Key Highlights:

- Payload capacity for non-CDL dump trucks ranges from 10,000 to 26,000 pounds, varying by configuration and regulations.

- Overloading can lead to safety hazards, mechanical issues, and legal consequences.

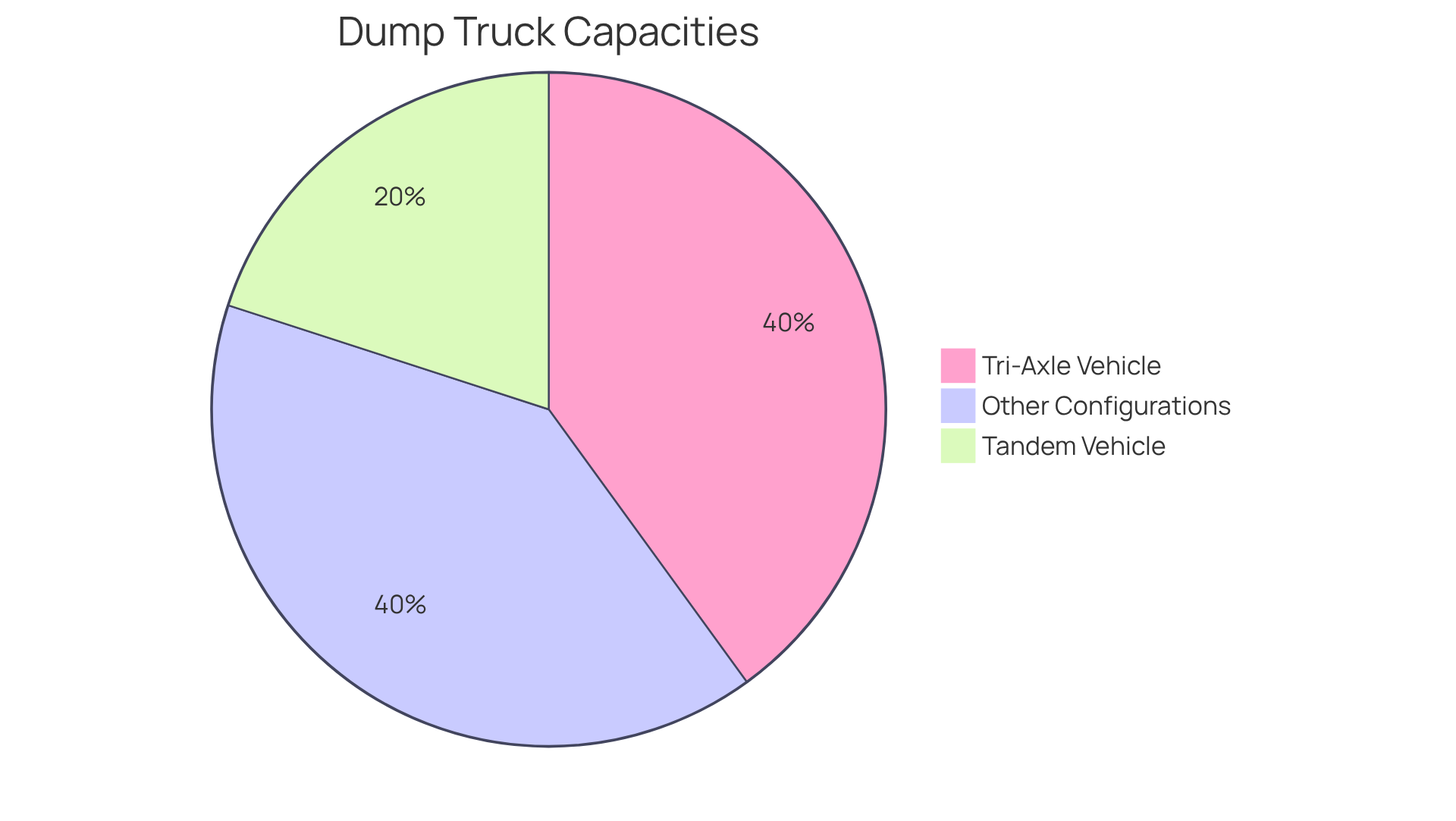

- Tandem trucks can transport 12 to 16 tonnes, while tri-axle models can handle up to 25 tonnes.

- Engine power typically ranges from 200 to 400 horsepower, with 350 to 400 hp recommended for challenging terrains.

- Manoeuvrability is crucial for urban job sites; shorter wheelbases and tighter turning radii enhance navigation.

- Safety features like backup alarms, visibility aids, and advanced braking systems are essential for worker protection.

- Durability and build quality are vital; high-quality materials and design features can extend a truck's lifespan.

- Maintenance accessibility is important for reducing downtime and operational costs; easy access to components facilitates upkeep.

- Fuel efficiency for non-CDL dump trucks averages 8 to 10 MPG, improving cost management compared to semi-vehicles.

- Integrating technology like telematics enhances operational efficiency and proactive maintenance scheduling.

- Versatility allows non-CDL dump trucks to adapt to various tasks, increasing their utility for diverse projects.

- Competitive pricing and flexible rental options from EZ Equipment Rental provide financial advantages for project managers.

Introduction

Evaluating a non-CDL dump truck involves more than just selecting a vehicle; it requires a thorough understanding of its capabilities and features that can significantly impact operational efficiency. This article explores ten essential aspects to consider, including:

- Payload capacity

- Engine power

- Safety features

- Maintenance accessibility

With the right knowledge, decision-makers can optimize their fleet for both performance and cost-effectiveness. But what are the critical elements that truly define the best non-CDL dump truck for a specific job? By examining these key features, we can make informed choices that enhance productivity and safety on the job site.

Evaluate Payload Capacity for Optimal Performance

Assessing the payload capacity of a non cdl dump truck is crucial for ensuring optimal performance and safety. Typically, these vehicles can carry between 10,000 and 26,000 pounds, depending on their configuration and local regulations. Understanding this capacity is essential for effectively managing materials required for various jobs, such as gravel, sand, or debris. Overloading a cargo vehicle presents significant safety hazards, including extended stopping distances and potential mechanical issues, while also leading to increased wear and tear on the vehicle and possible legal consequences.

For instance, a tandem vehicle can legally transport 12 to 16 tons, whereas tri-axle models can handle up to 25 tons, making them suitable for larger construction projects. It is imperative to consult the manufacturer's specifications and consider the density of the materials being transported. This ensures compliance with weight limits and helps maintain the vehicle's performance and longevity.

Assess Engine Power and Performance Requirements

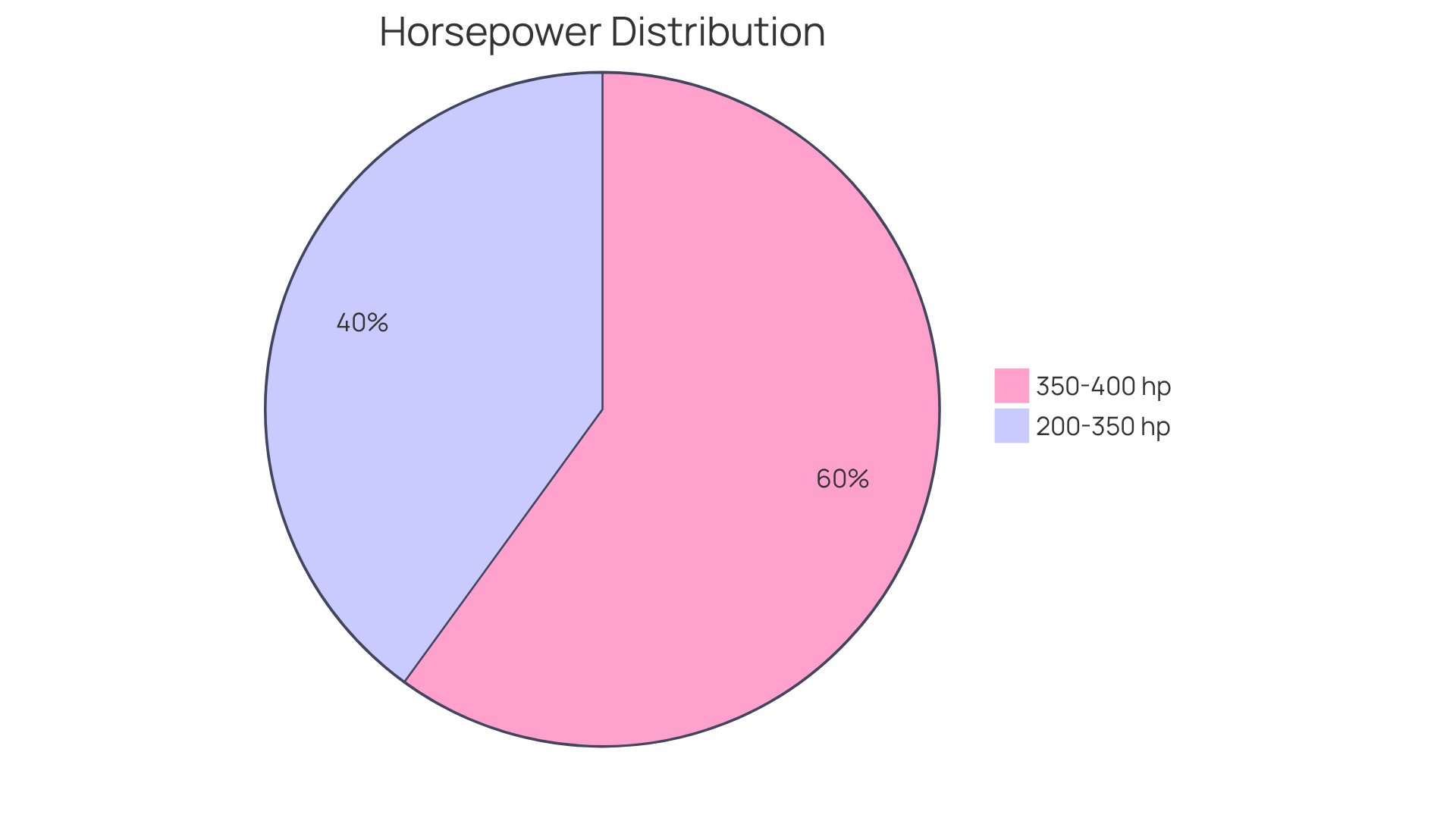

Engine power is a vital factor in the performance of a non-CDL dump truck used for hauling, typically ranging from 200 to 400 horsepower. This range is crucial for effectively managing various loads and terrains. For example, when transporting heavy materials or navigating steep inclines, a more powerful engine ensures optimal efficiency and minimizes strain on the vehicle. Additionally, torque ratings are significant, as they reflect the vehicle's ability to start and maintain speed under load.

Experts recommend that for most applications, a horsepower range of 350 to 400 is adequate, especially in challenging terrains. Samantha Parlier, a vocational marketing manager for Kenworth, states, "Generally, 350 to 400 hp is plenty for most applications." This balance of power not only enhances performance but also contributes to fuel efficiency, with fleets reporting notable improvements in fuel economy when using appropriately powered engines.

Furthermore, advancements in engine technology now allow smaller engines to perform comparably to larger ones. Understanding these dynamics is essential for selecting the right vehicle to meet specific operational requirements.

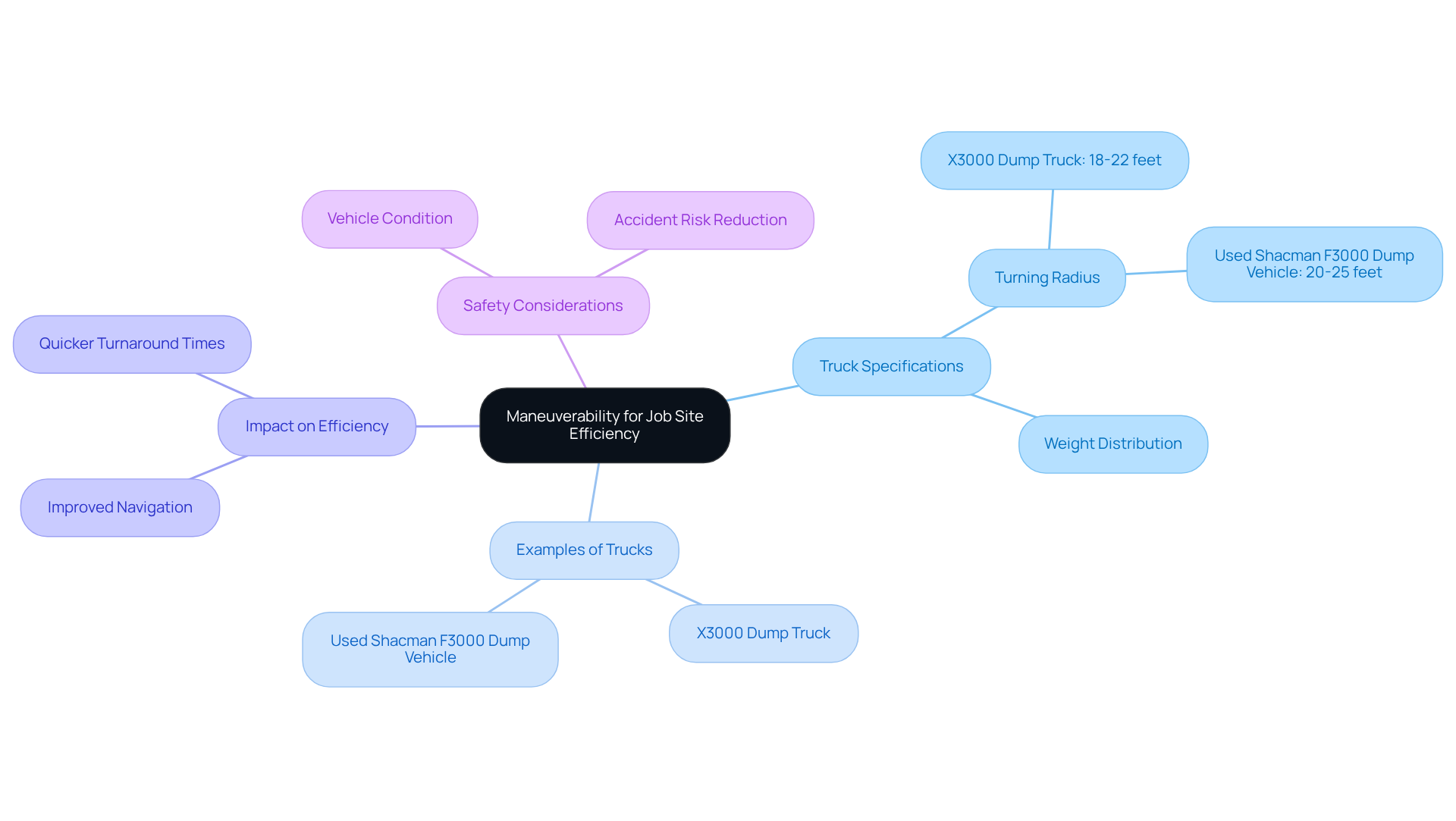

Consider Maneuverability for Job Site Efficiency

Maneuverability is a critical consideration when selecting a non cdl dump truck, especially for urban job sites or residential areas where space is limited. Trucks with a shorter wheelbase and tighter turning radius are generally easier to navigate, enabling operators to position the vehicle effectively for loading and unloading. For example, the X3000 Dump Truck features a turning radius of approximately 18 to 22 feet, making it well-suited for confined spaces. Similarly, the Used Shacman F3000 Dump Vehicle has a turning radius ranging from 20 to 25 feet, underscoring the importance of choosing the right vehicle for specific environments.

Moreover, the vehicle's weight distribution and overall condition significantly impact its handling capabilities. A well-balanced and well-maintained vehicle not only enhances operational efficiency but also reduces the risk of accidents. As noted by a construction site manager, "A vehicle that can maneuver easily saves us time and reduces the chances of mishaps on site."

Real-world examples further illustrate this point: projects that utilize vehicles with superior maneuverability report smoother operations and quicker turnaround times. For instance, a construction crew working in a densely populated area found that using a non cdl dump truck with a turning radius of 20 to 25 feet allowed them to navigate narrow streets and tight corners efficiently, ultimately improving their project schedule. Additionally, a smaller turning radius facilitates easier navigation, saving valuable time on the job.

In conclusion, prioritizing agility in non cdl dump trucks, along with maintaining the vehicle's overall condition, can lead to enhanced efficiency and safety on the job site. Integrating security messaging into the decision-making process is also essential, as it highlights the importance of maneuverability in fostering a secure working environment.

Prioritize Safety Features for Worker Protection

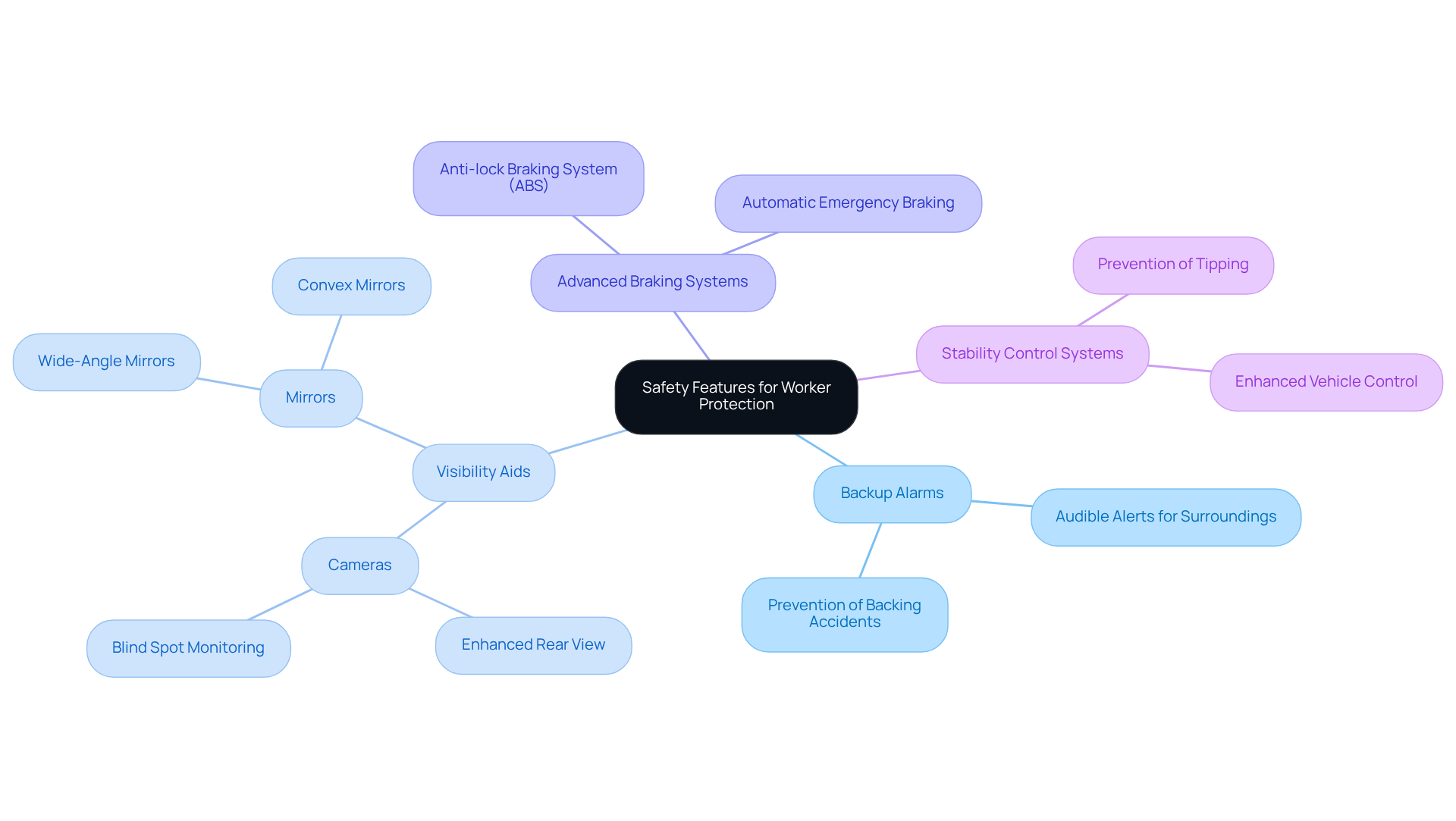

When evaluating a non cdl dump truck, it is crucial to highlight protective features that safeguard both the operator and nearby workers. Key protective elements include:

- Backup alarms

- Visibility aids such as cameras and mirrors

- Advanced braking systems

Trucks equipped with stability control systems are particularly valuable, as they help prevent tipping during operation.

According to industry specialists, adhering to strict safety standards not only protects your workforce but also significantly reduces liability on job sites. In 2023, a total of 114,552 large vehicles were involved in accidents resulting in injuries, underscoring the importance of protective features. Notably, 70% of fatalities in large vehicle collisions involved passengers of other automobiles, highlighting the need for enhanced protective features in non cdl dump trucks. This trend reflects a growing commitment to improving job site safety and worker protection.

Examine Durability and Build Quality for Longevity

When selecting a non cdl dump truck for hauling, durability and construction quality are paramount. Trucks constructed with high-quality materials, such as reinforced steel frames and heavy-duty components, are essential for withstanding the demands of construction work. Steel dump vehicle bodies are particularly notable for their exceptional durability and cost-effectiveness, capable of enduring extreme temperatures and abrasive materials. This makes them a preferred choice among many contractors. Furthermore, modern advancements have introduced composite materials that can reduce weight by up to 50% compared to steel, thereby enhancing payload capacity without compromising strength.

Design features significantly influence a vehicle's longevity. Corrosion-resistant coatings and robust suspension systems are critical for maintaining performance over time. For instance, vehicles equipped with advanced suspension components can better navigate off-road conditions, thereby minimizing wear and tear. Curtis Dorwart, a vocational marketing product manager for Mack Trucks, points out that "asphalt, gravel, and gritty materials create more wear and tear," underscoring the necessity of selecting durable materials.

Real-world examples further illustrate the importance of build quality in ensuring longevity. Specific models, such as ISUZU vehicles, are engineered to endure harsh conditions, demonstrating how high-quality construction can lead to extended operational life. On average, a non cdl dump truck used for hauling is expected to last between seven to ten years, with proper maintenance playing a crucial role in this lifespan. Investing in quality components and materials is vital for ensuring that your fleet remains reliable and cost-effective over time. As Dorwart notes, "Besides driver wages, fuel and tires are your largest operating cost on a vehicle used for hauling materials," highlighting the financial implications of material choices.

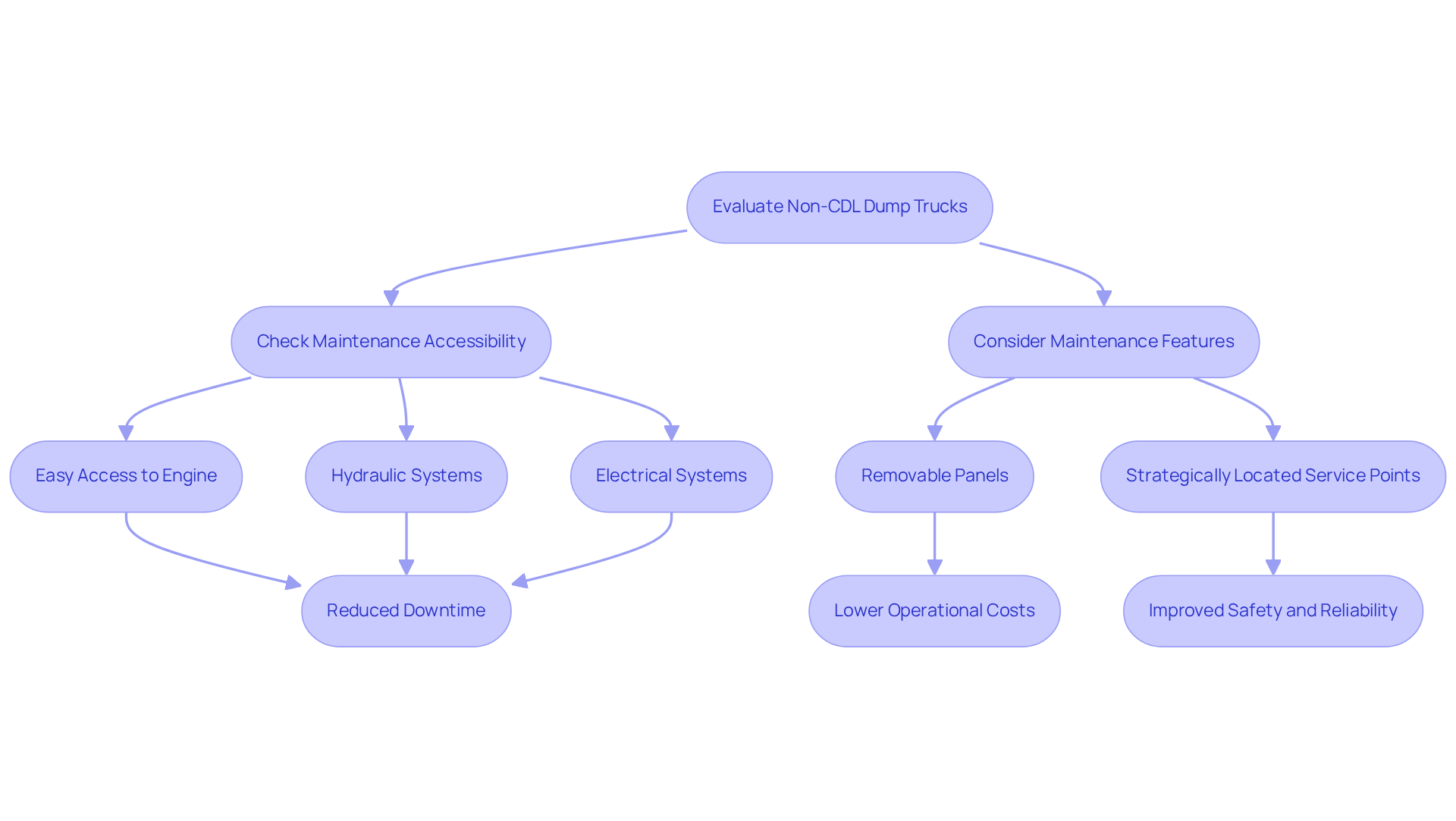

Ensure Maintenance Accessibility for Reduced Downtime

When evaluating a non cdl dump truck, it is crucial to prioritize maintenance accessibility. Choose models designed with easy access to essential components, such as the engine, hydraulic systems, and electrical systems. Features like removable panels and strategically located service points can significantly reduce the time and effort required for routine maintenance. Regular upkeep is vital for preventing breakdowns and ensuring optimal vehicle performance; thus, selecting a model that simplifies maintenance can lead to substantial long-term savings.

For instance, vehicles that are easier to maintain often experience reduced downtime, which allows for more efficient operations. Regular maintenance not only decreases downtime but also maximizes efficiency for heavy vehicles, underscoring the financial benefits of investing in maintenance-friendly designs. The average yearly maintenance expense for semi-vehicles ranges from $15,000 to $25,000, emphasizing the importance of considering maintenance costs when selecting a non cdl dump truck.

Real-world examples demonstrate that fleets with well-maintained vehicles experience lower operational costs, along with improved safety and reliability on job sites. As one mechanic noted, "Simple upkeep is essential for keeping vehicles on the road and reducing expensive repairs." This reinforces the idea that investing in maintenance-friendly designs is not just a choice but a strategic decision for long-term operational success.

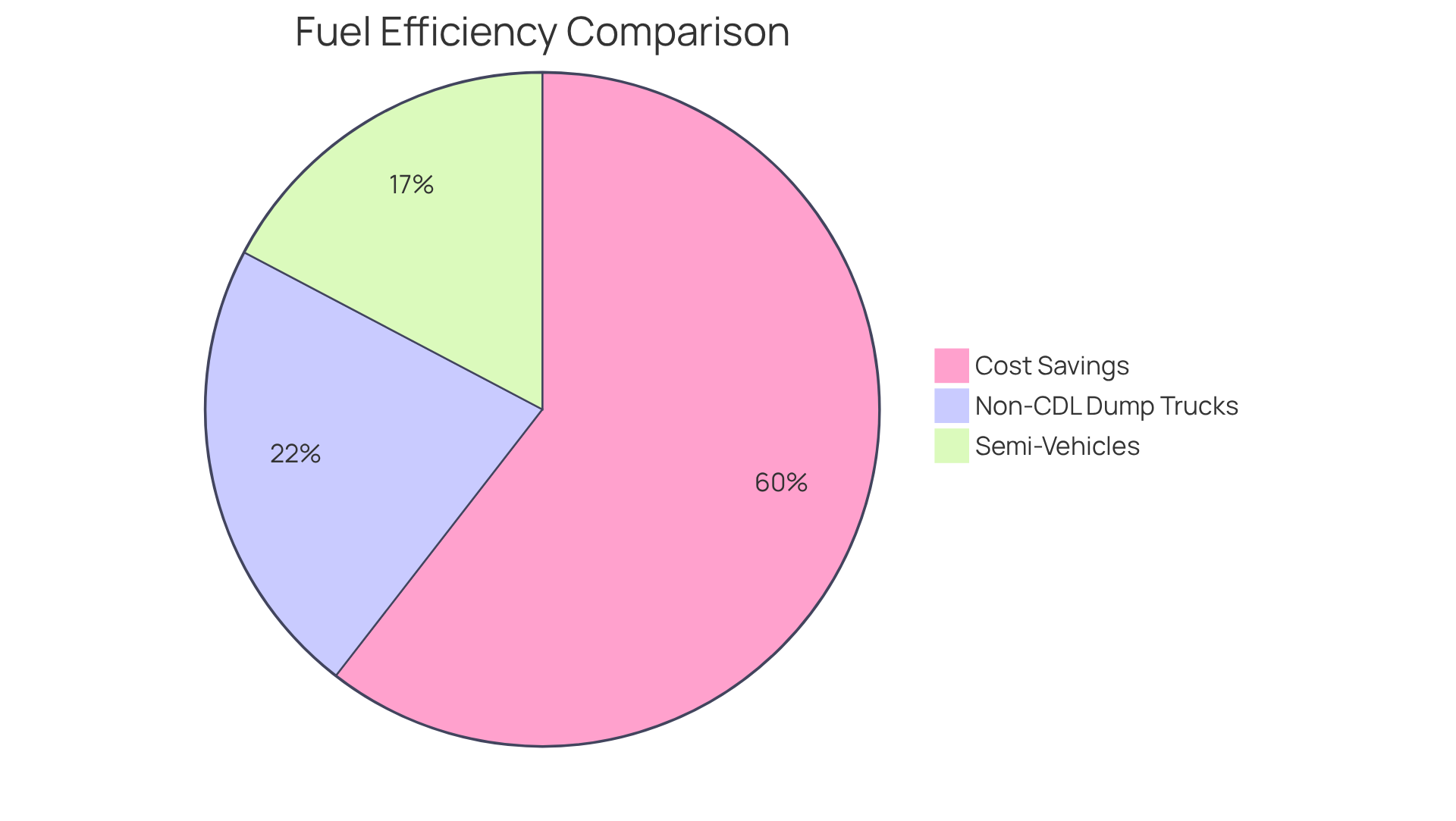

Evaluate Fuel Efficiency for Cost Management

When selecting a non cdl dump truck, fuel efficiency is a critical factor, as it directly impacts operational costs for companies engaged in regular material transport. In 2026, the average fuel consumption rates for non cdl dump trucks are expected to be approximately 8 to 10 miles per gallon (MPG), which is significantly more efficient than the average fuel efficiency of semi-vehicles at 6.5 to 7.5 MPG. This improvement reflects advancements in technology and design. Trucks equipped with cutting-edge engine technologies, such as the Detroit DD15 engine, known for its fuel efficiency, turbocharging, and hybrid systems, can greatly enhance fuel efficiency, resulting in substantial savings over time.

Additionally, the weight and aerodynamics of the vehicle are pivotal in determining fuel consumption. For example, lighter vehicles with streamlined designs can achieve superior fuel efficiency, thereby reducing overall operational costs. Real-world examples demonstrate that companies prioritizing fuel-efficient technologies, like Bickner Trucking, have experienced a reduction in fuel costs by up to 24.5%. This reduction translates into lower construction expenses and improved profit margins.

Transportation economists stress that effective cost management through fuel economy is vital for maintaining competitive pricing in the construction sector. As one economist noted, "By emphasizing fuel efficiency in your selection of non cdl dump trucks, you can ensure that operational expenses remain manageable while boosting productivity and profitability.

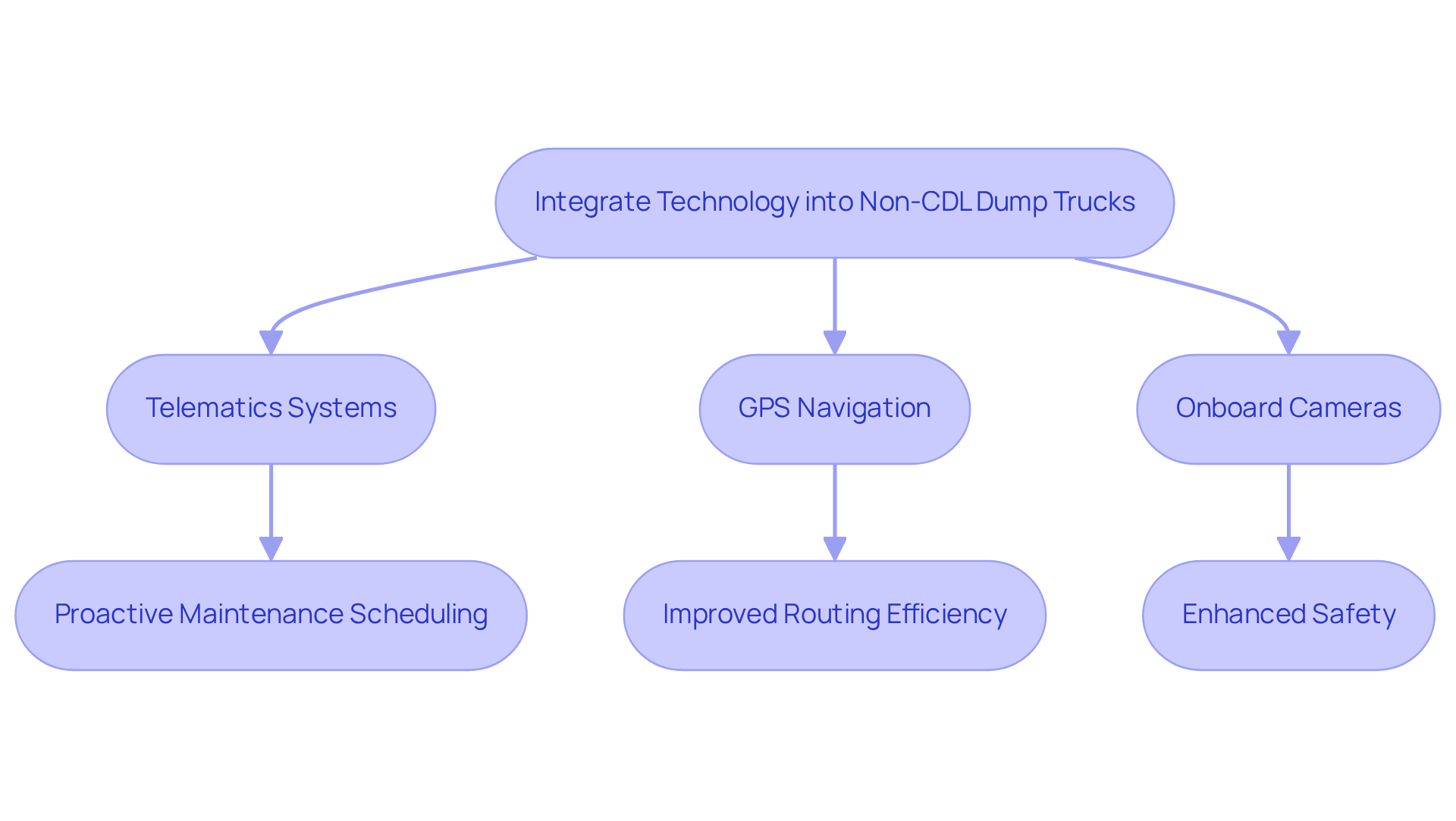

Incorporate Technology for Enhanced Operational Efficiency

In today's construction landscape, integrating advanced technology into non cdl dump trucks is essential for enhancing operational efficiency. Telematics systems are vital, providing real-time data on vehicle performance, location, and maintenance needs. For example, GPS navigation improves routing efficiency, while onboard cameras significantly enhance safety during loading and unloading.

Industry forecasts suggest that the refuse vehicle market will reach USD 54.0 billion by 2035, highlighting the growing importance of efficient operations. Implementing telematics not only streamlines processes but also reduces downtime, enabling proactive maintenance scheduling and informed decision-making.

As Tony Papania, a connectivity services territory manager at Volvo Construction Equipment, states, "Telematics are great for helping you stay on track with regular service, which is a way to prevent issues or catch them early."

This technological integration ultimately enhances overall productivity on job sites, making it a critical consideration for any construction project manager.

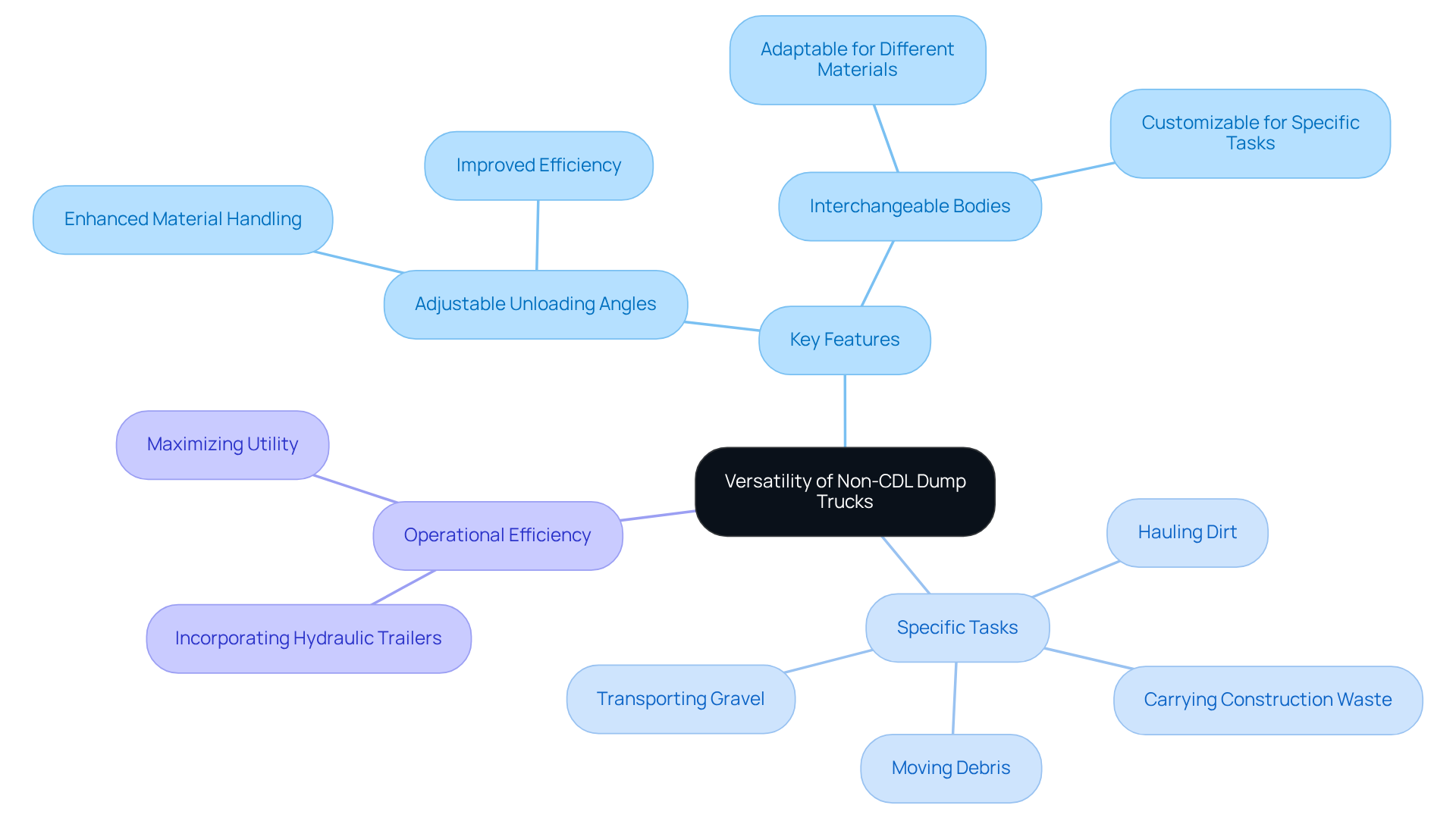

Look for Versatility to Handle Diverse Tasks

When selecting a non cdl dump truck for hauling, it's essential to consider its versatility in managing various tasks. Look for features that allow the vehicle to adapt to different job requirements, such as adjustable unloading angles or interchangeable bodies for diverse materials. A non cdl dump truck is a versatile vehicle that can handle everything from hauling dirt and gravel to transporting debris and construction waste.

Furthermore, incorporating hydraulic trailers into your fleet can significantly enhance operational efficiency, offering a practical solution for heavy-duty tasks. This adaptability not only maximizes the vehicle's utility but also increases its value for your business, enabling you to undertake a broader range of projects.

Consider Competitive Pricing and Rental Options from EZ Equipment Rental

When evaluating a non cdl dump truck, it's crucial to consider the competitive pricing and rental options provided by EZ Equipment Rental. Their flexible rental terms accommodate various project timelines and budgets, granting access to high-quality equipment, including a broad inventory of well-maintained machinery, without the financial burden of ownership. This flexibility is especially advantageous for construction project managers, facilitating efficient resource allocation and project management.

Furthermore, comparing rental prices with other providers can reveal the best deals tailored to specific needs, reinforcing the competitive advantage of EZ Equipment Rental. By choosing a rental solution from EZ Equipment Rental, you ensure that the appropriate equipment is available for your project while effectively managing financial resources.

Conclusion

Selecting the right non-CDL dump truck requires careful consideration of several key features that directly impact performance, safety, and cost-effectiveness. Understanding factors such as:

- Payload capacity

- Engine power

- Maneuverability

- Safety features

- Durability

- Maintenance accessibility

- Fuel efficiency

- Technology integration

- Versatility

- Competitive pricing

is essential for making an informed decision. Each of these elements plays a critical role in ensuring that the truck meets the specific demands of various construction projects while maximizing operational efficiency.

Evaluating payload capacity is crucial for compliance with regulations and enhancing safety. Engine power is vital for handling various terrains, while maneuverability is essential in tight job sites. Safety features protect workers, and durability ensures long-term reliability. Maintenance accessibility reduces downtime, and fuel efficiency helps manage costs effectively. Incorporating technology improves operational efficiency, and versatility allows the truck to adapt to diverse tasks. Finally, considering competitive pricing and rental options can provide financial flexibility.

Ultimately, investing time in evaluating these features can lead to significant benefits, including enhanced productivity, improved safety, and reduced operational costs. For construction project managers and operators, making informed choices about non-CDL dump trucks is not just about selecting a vehicle; it’s about ensuring the success and safety of every project. Prioritizing these considerations will pave the way for efficient operations and long-term success in the field.

Frequently Asked Questions

What is the typical payload capacity of a non-CDL dump truck?

A non-CDL dump truck typically has a payload capacity ranging from 10,000 to 26,000 pounds, depending on its configuration and local regulations.

Why is it important to understand the payload capacity of a dump truck?

Understanding the payload capacity is essential for effectively managing materials for various jobs, ensuring safety, and avoiding overloading, which can lead to safety hazards and legal consequences.

What are the legal weight limits for tandem and tri-axle dump trucks?

A tandem dump truck can legally transport between 12 to 16 tons, while tri-axle models can handle up to 25 tons.

How much engine power do non-CDL dump trucks typically have?

Non-CDL dump trucks usually have engine power ranging from 200 to 400 horsepower.

Why is engine power important for dump trucks?

Engine power is crucial for effectively managing loads and terrains, especially when transporting heavy materials or navigating steep inclines, as it ensures optimal efficiency and minimizes strain on the vehicle.

What horsepower range is recommended for most applications?

Experts recommend a horsepower range of 350 to 400 for most applications, particularly in challenging terrains.

How does engine technology affect performance?

Advancements in engine technology allow smaller engines to perform comparably to larger ones, enhancing performance and contributing to fuel efficiency.

Why is maneuverability important when selecting a non-CDL dump truck?

Maneuverability is critical for navigating urban job sites or residential areas with limited space, allowing operators to position the vehicle effectively for loading and unloading.

What features contribute to better maneuverability in dump trucks?

Trucks with a shorter wheelbase and tighter turning radius are generally easier to navigate. For example, the X3000 Dump Truck has a turning radius of approximately 18 to 22 feet.

How does a vehicle's overall condition impact its handling capabilities?

A well-balanced and well-maintained vehicle enhances operational efficiency and reduces the risk of accidents, contributing to safer job site conditions.

Can you provide an example of how maneuverability improves job site efficiency?

A construction crew using a non-CDL dump truck with a turning radius of 20 to 25 feet was able to navigate narrow streets and tight corners efficiently, which improved their project schedule and reduced turnaround times.

List of Sources

- Evaluate Payload Capacity for Optimal Performance

- How Many Tons Does a Dump Truck Hold? Load Capacity and Selection Recommendations - SANY Group (https://sanyglobal.com/blog/how-many-tons-does-a-dump-truck-hold)

- Dump Truck Weight Limits: Learn Limits of Its 3 Types | Freedom Heavy Haul (https://freedomheavyhaul.com/dump-truck-weight-limits)

- Dump Truck Weight Capacity Guide - How Much Can Different Types Hold - Hello Gravel (https://hellogravel.com/dump-truck-weight-capacity-guide-how-much-can-different-types-hold?srsltid=AfmBOooLihiyffpy5m9z5vA6E-1jPgMDFM6U5vvjUjLKE95r-pUugPr_)

- Dump Truck Capacity Chart 2025 | Tons, Yards & Legal Limits (https://theupfitinsider.com/p/how-many-tons-can-a-dump-truck-haul)

- How Much Can A Dump Truck Carry (https://lynchtruckcenter.com/manufacturer-information-how-much-can-a-dump-truck-carry.html?srsltid=AfmBOoptwDg7l_zbuJULdlkD9CjarQpVcXSAn3CWKhWUWo-XYaoxsHBm)

- Assess Engine Power and Performance Requirements

- How to reap the benefits of a lightweight engine | Cummins Inc. (https://cummins.com/news/2021/05/18/how-reap-benefits-lightweight-engine)

- Kenworth Offers Advice on Specs for Dump Trucks (https://truckinginfo.com/articles/kenworth-offers-advice-on-specs-for-dump-trucks)

- Do I Really Need All This Trucking Horsepower? (https://fleetequipmentmag.com/trucking-horsepower)

- 20 Trucks with Most Horsepower for 2026 - TrueCar (https://truecar.com/best-cars-trucks/trucks/by-horsepower)

- Technology to Meet Emissions Requirements Changes How to Spec Dump Trucks (https://forconstructionpros.com/equipment/earthmoving/site-dumpers/article/11175153/technology-to-meet-emissions-requirements-changes-how-to-spec-dump-trucks)

- Consider Maneuverability for Job Site Efficiency

- Construction Safety Quotes That Actually Get Read (https://armedamerican.supply/blogs/news/construction-safety-quotes?srsltid=AfmBOorRXxKE3DtvGKH7JA0oVFvkNlWzNaqpPM3TgbGXGP4kD6zY5B5A)

- 119 Construction Quotes that Hit the Nail on the Head | BigRentz (https://bigrentz.com/blog/construction-quotes?srsltid=AfmBOorMTa-2flaaJ_FZlE1L2hrbcVmDUBJDpVs8iMyTDo5eANp6Jgwy)

- What is the turning radius of a used dump truck? - Blog - Shengjia (https://lutongzk.com/blog/what-is-the-turning-radius-of-a-used-dump-truck-527805.html)

- Dump Truck Overturns Stats & Facts (https://bhhcsafetycenter.com/dump-truck-overturns-stats-facts)

- Prioritize Safety Features for Worker Protection

- ODOT tests autonomous crash trucks to increase worker safety (https://cleveland19.com/2026/02/13/odot-tests-autonomous-crash-trucks-increase-worker-safety)

- Large Trucks - Injury Facts (https://injuryfacts.nsc.org/motor-vehicle/road-users/large-trucks)

- 3 Safety Best Practices for Dump Truck Operators (https://tompeacetrucking.com/3-safety-best-practices-for-dump-truck-operators)

- Top 100 Inspirational Workplace Safety Quotes (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- Examine Durability and Build Quality for Longevity

- The owning and operating costs of dump trucks (https://equipmentworld.com/regulations/equipment/article/14948071/the-owning-and-operating-costs-of-dump-trucks)

- Exploring the Best Materials for Dump Truck Bodies (https://thendta.org/post/exploring-the-best-materials-for-dump-truck-bodies)

- Used Truck Lifespan Insights | North Carolina | Used Truck Dealer (https://transourcetrucks.com/blog/tips-to-calculate-the-expected-lifespan-of-a-used-truck--94903)

- Durability and Performance: ISUZU Dump Trucks (https://mjtrucknation.com/durability-and-performance-isuzu-dump-trucks)

- How Freightliner dump trucks outperform the rest in durability, performance, and uptime | Tracey Road Equipment, Inc. posted on the topic | LinkedIn (https://linkedin.com/posts/tracey-road-equipment_freightliner-dumptruck-builttowork-activity-7353467495590109185-7Qqm)

- Ensure Maintenance Accessibility for Reduced Downtime

- The Benefits of Preventative Maintenance for Heavy-Duty Trucks (https://dtservicesid.co/the-benefits-of-preventative-maintenance-for-heavy-duty-trucks)

- Dump Truck Maintenance: 6 Tips to Keep Your Fleet Running Smoothly - Load King (https://loadkingmfg.com/2022/01/dump-truck-maintenance-6-tips-to-keep-your-fleet-running-smoothly)

- Your Guide to Effective Dump Truck Maintenance - FieldInsight (https://fieldinsight.com/blog/dump-truck-maintenance)

- The Importance of Preventative Maintenance for Your Truck (https://prepassalliance.org/the-importance-of-preventative-maintenance-for-your-truck)

- What’s the Average Semi-Truck Maintenance Cost per Year? - Magana Transport (https://maganatransport.com/average-semi-truck-maintenance-cost-per-year)

- Evaluate Fuel Efficiency for Cost Management

- 10 Tips to Managing Semi-Truck Fuel Efficiency (https://haletrailer.com/blog/semi-truck-fuel-efficiency)

- 2024 Fuel Efficiency Guide for Truckers - TDI (https://drivebigtrucks.com/blog/fuel-efficiency-guide-for-truckers)

- NACFE: Fleet Fuel Study (https://nacfe.org/research/affs)

- Bickner Trucking achieves 36% better fuel economy (https://ccjdigital.com/ccj-innovators/article/15772876/bickner-trucking-achieves-36-better-fuel-economy)

- Incorporate Technology for Enhanced Operational Efficiency

- Industry Trends: Technology and Telematics (https://sidedumpindustries.com/industry-trends-telematics-and-dump-truck-technology)

- Proactive Maintenance Benefits of Telematics (https://forconstructionpros.com/construction-technology/machine-grade-control-gps-laser-other/article/22920412/proactive-maintenance-benefits-of-telematics)

- How Telematics Helps Optimize Construction Equipment Efficiency (https://aem.org/news/how-telematics-helps-optimize-construction-equipment-efficiency)

- Dump Trucks Market | Global Market Analysis Report - 2035 (https://futuremarketinsights.com/reports/dump-trucks-market)

- Look for Versatility to Handle Diverse Tasks

- 119 Construction Quotes that Hit the Nail on the Head | BigRentz (https://bigrentz.com/blog/construction-quotes?srsltid=AfmBOorrAKlEpBklPS0UBBUz1ima7adi1t50H250CsN0PFTjjuSaD7gv)

- Dump Trucks Market | Global Market Analysis Report - 2035 (https://futuremarketinsights.com/reports/dump-trucks-market)

- US Dump Trucks Manufacturer Market Competitive Analysis and Trends (https://introspectivemarketresearch.com/reports/us-dump-trucks-manufacturer-market)

- 15 of the Most Inspiring Quotes about Construction - Digital Builder (https://autodesk.com/blogs/construction/inspiring-construction-quotes)

- Dump Truck Services in the US Industry Analysis, 2025 (https://ibisworld.com/united-states/industry/dump-truck-services/5668)

- Consider Competitive Pricing and Rental Options from EZ Equipment Rental

- 10 ‘food for thought’ quotes on equipment rental in 2024 (https://internationalrentalnews.com/news/words-of-wisdom-of-2024-so-far-10-quotes-providing-food-for-thought/8038427.article)

- Dump Truck Rental Market Size, Growth, Trends 2035 (https://marketresearchfuture.com/reports/dump-truck-rental-market-37635)

- Dump Trailers Rental Prices: How Much to Rent With EZ Dump? (https://ezdumptrailers.com/ez-dump-trailers-rental-prices-how-much-to-rent)

- Strategic Analysis of Dump Truck Rental Service Market Growth 2026-2034 (https://datainsightsmarket.com/reports/dump-truck-rental-service-1434400)

- Dump Truck Rental Market | Global Market Analysis Report - 2035 (https://factmr.com/report/dump-truck-rental-market)