Key Highlights:

- Class 7 forklifts are designed for outdoor use on uneven surfaces, ideal for construction, landscaping, and agriculture.

- Key features include Four-Wheel Drive, high load capacity exceeding 10,000 pounds, and versatile attachments for various applications.

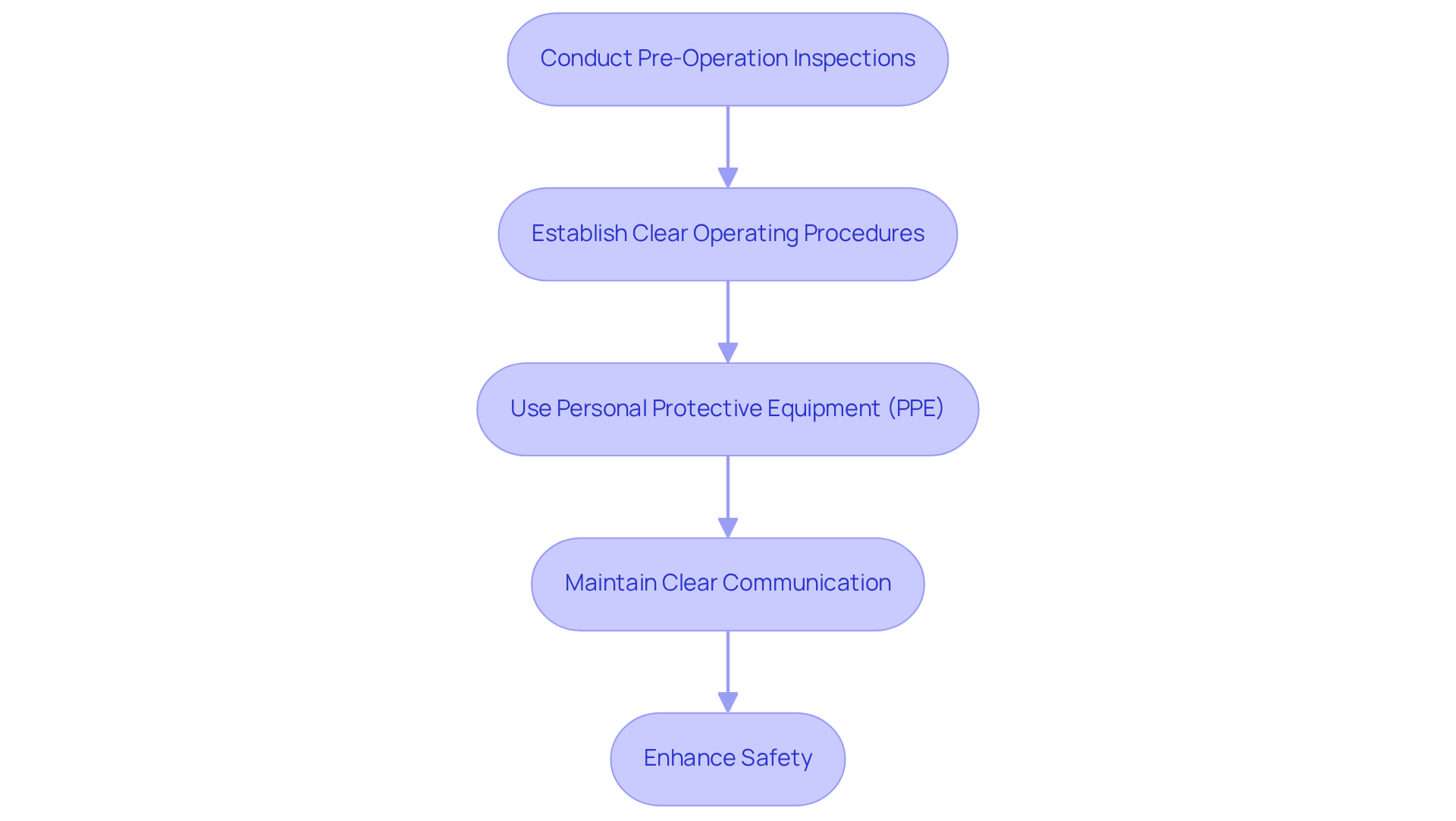

- Safety protocols for operating Class 7 forklifts include pre-operation inspections, clear operating procedures, use of personal protective equipment (PPE), and maintaining clear communication.

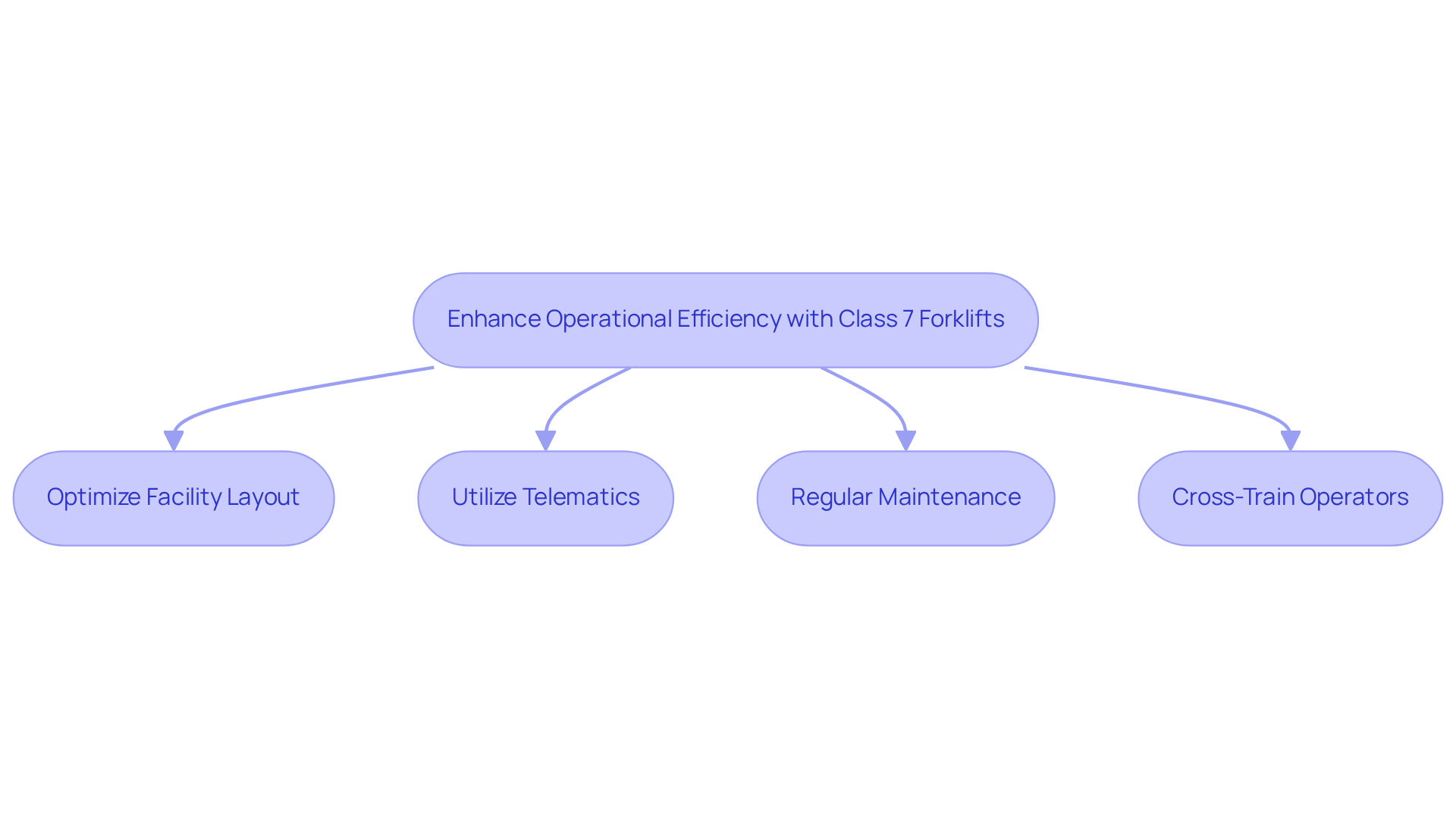

- Strategies to enhance operational efficiency include optimising facility layout, utilising telematics, scheduling regular maintenance, and cross-training operators.

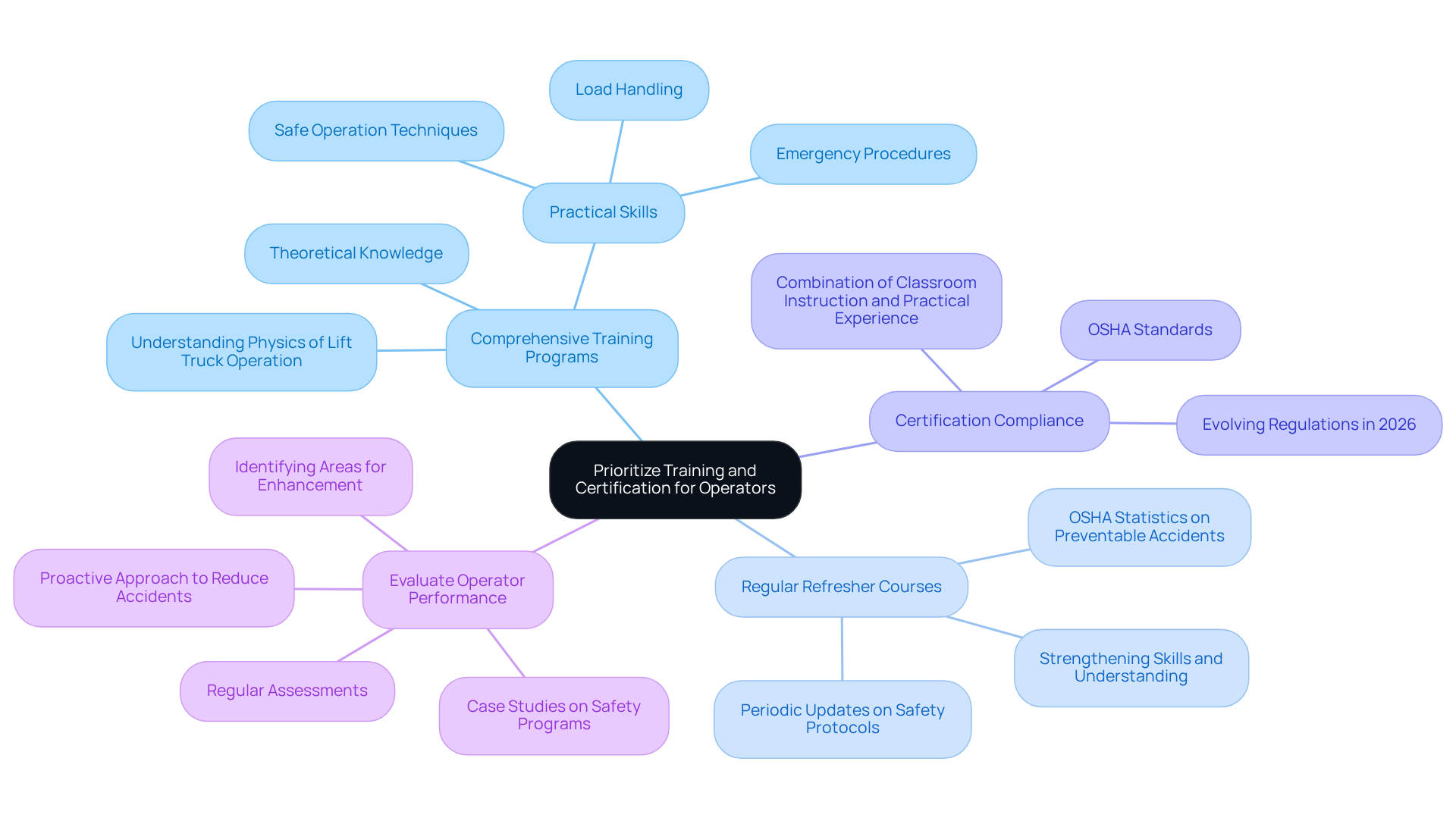

- Training and certification for operators should include comprehensive programmes, regular refresher courses, compliance with OSHA standards, and performance evaluations to reduce accident risks.

Introduction

Class 7 forklifts are recognized for their robust design and substantial load capacities, making them essential for outdoor operations in diverse industries, including construction and agriculture. To maximize productivity and minimize risks, organizations must understand best practices for operating these machines efficiently and safely. Given the complexities of operations and the potential hazards involved, how can companies ensure that their forklift usage is both effective and secure? This article explores key strategies and protocols that not only enhance the performance of Class 7 forklifts but also protect operators and the surrounding work environment.

Understand Class 7 Forklifts: Features and Applications

Class 7 forklift, commonly known as rough terrain movers, are engineered for outdoor operations on uneven surfaces. EZ Equipment Rental offers a diverse range of well-maintained lifting machines, ensuring clients find the perfect fit for their specific needs. Their robust design features large, pneumatic tires that provide outstanding traction and stability, making them essential for construction sites, landscaping, and agricultural tasks.

Key features include:

- Four-Wheel Drive (4WD): This capability significantly enhances maneuverability, allowing the forklift to navigate challenging terrains effortlessly.

- High Load Capacity: Class 7 forklift machines have a high load capacity, capable of lifting heavy loads that often exceed 10,000 pounds, which is crucial for transporting substantial materials in demanding environments.

- Versatile Attachments: Many models are equipped to utilize various attachments, such as forks, buckets, and grapples, broadening their functionality across numerous applications.

These features not only assist in selecting the right equipment for specific tasks but also ensure optimal performance and safety on job sites. At EZ Equipment Rental, our expert guidance and support help clients navigate their equipment rental needs, ensuring they choose the appropriate lifting vehicle for their projects.

Implement Safety Protocols for Class 7 Forklift Operation

To ensure the safe operation of Class 7 forklifts, it is essential to implement the following safety protocols:

-

Conduct Pre-Operation Inspections: Operators should perform thorough inspections before each use. This includes checking brakes, steering, and load capacity to confirm that the forklift is in safe working condition.

-

Establish Clear Operating Procedures: Develop and communicate standard operating procedures (SOPs) that outline safe driving practices, load handling techniques, and emergency protocols. Clear procedures help ensure that all operators using the class 7 forklift are aware of the necessary safety measures.

-

Use Personal Protective Equipment (PPE): Operators must wear suitable PPE, including hard hats, protective footwear, and high-visibility vests. This equipment is crucial for guarding against potential hazards in the work environment.

-

Maintain Clear Communication: Utilize hand signals or two-way radios to interact with ground personnel. Effective communication ensures that everyone is informed of the vehicle's movements, reducing the risk of accidents.

By adhering to these protocols, organizations can significantly reduce the risk of accidents and enhance overall safety on job sites.

Enhance Operational Efficiency with Class 7 Forklifts

To enhance the operational efficiency of Class 7 forklifts, organizations should consider several key strategies:

- Optimize Facility Layout: Designing the workspace to minimize travel distances for forklifts can significantly reduce cycle times and boost productivity.

- Utilize Telematics: Implementing telematics systems allows for monitoring equipment usage, tracking performance metrics, and identifying areas for improvement. This data-driven approach can lead to substantial efficiency gains.

- Regular Maintenance: Scheduling routine maintenance is essential to prevent breakdowns and ensure that lifting trucks operate at peak performance. A well-maintained fleet is both reliable and efficient.

- Cross-Train Operators: Educating operators on various types of equipment enhances flexibility and minimizes downtime when specific vehicles are unavailable.

By applying these strategies, organizations can significantly improve the efficiency of their operations with the Class 7 forklift, leading to enhanced productivity and reduced operational costs.

Prioritize Training and Certification for Operators

To ensure operators are well-prepared to handle a class 7 forklift, organizations should prioritize effective training and certification practices.

-

Comprehensive Training Programs: Organizations must develop training that encompasses both theoretical knowledge and practical skills. This training should cover safe operation techniques, load handling, and emergency procedures, ensuring operators understand the physics of lift truck operation and stability.

-

Regular Refresher Courses: It is essential to schedule periodic refresher courses to keep operators updated on safety protocols and operational best practices. These courses not only strengthen abilities and understanding but also acknowledge that OSHA estimates 70% of forklift accidents could be avoided with improved education.

-

Certification Compliance: All operators should be certified according to OSHA standards, which require a combination of classroom instruction and practical experience. As regulations evolve in 2026, the necessity for comprehensive instructional programs to meet compliance standards will become even more critical.

-

Evaluate Operator Performance: Regular assessments of operator performance are vital to identify areas for enhancement and provide additional instruction as needed. This proactive approach can significantly decrease the risk of accidents. Case studies indicate that companies adopting strong protection programs experience measurable declines in incidents. A recent event in Elm Mott, Texas, underscored the serious repercussions of insufficient preparation, highlighting the importance of adherence to safety regulations.

By prioritizing these training and certification practices, organizations can cultivate a culture of safety and efficiency, ultimately leading to enhanced performance and reduced risk on job sites.

Conclusion

Class 7 forklifts are essential for boosting productivity and safety in outdoor operations on uneven terrains. Recognizing their features - such as robust design, high load capacity, and versatile attachments - is vital for selecting the right equipment tailored to specific operational needs. Implementing best practices not only ensures efficient performance but also protects the well-being of operators and those working in proximity.

To maximize the efficiency and safety of Class 7 forklifts, key strategies include:

- Conducting thorough pre-operation inspections

- Establishing clear operating procedures

- Prioritizing personal protective equipment

- Optimizing facility layout

- Utilizing telematics for performance tracking

- Ensuring regular maintenance

Investing in comprehensive training and certification programs for operators further bolsters safety and minimizes the risk of accidents on job sites.

Ultimately, prioritizing safety and efficiency in Class 7 forklift operations is crucial for cultivating a productive work environment. Organizations are encouraged to adopt these best practices, ensuring their teams are well-prepared to tackle the challenges of rough terrain operations. By doing so, they not only safeguard their workforce but also drive operational excellence, paving the way for sustained success in their projects.

Frequently Asked Questions

What is a Class 7 forklift?

A Class 7 forklift, commonly known as a rough terrain mover, is designed for outdoor operations on uneven surfaces, making it ideal for construction sites, landscaping, and agricultural tasks.

What are the key features of Class 7 forklifts?

Key features of Class 7 forklifts include four-wheel drive (4WD) for enhanced maneuverability, a high load capacity that can exceed 10,000 pounds, and the ability to use versatile attachments like forks, buckets, and grapples.

How does the four-wheel drive (4WD) feature benefit Class 7 forklifts?

The four-wheel drive (4WD) feature significantly enhances maneuverability, allowing the forklift to navigate challenging terrains effortlessly.

What is the load capacity of Class 7 forklifts?

Class 7 forklifts have a high load capacity, capable of lifting heavy loads that often exceed 10,000 pounds, which is crucial for transporting substantial materials in demanding environments.

What types of attachments can be used with Class 7 forklifts?

Many models of Class 7 forklifts are equipped to utilize various attachments, such as forks, buckets, and grapples, which broaden their functionality across numerous applications.

How can EZ Equipment Rental assist clients with Class 7 forklifts?

EZ Equipment Rental offers a diverse range of well-maintained lifting machines and provides expert guidance and support to help clients navigate their equipment rental needs, ensuring they choose the appropriate lifting vehicle for their projects.

List of Sources

- Understand Class 7 Forklifts: Features and Applications

- Rough Terrain Forklift Industry Growth Trends and Analysis (https://marketreportanalytics.com/reports/rough-terrain-forklift-127924)

- Rough Terrain Forklift Market Size, Share, Trends & Forecast (https://verifiedmarketresearch.com/product/rough-terrain-forklift-market)

- Rough Terrain Forklift Market Analysis 2026, Market Size, Share, Growth, CAGR, Forecast, Trends, Revenue, Industry Experts, Consultation, Online/Offline Surveys, Syndicate Reports (https://cognitivemarketresearch.com/rough-terrain-forklift-market-report)

- Types, Considerations, and Classifications for Forklift Trucks (https://iqsdirectory.com/articles/forklift/forklift-trucks.html)

- Implement Safety Protocols for Class 7 Forklift Operation

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- National Forklift Safety Day Statistics │ MHEDA (https://mheda.org/journal/national-forklift-safety-day-statistics)

- Top Forklift Accident Statistics & Prevention Tips for 2025 | CertifyMe (https://certifyme.net/osha-blog/forklift-accidents)

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- Prioritize Training and Certification for Operators

- Why Train Forklift Operators: Complete Guide for 2025 - Top Osha Forklift Certification (https://forkliftacademy.com/why-train-forklift-operators?srsltid=AfmBOorrc2hb71GABaJLmoVf5gJoDHqsgg74zSTW6J5xHU_ZUdn-szT5)

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- Top Forklift Accident Statistics & Prevention Tips for 2025 | CertifyMe (https://certifyme.net/osha-blog/forklift-accidents)

- OSHA Top 10 Citations for 2024 (https://forklifttraining.com/osha-top-10-citations-2024)

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)