Key Highlights:

- Forklift jib extensions enhance standard forklifts, enabling them to lift heavy or awkwardly shaped loads.

- Types of jib booms include fixed and telescopic; fixed arms offer higher capacity, while telescopic arms provide reach flexibility.

- Modern jib arms feature safety innovations like internal stops and safety chains to enhance stability during operation.

- Businesses report up to a 35% increase in operational efficiency when using jib arms for oversized items.

- Jib arms can lift up to 2000 kg at a 1-metre reach and 1000 kg at a 3-metre reach, showcasing their substantial weight handling capabilities.

- Operators must follow safety protocols, including training, daily safety checks, and using personal protective equipment (PPE).

- Weight restrictions and specifications must be assessed before operation to prevent tipping or structural failure.

- Regular pre-use inspections of the jib and forklift components are crucial for operational safety and compliance.

- Renting from reputable companies ensures well-maintained equipment, reducing the risk of breakdowns.

Introduction

Understanding the complexities of forklift jib booms is essential for enhancing operational efficiency and safety across various industrial settings. These versatile attachments enable forklifts to lift heavy and awkward loads, significantly improving workflow and productivity. However, the challenge lies in ensuring that operators possess the necessary knowledge and protocols to navigate the potential risks associated with their use. Implementing best practices is crucial to maximizing safety and performance during forklift boom operations.

Understand Forklift Jib Booms and Their Applications

Forklift jib extensions are specialized accessories that enhance the functionality of standard forklifts, transforming them into versatile lifting machines capable of managing weights in ways conventional forks cannot. These attachments are invaluable in construction, warehousing, and industrial environments where the need to lift heavy or awkwardly shaped loads arises frequently.

Understanding the various types of jib booms - such as fixed and telescopic - is crucial for operators to select the appropriate tool for specific tasks. Fixed-length jib arms are simpler and often have higher capacity due to fewer moving parts, making them ideal for repetitive lifting tasks. In contrast, telescopic jib structures offer the flexibility to extend and retract, enabling operators to reach higher or further, which is particularly advantageous for lifting materials over obstacles.

Recent advancements in jib arm technology have focused on enhancing security and operational efficiency. Modern jib arms are equipped with features such as internal stops to prevent accidental disassembly and safety chains to secure the attachment to the forklift. These innovations are essential for maintaining stability and minimizing risks during operation.

Real-world applications of jib arms in warehousing illustrate their effectiveness in improving workflow. Businesses utilizing a forklift boom report up to a 35% improvement in operational efficiency, especially in scenarios involving oversized items. This efficiency is further supported by statistics indicating that jib arms can lift loads of up to 2000 kg at a 1-meter reach and 1000 kg at a 3-meter reach, showcasing their capability in handling substantial weights.

In summary, a proper understanding and application of the forklift boom not only enhance material handling capabilities but also contribute to safer and more efficient operations across various industrial settings.

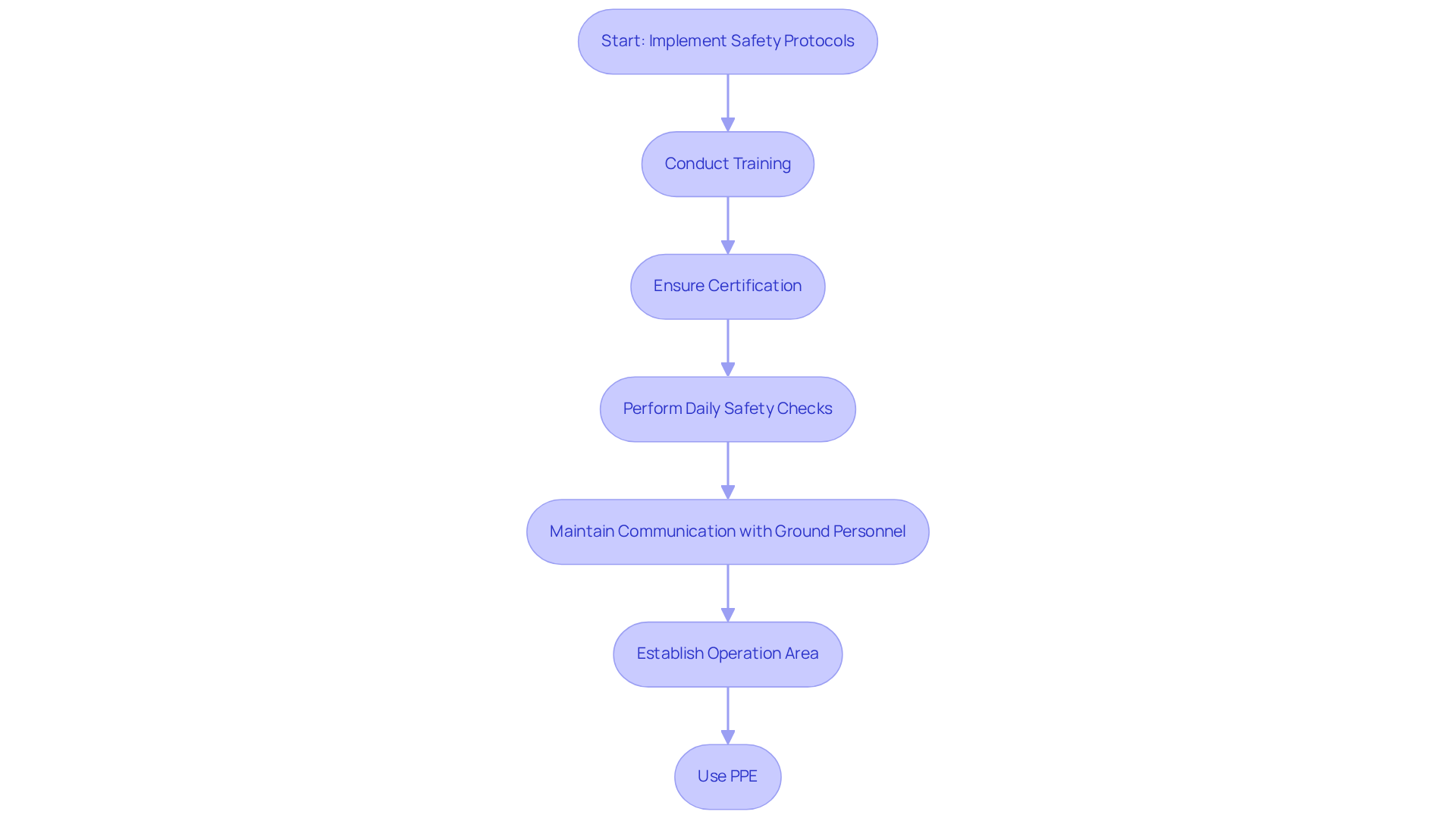

Implement Safety Protocols for Jib Boom Operations

To ensure safe jib boom operations, operators must adhere to established safety protocols. This includes conducting thorough training for all operators, ensuring they are certified and familiar with the equipment's operational guidelines. Daily safety checks should be performed before use, including inspecting the jib boom for any signs of wear or damage. Operators should also maintain clear communication with ground personnel and establish a designated area for operations to keep bystanders at a safe distance. Additionally, using personal protective equipment (PPE) such as hard hats and safety vests is essential. Following OSHA guidelines and manufacturer recommendations will further enhance safety during jib boom operations.

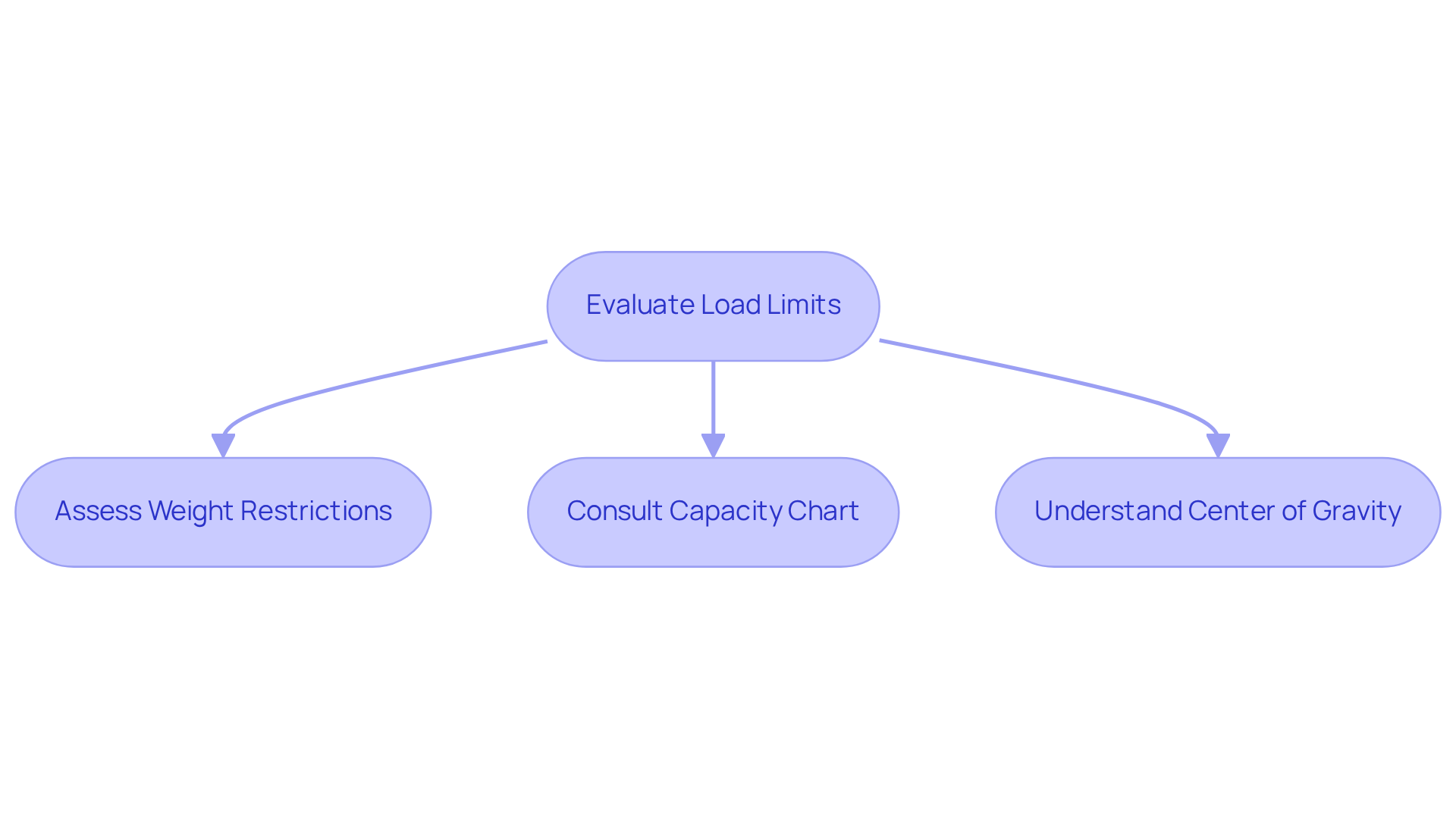

Evaluate Load Limits and Specifications for Optimal Performance

Before operating a forklift boom equipped with a jib arm, it is crucial to assess the weight restrictions and specifications provided by the manufacturer. Each jib arm has a designated maximum weight capacity that must not be exceeded to prevent risks such as tipping or structural failure. Operators should always refer to the capacity chart associated with their jib crane model, which outlines the safe lifting weights at various extension lengths.

For instance, the weight capacity of a forklift boom can vary significantly based on its configuration and the boom's extension, making it essential to consult these charts before each lift. Additionally, understanding the center of gravity of the load is vital, as it directly impacts stability during lifting operations.

Regular training focused on load assessment and strict adherence to weight limits not only enhances operational safety but also improves overall efficiency in material handling.

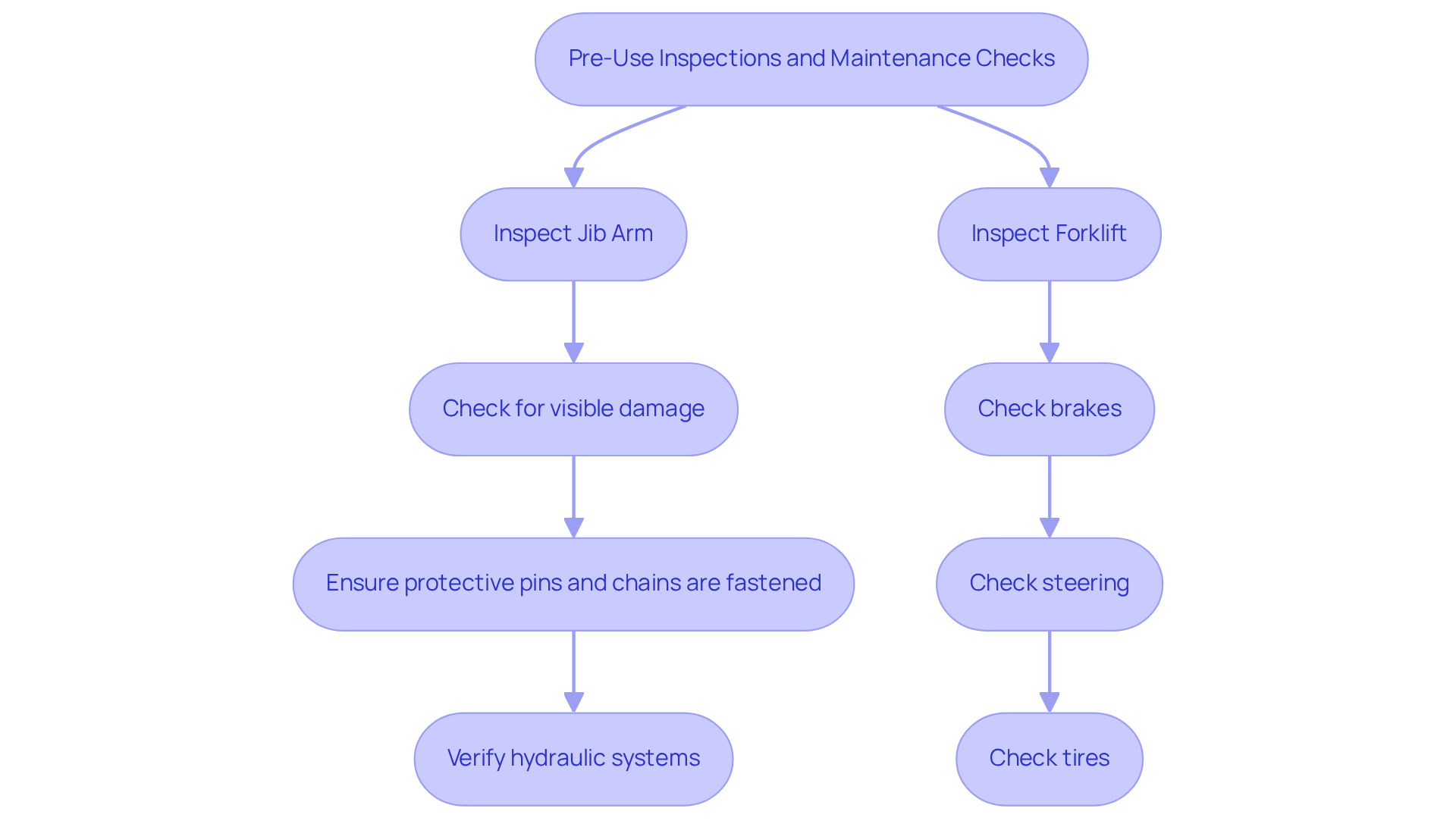

Conduct Pre-Use Inspections and Maintenance Checks

Before operating a forklift boom equipped with a jib, it is essential for operators to perform thorough pre-use checks to confirm the equipment's safety. This includes:

- Inspecting the jib arm for visible damage

- Ensuring that all protective pins and chains are securely fastened

- Verifying the proper functioning of hydraulic systems

Operators should also examine the forklift itself, focusing on critical components such as:

- Brakes

- Steering

- Tires

Renting from a reputable company like EZ Equipment Rental guarantees that the forklifts are well-maintained, as they undergo regular maintenance to minimize the risk of breakdowns during crucial operations. Keeping detailed records of inspections and maintenance tasks is vital for compliance with regulations and for monitoring the equipment's condition. Facilities that implement routine maintenance checks have reported significant improvements in forklift boom safety, which reduces the likelihood of mechanical failures and enhances overall operational safety.

By prioritizing these inspections, operators not only protect their own well-being but also foster a safer work environment for all personnel involved.

Conclusion

Understanding the best practices for safe forklift boom operations is essential for enhancing efficiency and safety in various industrial environments. By employing the right techniques and adhering to safety protocols, operators can maximize the capabilities of forklift jib booms while minimizing associated risks.

Key insights emphasize the importance of:

- Selecting the appropriate jib boom type for specific tasks

- Implementing rigorous safety measures

- Conducting thorough pre-use inspections

Recognizing load limits and specifications is crucial for optimal performance, as is maintaining clear communication and following established safety guidelines. These practices not only improve operational efficiency but also ensure a safer working environment for all personnel involved.

In conclusion, prioritizing safety and proper operational procedures when using forklift jib booms is vital for any organization. By committing to best practices, companies can enhance productivity while safeguarding their workforce. Embracing these strategies leads to a more efficient, secure, and reliable operation, ultimately contributing to the overall success of material handling efforts in construction, warehousing, and industrial settings.

Frequently Asked Questions

What are forklift jib booms?

Forklift jib booms are specialized accessories that enhance the functionality of standard forklifts, allowing them to lift heavy or awkwardly shaped loads that conventional forks cannot manage.

What types of jib booms are there?

There are two main types of jib booms: fixed and telescopic. Fixed-length jib arms are simpler and often have higher capacity, while telescopic jib structures can extend and retract, providing flexibility for reaching higher or further.

What are the advantages of fixed-length jib arms?

Fixed-length jib arms are ideal for repetitive lifting tasks due to their simplicity and higher capacity, as they have fewer moving parts.

How do telescopic jib arms benefit operators?

Telescopic jib arms allow operators to extend and retract the boom, making it easier to lift materials over obstacles and reach elevated areas.

What recent advancements have been made in jib arm technology?

Recent advancements include features such as internal stops to prevent accidental disassembly and safety chains to secure the attachment to the forklift, enhancing security and operational efficiency.

How do jib arms improve workflow in warehousing?

Businesses using forklift booms report up to a 35% improvement in operational efficiency, particularly when dealing with oversized items.

What are the lifting capabilities of jib arms?

Jib arms can lift loads of up to 2000 kg at a 1-meter reach and 1000 kg at a 3-meter reach, showcasing their ability to handle substantial weights.

Why is understanding forklift jib booms important?

A proper understanding and application of forklift jib booms enhance material handling capabilities and contribute to safer and more efficient operations in various industrial settings.

List of Sources

- Understand Forklift Jib Booms and Their Applications

- How to use a forklift jib boom safely - Star Industries (https://starindustries.com/how-to-use-a-forklift-jib-boom-safely-and-what-to-look-for-when-buying-or-renting-one)

- Forklift Jib Boom Market Size, Projections, Insights & Strategy 2026-2033 (https://linkedin.com/pulse/forklift-jib-boom-market-size-projections-insights-strategy-kbgcc)

- Everything To Know About Forklift Booms | Micron Engineering (https://microneng.co.za/how-to-use-a-forklift-jib-boom-safely-and-what-to-look-for-when-buying-or-renting-one)

- Forklift Jib Attachments – Material Handling Solutions (https://materialhandlingequipment.com.au/forklift-jib-attachments?srsltid=AfmBOoohucCbQWjiNI4twxZ2gxzqA0IUhhSZ6R7nW8yuzozovRnyY8UF)

- Implement Safety Protocols for Jib Boom Operations

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- How to use a forklift jib boom safely - Star Industries (https://starindustries.com/how-to-use-a-forklift-jib-boom-safely-and-what-to-look-for-when-buying-or-renting-one)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Commonly Used Statistics | Occupational Safety and Health Administration (https://osha.gov/data/commonstats)

- Important Crane Safety Statistics From 2026 (https://oshaoutreachcourses.com/blog/crane-safety-statistics)

- Evaluate Load Limits and Specifications for Optimal Performance

- How to Select the Jib Crane Capacity for Your Needs (https://bettercrane.com/resouces/news/how-to-confirm-your-jib-crane-capacity.html)

- How to use a forklift jib boom safely - Star Industries (https://starindustries.com/how-to-use-a-forklift-jib-boom-safely-and-what-to-look-for-when-buying-or-renting-one)

- What To Know About Forklift Load Capacity | Burns Equipment (https://burnslift.com/blog/everything-you-need-to-know-about-forklift-load-capacity)

- Understanding Load Charts for Safe Crane Operations (https://tntcrane.ca/understanding-load-charts-for-safe-crane-operations)

- Conduct Pre-Use Inspections and Maintenance Checks

- Top Forklift Accident Statistics & Prevention Tips for 2025 | CertifyMe (https://certifyme.net/osha-blog/forklift-accidents)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Top 10 Most Common Forklift Accidents [With Statistics] | Conger (https://conger.com/forklift-accidents)

- Forklift Accidents: 2025 Stats, Top Causes & OSHA Rules (https://damotech.com/blog/forklift-accidents-causes-and-prevention)

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)