Key Highlights:

- Asphalt rollers come in various types, including static, vibratory, and pneumatic, each suited for specific road construction applications.

- Vibratory rollers compact asphalt using rapid vibrations at frequencies of 55 to 70 Hz, while pneumatic rollers use air-filled tyres for consistent pressure.

- Key specifications such as drum widths (59.1 to 84.3 inches) and operating weights (10 to 25 tonnes) are crucial for selecting the right asphalt roller.

- Water spray systems on rollers prevent asphalt from sticking, impacting density quality and project outcomes.

- Regular maintenance, including daily checks of fluid levels and drum conditions, is essential to ensure peak performance and extend machinery lifespan.

- Using a detailed inspection checklist helps identify issues early, reducing risks and downtime.

- Effective planning of roller operations, including optimal rolling patterns and collaboration with paving teams, enhances workflow and productivity.

- Connected compaction systems like BOMAP Connect enable real-time monitoring of asphalt compaction, improving quality assurance.

- Integrating technology, such as intelligent densification systems and GPS tracking, enhances performance and provides critical data insights for better decision-making.

Introduction

Understanding the complexities of asphalt rollers is essential for achieving outstanding results in road construction. These machines are vital for ensuring proper compaction and surface quality. By maximizing their efficiency, you can significantly improve project timelines and reduce costs. Yet, many operators may overlook key practices that enhance performance.

So, what are the best strategies to ensure your asphalt rollers operate at peak efficiency? This article explores four best practices that not only boost the effectiveness of asphalt rollers but also empower operators to achieve exceptional results in their paving projects.

Understand Asphalt Roller Functionality and Features

Asphalt rollers, which include various types such as static, vibratory, and pneumatic models, are designed for specific applications in road construction. Understanding how these devices operate is crucial for achieving optimal compaction results. For example, vibratory machines use rapid vibrations, typically operating at frequencies between 55 to 70 Hz, to compact asphalt effectively. In contrast, pneumatic devices, featuring air-filled tires, excel in finishing work by applying consistent pressure. Key features, such as drum widths ranging from 59.1 to 84.3 inches and operating weights varying from 10 to 25 tons for asphalt rollers, significantly influence the selection of the appropriate asphalt roller for a project, directly impacting operational efficiency and the quality of the finished surface.

Furthermore, operators must recognize the importance of additional features like water spray systems, which prevent asphalt from sticking to the drums. This aspect is vital, as it can greatly affect density quality and overall project outcomes. As Brian Bieller emphasizes, understanding the specific uses and benefits of each roller type is essential for maximizing efficiency. By familiarizing themselves with these features and specifications, personnel can make informed choices that enhance their compaction efforts. Additionally, educating staff on these technologies is crucial, as it directly influences the success of compaction operations.

Implement Regular Maintenance and Inspection Routines

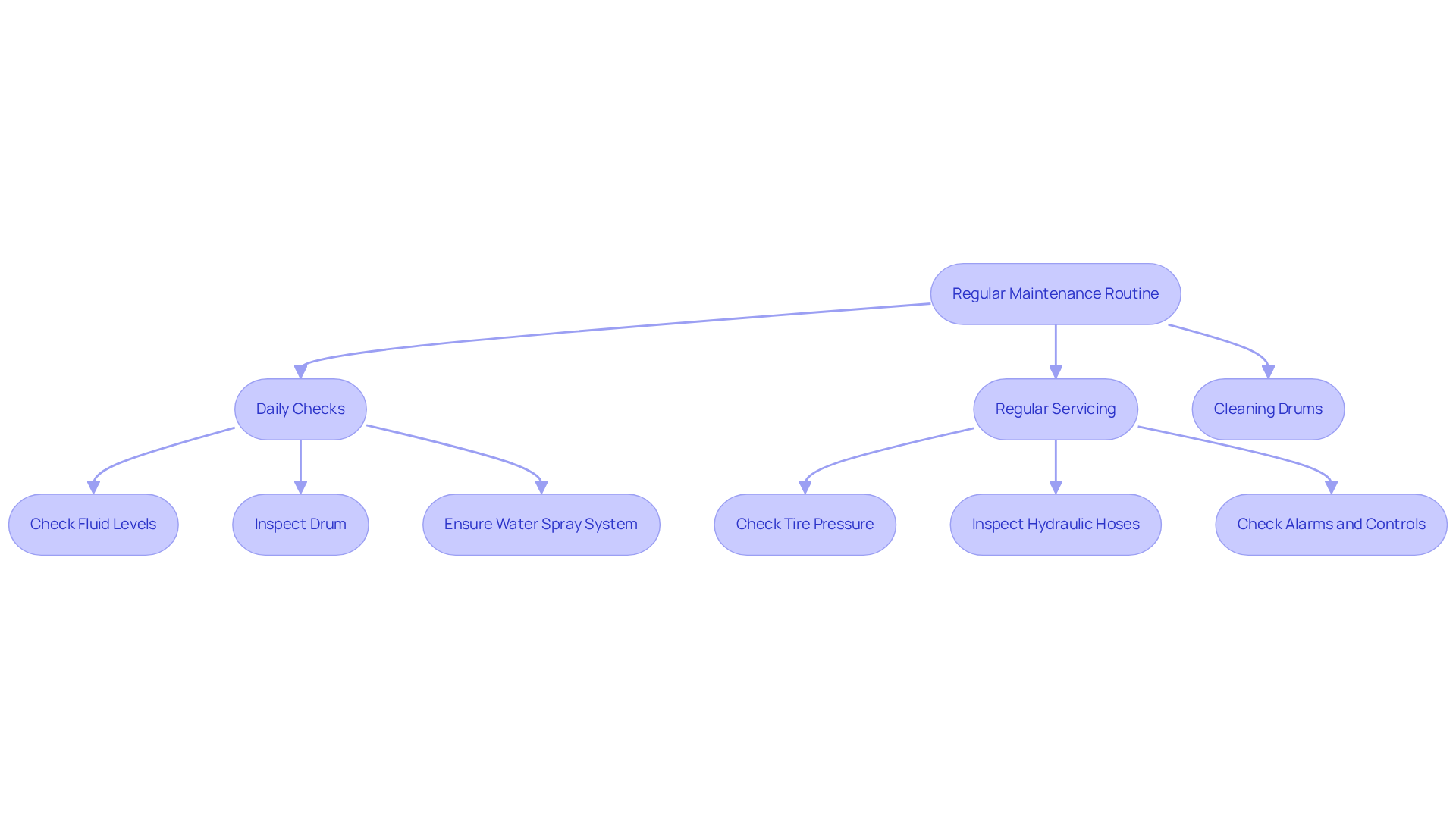

To enhance the effectiveness of the asphalt roller, it is essential for personnel to establish a well-organized maintenance plan that emphasizes daily checks and regular servicing. Key maintenance tasks include:

- Checking fluid levels - engine oil, hydraulic fluid, and coolant

- Inspecting the drum for signs of wear and tear

- Ensuring the water spray system operates effectively

Moreover, cleaning the drums after each use prevents asphalt buildup, which can significantly hinder functionality.

Utilizing a detailed checklist for daily inspections allows personnel to identify potential issues early, ensuring the asphalt roller remains in peak condition throughout the project. Regular maintenance not only enhances the efficiency of the asphalt roller but also extends the lifespan of the machinery, ultimately contributing to smoother operations and reduced downtime. As Francisco emphasizes, "Maintenance is a necessity that you can’t afford to overlook, and proper maintenance begins long before a plant breakdown." Furthermore, with 82% of companies experiencing unplanned downtime in the last three years, the stakes of neglecting maintenance are high.

A practical inspection checklist might include tasks such as:

- Checking tire pressure

- Inspecting hydraulic hoses for leaks

- Ensuring all alarms and controls are functioning properly

By following these practices, users can reduce risks and improve the reliability of their equipment. Don't wait for a breakdown - implement these maintenance strategies today to ensure your machinery operates at its best.

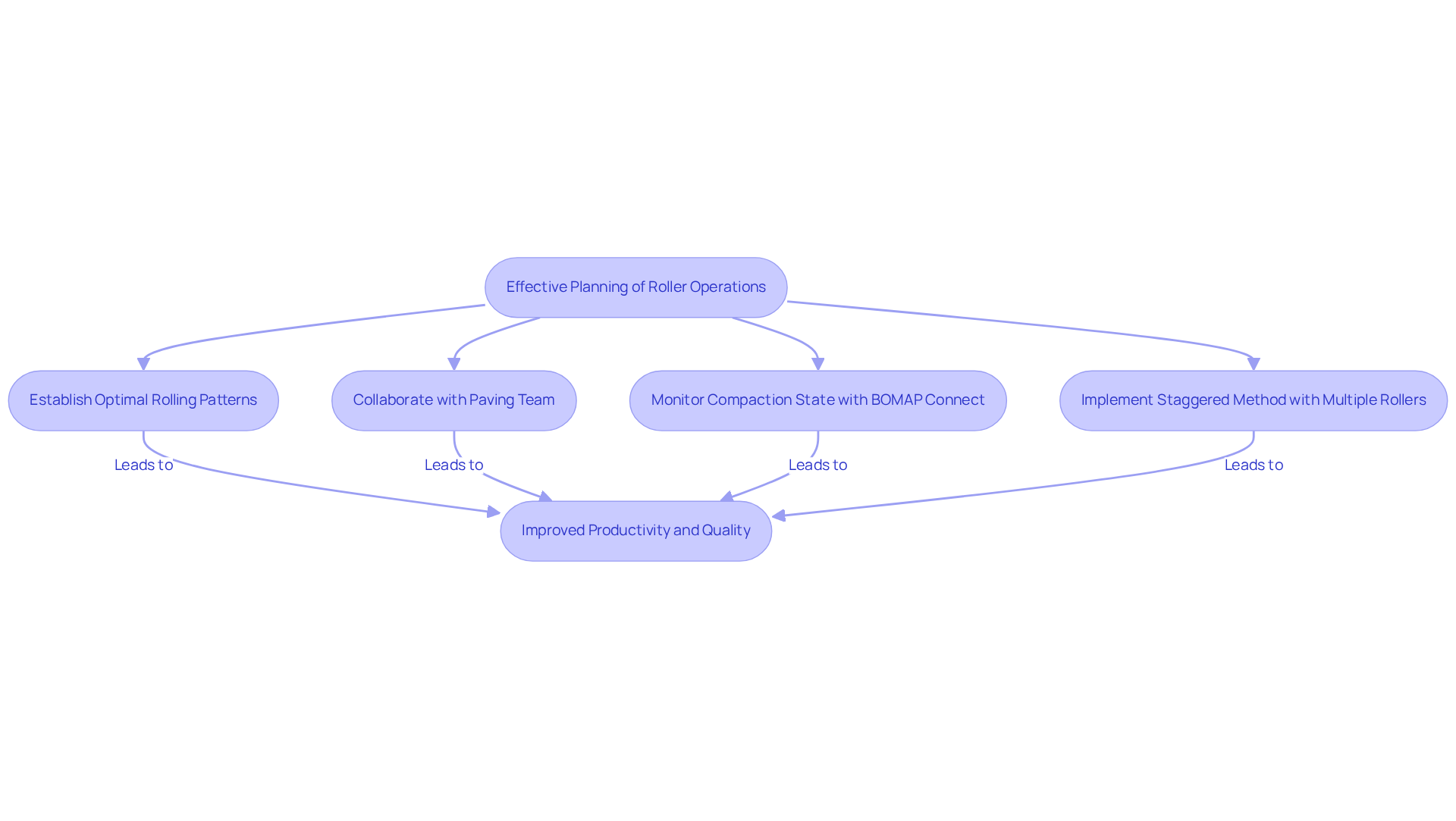

Plan Efficient Roller Operations and Job Site Coordination

Effective planning of operations involving the asphalt roller is essential for a seamless workflow on job sites. Operators must establish optimal rolling patterns that maximize coverage while minimizing overlaps, which can lead to over-compaction and material waste. By collaborating closely with the paving team, operators can ensure they remain updated on paving speeds and adjust their rolling speeds accordingly to maintain ideal temperature levels.

In addition, employing connected compaction systems like BOMAP Connect allows users to monitor the compaction state of asphalt projects in real time. This capability significantly enhances their ability to optimize rolling patterns and ensure quality results. Implementing a staggered method with multiple rollers can further boost productivity, enabling continuous operation without delays.

By prioritizing thorough planning and effective coordination, operators can dramatically increase the overall productivity of the asphalt paving process. This approach not only enhances productivity but also elevates the quality of the finished surface, showcasing the pride and craftsmanship of the construction team. As Edwards noted, linked compression systems provide reassurance, ensuring that all areas are compressed accurately, which minimizes callbacks and rework. Take action now to enhance your asphalt paving operations with effective planning and the right asphalt roller for optimal results.

Leverage Technology for Enhanced Performance and Data Insights

Integrating technology into asphalt roller operations significantly enhances performance and efficiency. Intelligent densification systems, equipped with advanced sensors, provide real-time data on material density and quality of consolidation. This capability enables operators to make prompt adjustments, ensuring optimal results. As Dr. David Cist, CTO of GSSI, noted, "DOTs pay bonuses for good density because their research shows that each 1% change in packing can extend or shorten road life by 10% or more," underscoring the critical importance of accurate packing.

Furthermore, GPS tracking enhances efficiency by optimizing roller paths and monitoring equipment usage. This ensures resources are allocated effectively, maximizing productivity on every project. Additionally, data analytics reveal trends and pinpoint areas for improvement in compaction processes, facilitating better decision-making and project outcomes. As stated, "Real-time, high-accuracy data isn’t just nice to have anymore-it’s a necessity."

By adopting these technologies, operators not only enhance the quality of their work but also achieve significant cost reductions. The integration of advanced systems leads to increased overall productivity, making it essential for those in the industry to stay ahead. Embrace these innovations today to elevate your operations and ensure long-lasting results.

Conclusion

Maximizing the efficiency of asphalt rollers is essential for achieving high-quality road construction results. Understanding the functionality and features of various roller types, implementing regular maintenance routines, planning operations effectively, and leveraging technology are key strategies that operators can employ to significantly enhance their compaction efforts. Each of these practices contributes to improved operational efficiency, ensuring that projects are completed smoothly and to a high standard.

Selecting the right asphalt roller based on its features is crucial. Maintaining equipment to prevent breakdowns is equally important, as is employing strategic job site coordination. Furthermore, integrating advanced technologies facilitates real-time monitoring and data-driven decision-making, which are vital for optimizing performance and reducing costs. These practices not only enhance the quality of asphalt paving but also extend the lifespan of the machinery involved.

As the industry evolves, embracing these best practices will be vital for staying competitive and ensuring successful project outcomes. Operators are encouraged to take proactive steps in implementing these strategies - from regular inspections to adopting cutting-edge technology - to maximize asphalt roller efficiency. By doing so, they contribute to the overall success of their construction projects.

Frequently Asked Questions

What are the different types of asphalt rollers?

The different types of asphalt rollers include static, vibratory, and pneumatic models, each designed for specific applications in road construction.

How do vibratory asphalt rollers operate?

Vibratory asphalt rollers operate using rapid vibrations, typically at frequencies between 55 to 70 Hz, to effectively compact asphalt.

What is the advantage of using pneumatic asphalt rollers?

Pneumatic asphalt rollers, which feature air-filled tires, excel in finishing work by applying consistent pressure, making them suitable for achieving a smooth surface.

What are the key specifications to consider when selecting an asphalt roller?

Key specifications include drum widths ranging from 59.1 to 84.3 inches and operating weights varying from 10 to 25 tons, which significantly influence the selection of the appropriate asphalt roller for a project.

Why is it important to understand the features of asphalt rollers?

Understanding the features of asphalt rollers is crucial for achieving optimal compaction results and directly impacts operational efficiency and the quality of the finished surface.

What is the role of water spray systems in asphalt rollers?

Water spray systems prevent asphalt from sticking to the drums, which is vital for maintaining density quality and ensuring successful project outcomes.

How can operators maximize the efficiency of asphalt compaction?

Operators can maximize efficiency by understanding the specific uses and benefits of each roller type and familiarizing themselves with the features and specifications of asphalt rollers.

Why is educating staff on asphalt roller technologies important?

Educating staff on asphalt roller technologies is crucial as it directly influences the success of compaction operations and improves overall project outcomes.