Key Highlights:

- Roofing safety equipment is essential for preventing falls and protecting workers from hazards.

- Personal Fall Arrest Systems (PFAS) significantly reduce fall-related injuries, with proper training reducing incidents by 19.6%.

- Guardrails must meet OSHA standards, providing a physical barrier to prevent falls.

- Safety nets catch workers during falls, especially in areas where guardrails can't be installed.

- Retractable lifelines allow movement while securing workers and minimise fall distances.

- Secure roof anchors are critical for attaching safety harnesses and must be properly installed.

- Compliance with OSHA regulations is vital, especially for work at heights of six feet or more.

- Regular security audits and documentation of training and inspections are essential for compliance.

- Routine inspections and maintenance of safety equipment ensure its effectiveness and safety.

- Comprehensive training programmes for workers, including initial orientation and regular refreshers, significantly reduce workplace injuries.

- Emergency response training is crucial for ensuring quick action during incidents.

Introduction

The construction industry faces a significant challenge: ensuring the safety of workers on rooftops, where falls can result in severe consequences. Accidents account for a considerable portion of fatalities in this sector, making the implementation of effective roofing safety equipment not only a regulatory requirement but also a vital aspect of workplace culture. This article explores best practices for roofing safety equipment, highlighting essential tools and training methods that can substantially mitigate risks.

How can construction companies effectively integrate these practices to protect their workers and adhere to evolving safety regulations?

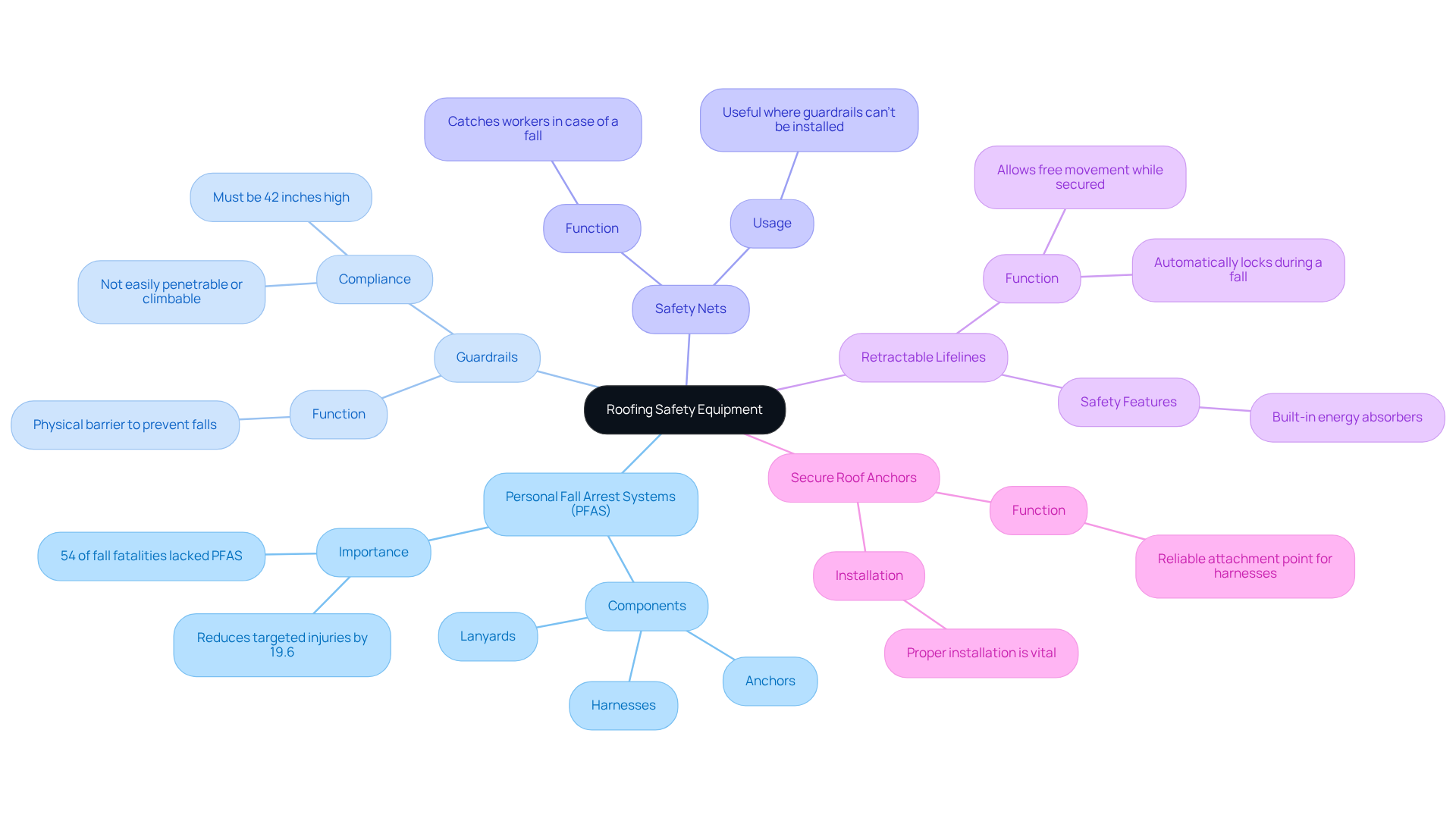

Understand Types of Roofing Safety Equipment

Roofing safety equipment is essential for protecting employees from falls and other hazards. Key types of equipment include:

- Personal Fall Arrest Systems (PFAS): These systems, which consist of harnesses, lanyards, and anchors, are designed to prevent falls from heights. Proper fitting and maintenance of PFAS are crucial, as studies indicate that training employees in their use can reduce targeted injury occurrences by 19.6%. Furthermore, it is important to note that 54% of individuals who died in falls did not have access to a personal arrest system, underscoring the necessity of providing such equipment.

- Guardrails: Installed around the roof's edge, guardrails serve as a physical barrier to prevent falls. They must comply with OSHA standards, which require a minimum height of 42 inches and stipulate that they should not be easily penetrable or climbable.

- Safety Nets: These nets provide an additional layer of security by catching workers in the event of a fall. They are particularly useful in areas where guardrails cannot be installed, ensuring that protective measures are in place even in challenging environments.

- Retractable Lifelines: These devices allow for free movement while secured and automatically lock during a fall, minimizing the distance descended. The latest designs include built-in energy absorbers to reduce impact forces, enhancing worker safety.

- Secure Roof Anchors: Installed on the roof, these anchors offer a reliable point for attaching safety harnesses. Proper installation is vital, as a weak anchor can lead to serious accidents.

As Clark Roofing emphasizes, 'No roofer should be on a pitched surface without a properly fitted harness, as this is the first line of defense when a slip becomes a drop.' Understanding roofing safety equipment is crucial for ensuring that all workers have the necessary tools to perform their jobs safely. With accidents accounting for over 36% of deaths in the construction sector, implementing effective protective measures is not just a regulatory requirement but a moral obligation.

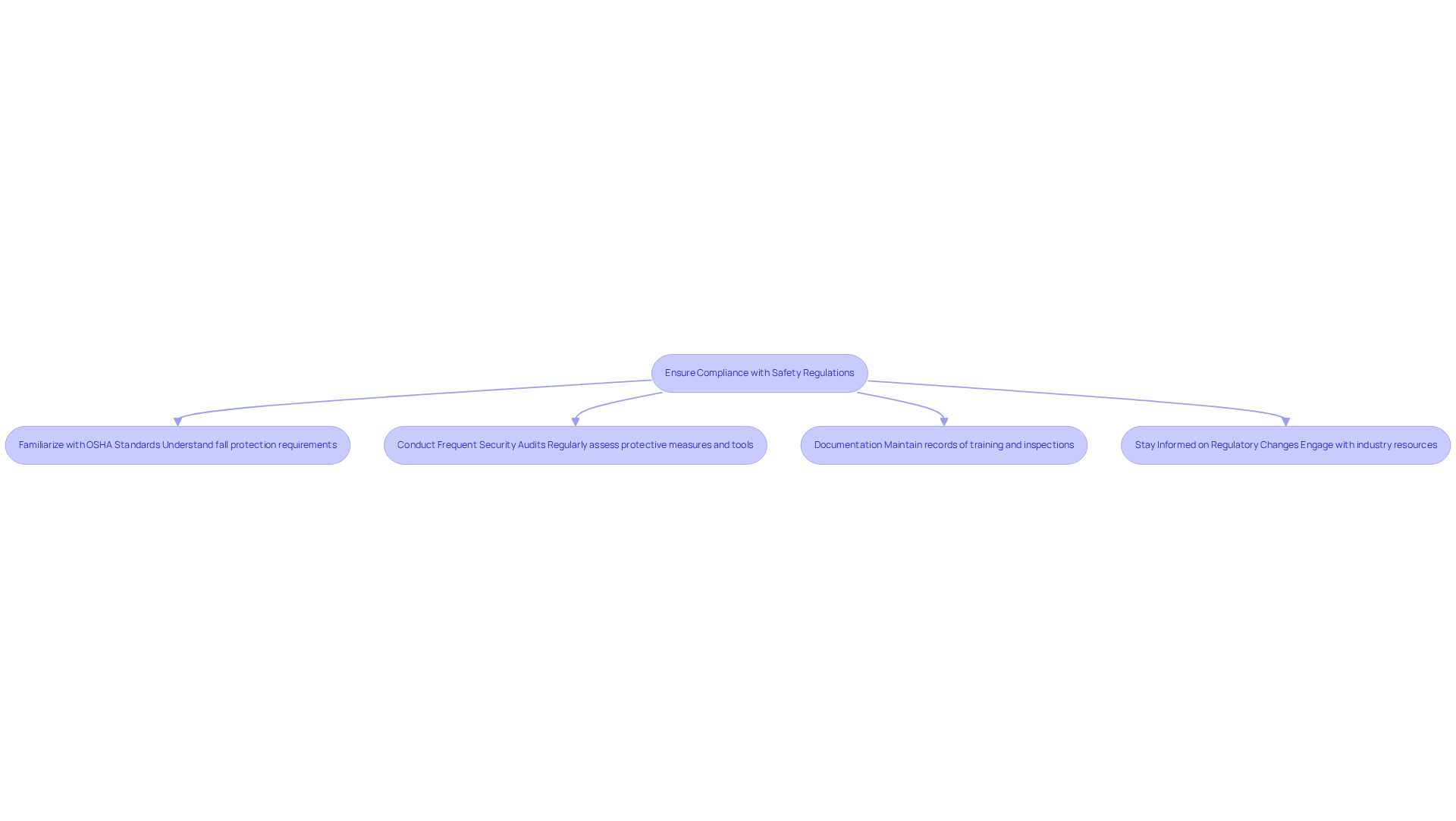

Ensure Compliance with Safety Regulations

In the roofing industry, adherence to security regulations is essential for the effective use of roofing safety equipment. To ensure compliance, consider the following key practices:

-

Familiarize with OSHA Standards: It is crucial to understand the specific OSHA regulations that apply to roofing work, particularly the fall protection requirements. These regulations mandate that roofing safety equipment, including fall protection systems, must be in place for work conducted at heights of six feet or more.

-

Conduct Frequent Security Audits: Regular assessments of protective measures and tools are necessary to ensure alignment with current regulations. This includes inspecting the condition of roofing safety equipment and confirming that all tools meet OSHA standards. Companies like XYZ Roofing have successfully integrated routine audits, resulting in a significant reduction in workplace incidents.

-

Documentation: Maintaining thorough records of training, equipment inspections, and compliance checks is vital. This documentation can be crucial during inspections or incidents, demonstrating a company's commitment to security and regulatory compliance.

-

Stay Informed on Regulatory Changes: Regulations are subject to change, making it essential to remain updated on any modifications to OSHA standards or local laws that may impact roofing practices. Engaging with industry resources and participating in workshops can help ensure that companies remain compliant and proactive in their protective measures.

According to the Bureau of Labor Statistics, 134 roofers lost their lives in the last recorded year, underscoring the critical need for these practices. By prioritizing compliance, companies can foster a safer work environment and mitigate the risk of accidents.

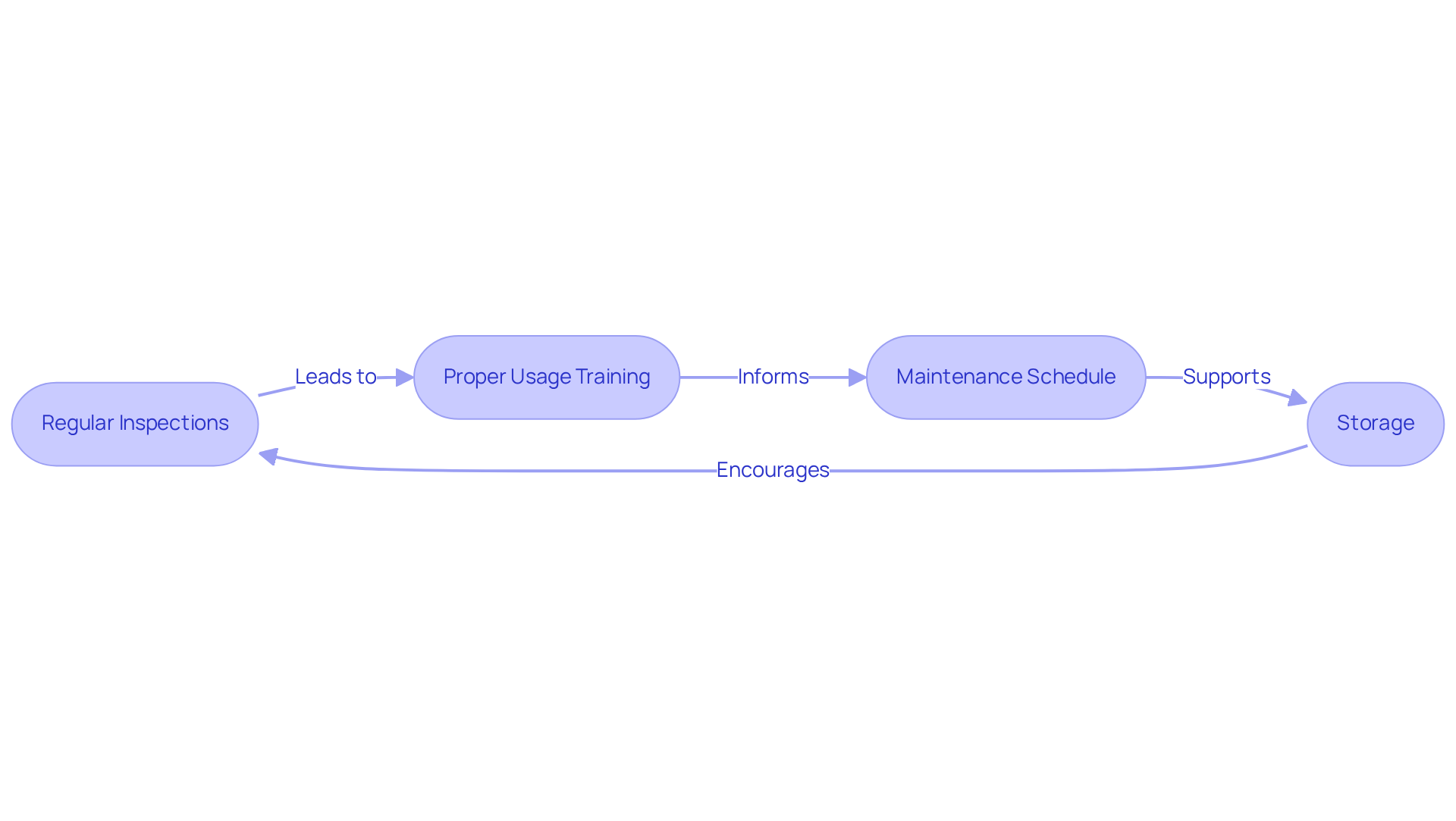

Implement Effective Usage and Maintenance Practices

To maximize the effectiveness of roofing safety equipment, it is essential to implement the following practices:

- Regular Inspections: Conduct routine inspections of all safety equipment to check for wear and tear. Inspect harnesses for fraying, lanyards for damage, and anchors for looseness. Any faulty apparatus should be replaced promptly to ensure safety.

- Proper Usage Training: Ensure that all workers receive training on the correct use of protective gear. This training should cover how to wear harnesses properly, how to attach lanyards to anchors, and the importance of utilizing guardrails.

- Maintenance Schedule: Establish a maintenance timetable for all protective gear. This schedule should include cleaning, repairs, and necessary replacements. Keeping tools in proper condition is crucial for maintaining safety standards.

- Storage: Store protective equipment in a clean, dry location to prevent damage. Equipment should be easily accessible to personnel, encouraging its regular use.

By adopting these practices, companies can enhance the safety of their roofing operations by utilizing roofing safety equipment and ensure that employees are adequately protected.

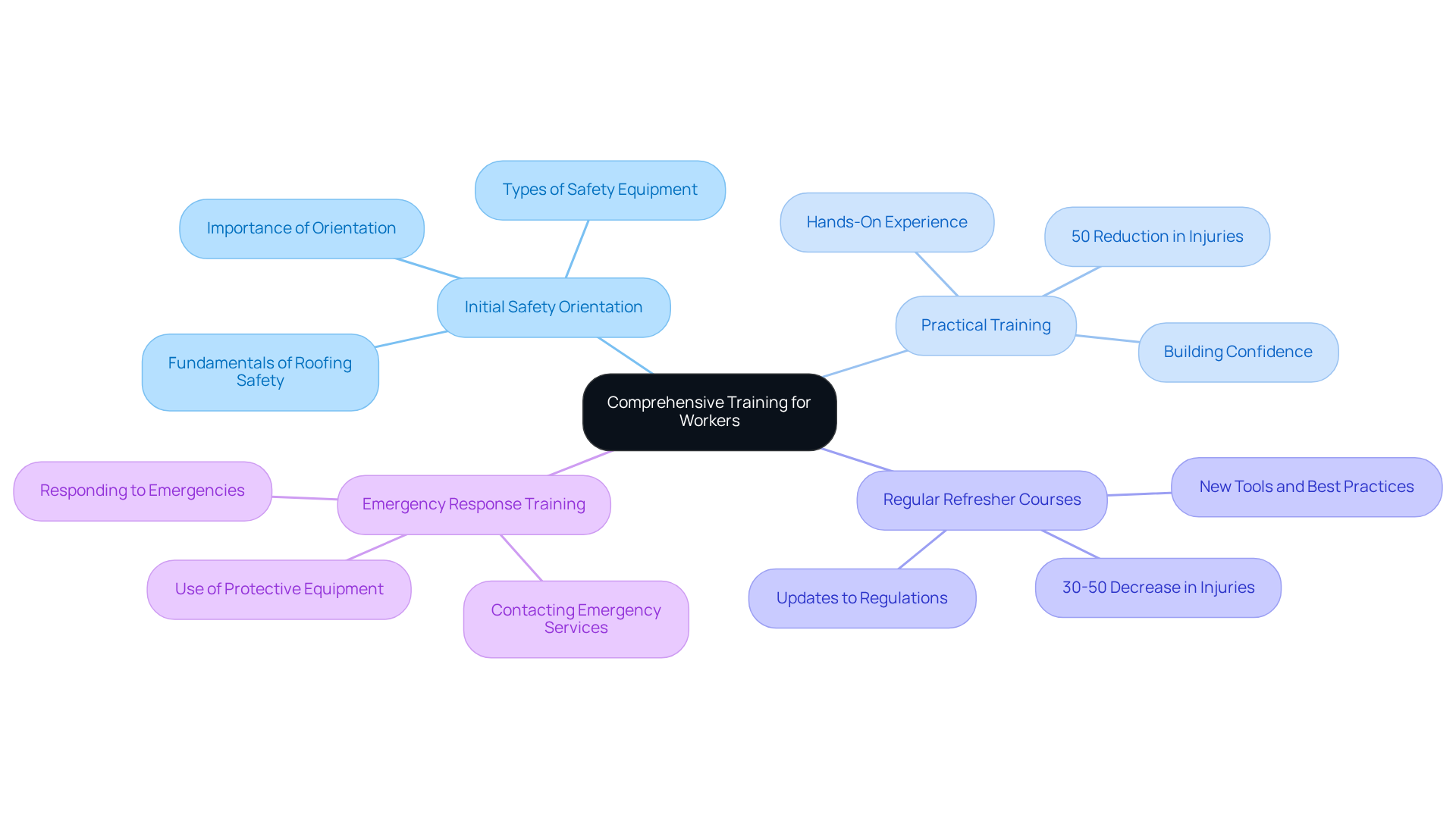

Provide Comprehensive Training for Workers

Training is a cornerstone of effective roofing protection practices. A comprehensive training program should include several key components:

-

Initial Safety Orientation: New workers should receive an orientation that covers the fundamentals of roofing safety, including the types of safety equipment available and their proper use. This foundational knowledge is essential for fostering a safe work environment.

-

Practical Training: Practical training sessions are crucial, allowing staff to practice using protective equipment in a controlled setting. Research indicates that companies with thorough training programs experience a 50% reduction in workplace injuries compared to those without structured initiatives. This hands-on experience reinforces proper techniques and builds confidence, ensuring that workers are well-prepared for real-world scenarios.

-

Regular Refresher Courses: Frequent refresher courses should be arranged to keep best practices at the forefront. These sessions can cover updates to regulations, new tools, and best practices. OSHA training has been shown to decrease workplace injuries by 30-50%, making it a highly effective protective measure.

-

Emergency Response Training: Employees must be educated on how to respond in emergencies, including the use of protective equipment to assist injured individuals and how to contact emergency services. This training is vital for minimizing risks and ensuring swift action during incidents.

By investing in comprehensive training, companies can cultivate a culture of safety that prioritizes the well-being of all workers, ultimately leading to a safer and more productive work environment.

Conclusion

Roofing safety equipment is not just a regulatory requirement; it is a vital element in fostering a secure working environment for all employees engaged in roofing tasks. By understanding and implementing various types of safety equipment - such as Personal Fall Arrest Systems, guardrails, and safety nets - companies can significantly lower the risk of accidents and fatalities on construction sites.

This article underscores the necessity of compliance with safety regulations, regular inspections, effective maintenance practices, and comprehensive training programs. Each of these components is crucial in ensuring that roofing safety equipment is not only available but also utilized correctly and maintained in optimal condition. By cultivating a culture of safety through education and adherence to OSHA standards, the construction industry can address the concerning statistics related to roofing injuries and fatalities.

Ultimately, prioritizing roofing safety equipment and its proper use is both a moral and legal obligation that every construction company must uphold. Investing in safety measures and training not only safeguards workers but also boosts overall productivity and morale. As the industry progresses, embracing these best practices will be essential in ensuring that all employees can perform their duties without unnecessary risk.

Frequently Asked Questions

What is the purpose of roofing safety equipment?

Roofing safety equipment is essential for protecting employees from falls and other hazards associated with working at heights.

What are Personal Fall Arrest Systems (PFAS)?

PFAS are systems that include harnesses, lanyards, and anchors designed to prevent falls from heights. Proper fitting and maintenance are crucial for their effectiveness.

How can training in the use of PFAS impact safety?

Training employees in the use of PFAS can reduce targeted injury occurrences by 19.6%, highlighting the importance of proper training.

What percentage of individuals who died from falls did not have access to a personal arrest system?

54% of individuals who died in falls did not have access to a personal arrest system, emphasizing the necessity of providing such equipment.

What are guardrails and what standards do they need to meet?

Guardrails are physical barriers installed around the roof's edge to prevent falls. They must comply with OSHA standards, requiring a minimum height of 42 inches and must not be easily penetrable or climbable.

How do safety nets contribute to roofing safety?

Safety nets provide an additional layer of security by catching workers in the event of a fall, particularly in areas where guardrails cannot be installed.

What are retractable lifelines and how do they enhance safety?

Retractable lifelines allow for free movement while secured and automatically lock during a fall, minimizing descent distance. Modern designs include built-in energy absorbers to reduce impact forces.

What are secure roof anchors and why are they important?

Secure roof anchors are installed on the roof to provide a reliable point for attaching safety harnesses. Proper installation is vital, as a weak anchor can lead to serious accidents.

What is the significance of using a properly fitted harness on pitched surfaces?

Using a properly fitted harness on a pitched surface is crucial as it serves as the first line of defense when a slip occurs, preventing falls.

Why is implementing roofing safety measures considered a moral obligation?

With accidents accounting for over 36% of deaths in the construction sector, implementing effective protective measures is not just a regulatory requirement but a moral obligation to ensure worker safety.

List of Sources

- Understand Types of Roofing Safety Equipment

- 42 percent of construction worker deaths involve falls, new database shows | 2018-01-30 (https://safetyandhealthmagazine.com/articles/16646-percent-of-construction-worker-deaths-involve-falls-new-database-shows)

- Fall Protection Equipment: Stats, Latest Improvements, & More - SkillSignal (https://skillsignal.com/fall-protection-equipment-stats-improvements)

- OSHA's Fall Prevention Campaign | Occupational Safety and Health Administration (https://osha.gov/stop-falls)

- Roof Safety Equipment Explained: What You Need to Know (https://clarkroofingtx.com/roof-safety-equipment-explained)

- Ensure Compliance with Safety Regulations

- Roofing Accidents Per Year (Updated Statistics) (https://roofingwebmasters.com/roofing-accidents)

- Roofing Accidents Statistics: Data Reports 2026 (https://wifitalents.com/roofing-accidents-statistics)

- Roofing Fatalities Increased by 20% in 2021 (https://roofingcontractor.com/articles/98250-roofing-fatalities-increased-by-20-in-2021)

- Can't be too careful by Cheryl Ambrose, CHST, OHST 2023-12-01 (https://professionalroofing.net/Articles/Can-t-be-too-careful--12-01-2023/5329)

- Roofing Safety (Multiple-Unit Roof Coverings) Stats and Facts (https://coactionspecialty.safetynow.com/roofing-safety-multiple-unit-roof-coverings-stats-and-facts?print=pdf)

- Implement Effective Usage and Maintenance Practices

- Commonly Used Statistics | Occupational Safety and Health Administration (https://osha.gov/data/commonstats)

- BREAKING DOWN THE NUMBERS: INDUSTRY STATISTICS THAT PROVE THE IMPORTANCE OF SAFETY (https://certex.com/breaking-down-the-numbers-industry-statistics-that-prove-the-importance-of-safety)

- Construction Safety: 5 Statistics Everyone in the Industry Should Know (https://autodesk.com/blogs/construction/construction-safety-statistics)

- Construction Safety Statistics (2026) (https://blog.oshaonlinecenter.com/construction-safety-statistics)

- 34 Key Construction Safety Statistics | Procore (https://procore.com/library/construction-safety-statistics)

- Provide Comprehensive Training for Workers

- Safety Quotes: Motivation to Improve Work Safety Culture (https://osha.com/blog/work-safety-quotes)

- Construction Safety: 5 Statistics Everyone in the Industry Should Know (https://autodesk.com/blogs/construction/construction-safety-statistics)

- Construction Safety Statistics (2026) (https://blog.oshaonlinecenter.com/construction-safety-statistics)

- OSHA Training Statistics: Key Data and Impact on Workplace Safety (https://blog.oshaonlinecenter.com/osha-training-statistics)

- Fostering Employee Success and Retention Through Inclusive Workplace Safety Training (https://asisonline.org/security-management-magazine/articles/2025/03/inclusion/workplace-safety-training)