 Construction Quotes to Inspire Your Project (https://horstconstruction.com/10-wise-construction-quotes-to-inspire-your-next-project-2)

- Ensure Durability and Reliability with Trench Compactors

- The Role of Reversible Plate Compactors in Pipeline and Trench Work – Excalibur Generator (https://excalibur-generator.com/the-role-of-reversible-plate-compactors-in-pipeline-and-trench-work)

- Utility Trench Backfill Compaction Using Vibratory Plate Compactor Versus Excavator-Mounted Hydraulic Plate Compactor - TRID (https://trid.trb.org/View/1974064)

- Case Study of Trenchless Technology Around The Globe (https://academia.edu/81960424/Case_Study_of_Trenchless_Technology_Around_The_Globe)

- Promote Environmental Sustainability with Trench Compactors

- 21 Conservation Quotes From President Theodore Roosevelt (https://gearjunkie.com/outdoor/hunt-fish/conservation-quotes-president-theodore-roosevelt)

- 10 Inspirational Quotes from Celebrities on Protecting the Environment | Earth.Org (https://earth.org/inspirational-quotes-from-celebrities-on-environment)

- 12 Quotes by Environmentalists to Inspire a Sustainable and Just Future (https://medium.com/environmental-intelligence/12-quotes-by-environmentalists-to-inspire-a-sustainable-and-just-future-21db4521b933)

- Sustainable Rental Equipment Solutions | Sunbelt Rentals (https://sunbeltrentals.com/resources/sustainability)

- Leverage Advanced Technology in Trench Compactors

- Get Motivated with 20 Classic Quotes About Construction (https://planhub.com/resources/get-motivated-with-20-classic-quotes-about-construction)

- Top 10 Compacting Machinery You Need for Efficient Construction Projects (https://cnchanglin.com/blog/top-10-compacting-machinery-for-efficient-construction)

- 30 Engineer Quotes That Help You Work Smarter - Keysight Technologies (https://keysight.com/used/us/en/knowledge/guides/engineer-quotes-that-help-you-work-smarter)

- Compaction Equipment Market (https://market.us/report/compaction-equipment-market)

- Trench Compactor Market Size, Share, Growth | CAGR Forecast 2032 (https://futuremarketreport.com/industry-report/trench-compactor-market)

- Access Comprehensive Support and Rental Options for Trench Compactors

- 10 ‘food for thought’ quotes on equipment rental in 2024 (https://internationalrentalnews.com/news/words-of-wisdom-of-2024-so-far-10-quotes-providing-food-for-thought/8038427.article)

- Case study: Construction Company Saves Big with Managed Tools (https://unitedrentals.com/our-company/case-studies/specialty-solutions/managed-tool-trailer-construction)

- Trench Safety - Home (https://unitedrentals.com/solutions/specialty-solutions/trench-safety)