Key Highlights:

- EZ Equipment Rental is a leading supplier of 10k forklifts in the Dallas-Fort Worth area, prioritising customer satisfaction.

- The 10k forklift can lift up to 10,000 pounds, enhancing efficiency in heavy-duty construction tasks.

- Designed for versatility, the 10k forklift can operate on various terrains, crucial for productivity on uneven job sites.

- Dual fuel options (gasoline and propane) provide flexibility and cost-effectiveness, supporting sustainability initiatives.

- Advanced safety features, including stability control and operator presence sensors, reduce accident risks on construction sites.

- User-friendly controls simplify operation for all skill levels, boosting operator confidence and productivity.

- Low maintenance needs ensure long-term reliability and minimise downtime, enhancing project efficiency.

- Exceptional manoeuvrability allows the 10k forklift to navigate tight spaces, improving workflow on congested job sites.

- Telematics technology facilitates real-time performance monitoring, aiding in informed decision-making to enhance productivity.

- The overall value of the 10k forklift lies in its combination of efficiency, safety, and cost savings, making it a smart investment for contractors.

Introduction

The construction industry is in a state of constant evolution, with the demand for efficient and reliable equipment reaching unprecedented levels. Among the essential tools in this sector, the 10K forklift stands out due to its remarkable capabilities, specifically engineered to address the toughest challenges encountered on job sites. This article explores ten key features of the 10K forklift, emphasizing how its advanced technology, safety enhancements, and operational versatility can significantly enhance productivity and safety in construction projects. What, then, makes this machinery a pivotal asset for contractors and project managers navigating the complexities of modern construction?

EZ Equipment Rental: Your Source for 10K Forklifts in Construction

EZ Equipment Rental stands out as the premier supplier of 10k forklifts in the Dallas-Fort Worth area, offering a diverse range of high-quality machinery tailored to meet various construction needs. Their steadfast commitment to customer satisfaction ensures that clients receive dependable and efficient equipment, reinforcing their status as the go-to choice for contractors and project managers alike. As the construction industry increasingly recognizes the importance of reliable equipment rental, EZ Equipment Rental allows teams to focus on critical tasks without the burdens of ownership.

The 10k forklift available is equipped with advanced technology, which enhances both operational efficiency and safety on job sites. Furthermore, renting from EZ Equipment Rental provides essential flexibility and cost-effectiveness, crucial for successful project execution in Texas. By choosing EZ Equipment Rental, construction professionals can access state-of-the-art machinery while enjoying expert support and maintenance-free operations, ultimately driving project success.

High Lifting Capacity: Handling Up to 10,000 Pounds

The 10K forklift is specifically engineered for heavy-duty applications, providing a lifting capacity of up to 10,000 pounds. This impressive capability enables operators to efficiently lift and transport substantial materials, such as steel beams and concrete blocks, which are essential for various construction activities.

To ensure safety and operational efficiency, proper load distribution and adherence to regulations are crucial. The 10K forklift significantly enhances building efficiency and safety, which are vital for meeting project timelines.

By utilizing this equipment from EZ Equipment Rental, project managers can guarantee that their operations proceed smoothly and effectively.

Versatile Operation: Suitable for Various Terrain Types

The 10k forklift is designed for versatile operation, effectively navigating various terrain types, including rough and uneven surfaces. This adaptability is crucial, as approximately 70% of building sites encounter uneven terrain, which can hinder productivity and safety. Operators can perform tasks efficiently, regardless of environmental challenges, ensuring a seamless workflow on job sites.

Construction site managers often highlight the significance of terrain adaptability, noting that the right equipment can greatly enhance operational efficiency and minimize the risk of accidents. With features engineered for stability and maneuverability, including options like electric and rough terrain lifters, the 10k forklift emerges as an essential asset for any construction project, particularly in demanding conditions.

Dual Fuel Options: Gas and Propane for Flexibility

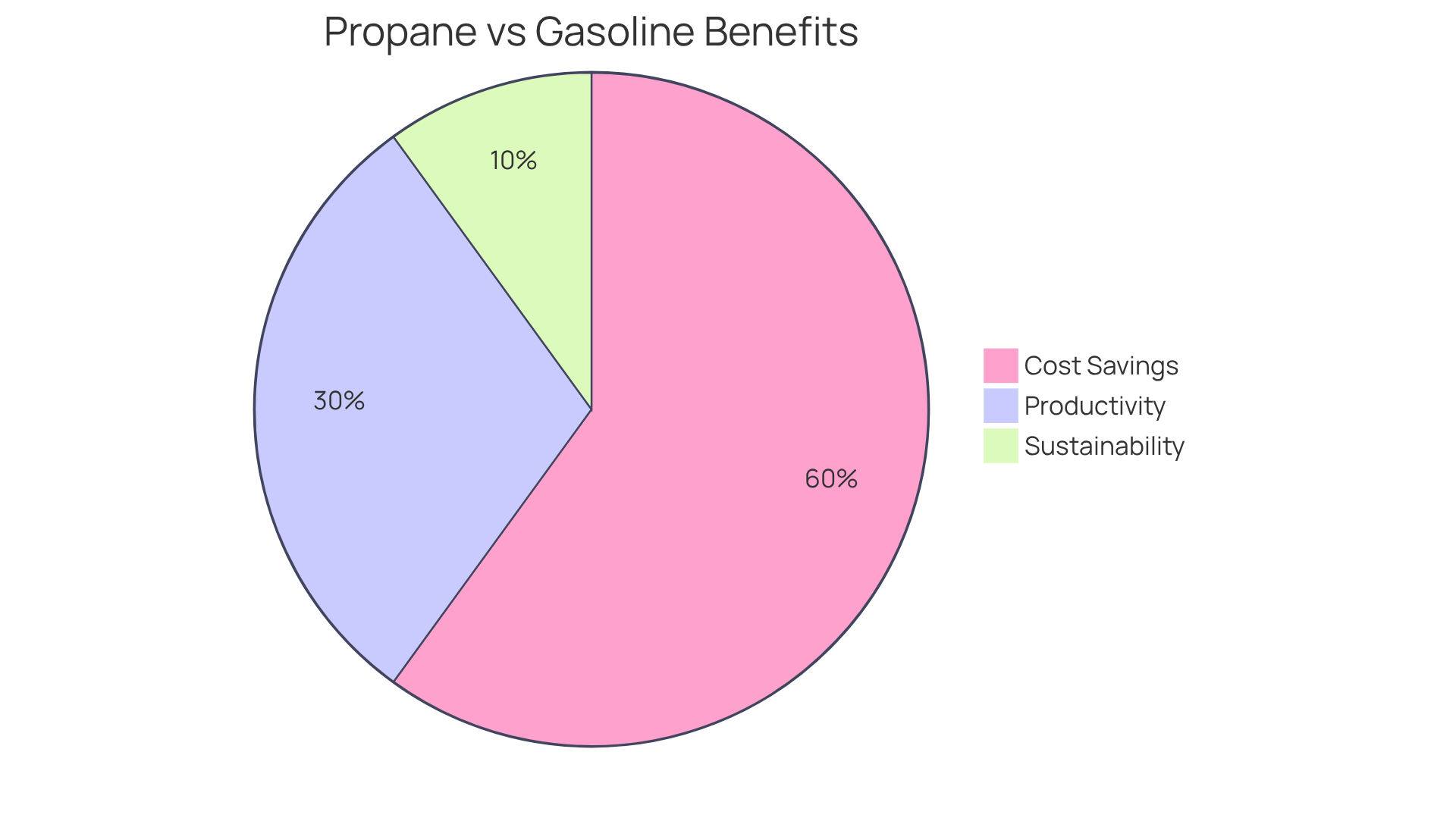

The 10k forklift's dual fuel capability enables operation on either gasoline or propane, offering operators the flexibility to select the most economical and accessible fuel source. This adaptability is essential for maintaining smooth operations on construction sites, where fuel availability can fluctuate.

For example, propane-powered vehicles deliver consistent power throughout their operational cycle, ensuring high productivity without interruptions. According to the Propane Education & Research Council, "Propane lift trucks provide 100 percent power, inside and out, for better productivity."

Furthermore, a cost comparison between gasoline and propane indicates that propane often emerges as a more economical choice, especially in environments with fluctuating fuel prices. Practical applications, such as those observed at Seaonus Stevedoring, demonstrate that businesses utilizing dual fuel handling equipment can enhance operational efficiency while reducing costs, making them a prudent option for various construction projects.

This fuel flexibility not only boosts productivity but also supports sustainability initiatives by lowering emissions associated with traditional fuel sources. Additionally, it is vital to emphasize that proper training and equipment maintenance can significantly reduce the likelihood of incidents, which are prevalent on construction sites.

Enhanced Safety Features: Prioritizing Operator Protection

The 10k forklift features advanced security measures that prioritize operator safety, including:

- Stability control systems

- Operator presence sensors

- Robust overhead guards

These enhancements significantly lower the risk of accidents, fostering a safer working environment on construction sites. Statistics reveal that approximately 11% of lift trucks in the U.S. are involved in accidents each year, with an estimated 35,000 to 62,000 lift-related injuries occurring annually. This underscores the importance of implementing precautionary measures.

Furthermore, experts emphasize that effective protection programs should include:

- Routine training

- Assessments

As equipment operators must be evaluated at least once every three years to maintain high security standards. As the lift truck market evolves, modern models now integrate cutting-edge safety technologies, such as telematics systems that monitor speed, impact, and operator behavior, further enhancing workplace safety. By investing in lifts equipped with these features, site managers can effectively mitigate risks and protect their workforce.

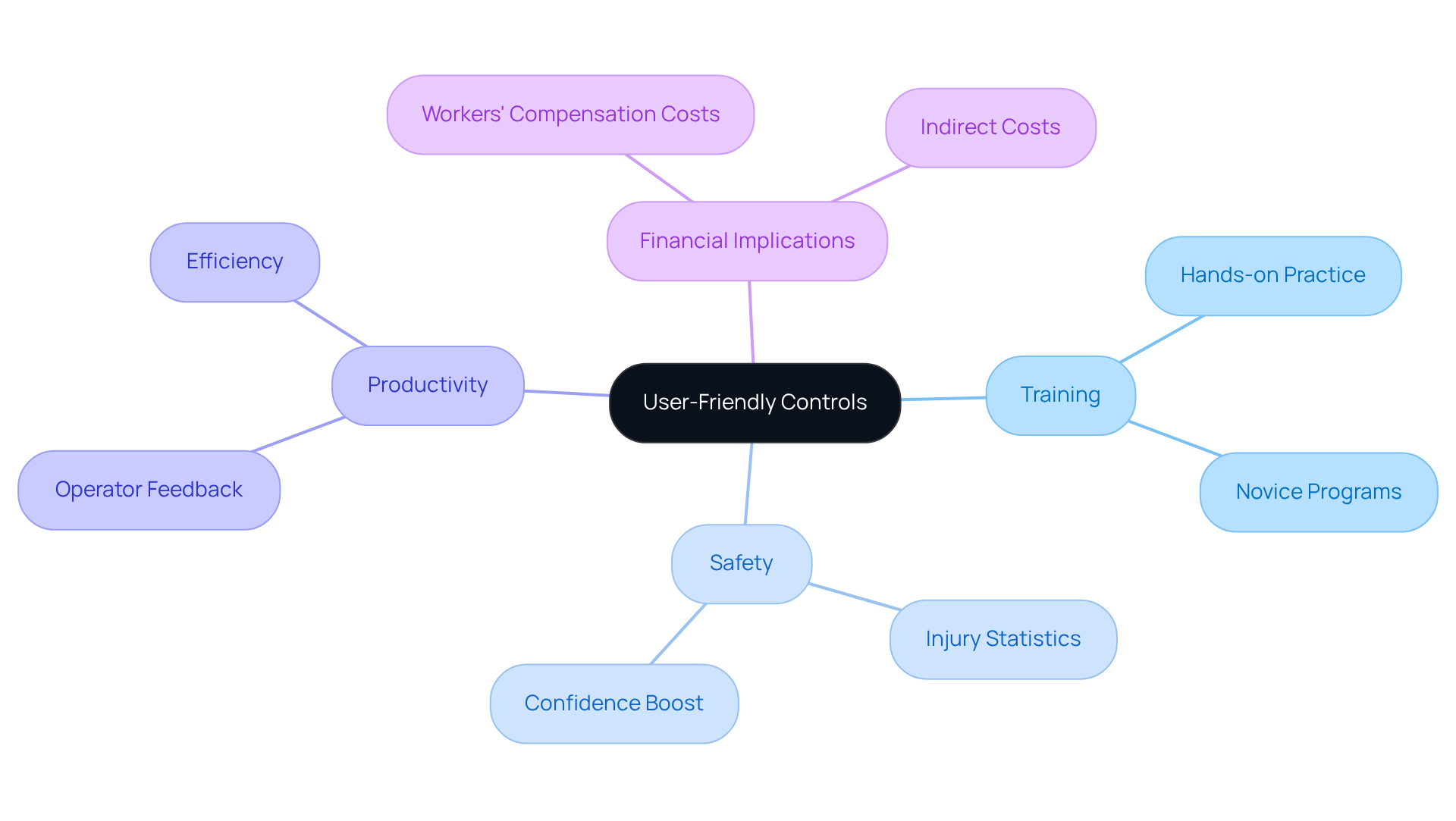

User-Friendly Controls: Simplifying Operation for All Skill Levels

User-Friendly Controls: Simplifying Operation for All Skill Levels

The 10K forklift is designed with user-friendly controls that simplify operation for both novice and experienced operators. Featuring intuitive joystick controls and clear instrumentation, users can quickly grasp the mechanics of operation, which is essential in fast-paced building environments. Training programs tailored for novice operators emphasize hands-on practice with these controls, ensuring safe and efficient machinery operation from the outset. Operators have reported that the ease of use provided by these controls boosts their confidence and enhances overall productivity on the job site. This streamlined approach to handling a 10K forklift is vital for maintaining safety and efficiency in construction projects.

Moreover, investing in user-friendly controls can lead to significant financial savings. The typical direct expense of a workers' compensation claim for a lifting equipment injury ranges from $38,000 to $41,000, with indirect costs potentially four to six times greater. Statistics indicate that approximately 35,000 to 62,000 injuries occur annually involving forklifts, underscoring the importance of effective training programs. As one operator noted, "The intuitive controls have made a world of difference in my productivity; I can focus on the task at hand rather than struggling with the machine." This highlights the critical role of user-friendly designs in enhancing safety and operational efficiency.

For construction project managers, prioritizing training on these user-friendly controls can not only improve safety but also enhance overall project efficiency.

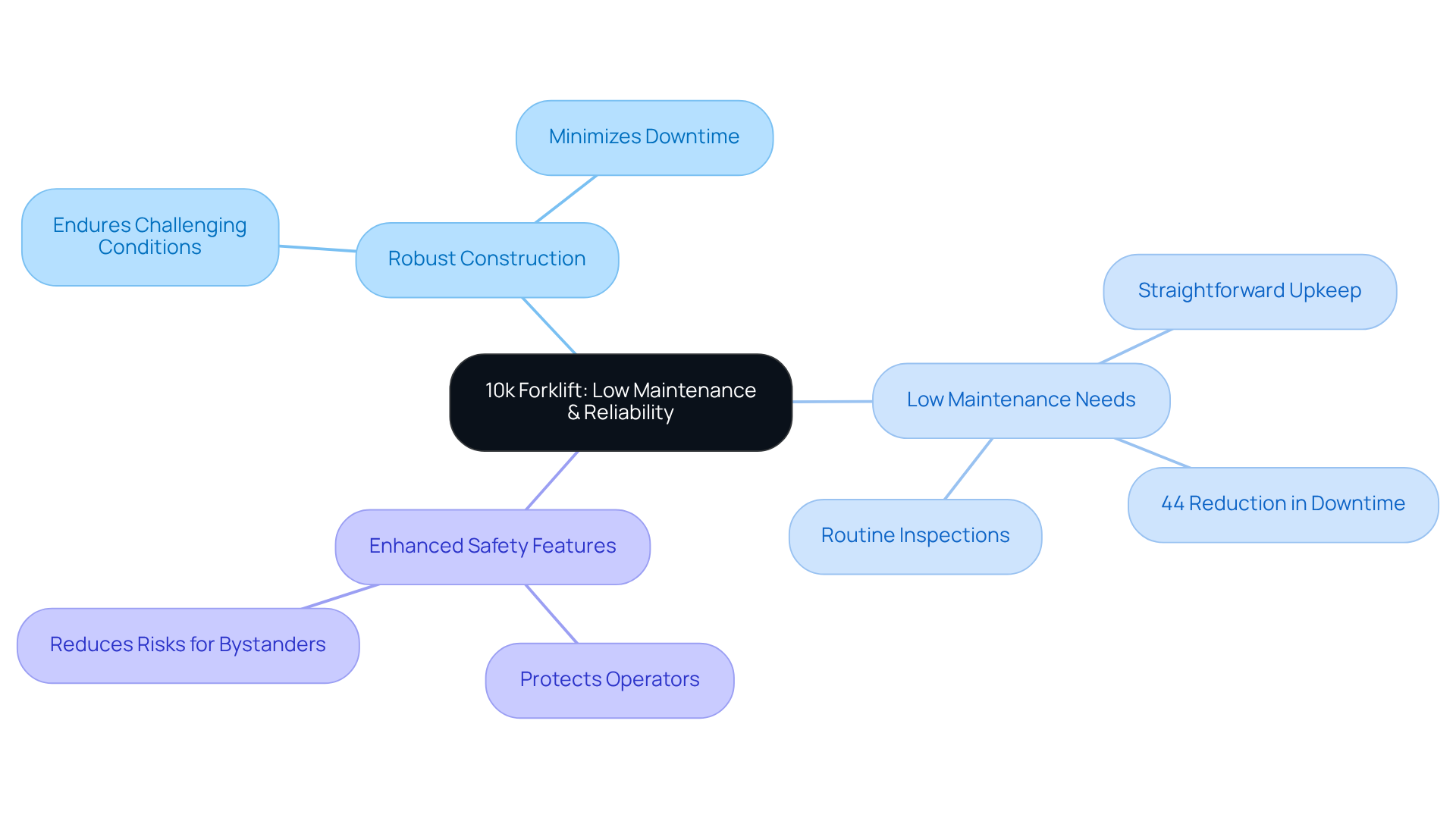

Low Maintenance Needs: Ensuring Long-Term Reliability

Engineered for durability, the 10k forklift is distinguished by its low maintenance requirements, significantly enhancing its long-term reliability. Key features include:

- Robust Construction: Built to endure challenging job site conditions.

- Low Maintenance Needs: Routine inspections and straightforward upkeep are all that’s necessary to keep this equipment in peak condition.

- Enhanced Safety Features: Fitted with advanced safety mechanisms to protect both operators and bystanders.

This proactive approach minimizes downtime, ensuring that construction projects remain on schedule. Research indicates that organizations investing in maintenance programs can reduce downtime by an average of 44%, highlighting the essential role of effective maintenance in boosting equipment performance. Moreover, equipment managers assert that reducing maintenance not only extends the lifespan of machinery but also cultivates a culture of reliability on job sites. In 2026, the durability of construction equipment such as the 10k forklift is crucial, as it directly influences project efficiency and overall operational success, especially in warehouse environments where effective material handling is vital.

Maneuverability: Navigating Tight Spaces with Ease

The 10k forklift stands out for its exceptional maneuverability, making it an ideal choice for navigating tight spaces on congested job sites. Its compact design, paired with responsive steering, enables operators to position materials with precision, thereby enhancing overall workflow efficiency. Project managers have noted that the ability to navigate in confined areas significantly reduces downtime and improves safety.

For instance, compact lifting machines like the TCM models have played a pivotal role in transforming operations at locations such as ÖSTU-Szczecin, where a 10k forklift was utilized to bolster security and facilitate movement. This adaptability not only streamlines operations but also ensures that equipment size does not impede productivity, allowing teams to operate effectively even in challenging environments.

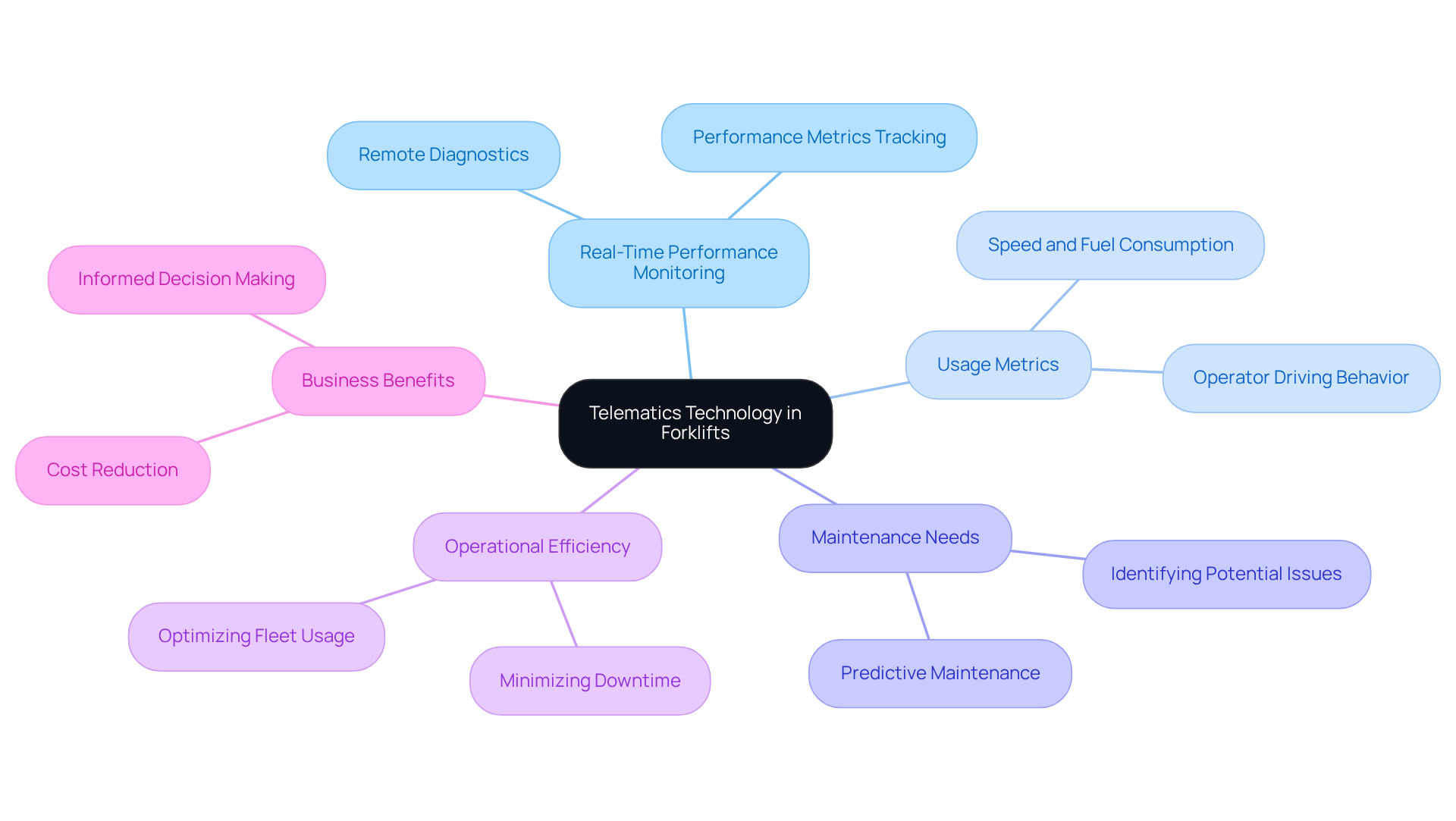

Advanced Technology: Utilizing Telematics for Performance Monitoring

The 10k forklift features cutting-edge telematics technology, which facilitates real-time performance monitoring. This allows operators to track essential usage metrics, identify maintenance needs, and assess operational efficiency. By leveraging this data, businesses can make informed decisions that not only enhance productivity but also help reduce costs. The integration of such advanced technology underscores the reliability and quality that customers can expect from our equipment.

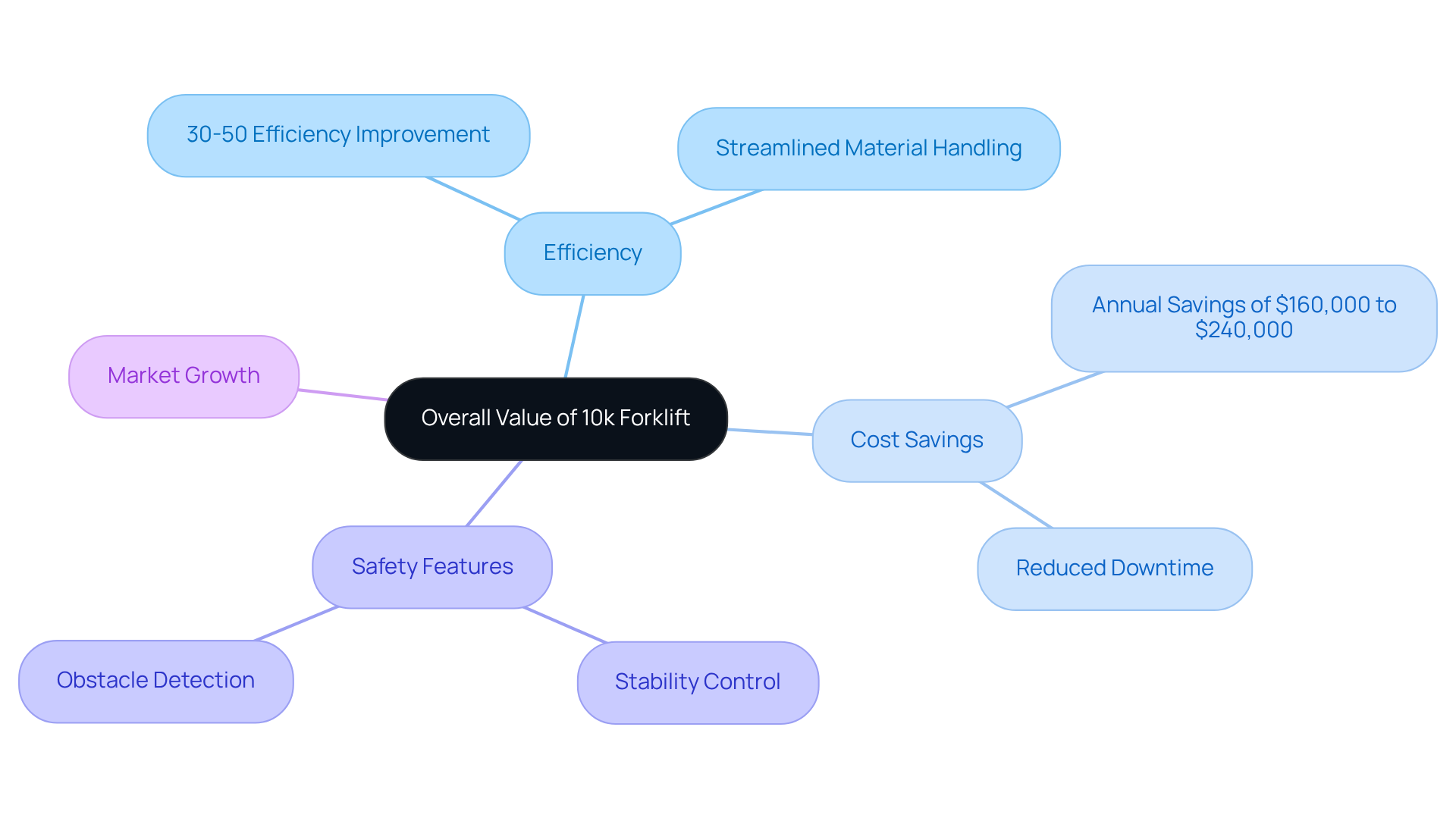

Overall Value: Maximizing Efficiency in Construction Projects

The 10k forklift is a valuable asset for construction projects, providing a remarkable combination of high lifting capacity, versatility, and advanced safety features - all at a competitive price point. This equipment maximizes efficiency and significantly reduces downtime, making it a smart investment for contractors and project managers focused on timely and budget-conscious project completion.

Statistics show that using advanced lifting machines can enhance efficiency by 30% to 50%, leading to smoother operations and increased productivity on job sites. Contractors have noted that the overall value of the 10k forklift extends beyond its initial cost; it contributes to substantial savings in labor and operational expenses, with some reporting annual savings of $160,000 to $240,000 when transitioning from manual to autonomous models.

Integrating the 10k forklift into building projects streamlines material handling and aligns with the industry's shift towards automation and efficiency, ensuring projects are completed on schedule and within budget. Additionally, the advanced safety features of the 10k forklift, such as stability control systems and obstacle detection, significantly enhance operator safety and reduce accident risks, further solidifying its value in the construction sector. As the forklift market is projected to grow significantly, investing in advanced models such as the 10k forklift positions contractors to effectively meet future demands.

Conclusion

The 10K forklift stands out as an essential asset for construction projects, offering a high lifting capacity, versatility, and advanced safety features that significantly boost operational efficiency. By opting for EZ Equipment Rental, construction professionals gain access to dependable machinery that meets diverse project requirements, facilitating smoother workflows and enhancing safety on job sites.

Key features of the forklift include:

- Impressive ability to handle loads of up to 10,000 pounds

- Adaptability to various terrains

- Dual fuel options

- User-friendly controls

Furthermore, the focus on enhanced safety measures and low maintenance needs highlights the importance of investing in equipment that prioritizes operator protection and long-term reliability. Collectively, these attributes maximize efficiency and minimize downtime, both of which are critical for successful project execution.

Leveraging the capabilities of the 10K forklift can lead to significant cost savings and increased productivity, making it a prudent investment for contractors and project managers. As the construction industry evolves, embracing advanced technology and reliable equipment becomes vital for maintaining competitiveness. The 10K forklift not only addresses current demands but also positions businesses for future success, ensuring that projects are completed on time and within budget.

Frequently Asked Questions

What is EZ Equipment Rental known for?

EZ Equipment Rental is recognized as the premier supplier of 10k forklifts in the Dallas-Fort Worth area, offering a diverse range of high-quality machinery for various construction needs.

What benefits does EZ Equipment Rental provide to its clients?

EZ Equipment Rental ensures customer satisfaction by providing dependable and efficient equipment, allowing construction teams to focus on critical tasks without the burdens of ownership.

What features does the 10k forklift offer?

The 10k forklift is equipped with advanced technology that enhances operational efficiency and safety on job sites, with a lifting capacity of up to 10,000 pounds for heavy-duty applications.

Why is load distribution important when using a 10k forklift?

Proper load distribution is crucial for safety and operational efficiency, ensuring that the forklift can lift and transport substantial materials like steel beams and concrete blocks effectively.

How does the 10k forklift adapt to different terrains?

The 10k forklift is designed for versatile operation, allowing it to navigate various terrain types, including rough and uneven surfaces, which is essential for maintaining productivity and safety on construction sites.

What are the advantages of renting a 10k forklift from EZ Equipment Rental?

Renting from EZ Equipment Rental provides flexibility and cost-effectiveness, access to state-of-the-art machinery, and expert support, all of which drive project success without maintenance concerns.

How does terrain adaptability impact construction projects?

Terrain adaptability is significant as it enhances operational efficiency and minimizes the risk of accidents, especially since approximately 70% of building sites encounter uneven terrain.

List of Sources

- EZ Equipment Rental: Your Source for 10K Forklifts in Construction

- 10K Industrial Forklift Gas/Propane | Sunbelt Rentals (https://sunbeltrentals.com/equipment-rental/forklifts/10-000-lb-dual-fuel-14-17-industrial-forklift-gas-propane/0550610)

- 7 Benefits of 10k Forklift Rental for Construction Projects (https://blog.ezequipmentrental.com/7-benefits-of-10-k-forklift-rental-for-construction-projects)

- Construction Equipment Rental Market Statistics 2025-2034 (https://statifacts.com/outlook/us-construction-equipment-rental-market)

- 10 ‘food for thought’ quotes on equipment rental in 2024 (https://internationalrentalnews.com/news/words-of-wisdom-of-2024-so-far-10-quotes-providing-food-for-thought/8038427.article)

- 2025 Heavy Equipment Rental Industry Market Research Report (https://kentleyinsights.com/heavy-equipment-rental-industry-market-research-report)

- High Lifting Capacity: Handling Up to 10,000 Pounds

- Case Studies | Maxim Crane (https://maximcrane.com/case-study)

- Forklift Weight Capacity: Everything You Need to Know (https://conger.com/forklift-weight-capacity)

- High-capacity telehandlers face test of strength amid economic headwinds (https://internationalrentalnews.com/news/high-capacity-telehandlers-face-test-of-strength-amid-economic-headwinds/8083420.article)

- Versatile Operation: Suitable for Various Terrain Types

- 113 Construction Statistics You Need to Know in 2024 - Neuroject (https://neuroject.com/construction-statistics)

- Rough Terrain Forklifts: Key Benefits, Features, and Why You Need One (https://forklifttire.com/articles/rough-terrain-forklifts-key-benefits-features-and-why-you-need-one?srsltid=AfmBOoqDQuvTPBdQPYT2h94BEYWuNFEWqfP6Jn0Xg6o8wd8iGsGzNPX9)

- Construction safety in 2022 – In-Depth Statistics (https://remato.com/blog/construction-safety-in-2022)

- The Best Forklifts for Outdoor and Rough Terrain Applications | Equipment Depot (https://blog.eqdepot.com/rough-terrain-forklifts)

- 7 Benefits of Choosing an All-Terrain Forklift (https://intellaparts.com/blog/7-benefits-of-choosing-an-all-terrain-forklift?srsltid=AfmBOorXJrMF-LtFTTFn1w-2nqGiGxgTFUiceuElzKmeMWG862hblcwo)

- Dual Fuel Options: Gas and Propane for Flexibility

- Forklift Market | Global Market Analysis Report - 2035 (https://factmr.com/report/forklift-market)

- Materials Handling and Forklift Case Studies | Hyster (https://hyster.com/en-us/north-america/support-resources/case-studies)

- Heavy Equipment Case Studies: Off-Road & Dual Fuel Forklifts-HZZG (https://hezhongmachinery.com/case-center)

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- Get Powerful Indoor and Outdoor Performance with Propane Forklifts (https://mmh.com/article/get_powerful_indoor_and_outdoor_performance_with_propane_forklifts/News)

- Enhanced Safety Features: Prioritizing Operator Protection

- 5 Common Forklift Accidents and How to Prevent Them - OSHA.com (https://osha.com/blog/5-most-common-forklift-accidents-and-how-to-prevent-them)

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- National Forklift Safety Day Statistics │ MHEDA (https://mheda.org/journal/national-forklift-safety-day-statistics)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Contact Us | Outside US & Canada | Damotech (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- User-Friendly Controls: Simplifying Operation for All Skill Levels

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Smart Forklift Launch: Revolutionising Warehouse Operations (https://en.autoxing.com/news/revolutionising-warehouse-operations-the-launch-of-our-smart-forklift)

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- Productivity Quotes Quotes (66 quotes) (https://goodreads.com/quotes/tag/productivity-quotes)

- 85 quotes for operational excellence and leadership | Rever, Inc posted on the topic | LinkedIn (https://linkedin.com/posts/rever-inc_85-quotes-operational-excellence-and-continuous-activity-7308865005079126019-a8iz)

- Low Maintenance Needs: Ensuring Long-Term Reliability

- 5 "Genius" Quotes to Inspire Better Facilities Maintenance (https://brightlysoftware.com/blog/5-genius-quotes-to-inspire-better-facilities-maintenance)

- 30 Key Maintenance Statistics & Facts Highlighting 2026 Trends (https://coastapp.com/blog/maintenance-metrics-statistics-facts)

- CAUTION: If You Don’t Schedule Time For Maintenance, Your Equipment Will Schedule It For You (https://tabletscapsules.com/3641-Technical-Articles/613473-CAUTION-If-You-Don-t-Schedule-Time-For-Maintenance-Your-Equipment-Will-Schedule-It-For-You-Optimizing-Encapsulation-Efficiency-With-A-Focus-On-Maintenance)

- 10 Compelling Statistics About Manufacturing Maintenance (https://worktrek.com/blog/manufacturing-maintenance-statistics)

- Maneuverability: Navigating Tight Spaces with Ease

- TCM Case Studies | TCM Forklifts (https://tcm.eu/tcm-case-studies-tcm-forklifts)

- Contact Us | Outside US & Canada | Damotech (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- Advanced Technology: Utilizing Telematics for Performance Monitoring

- Telematics Construction Equipment Market: Global Industry Analysis and Forecast (2025 -2032) (https://maximizemarketresearch.com/market-report/telematics-construction-equipment-market/280401)

- Construction Machinery Telematics Market Size, Share & Growth Graph by 2033 (https://straitsresearch.com/report/construction-machinery-telematics-market)

- Understanding Forklift Telemetry for Optimal Fleet Management (https://toyotaforklift.com/resource-library/blog/digital-solutions/understanding-forklift-telemetry-for-optimal-fleet-management)

- The key to achieving maximum forklift efficiency (https://forkliftbriefing.com/increase-productivity/the-key-to-achieving-maximum-forklift-efficiency)

- Overall Value: Maximizing Efficiency in Construction Projects

- U.S. Forklift Market Size And Share Analysis | Report, 2030 (https://grandviewresearch.com/industry-analysis/us-forklift-market-report)

- Forklift Market Statistics 2025-2034 (https://statifacts.com/outlook/forklift-market)

- Cost of Self-driving Forklifts and ROI for Warehouses – AITEN Robotics (https://aitenrobot.com/news/cost-of-self-driving-forklifts-and-roi-for-warehouses)

- Maximizing Warehouse Efficiency with Forklifts—The Ultimate Solution (https://acepalletracking.com/news/maximizing-warehouse-efficiency-with-forklifts.html)

- Forklift Market Size & Share, Statistics Report 2025-2034 (https://gminsights.com/industry-analysis/forklift-market)