Key Highlights:

- Thorough assessment of equipment condition is crucial for effective repairs, starting with visual inspections to identify wear and damage.

- Approximately 42% of equipment failures are due to lack of visual evaluations, highlighting their importance in preventive maintenance.

- Performance monitoring techniques, such as vibration analysis and thermography, provide deeper insights into equipment issues.

- Maintaining detailed documentation of inspections and repairs helps in recognising patterns and planning future maintenance.

- Structured maintenance workflows reduce errors and repair times, with 88% of companies utilising preventive maintenance strategies.

- Role assignments within maintenance teams enhance accountability and communication, improving overall team performance.

- Implementing a Computerised Maintenance Management System (CMMS) is common among 59% of facilities for tracking and managing repairs.

- Routine maintenance schedules aligned with manufacturer recommendations help extend equipment life and reduce failures.

- Creating a feedback loop encourages technicians to report anomalies, enhancing maintenance strategies.

- Investing in ongoing technician education and mentorship programmes fosters skill development and job satisfaction, with 74% of employees feeling underdeveloped.

- Regular performance evaluations tailored to technician needs improve engagement and retention, as 41% value career advancement opportunities.

Introduction

Effective industrial equipment repair goes beyond merely fixing machinery; it represents a strategic initiative that can greatly influence operational efficiency and profitability. By implementing best practices such as:

- Comprehensive equipment assessments

- Organized repair workflows

- A strong emphasis on technician training

organizations can significantly improve their maintenance strategies and minimize costly downtime. With the rising costs associated with machinery failure, companies must consider how to not only maintain but also enhance their repair processes. This article explores essential practices that can shift industrial equipment repair from a reactive stance to a proactive, efficient system.

Assess Equipment Condition Thoroughly

To effectively perform industrial equipment repair, a thorough assessment of its condition is essential. This process begins with clear steps:

-

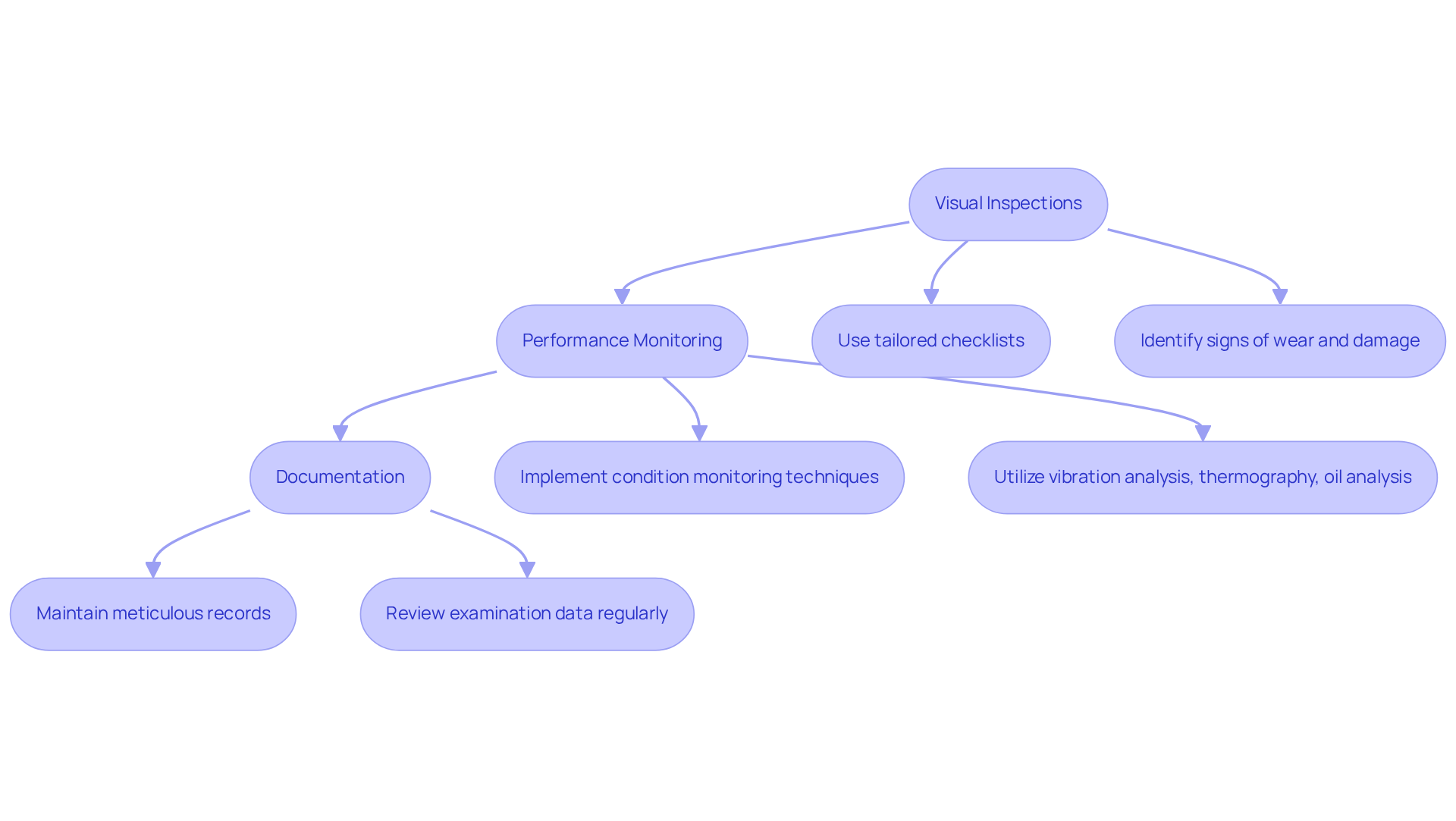

Visual Inspections: Regular inspections are crucial for identifying visible signs of wear, damage, or corrosion. Utilizing tailored checklists for each type of machinery ensures that no critical components are overlooked. Visual evaluations are vital, as approximately 42% of equipment failures stem from a lack of such assessments. They not only aid in the early detection of potential issues but also enhance compliance and safety standards. Furthermore, 67% of producers actively engage in preventive maintenance to minimize downtime, underscoring the strategic importance of these evaluations. The typical manufacturing plant faces 25 unexpected downtime events each month, highlighting the necessity of routine visual evaluations to avoid costly failures.

-

Performance Monitoring: Implementing condition monitoring techniques, such as vibration analysis, thermography, and oil analysis, can reveal underlying problems before they escalate into expensive failures. These techniques complement visual evaluations by providing data-driven insights into machinery condition.

-

Documentation: Maintaining meticulous records of all evaluations and repairs is essential. This documentation helps recognize patterns in equipment performance and forecast future failures, facilitating more strategic planning for industrial equipment repair. Regularly reviewing examination data can uncover trends that inform proactive upkeep strategies. It is also crucial to employ appropriate documentation methods for reporting results during visual inspections, which is important for accountability.

By adopting these best practices, including training technicians to identify early indicators of equipment malfunction, you can ensure that repairs are informed by precise information, leading to more effective and efficient maintenance outcomes.

Implement a Structured Repair Workflow

A structured maintenance workflow is crucial for conducting industrial equipment repair efficiently and effectively. Key components include:

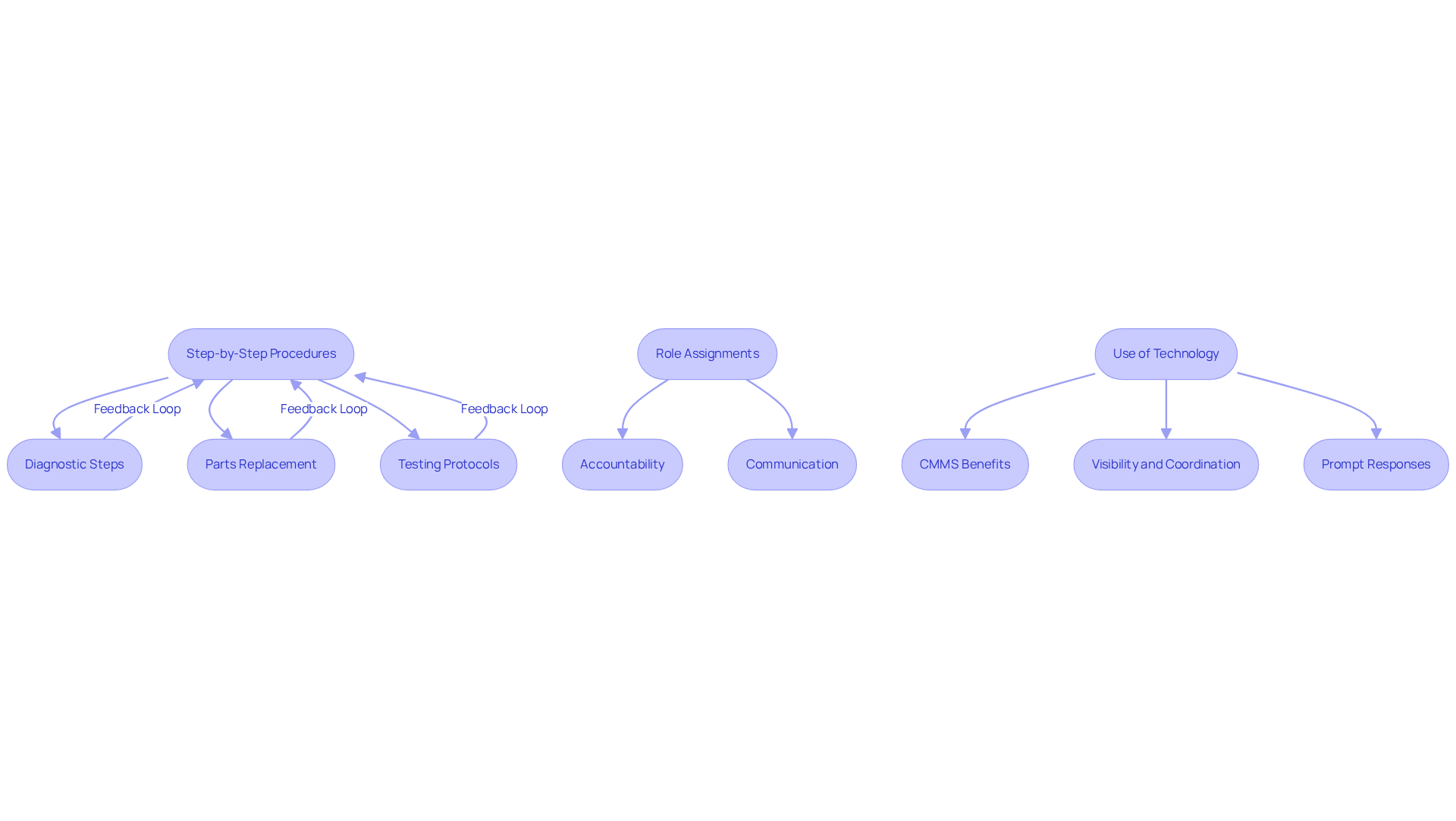

- Step-by-Step Procedures: Establish clear, documented procedures for each repair type, covering diagnostic steps, parts replacement, and testing protocols. This systematic approach ensures that all necessary actions are taken, thereby reducing the likelihood of errors and omissions. Research indicates that 88% of manufacturing companies utilize preventive maintenance, underscoring the importance of structured procedures in minimizing downtime.

- Role Assignments: Clearly define roles and responsibilities within the maintenance team. This clarity fosters accountability and simplifies communication, allowing team members to understand their specific contributions to the restoration process. As noted in external sources, effective role assignments can significantly enhance team performance and reduce miscommunication.

- Use of Technology: Implement a Computerized Maintenance Management System (CMMS) to track work orders, manage inventory, and schedule repairs. A CMMS enhances visibility and coordination among team members, facilitating prompt responses to maintenance needs. Notably, 59% of facilities employ a CMMS, highlighting its essential role in contemporary maintenance practices.

By adhering to a structured workflow, teams can significantly minimize errors, reduce repair times, and improve the overall quality of industrial equipment repair work performed. Integrating these practices not only enhances efficiency but also aligns with expert perspectives that emphasize the shift from experimentation to implementation in operational tasks.

Prioritize Regular Maintenance and Inspections

Routine care and evaluations are essential for enhancing the durability and effectiveness of industrial machinery. By implementing best practices, organizations can significantly improve operational reliability.

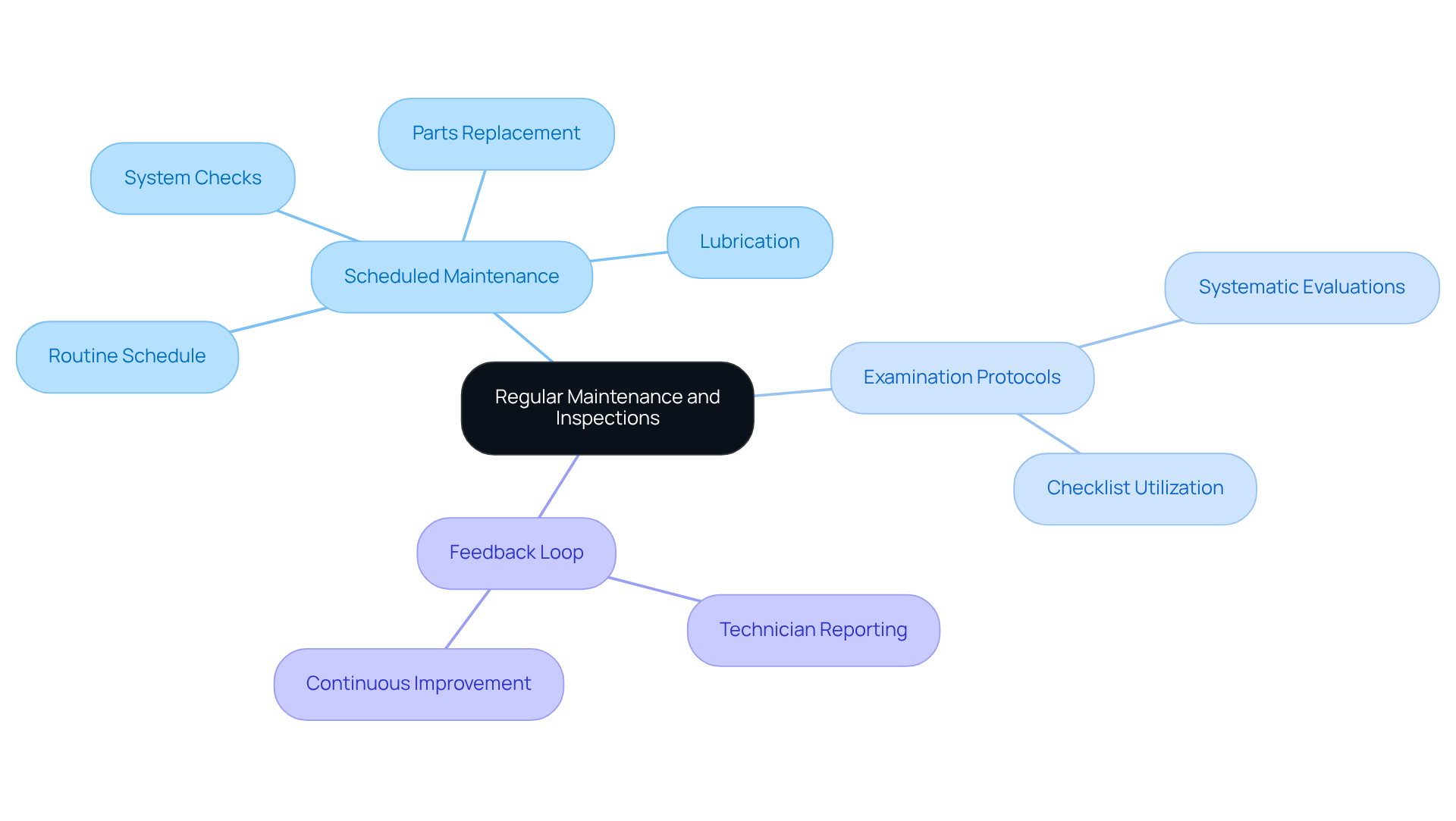

Scheduled Maintenance: Establish a routine maintenance schedule that aligns with manufacturer recommendations and equipment usage patterns. This schedule should include lubrication, parts replacement, and comprehensive system checks to ensure optimal performance. Industry data indicates that 88% of facilities utilize a preventive maintenance strategy to extend equipment life and reduce failures.

Examination Protocols: Conduct systematic evaluations to identify wear and tear early. Utilizing a comprehensive checklist during these evaluations ensures that all essential components are thoroughly assessed, minimizing the risk of oversight. Recent statistics reveal that the average cost of machinery downtime per hour is approximately $260,000, underscoring the importance of efficient evaluation protocols.

Feedback Loop: Create an environment where technicians feel encouraged to report any anomalies or concerns identified during inspections. This feedback loop is vital for enhancing maintenance strategies and improving overall equipment reliability. Service leaders note that 45% cite a lack of resources as their biggest challenge, highlighting the need to leverage technician insights for continuous improvement.

By prioritizing these practices, organizations can effectively mitigate the risk of unexpected breakdowns, thereby enhancing operational efficiency and reducing costly downtime. A case study on the cost-effectiveness of maintenance versus replacement illustrates that investing in maintenance can decrease downtime by an average of 44%, further emphasizing the value of these best practices.

Invest in Technician Training and Development

To maximize the effectiveness and efficiency of your maintenance team, prioritizing their training and development is essential. Key strategies include ongoing education, mentorship programs, and performance evaluations.

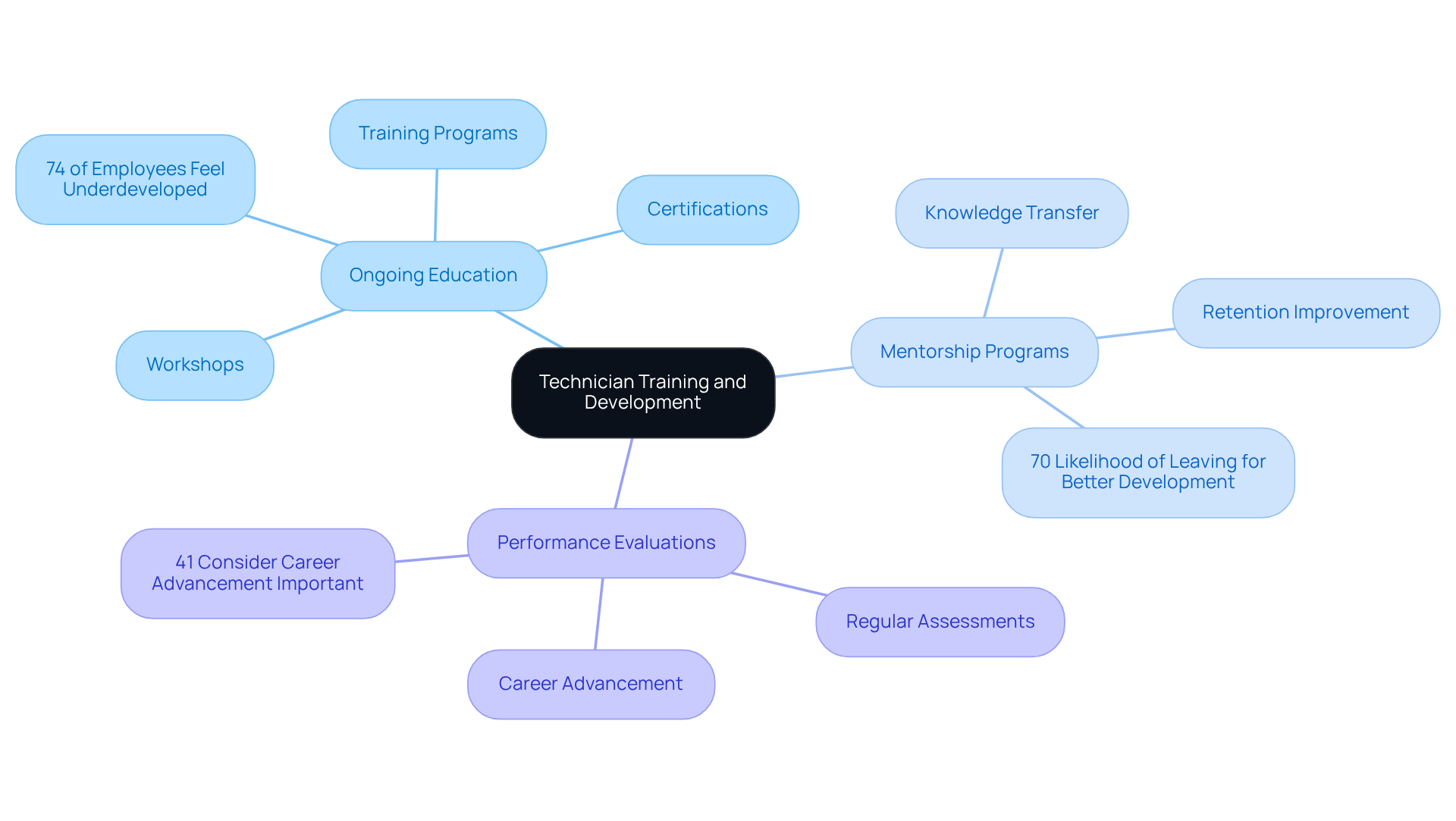

Ongoing Education: Equip technicians with access to training programs that encompass the latest repair techniques, safety protocols, and advancements in equipment technology. This can involve workshops, online courses, and certifications that keep them updated and proficient. Notably, 74% of surveyed employees feel they aren’t reaching their full potential at work due to a lack of development opportunities, underscoring the necessity of ongoing education.

Mentorship Programs: Establish mentorship initiatives that pair less experienced technicians with seasoned professionals. This approach facilitates knowledge transfer, enhances skill development, and fosters a collaborative learning environment. Investing in mentorship can significantly improve retention; 70% of employees would be somewhat likely to leave their current job for an organization known for investing in employee development.

Performance Evaluations: Conduct regular assessments of technician performance, providing constructive feedback to identify areas for improvement. Tailoring training programs based on these evaluations ensures that technicians receive the support they need to excel. Importantly, 41% of employees consider their organization’s career advancement opportunities a very important factor in their job satisfaction, making performance evaluations crucial for employee engagement.

Investing in your technicians not only enhances their skills but also cultivates a culture of excellence and safety within your organization. This ultimately leads to improved performance metrics and reduced downtime. Organizations with poor onboarding processes are twice as likely to experience employee turnover, highlighting the importance of a robust training program.

Conclusion

Effective industrial equipment repair relies on several best practices that ensure machinery operates at peak performance while minimizing downtime. By thoroughly assessing equipment condition, implementing structured repair workflows, prioritizing regular maintenance, and investing in technician training, organizations can significantly enhance their operational reliability and efficiency.

Key insights emphasize the importance of comprehensive equipment evaluations, which include visual inspections and performance monitoring. Establishing a structured workflow with clear procedures and roles is essential for reducing errors and improving communication among maintenance teams. Additionally, regular maintenance schedules and feedback loops enable early identification of potential issues, while ongoing technician development fosters a culture of excellence in repair practices.

Ultimately, embracing these best practices not only mitigates the risk of unexpected breakdowns but also highlights the value of investing in both equipment and personnel. By prioritizing maintenance and training, organizations can create a resilient operational framework that reduces costs and enhances overall productivity. Adopting these strategies leads to a more sustainable and efficient industrial environment, positioning companies for long-term success in an increasingly competitive landscape.

Frequently Asked Questions

Why is assessing the condition of industrial equipment important?

Assessing the condition of industrial equipment is essential to identify visible signs of wear, damage, or corrosion, which can prevent costly failures and enhance compliance and safety standards.

What are the main steps involved in assessing equipment condition?

The main steps include visual inspections, performance monitoring using techniques like vibration analysis and thermography, and maintaining meticulous documentation of evaluations and repairs.

What role do visual inspections play in equipment assessment?

Visual inspections are crucial for detecting visible issues and are responsible for preventing approximately 42% of equipment failures. They help in early detection of potential problems and improve compliance and safety standards.

How often do manufacturers experience unexpected downtime, and why is this relevant?

The typical manufacturing plant faces about 25 unexpected downtime events each month, highlighting the need for routine visual evaluations to avoid costly failures.

What techniques can be used for performance monitoring?

Techniques for performance monitoring include vibration analysis, thermography, and oil analysis, which provide data-driven insights into the condition of machinery.

Why is documentation important in the equipment assessment process?

Documentation is important because it helps recognize patterns in equipment performance, forecast future failures, and facilitates strategic planning for repairs. It also ensures accountability during inspections.

How can technician training improve equipment maintenance outcomes?

Training technicians to identify early indicators of equipment malfunction ensures that repairs are based on precise information, leading to more effective and efficient maintenance outcomes.

List of Sources

- Assess Equipment Condition Thoroughly

- Why Maintenance Visual Inspections Will Never Go Out Of Style (https://maintworld.com/Asset-Management/Why-Maintenance-Visual-Inspections-Will-Never-Go-Out-Of-Style)

- The Strategic Benefits of Visual Inspections in Industrial Maintenance (https://linkedin.com/pulse/strategic-benefits-visual-inspections-industrial-qxkne)

- 30 Key Maintenance Statistics & Facts Highlighting 2026 Trends (https://coastapp.com/blog/maintenance-metrics-statistics-facts)

- The Latest Statistics from the Maintenance Industry [2025] (https://getsockeye.com/blog/maintenance-statistics)

- 25 Maintenance Stats, Trends, And Insights For 2026 (https://getmaintainx.com/blog/maintenance-stats-trends-and-insights)

- Implement a Structured Repair Workflow

- Lean Manufacturing Quotes to Drive Efficient Industrial Operations (https://mapcon.com/blog/2014/07/11-lean-manufacturing-quotes-to-inspire-you)

- Lean Manufacturing Quotes: Here's 12 More to Inspire You (https://swipeguide.com/insights/12-lean-manufacturing-quotes-to-inspire)

- Enterprise Asset Management Market Trends & Growth Insights 2026 (https://verdantis.com/predictive-and-preventive-maintenance-statistics)

- 25 Maintenance Stats, Trends, And Insights For 2026 (https://getmaintainx.com/blog/maintenance-stats-trends-and-insights)

- The Top 200 Manufacturing & Operations Quotes (https://praxie.com/top-business-operations-manufacturing-quotes)

- Prioritize Regular Maintenance and Inspections

- The Latest Statistics from the Maintenance Industry [2025] (https://getsockeye.com/blog/maintenance-statistics)

- 25 Maintenance Stats, Trends, And Insights For 2026 (https://getmaintainx.com/blog/maintenance-stats-trends-and-insights)

- Manufacturing Maintenance Statistics & Data You Need to Know (https://caisoft.com/resources/manufacturing-maintenance-statistics)

- 30 Key Maintenance Statistics & Facts Highlighting 2026 Trends (https://coastapp.com/blog/maintenance-metrics-statistics-facts)

- Maintenance Statistics: Predictive & Preventive, Labor & Costs (https://upkeep.com/learning/maintenance-statistics)

- Invest in Technician Training and Development

- Why Proper Training Matters for Plant Machinery Repair Technician (https://bp-services.com.au/why-proper-training-is-important-for-plant-machinery-repair-technicians)

- 39 Statistics that Prove the Value of Employee Training (https://lorman.com/blog/post/39-statistics-that-prove-the-value-of-employee-training?srsltid=AfmBOoplsSuDsQL7Qp-0yJ9QOMQAuoQtzGbU0qh8a-MT43cLFk2c__JG)

- TechForce releases 2023 Technician Supply & Demand Report (https://techforce.org/techforce-releases-2023-technician-supply-demand-report)

- TOP 25 TECHNICIANS QUOTES (of 116) | A-Z Quotes (https://azquotes.com/quotes/topics/technicians.html)