Key Highlights:

- Establishing a consistent maintenance schedule enhances machinery reliability and reduces unexpected breakdowns.

- Regular upkeep checks, recommended every 250 hours, include essential tasks like oil changes and hydraulic inspections.

- Neglecting maintenance can lead to significant costs, averaging $260,000 per hour in unplanned downtime.

- Organisations using preventive care strategies can experience up to a 70% reduction in equipment failures.

- Quality parts and tools are essential for optimal performance; OEM parts enhance machine life and reduce maintenance costs.

- Switching to OEM parts can result in up to a 20% decrease in unplanned downtime.

- Investing in technician training improves repair outcomes and employee satisfaction, with a projected job growth of 6% for service specialists from 2024 to 2034.

- Leveraging technology such as diagnostic software and telematics systems enhances maintenance efficiency and reduces operational downtime.

- Remote diagnostics can resolve a significant percentage of issues without field visits, optimising maintenance operations.

Introduction

Heavy equipment is essential across various industries, and its reliability is fundamentally tied to effective maintenance and repair practices. By adopting proven strategies, organizations can significantly extend the lifespan of their machinery and reduce costly downtimes. However, many face challenges in managing maintenance schedules, sourcing quality parts, training technicians, and integrating technology. What strategies can ensure that heavy equipment remains operational and efficient while minimizing unexpected failures?

To tackle these challenges, organizations must prioritize a proactive maintenance approach. This involves regular inspections and timely repairs, which not only enhance reliability but also prevent costly breakdowns. For instance, companies that implement routine maintenance schedules often report a marked decrease in equipment failures, leading to smoother operations and increased productivity. Furthermore, investing in quality parts ensures that machinery operates at peak performance, reducing the likelihood of unexpected downtimes.

In addition, technician training plays a crucial role in maintaining equipment efficiency. Skilled technicians are better equipped to identify potential issues before they escalate, ensuring that machinery remains in optimal condition. By fostering a culture of continuous learning and development, organizations can enhance their maintenance capabilities and improve overall equipment reliability.

Ultimately, the integration of technology can further streamline maintenance processes. Utilizing advanced monitoring systems allows for real-time tracking of equipment performance, enabling organizations to address issues proactively. This not only enhances operational efficiency but also fosters a culture of reliability and quality within the organization.

In conclusion, by implementing effective maintenance strategies, organizations can ensure their heavy equipment remains operational and efficient. The combination of proactive maintenance, quality parts, skilled technicians, and technology integration creates a robust framework for minimizing unexpected failures. Now is the time to take action and invest in the reliability of your heavy equipment.

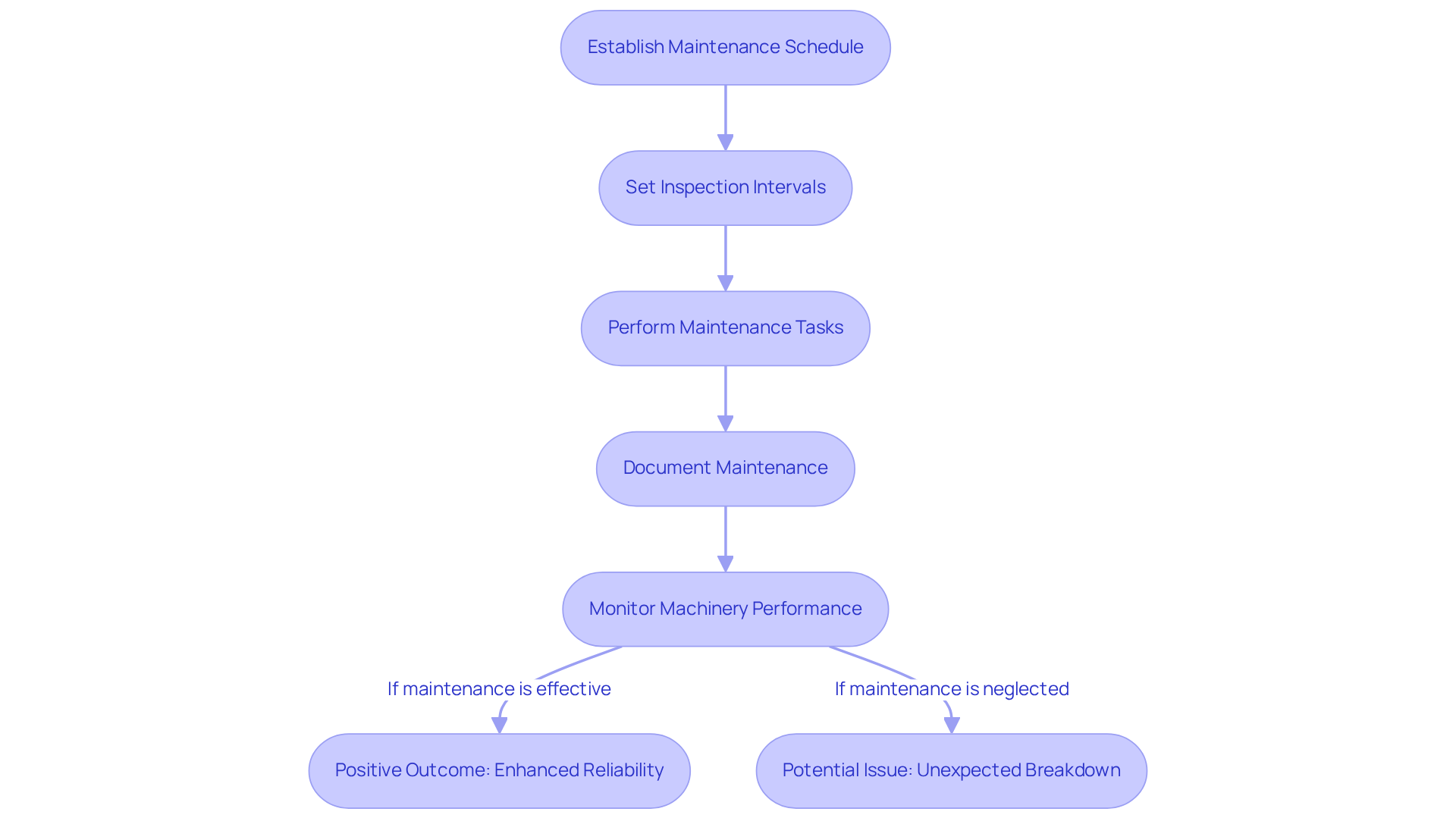

Implement Regular Maintenance Schedules

Establishing a consistent servicing timetable is crucial for the efficient restoration and care involved in heavy equipment repair. By setting specific intervals for inspections, servicing, and maintenance according to manufacturer recommendations and operational use, you can significantly enhance machinery reliability. For example, upkeep checks are often recommended every 250 hours of operation, covering essential tasks like oil changes, filter replacements, and hydraulic system inspections.

Following a systematic upkeep timetable greatly reduces the likelihood of unexpected machinery breakdowns, which can lead to considerable downtime and the need for heavy equipment repair. In fact, unanticipated downtime can cost companies an average of $260,000 each hour, underscoring the financial implications of neglecting heavy equipment repair and maintenance. Furthermore, precise documentation of maintenance tasks not only aids in monitoring machinery performance but also informs future heavy equipment repair decisions, ultimately improving overall operational efficiency.

A compelling case study reveals that organizations employing preventive care strategies experience up to a 70% reduction in failures. This statistic illustrates the effectiveness of organized upkeep in extending machinery lifespan and ensuring dependability. As industry leaders emphasize, "If you don't have time to do it right, you must have time to do it over," highlighting the necessity of diligent maintenance practices to avoid costly rework and inefficiencies.

At EZ Equipment Rental, our knowledgeable professionals provide expert guidance and support, ensuring smooth operations throughout the rental period. Don't wait - partner with us today to secure reliable equipment and maintain your machinery effectively!

Utilize Quality Parts and Tools for Repairs

The quality of components and tools used in heavy equipment repair is vital for ensuring optimal performance and safety. Sourcing parts from reputable manufacturers or authorized dealers is essential, as it guarantees compatibility and reliability. For example, OEM (Original Equipment Manufacturer) parts are designed to meet the exact specifications of the original equipment, significantly enhancing machine life and reducing maintenance costs. In contrast, aftermarket parts can lead to unpredictable results, including increased downtime and higher long-term expenses due to inferior quality.

At EZ Equipment Rental, we prioritize reliability and quality service. Our extensive inventory features high-quality air compressors and tools tailored for your maintenance needs. Investing in top-notch tools not only boosts the efficiency of heavy equipment repair but also enhances safety for technicians. Regularly assessing and refreshing our inventory of components and tools is crucial for maintaining high standards in heavy equipment repair tasks. Industry professionals consistently emphasize that using quality components in heavy equipment repair can lead to a reduction in unplanned downtime, with some reports indicating that companies experience up to a 20% decrease in downtime when switching to OEM parts. This proactive approach to maintenance ultimately supports smoother operations and keeps projects on schedule.

Don't compromise on quality. Choose EZ Equipment Rental for your maintenance needs and experience the difference that high-quality tools can make. Our commitment to excellence ensures that you have the best equipment at your disposal, ready to tackle any challenge. Contact us today to learn more about our offerings and how we can support your projects.

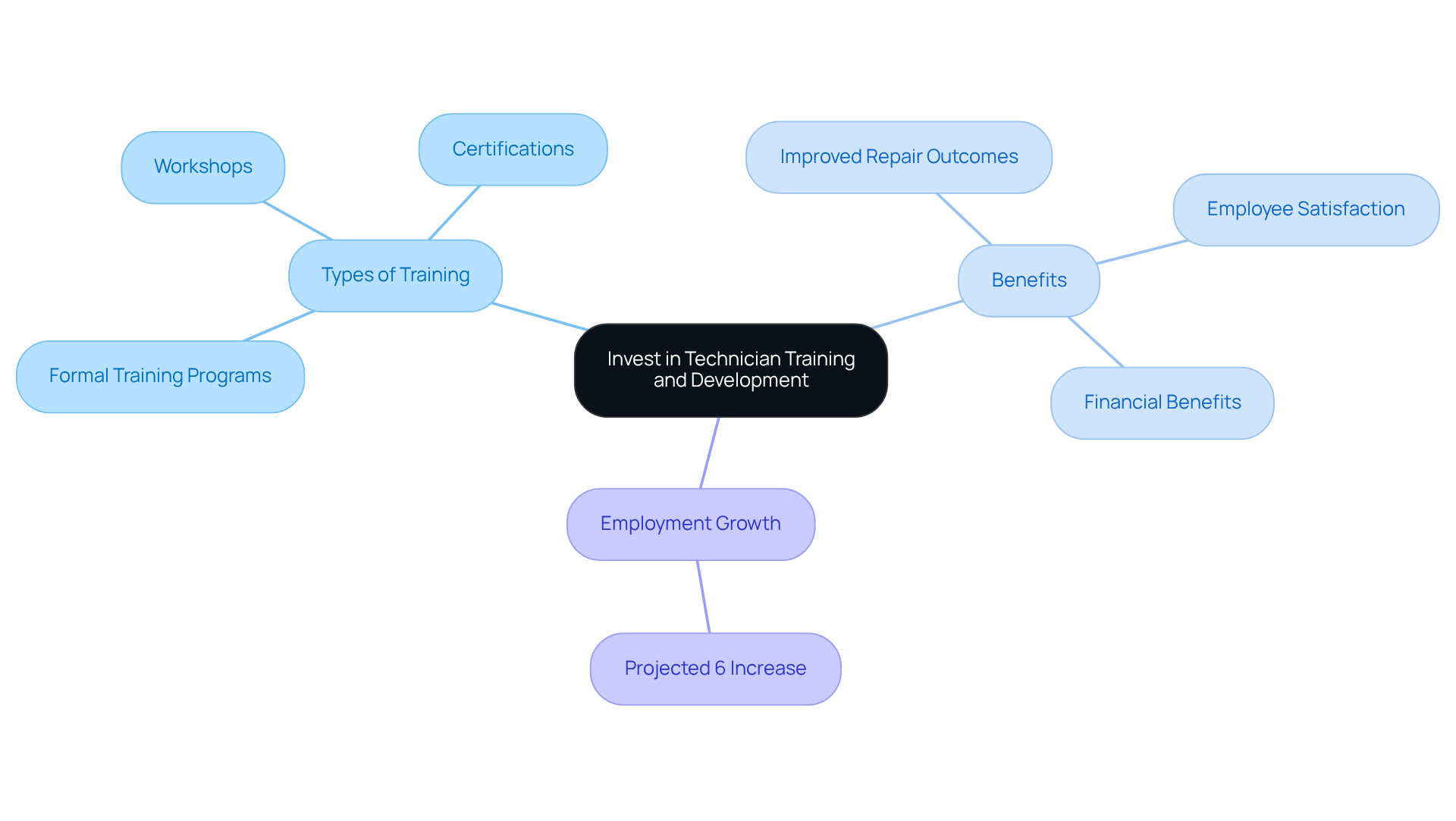

Invest in Technician Training and Development

To ensure the efficient maintenance of heavy machinery, investing in staff training and development for heavy equipment repair is essential. Formal training programs, workshops, and certifications focusing on the latest techniques and technologies in heavy equipment repair are key components of this investment. For example, training on advanced diagnostic tools and software empowers specialists to identify issues with greater accuracy and efficiency. Furthermore, fostering a culture of ongoing education within the organization encourages specialists to enhance their skills and stay updated on industry trends.

Organizations that prioritize staff development often witness improved repair outcomes and heightened employee satisfaction. With the median yearly salary for heavy vehicle and mobile machinery service professionals at $62,740, investing in training not only sharpens skills but also yields significant financial benefits. Moreover, the total employment of heavy vehicle and mobile machinery service specialists, particularly in heavy equipment repair, is projected to grow by 6 percent from 2024 to 2034, underscoring the increasing demand for skilled professionals and the critical role of robust training programs.

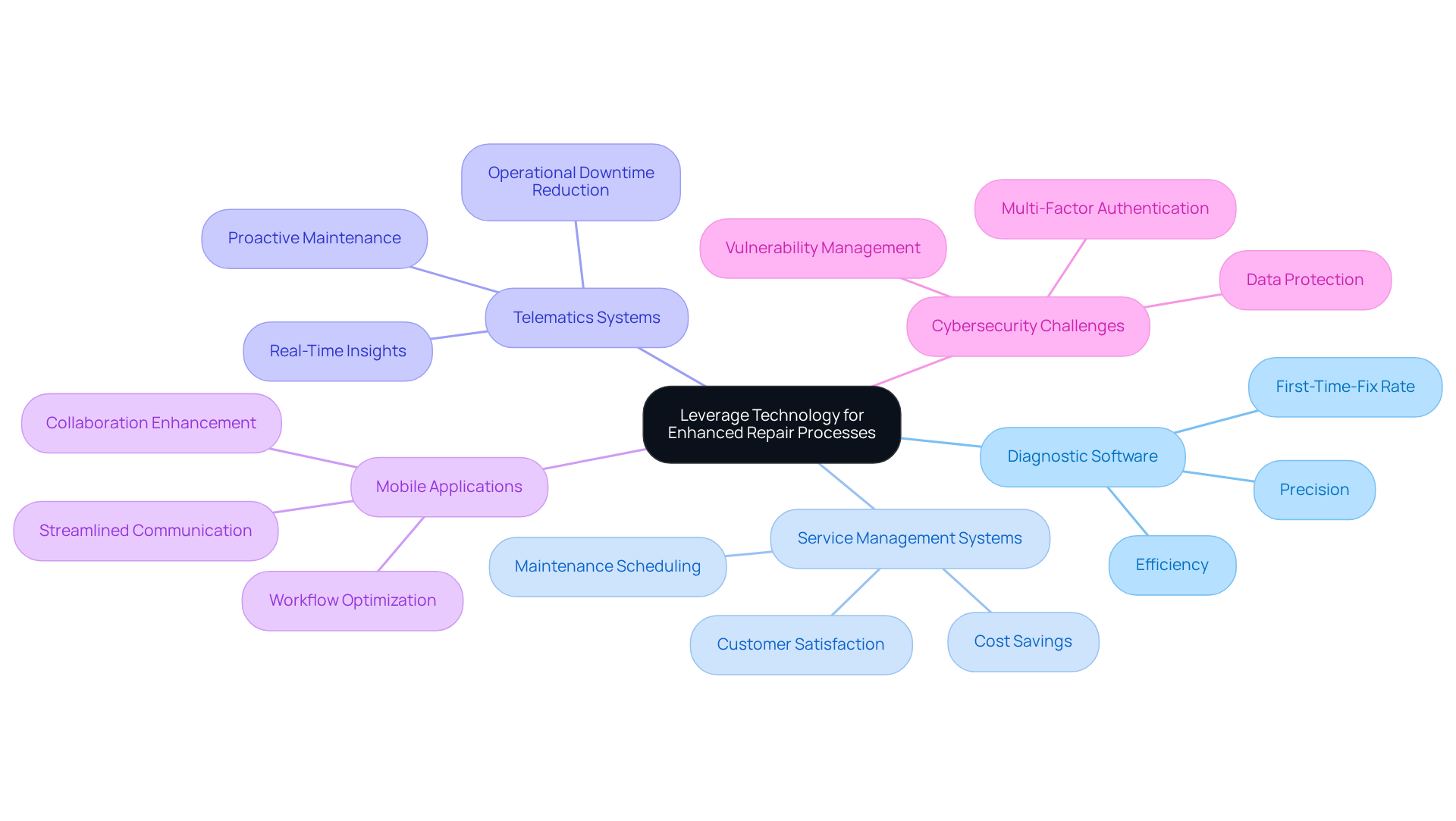

Leverage Technology for Enhanced Repair Processes

Incorporating advanced technology into heavy equipment repair processes significantly enhances both efficiency and precision. Diagnostic software empowers technicians to swiftly identify issues, while service management systems meticulously track service records and schedule upcoming maintenance. For instance, telematics systems deliver real-time insights into machinery performance, facilitating proactive maintenance and timely repairs that can drastically minimize operational downtime.

A compelling case study illustrates this point: a major construction machinery fleet adopted remote diagnostic capabilities, resolving 60% of sensor-related issues without requiring field visits. This showcases the effectiveness of such technologies in optimizing maintenance operations. Furthermore, mobile applications tailored for technicians streamline communication and workflows on job sites, fostering collaboration and elevating service delivery.

By embracing these technological advancements, organizations can not only enhance their maintenance capabilities but also realize substantial cost savings and improved equipment reliability. However, it is crucial to address the cybersecurity challenges associated with connected heavy machinery, as these systems can introduce vulnerabilities that must be managed effectively.

Additionally, metrics such as first-time-fix rates and mean time to repair (MTTR) are vital for assessing the success of these technologies. They provide valuable insights into their impact on productivity and operational costs, ensuring that organizations can make informed decisions about their maintenance strategies.

Conclusion

Establishing effective practices in heavy equipment repair is crucial for maximizing operational efficiency and minimizing downtime. Regular maintenance schedules, quality parts and tools, technician training, and advanced technology are essential strategies that significantly enhance machinery reliability and performance. These practices not only prevent unexpected failures but also cultivate a culture of continuous improvement and safety in the workplace.

Key insights emphasize the importance of systematic maintenance. Adhering to recommended service intervals can drastically reduce equipment failures and associated costs. Utilizing high-quality components, such as OEM parts, directly impacts machinery longevity and efficiency. A well-trained workforce, equipped with the latest skills and knowledge, ensures repairs are performed accurately and effectively. Furthermore, integrating technology streamlines repair processes, leading to quicker diagnostics and enhanced service delivery.

Prioritizing these best practices is essential for any organization relying on heavy equipment. By committing to regular maintenance, investing in quality resources, and embracing technological advancements, companies can safeguard their assets while driving productivity and profitability. Taking proactive steps in these areas ensures that heavy equipment remains a reliable asset rather than a costly liability. Don't wait - implement these strategies today to secure your operational success!

Frequently Asked Questions

Why is establishing a regular maintenance schedule important for heavy equipment?

Establishing a regular maintenance schedule is crucial for efficient restoration and care of heavy equipment, as it enhances machinery reliability and reduces the likelihood of unexpected breakdowns.

How often should maintenance checks be performed on heavy equipment?

Maintenance checks are often recommended every 250 hours of operation, which includes essential tasks like oil changes, filter replacements, and hydraulic system inspections.

What are the financial implications of neglecting heavy equipment maintenance?

Neglecting maintenance can lead to unexpected downtime, which can cost companies an average of $260,000 each hour.

How does systematic maintenance impact machinery performance?

Systematic maintenance reduces the likelihood of machinery failures and can lead to a 70% reduction in failures for organizations that employ preventive care strategies, ultimately improving operational efficiency.

What role does documentation play in heavy equipment maintenance?

Precise documentation of maintenance tasks aids in monitoring machinery performance and informs future repair decisions, enhancing overall operational efficiency.

What support does EZ Equipment Rental provide for maintenance?

EZ Equipment Rental offers expert guidance and support to ensure smooth operations throughout the rental period, helping customers maintain their machinery effectively.