Key Highlights:

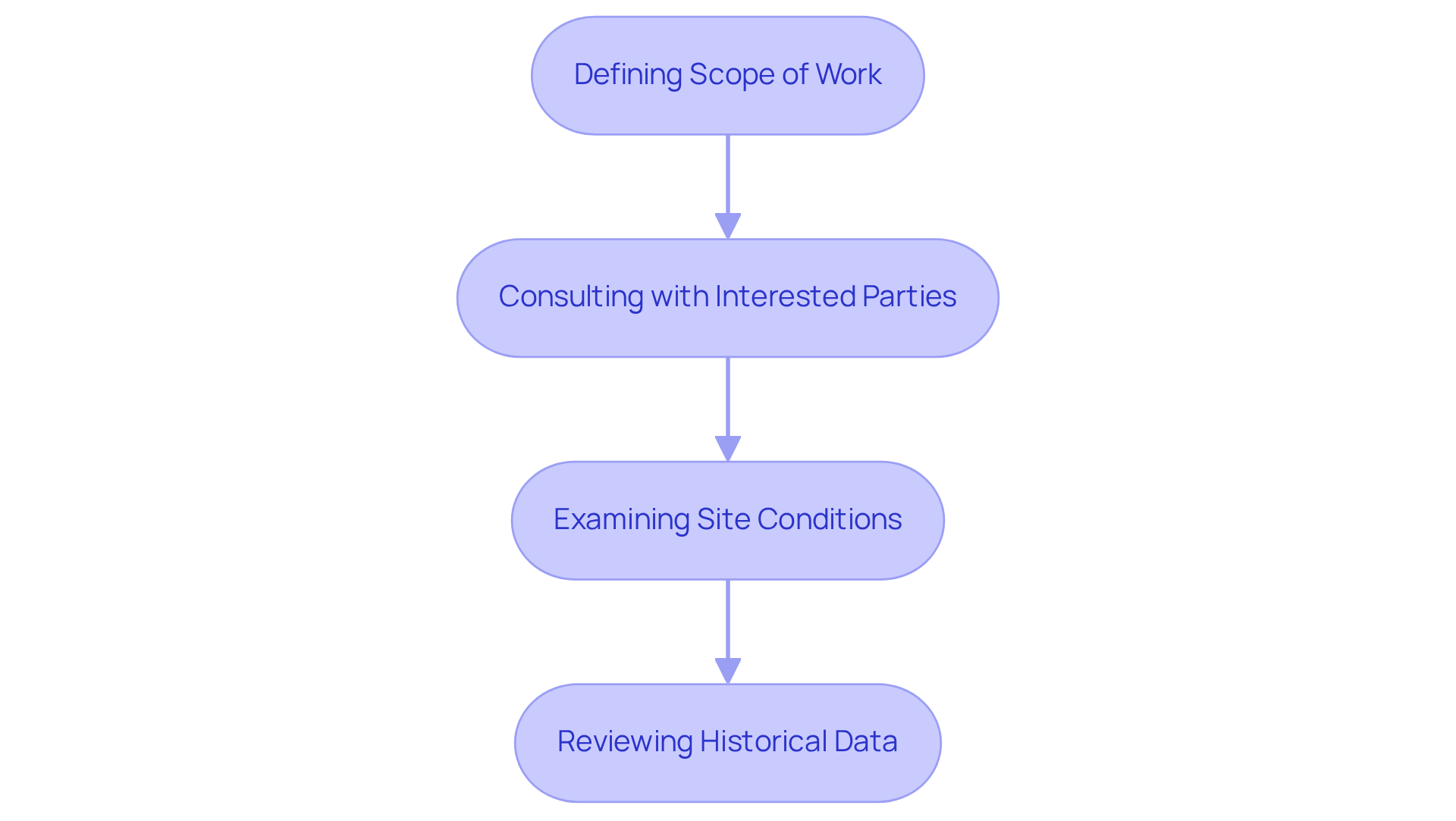

- Evaluate tool needs by defining the scope of work, consulting stakeholders, examining site conditions, and reviewing historical data.

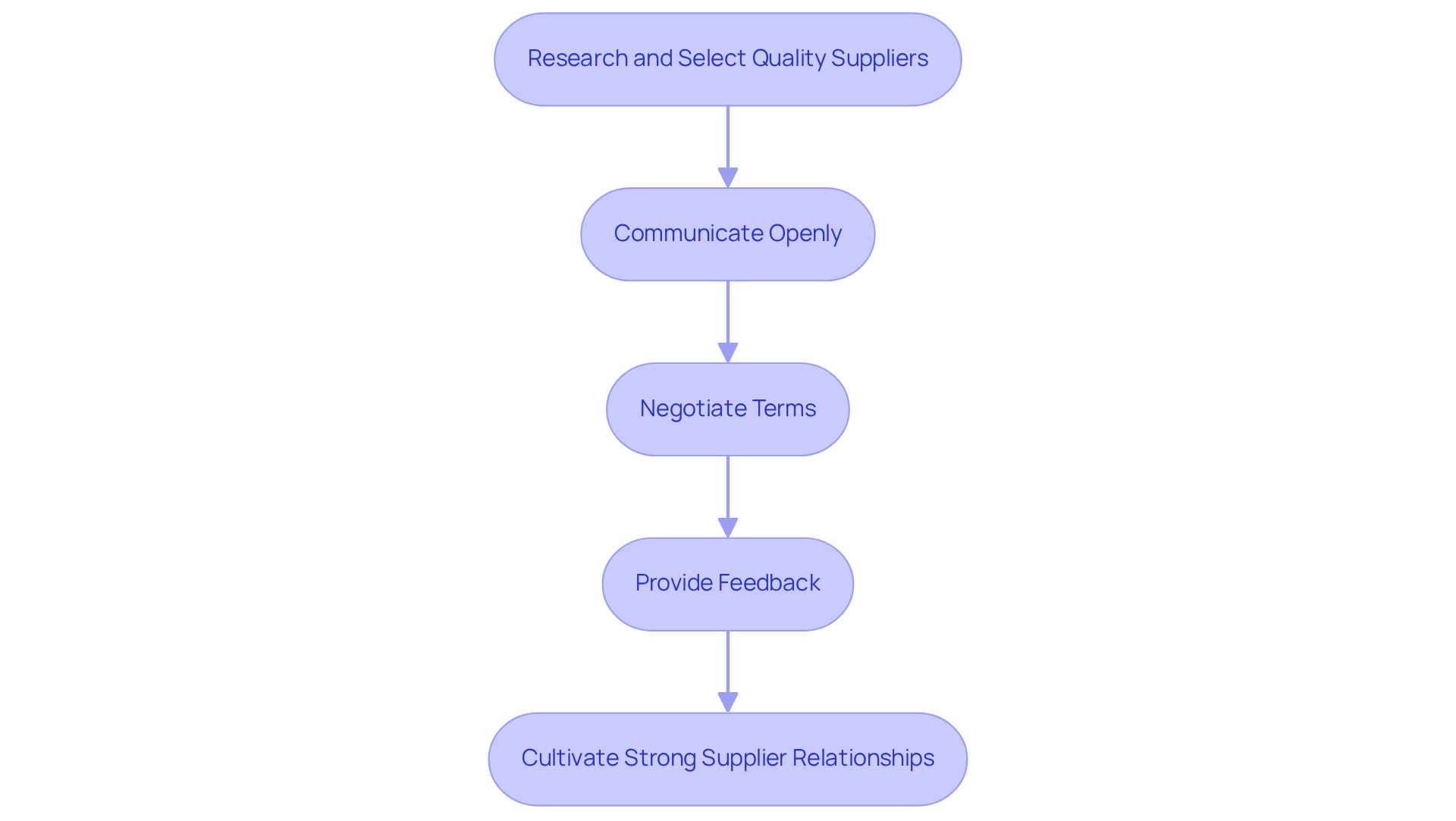

- Build relationships with reliable suppliers by researching quality vendors, maintaining open communication, negotiating favourable terms, and providing feedback.

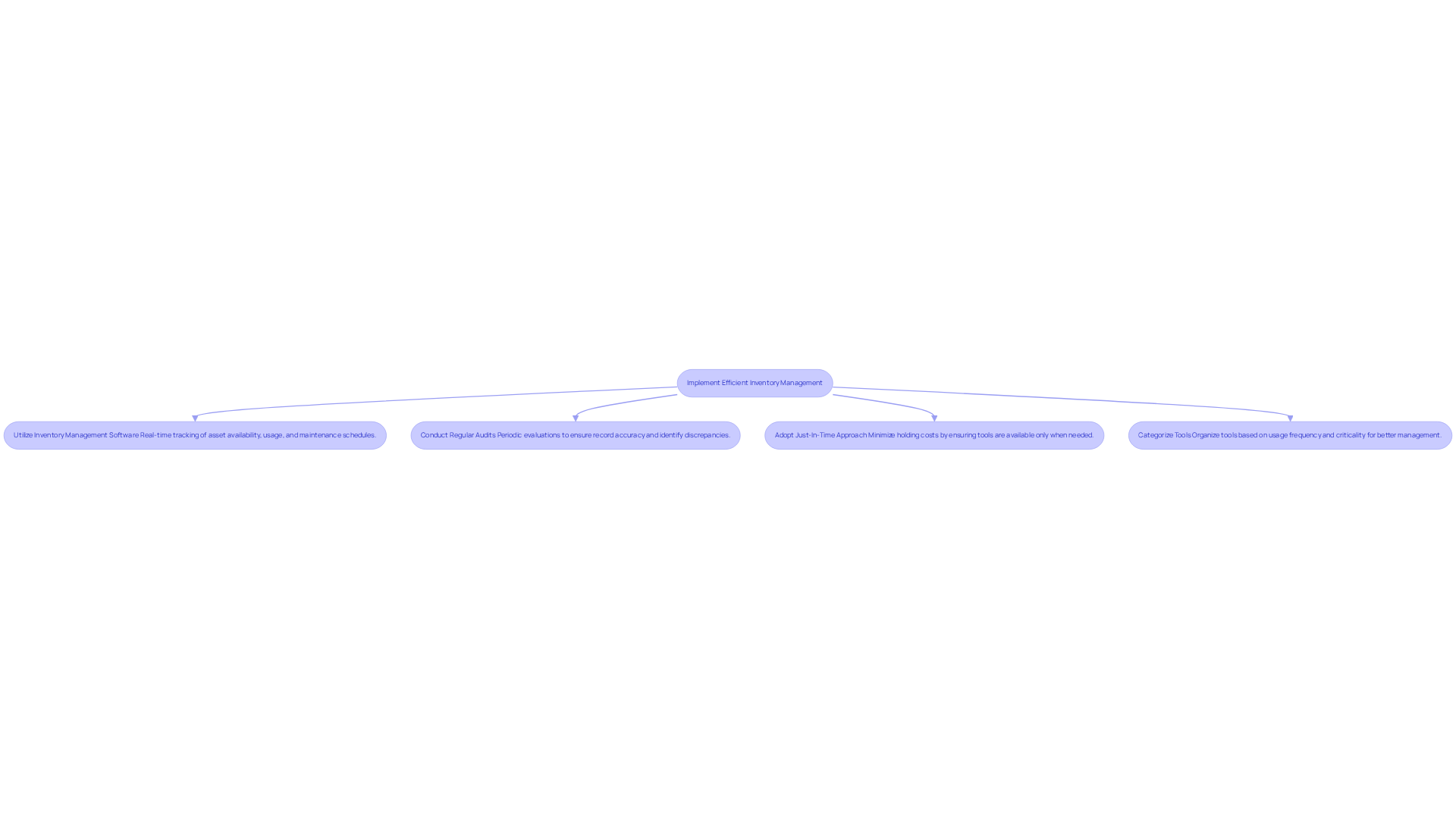

- Implement efficient inventory management through the use of software for tracking, conducting regular audits, adopting a just-in-time approach, and categorising tools.

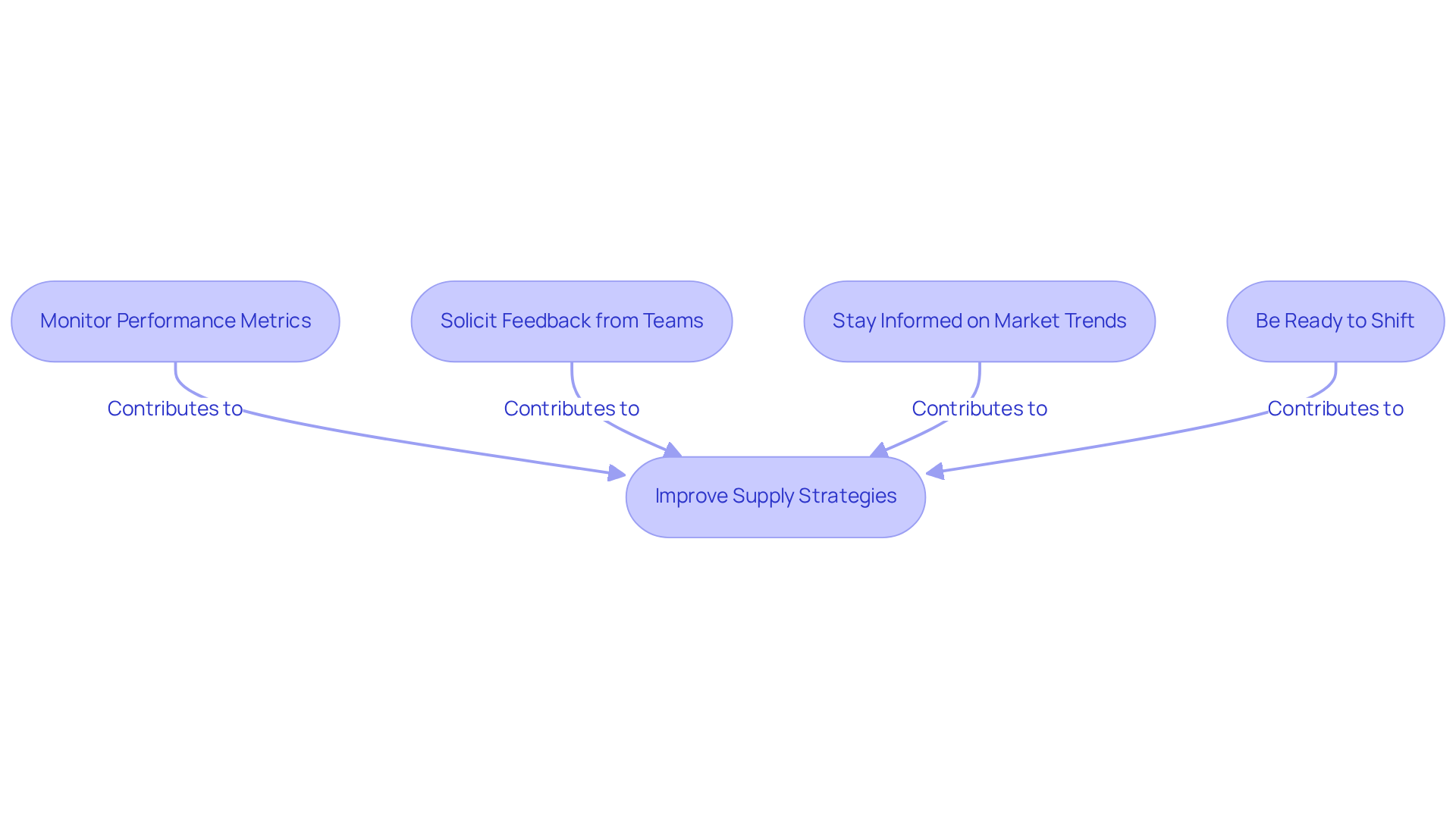

- Regularly assess and adapt equipment supply strategies by monitoring performance metrics, soliciting team feedback, staying informed on market trends, and preparing for potential disruptions.

Introduction

Effective equipment supply management is crucial for successful project execution, yet many organizations find it challenging to optimize their strategies. By adopting best practices in:

- Assessing equipment needs

- Nurturing supplier relationships

- Managing inventory

teams can significantly improve their operational efficiency and project outcomes. With the construction industry's evolving demands and anticipated market growth, how can companies ensure they meet current requirements while also adapting to future challenges? This article examines essential practices that can assist organizations in navigating the complexities of equipment supply management and maintaining a competitive edge.

Assess Project Equipment Requirements

To effectively manage the equipment supply of tools, start with a thorough evaluation of your initiative's tool needs. This process involves several key steps:

- Defining Scope of Work: Clearly articulate the objectives, timelines, and specific tasks that will require tools. This clarity helps identify the types and quantities of tools necessary for success.

- Consulting with Interested Parties: Engage with managers, team members, and other stakeholders to gather insights on essential tools based on their expertise and experience. Collaboration can lead to more informed decisions and improved resource allocation.

- Examining Site Conditions: Assess the physical conditions of the site, including terrain and accessibility, as these factors significantly influence the types of tools required. For example, operations in challenging environments may necessitate specialized machinery to ensure efficiency and safety.

- Reviewing Historical Data: Analyze previous initiatives of a similar nature to understand which tools were utilized and how effective they were in achieving objectives. This analysis can provide valuable insights and help avoid common pitfalls.

By adhering to these best practices, you can ensure an adequate equipment supply of the appropriate tools, which is crucial for maintaining timelines and budgets. In 2026, the anticipated machinery requirements for construction projects are expected to encompass a diverse range of tools, reflecting the industry's ongoing evolution and the necessity for flexibility in resource management.

Build Relationships with Reliable Suppliers

Building strong connections with dependable vendors is essential for efficient equipment management, especially in a growing market projected to reach $164.6 billion by 2029. Here are some best practices:

-

Research and Select Quality Suppliers: Identify suppliers with a proven track record of reliability and quality. Look for reviews, testimonials, and case studies that demonstrate their capabilities. For instance, the European Rental Association notes that 58% of market revenue comes from small-sized companies, underscoring the importance of selecting suppliers who can adapt to market demands.

-

Communicate Openly: Maintain regular communication with suppliers to discuss expectations, project timelines, and any potential issues. This fosters transparency and trust, which are crucial in an industry facing challenges such as supply chain disruptions and a shortage of skilled operators.

-

Negotiate Terms: Collaborate with suppliers to negotiate favorable terms, including pricing, delivery schedules, and maintenance agreements. A win-win approach can lead to long-term partnerships. As the market for construction tools rental is anticipated to expand from USD 45,397.7 million in 2025 to USD 79,779.4 million by 2035, creating advantageous conditions now can be beneficial in the long run.

-

Provide Feedback: Share insights on device performance and service quality. This helps suppliers enhance their offerings and strengthens the partnership. Incorporating insights from industry experts can further improve this process, ensuring that both parties are aligned in their goals.

By dedicating time to cultivating these connections, you can ensure a more dependable and effective chain for your resource needs, ultimately supporting the success of your projects.

Implement Efficient Inventory Management

Effective stock management is essential for maintaining a seamless supply chain for equipment supply of tools. Here are actionable strategies to enhance your operations:

-

Utilize Inventory Management Software: Implement software solutions that enable real-time tracking of asset availability, usage, and maintenance schedules. This approach significantly improves visibility and control over your stock, facilitating proactive management.

-

Conduct regular audits of your equipment supply: Schedule periodic evaluations of your equipment stock to ensure record accuracy and identify discrepancies or maintenance needs. Frequent audits can lead to improved operational efficiency. Case studies indicate that construction firms have reported increased jobsite productivity through effective stock management practices. Notably, 28% of warehouse leaders emphasize the importance of enhancing customer satisfaction, which is directly linked to efficient stock management.

-

Adopt a Just-In-Time Approach: Where feasible, apply a just-in-time stock strategy to minimize holding costs and ensure that tools are available only when needed. This method not only reduces excess inventory but also aligns with current trends, as 62.3% of companies are increasing investments in domestic supply to enhance responsiveness.

-

Categorize Tools: Organize tools into categories based on usage frequency and criticality. This categorization aids in prioritizing maintenance and procurement efforts for equipment supply, ensuring that essential equipment is readily available when required.

By adopting these best practices, you can improve your stock management, leading to reduced costs and enhanced project efficiency. Regular audits are particularly crucial; as noted, 28% of warehouse leaders prioritize improving customer satisfaction, which is directly linked to effective inventory oversight.

Evaluate and Adapt Equipment Supply Strategies

To maintain efficiency in resource management, it's crucial to regularly assess and adjust your strategies. Here are some best practices to consider:

-

Monitor Performance Metrics: Consistently track key performance indicators (KPIs) such as equipment utilization rates and equipment supply, which can average around 50% in construction projects, along with maintenance costs. Notably, over 90% of logistics chain leaders report significant disruptions, underscoring the importance of monitoring performance metrics. This data is vital for making informed adjustments to your supply strategies. For example, a case study showed that companies managing their machinery utilization effectively achieved a 20% reduction in idle time, resulting in substantial cost savings.

-

Solicit Feedback from Teams: Actively gather input from project teams regarding tool performance and any challenges faced. As Mitch Belsley states, "a single failure point can break a perfect order." This feedback is invaluable, revealing areas that need improvement and ensuring that tools meet the demands of various tasks effectively.

-

Stay Informed on Market Trends: Keep abreast of industry trends and technological advancements that may impact tools and management practices. Understanding these trends enables you to anticipate changes and adapt your strategies accordingly.

-

Be Ready to Shift: Develop backup strategies for potential material delivery interruptions. Proactive measures can mitigate risks associated with unexpected changes in scope or supplier reliability, ensuring that your operations remain smooth and efficient.

By continuously evaluating and adapting your strategies for equipment supply, including monitoring the Perfect Order Rate and other relevant KPIs, you can enhance project outcomes and maintain a competitive edge in the industry.

Conclusion

Effective equipment supply management is essential for the success of any project, ensuring that the right tools are available at the right time and place. By implementing best practices - such as assessing project equipment requirements, building strong supplier relationships, managing inventory efficiently, and regularly evaluating strategies - organizations can optimize resource management and enhance overall project outcomes.

Key insights highlight the importance of thorough project assessments, fostering reliable supplier connections, and utilizing advanced inventory management techniques. Engaging with stakeholders to determine equipment needs, maintaining open communication with suppliers, and leveraging technology for inventory tracking are essential components that contribute to a streamlined supply chain. Additionally, adapting strategies based on performance metrics and market trends ensures that organizations remain agile and responsive to changing demands.

In a rapidly evolving landscape, prioritizing effective equipment supply management not only improves operational efficiency but also positions organizations for long-term success. By embracing these best practices, teams can mitigate risks, reduce costs, and ultimately deliver projects on time and within budget. Taking action now to refine equipment management strategies will pave the way for a more resilient and competitive future in the industry.

Frequently Asked Questions

What is the first step in assessing project equipment requirements?

The first step is to define the scope of work by clearly articulating the objectives, timelines, and specific tasks that will require tools.

Why is it important to consult with interested parties during the equipment assessment?

Consulting with managers, team members, and stakeholders is important to gather insights on essential tools based on their expertise and experience, leading to more informed decisions and improved resource allocation.

How do site conditions affect the types of tools needed for a project?

Site conditions, including terrain and accessibility, significantly influence the types of tools required. Operations in challenging environments may necessitate specialized machinery to ensure efficiency and safety.

What role does historical data play in assessing equipment needs?

Reviewing historical data from previous initiatives helps understand which tools were utilized and how effective they were, providing valuable insights and helping to avoid common pitfalls.

What is the anticipated trend for machinery requirements in construction projects by 2026?

By 2026, the anticipated machinery requirements for construction projects are expected to encompass a diverse range of tools, reflecting the industry's ongoing evolution and the necessity for flexibility in resource management.

List of Sources

- Assess Project Equipment Requirements

- U.S. Construction Industry Data (Updated January 2026) (https://constructioncoverage.com/data/us-construction-spending)

- 100+ Construction Industry Statistics | Autodesk (https://autodesk.com/blogs/construction/construction-industry-statistics)

- 73 Must-Know Construction Statistics (2024) (https://bigrentz.com/blog/construction-statistics?srsltid=AfmBOooPgUwLzeZbUVbYLdwhO1ahQR3vTqJnqHKt5qKW-tXVSq0tOJTV)

- Construction Equipment Rental Market Statistics 2025-2034 (https://statifacts.com/outlook/us-construction-equipment-rental-market)

- 30+ Must-Know United States Construction Statistics (https://jonasconstruction.com/united-states-construction-statistics)

- Build Relationships with Reliable Suppliers

- 7 Must-Know Statistics About Equipment Rentals (https://gocodes.com/construction/equipment-rentals-statistics)

- Construction Equipment Rental Market Statistics 2025-2034 (https://statifacts.com/outlook/us-construction-equipment-rental-market)

- Topic: Equipment rental market worldwide (https://statista.com/topics/7873/equipment-rental-market-worldwide?srsltid=AfmBOoqyBW37tkNv_XG_dEtwBwS1nZve48iBk2RB4uKF5x16j0cOJx6s)

- General Equipment Rental Services Market | Global Market Analysis Report - 2035 (https://futuremarketinsights.com/reports/general-equipment-rental-services-market)

- Implement Efficient Inventory Management

- 8 Great Inventory Management Quotes - Fishbowl (https://fishbowlinventory.com/blog/8-great-inventory-management-quotes)

- 8 Inspirational Quotes About Inventory Management (https://cleverence.com/articles/business-blogs/8-inspirational-quotes-about-inventory-management)

- The ultimate list of inventory management statistics (https://netstock.com/blog/the-ultimate-list-of-inventory-management-statistics)

- 19 Inventory Management Statistics & Industry Benchmarks for 2024 (https://unleashedsoftware.com/blog/inventory-management-statistics)

- Inventory Management Software Market Trends | Growth [2034] (https://fortunebusinessinsights.com/inventory-management-software-market-108589)

- Evaluate and Adapt Equipment Supply Strategies

- 8 Critical Supply Chain KPIs That Matter Most in 2026 (https://gpx.co/blog/important-supply-chain-kpis)

- Top Maintenance KPIs to Track in 2026: MTBF, OEE (https://cryotos.com/blog/maintenance-kpis-the-most-important-metrics-to-track-in-2026)

- Top 11 Supply Chain KPIs – Guide for 2026 | MRPeasy Blog (https://mrpeasy.com/blog/supply-chain-kpis)

- The Construction Metric Everyone Ignores (Until It’s Too Late) (https://zenduit.com/the-construction-metric-everyone-ignores-until-its-too-late)

- Supply Chain KPIs to Measure in 2026 - iGPS (https://igps.net/supply-chain-kpis-to-measure-in-2026)