Overview

This article presents 30 lift strategies essential for effective equipment management. It underscores the critical nature of selecting appropriate lift equipment, implementing robust safety protocols, and maintaining machinery to achieve optimal performance. By detailing various types of lifts, necessary project considerations, and the financial advantages of proactive maintenance, it emphasizes that effective management can significantly reduce downtime while enhancing project efficiency.

Key Highlights:

- Lift equipment includes boom lifts, scissor platforms, forklifts, and telehandlers, each designed for specific tasks.

- Boom lifts extend vertically and horizontally, ideal for construction and maintenance work.

- Scissor platforms provide a stable surface for larger work areas at height, suitable for indoor and outdoor tasks.

- Forklifts are crucial for material handling in warehouses and construction sites, with a significant market presence.

- Telehandlers combine forklift and crane functions, offering versatility in lifting heavy loads.

- Selecting the right lift requires understanding project requirements, site conditions, load capacity, and ensuring operator training.

- Safety protocols include pre-operation inspections, use of PPE, clear communication, and monitoring environmental conditions.

- Regular maintenance schedules, documentation of servicing, operator training, and use of quality parts are essential for optimal equipment performance.

- Effective maintenance practises can reduce downtime and enhance project efficiency, with significant cost savings reported from proactive approaches.

Introduction

Understanding the intricacies of lift equipment management is essential in today’s fast-paced construction and logistics environments. With a wide array of lifting solutions—from boom lifts to telehandlers—selecting the right equipment is pivotal in enhancing project efficiency and ensuring safety. The pressing question for project managers is: how can they make the best choices in the face of evolving technologies and stringent safety protocols? This article explores 30 effective strategies for managing lift equipment, providing insights that empower professionals to optimize their operations while placing safety and performance at the forefront.

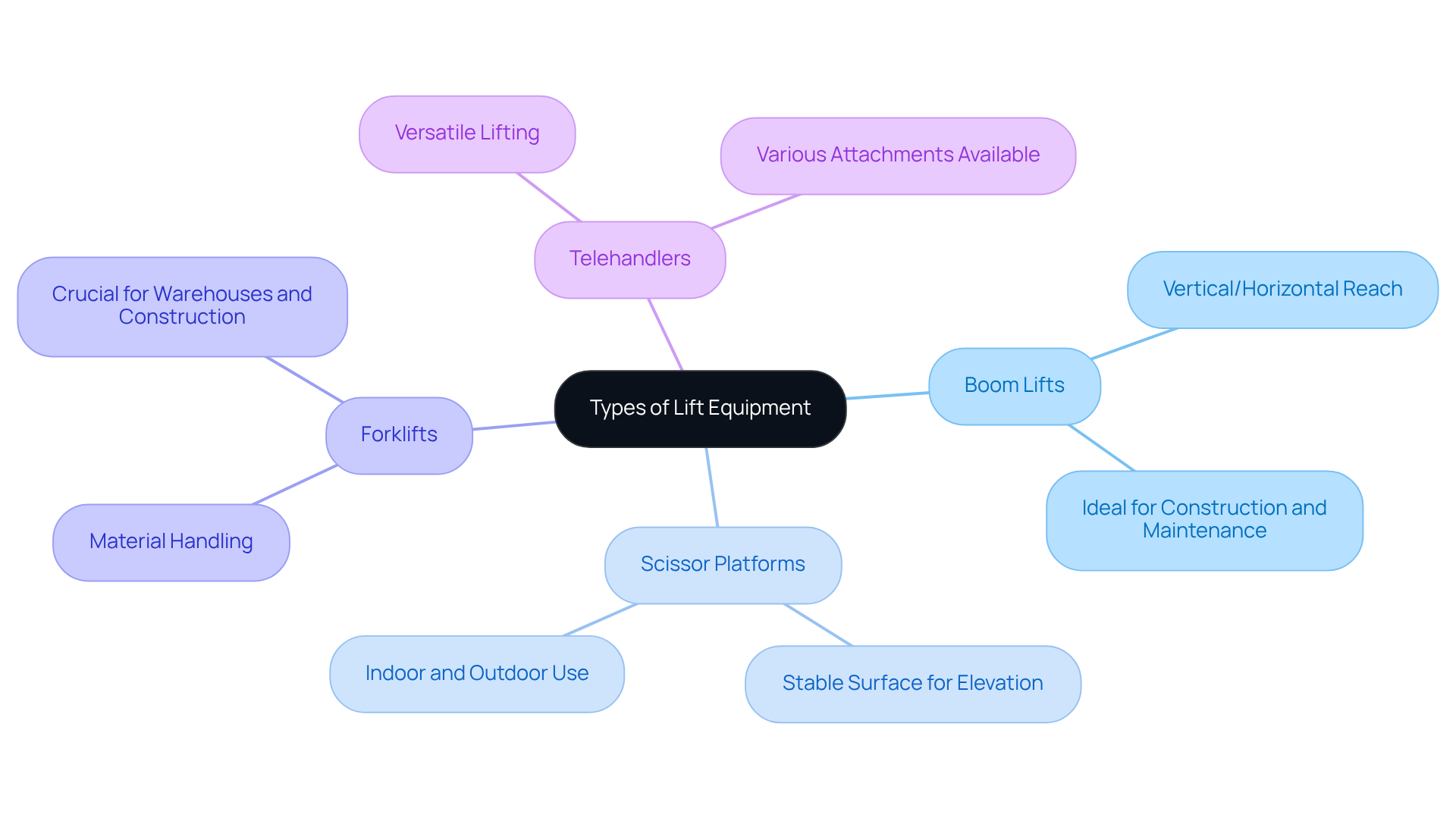

Understand Types of Lift Equipment

Lift equipment encompasses a variety of forms, each tailored for specific tasks and environments. The primary types include:

-

Boom Lifts: Essential for reaching elevated areas, boom lifts are capable of extending both vertically and horizontally. Their versatility makes them ideal for construction and maintenance tasks, allowing workers to access hard-to-reach spots safely.

-

Scissor Platforms: Designed to offer a stable surface that ascends vertically, scissor platforms are perfect for tasks needing a larger work area at elevation. Their design guarantees security and stability, making them a favored option for both indoor and outdoor uses.

-

Forklifts: Primarily utilized for lifting and transporting materials, forklifts are indispensable in warehouses and construction sites. With a significant market share, they are crucial for efficient material handling, particularly in high-demand sectors like retail and logistics.

-

Telehandlers: Combining the functionalities of a forklift and a crane, telehandlers offer versatility in lifting heavy loads to considerable heights. Their unique design allows for various attachments, enhancing their utility across different construction and agricultural applications.

Understanding these categories of raising apparatus, including the 30 lift, is essential for selecting the suitable machinery according to project needs, site circumstances, and safety factors. As the market for construction raising tools is anticipated to expand considerably, with a compound annual growth rate (CAGR) of 5.5% from 2026 to 2033, staying updated on the latest innovations and applications in this sector is crucial for efficient management.

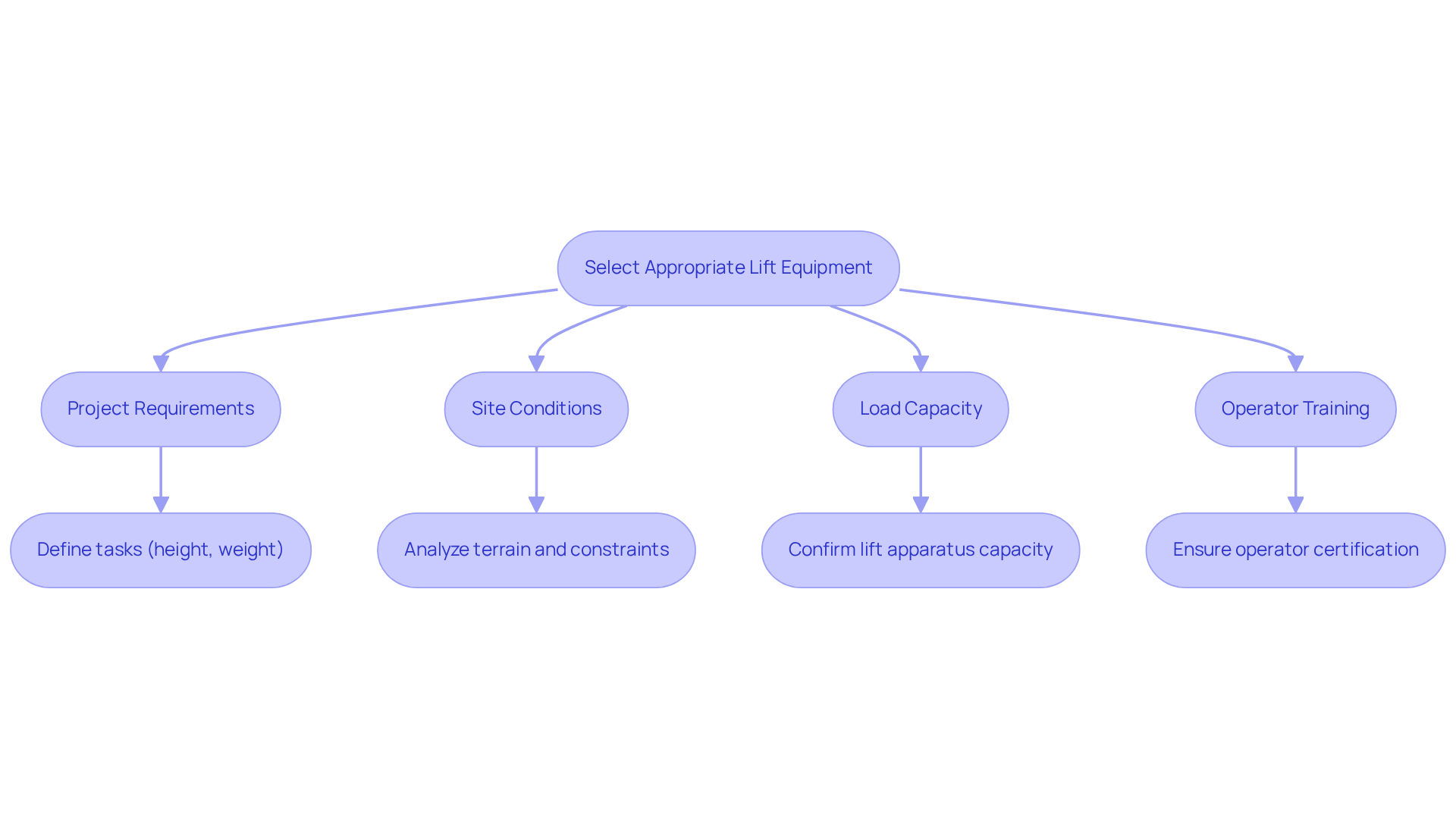

Select Appropriate Lift Equipment for Your Project

Selecting the right hoisting tools, including a 30 lift, is essential for the success of the project. To ensure optimal outcomes, consider the following key factors:

- Project Requirements: It is essential to clearly define the tasks at hand, including the height and weight of materials to be lifted. Comprehending these particulars aids in selecting tools that fulfill the specific needs of the project.

- Site Conditions: Analyze the terrain and spatial constraints carefully. Identify any barriers that could obstruct machinery operation, ensuring that the chosen hoist can traverse the site efficiently. As one construction project manager remarked, "Assessing site conditions is crucial to guarantee that the machinery can function safely and efficiently."

- Load Capacity: Confirm that the lift apparatus can safely manage the maximum weight of the load. For example, a forklift attachment with a maximum breaking load of 5,000 pounds should have a working load limit of at least 1,000 pounds, following load factors usually varying from 4:1 to 7:1. Understanding the working load limit (WLL) is critical for preventing accidents and ensuring safe lifting operations with a 30 lift.

- Operator Training: Ensure that operators are adequately trained and certified for the equipment they will be using. Proper training is crucial for maintaining security standards and enhancing operational efficiency.

At EZ Equipment Rental, our knowledgeable team ensures a seamless rental experience by providing expert guidance and support throughout the process. By thoroughly assessing these factors and utilizing our expertise, project managers can make informed choices that improve productivity and security on the job site.

Implement Safety Protocols for Lift Operations

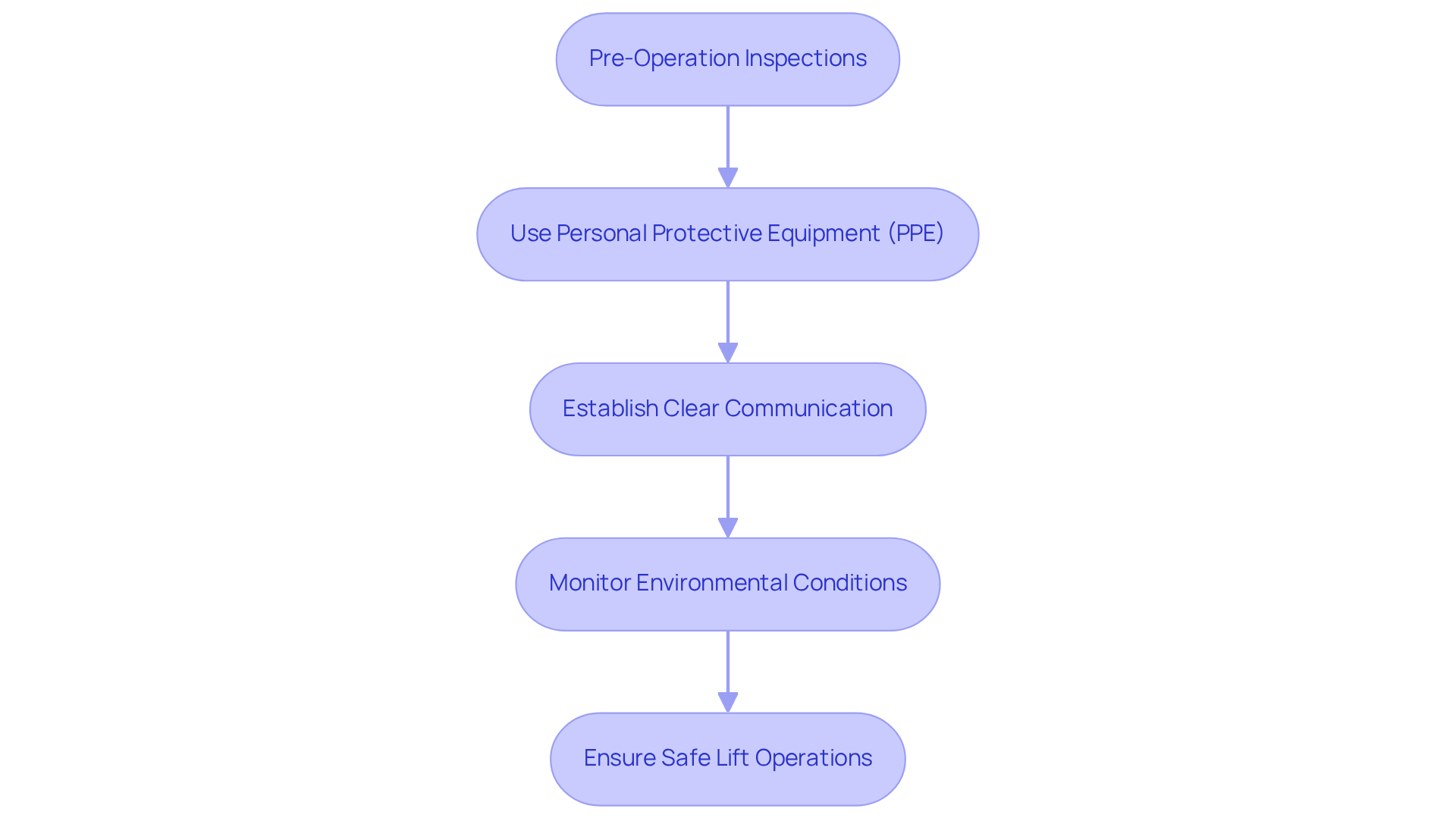

To ensure safe lift operations, it is imperative to implement the following protocols:

-

Pre-Operation Inspections: Conduct thorough inspections of the lift equipment before use, checking for any signs of wear or malfunction. This step is crucial in identifying potential issues that could compromise safety.

-

Use Personal Protective Equipment (PPE): Ensure all operators and personnel in the vicinity wear appropriate PPE, such as hard hats, gloves, and protective eyewear. Proper PPE is essential for minimizing risks and enhancing safety during operations.

-

Establish Clear Communication: Utilize hand signals or radios to maintain clear communication among team members during raising operations. Effective communication is key to coordinating efforts and ensuring everyone is aware of their roles.

-

Monitor Environmental Conditions: Be aware of weather conditions, such as wind or rain, that may impact stability and security. Understanding the environment is vital for making informed decisions during operations.

By adhering to these safety protocols, teams can significantly reduce the risk of accidents and ensure a safer working environment. Take action now to prioritize safety in all lift operations.

Maintain Lift Equipment for Optimal Performance

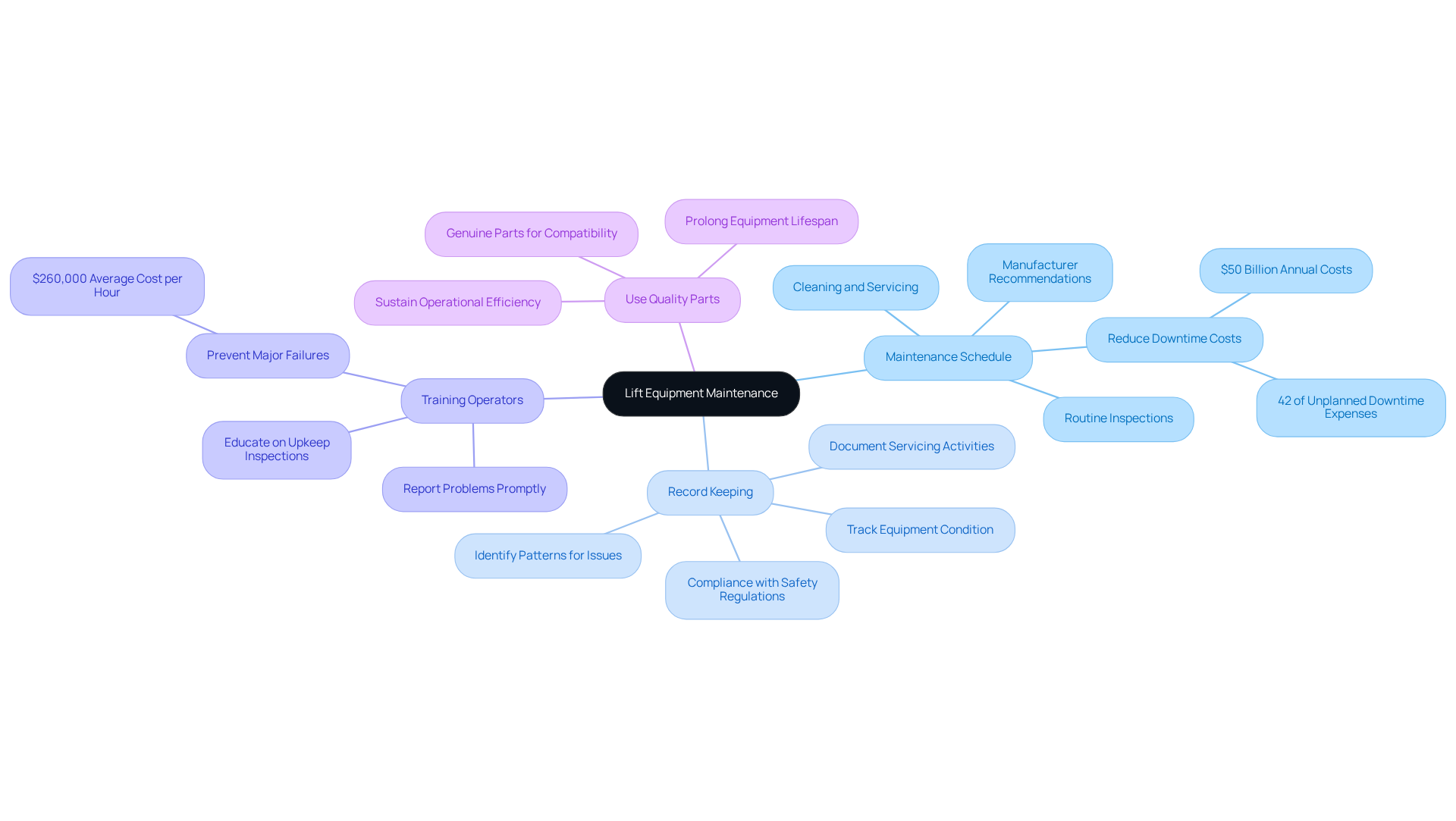

To maintain lift equipment effectively, it is essential to adhere to best practices that ensure reliability and operational efficiency.

-

Establish a Maintenance Schedule: Developing a routine maintenance schedule is crucial. This schedule should include regular inspections, cleaning, and servicing based on manufacturer recommendations. Such a proactive strategy significantly decreases downtime; machinery failures account for 42% of unplanned downtime expenses in construction projects. Moreover, unforeseen downtime costs manufacturers as much as $50 billion annually, underscoring the financial implications of effective maintenance methods.

-

Keep Records: Documenting all servicing activities, repairs, and inspections is vital for tracking the equipment's condition over time. This practice not only aids in compliance with safety regulations but also helps identify patterns that may indicate underlying issues, ensuring that potential problems are addressed before they escalate.

-

Train Operators: Ensuring that operators are educated in basic upkeep inspections is imperative. They must comprehend the significance of promptly reporting any problems. Proper training can prevent minor issues from evolving into major failures, which can cost businesses an average of $260,000 per hour in downtime.

-

Use Quality Parts: When repairs are necessary, it is critical to use genuine parts to guarantee compatibility and reliability. Utilizing quality components can prolong the lifespan of the equipment and sustain its operational efficiency.

By adopting these maintenance practices, project managers can ensure that the 30 lift machinery remains in peak condition, thereby minimizing the likelihood of unforeseen breakdowns and enhancing project efficiency. Industry experts emphasize that a well-organized maintenance timetable is essential for improving equipment reliability and reducing operational interruptions. As highlighted by the Infraspeak Team, maintenance is evolving into a collaborative effort, reflecting the importance of teamwork in effective maintenance practices. Furthermore, a case study of a commercial construction company demonstrates that implementing predictive maintenance reduced downtime by 25% and saved approximately $100,000 in maintenance costs, showcasing the tangible benefits of a proactive maintenance approach.

Conclusion

Selecting and managing lift equipment effectively is crucial for ensuring safety, efficiency, and productivity on construction sites and in various operational environments. Understanding the different types of lift equipment—such as boom lifts, scissor platforms, forklifts, and telehandlers—each designed for specific tasks and conditions, is essential. A well-considered selection of equipment tailored to project requirements, site conditions, load capacity, and operator training can significantly impact the success of any undertaking.

Key strategies for managing lift equipment effectively include:

- Implementing rigorous safety protocols

- Conducting regular maintenance

- Ensuring that operators are well-trained

Establishing a maintenance schedule and documenting all servicing activities are vital practices that enhance equipment reliability and minimize downtime. Furthermore, adhering to safety guidelines, such as pre-operation inspections and effective communication among team members, can drastically reduce the risk of accidents and injuries during lift operations.

Ultimately, the significance of effective equipment management for lifts cannot be overstated. By prioritizing safety, proper selection, and maintenance of lift equipment, project managers and operators can enhance operational efficiency and foster a safer work environment. As the demand for lift equipment continues to grow, incorporating these best practices will be essential for navigating the complexities of modern construction and maintenance projects. Embracing these strategies will lead to improved outcomes and a commitment to excellence in equipment management.

Frequently Asked Questions

What are the main types of lift equipment?

The main types of lift equipment include boom lifts, scissor platforms, forklifts, and telehandlers. Each type is designed for specific tasks and environments.

What is the purpose of boom lifts?

Boom lifts are essential for reaching elevated areas and can extend both vertically and horizontally, making them ideal for construction and maintenance tasks.

How do scissor platforms differ from other lift equipment?

Scissor platforms provide a stable surface that ascends vertically and are designed to offer security and stability, making them suitable for tasks requiring a larger work area at elevation.

What are forklifts primarily used for?

Forklifts are primarily utilized for lifting and transporting materials and are indispensable in warehouses and construction sites, particularly in sectors like retail and logistics.

What is a telehandler and what are its benefits?

A telehandler combines the functionalities of a forklift and a crane, allowing it to lift heavy loads to considerable heights. Its unique design permits various attachments, enhancing its utility in construction and agricultural applications.

Why is it important to understand different types of lift equipment?

Understanding the different categories of lift equipment is essential for selecting the suitable machinery according to project needs, site circumstances, and safety factors.

What is the projected market growth for construction raising tools?

The market for construction raising tools is anticipated to expand considerably, with a compound annual growth rate (CAGR) of 5.5% from 2026 to 2033.