Key Highlights:

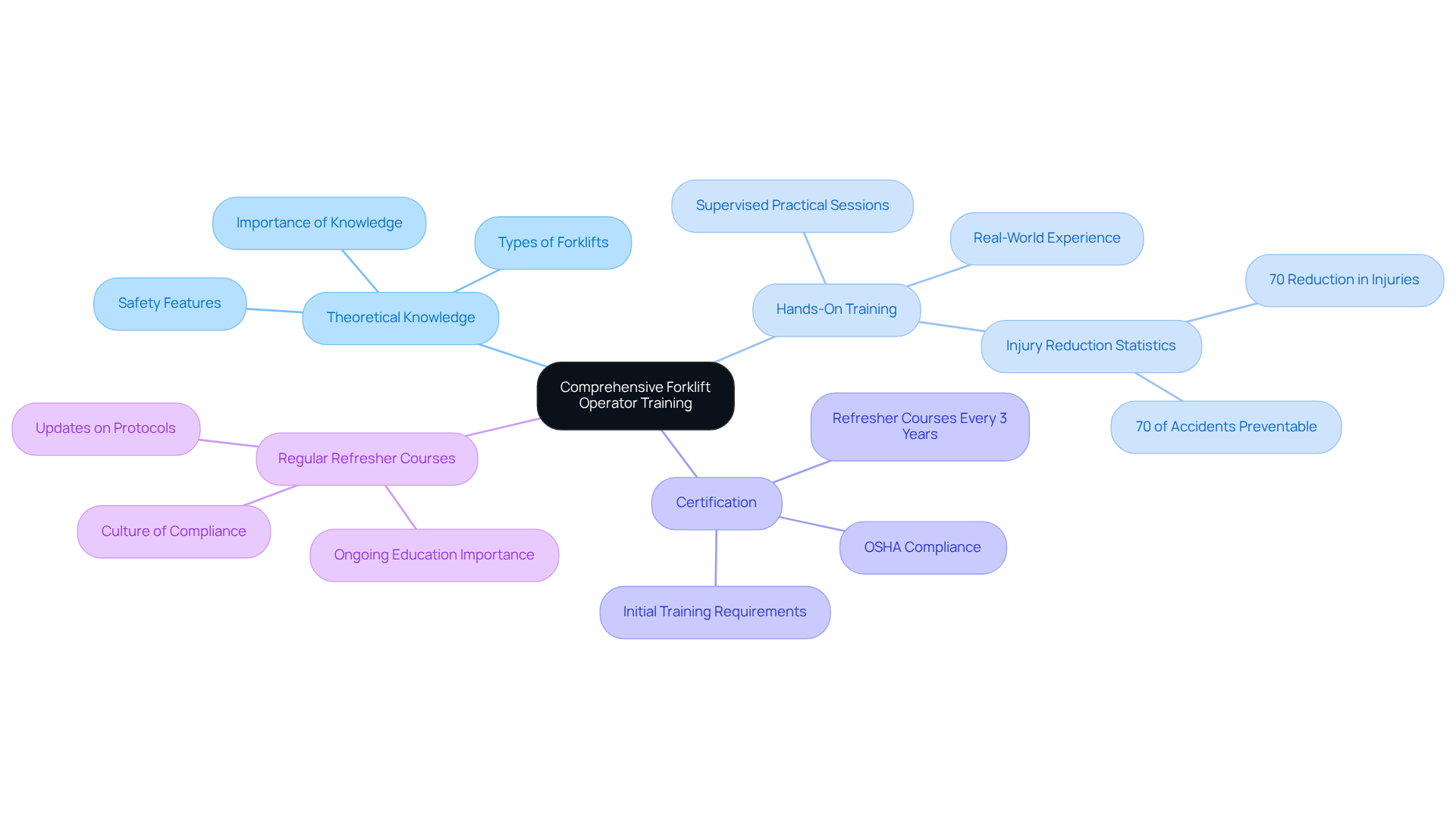

- Implementing comprehensive training for forklift operators is essential for safe operations, covering theoretical knowledge and hands-on experience.

- Effective training can lead to a 70% reduction in injuries, with 70% of lifting equipment accidents being preventable through proper education.

- Certification is required for operators, ensuring they meet safety standards and are skilled in equipment management, with refresher courses mandated by OSHA every three years.

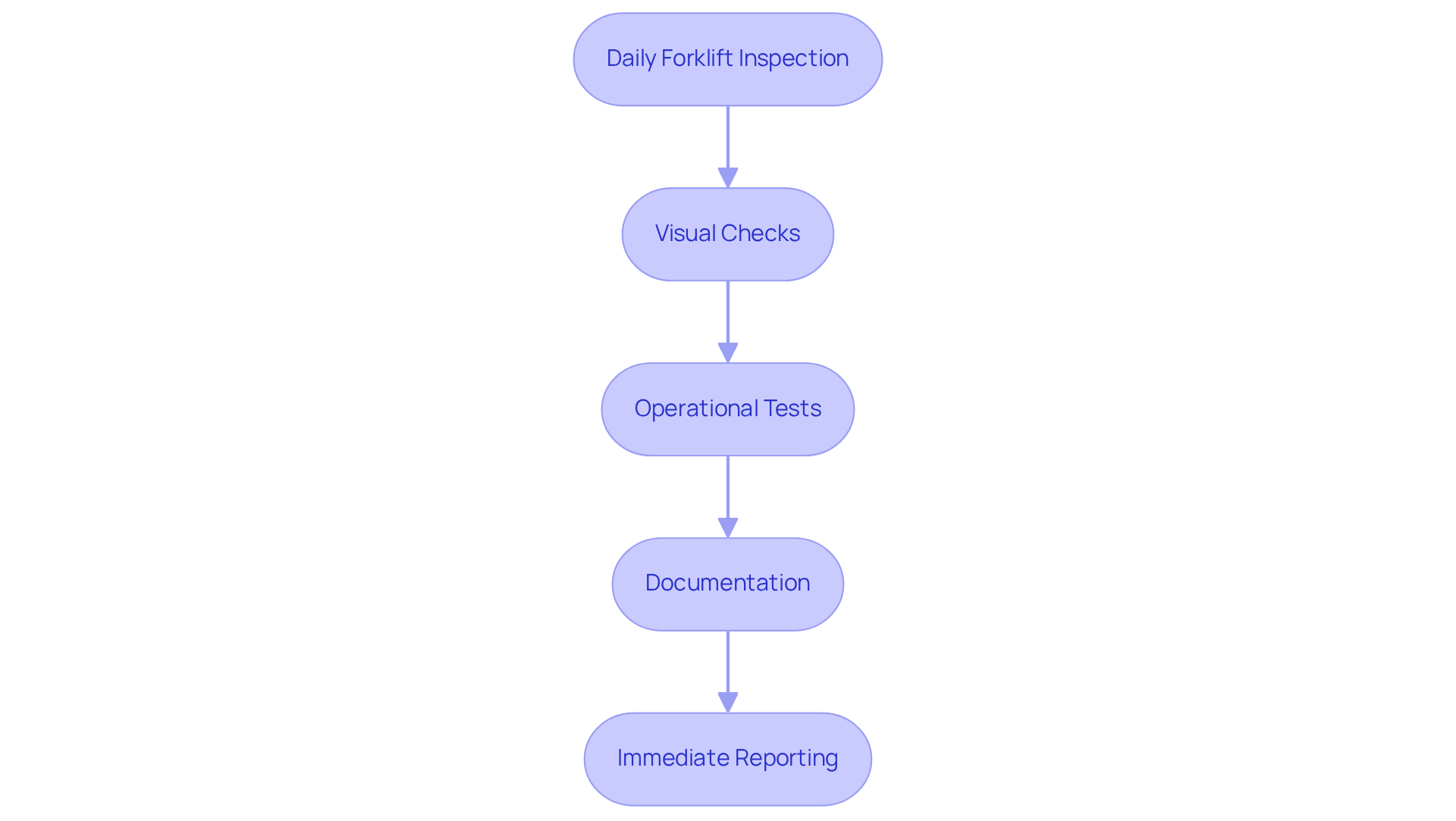

- Daily forklift inspections must include visual checks, operational tests, documentation, and immediate reporting of issues to enhance safety and compliance.

- OSHA reports approximately 34,900 forklift injuries annually, with tip-overs accounting for 24-25% of these incidents, highlighting the importance of daily inspections.

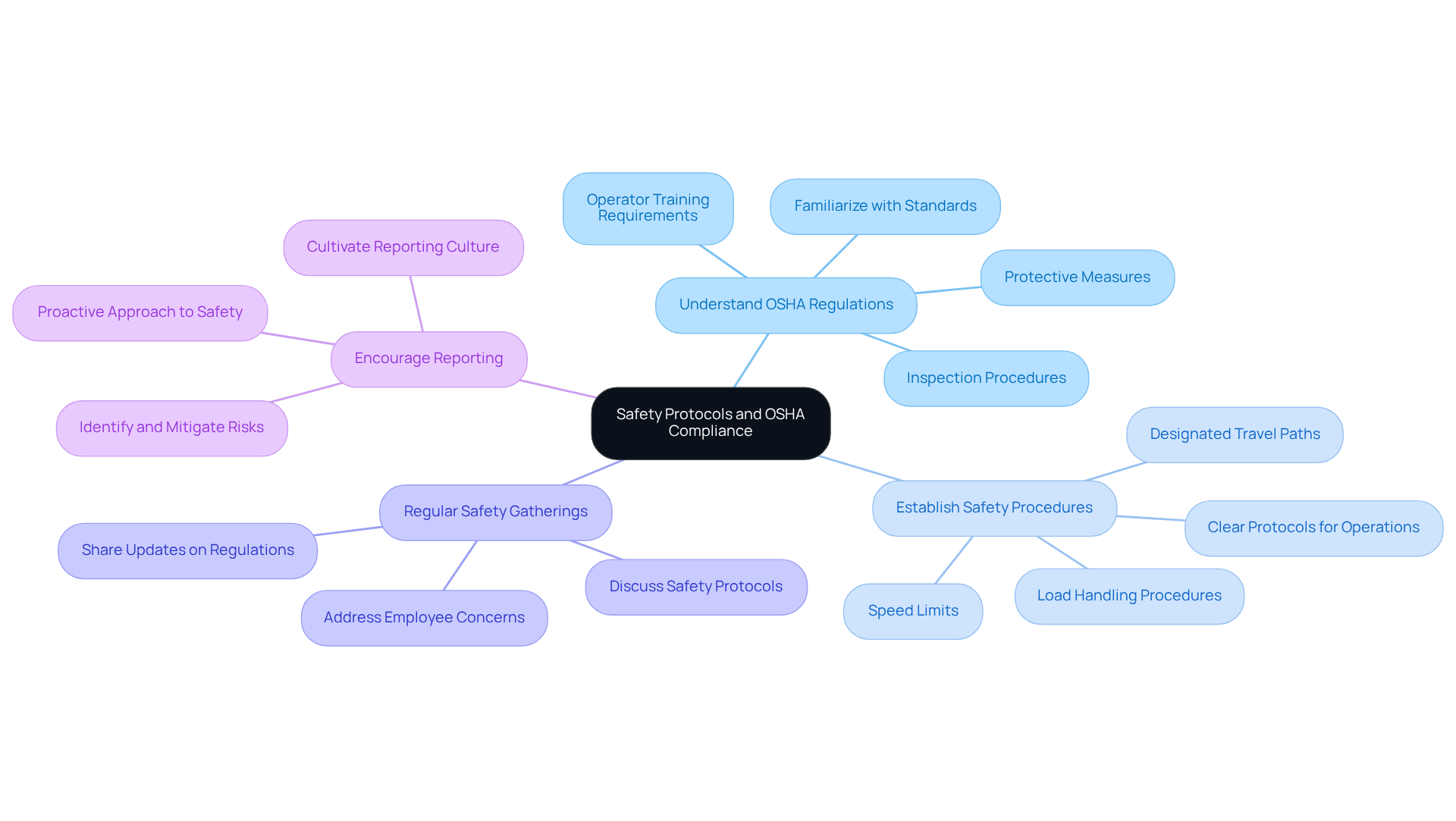

- Adhering to OSHA regulations and establishing clear safety procedures improves operational efficiency and reduces accident risks.

- Regular safety meetings and an encouraging reporting culture can significantly reduce incidents by identifying and mitigating risks proactively.

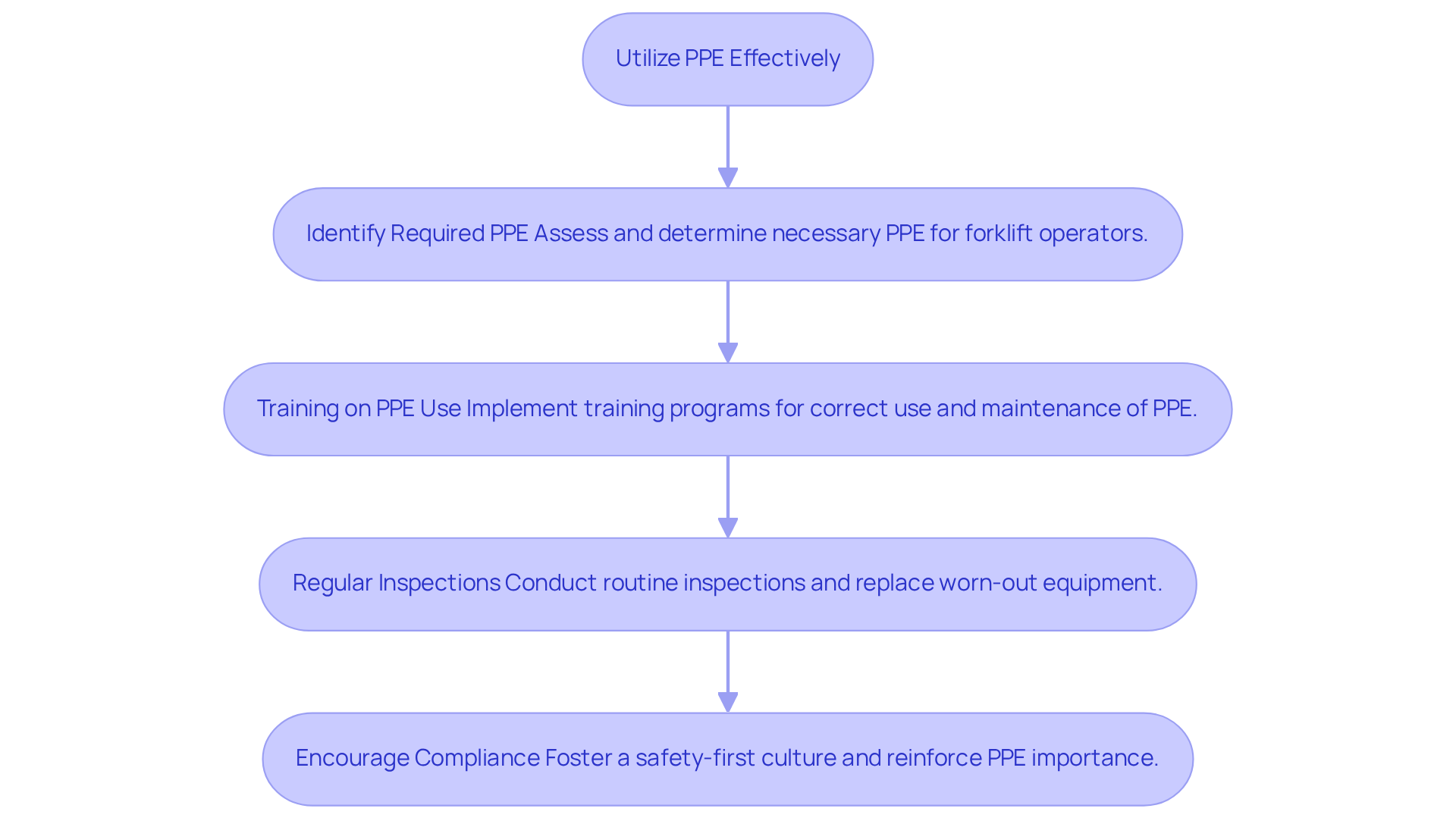

- Proper use of PPE, including hard hats and safety glasses, is crucial for operator safety, with effective PPE use potentially preventing 37.6% of occupational injuries.

- Routine inspections of PPE and fostering a safety-first culture are vital for maintaining compliance and ensuring a safe working environment.

Introduction

Ensuring safety in warehouse forklift operations is not merely a regulatory requirement; it is essential for operational efficiency and employee well-being. By implementing best practices such as:

- Comprehensive operator training

- Daily inspections

- Adherence to safety protocols

- Effective use of personal protective equipment (PPE)

organizations can significantly mitigate the risk of accidents and injuries. Despite this, statistics indicate that many facilities still do not meet OSHA compliance standards. This raises a critical question: how can warehouses effectively implement these safety measures to safeguard their workforce and enhance productivity?

Implement Comprehensive Forklift Operator Training

To ensure safe operations of warehouse forklifts, implementing a comprehensive training program for all vehicle handlers is essential. This program should encompass several key components:

- Theoretical Knowledge: Operators must understand the various types of forklifts, their specific functions, and the safety features they possess. This foundational knowledge is crucial for safe equipment operation.

- Hands-On Training: Practical training sessions should be conducted under the supervision of experienced trainers, allowing operators to gain real-world experience in a controlled environment. Effective training has been shown to lead to a 70% reduction in injuries, underscoring its importance. Moreover, statistics indicate that 70% of lifting equipment accidents are preventable through adequate training, emphasizing the critical need for comprehensive education.

- Certification: Operators must be certified before operating forklifts independently. Certification guarantees adherence to standards and verifies that users are skilled in managing the equipment. OSHA requires that personnel undergo initial training and refresher courses every three years or sooner after incidents, emphasizing the importance of continuous education.

- Regular Refresher Courses: Ongoing education is essential for upholding security. Regular refresher courses should be arranged to keep operators informed on protocols and any changes in regulations. This practice not only improves security but also promotes a culture of compliance within the organization.

Investing in comprehensive training significantly reduces the risk of accidents and injuries related to material handling operations. For instance, the unfortunate event at a tire distribution facility in Elm Mott, Texas, where a lift operator suffered fatal injuries due to insufficient training, highlights the real-world repercussions of overlooking precautionary measures. With statistics indicating that 79 workers lost their lives to forklift-related incidents in a single year, organizations can protect their employees and improve operational efficiency by prioritizing effective training.

Conduct Daily Forklift Inspections

Daily inspections of warehouse forklifts are vital for maintaining safety in warehouse operations. Incorporating the following key components into your inspection routine is essential:

- Visual Checks: Operators must conduct a thorough visual inspection of the forklift before each shift. This includes checking for hydraulic leaks, assessing tire conditions, and ensuring that all lights and signals are operational.

- Operational Tests: Testing the brakes, steering, and lifting mechanisms is crucial to verify their proper functioning. Any irregularities should be reported immediately to prevent accidents.

- Documentation: Keeping a detailed record of daily inspections is essential for monitoring the condition of each lift truck. This documentation supports compliance with OSHA regulations and serves as a valuable resource during audits. Employers must certify each lift operator before allowing equipment use, which is critical for compliance.

- Immediate Reporting: Any issues identified during inspections should be promptly reported to a supervisor, and the vehicle must not be used until repairs are completed.

Statistics show that OSHA reports approximately 34,900 forklift injuries annually, with tip-overs accounting for 24-25% of these incidents. Furthermore, research indicates that 70% of these incidents could be avoided with consistent operator training. Implementing a stringent daily inspection routine significantly enhances safety and extends the lifespan of the equipment, while also reducing the risk of incurring fines that can reach $15,625 per violation for non-compliance.

Adhere to Safety Protocols and OSHA Compliance

Following precautionary measures and OSHA compliance is essential in warehouse forklift operations. Adhering to these practices not only ensures safety but also enhances operational efficiency.

-

Understand OSHA Regulations: Familiarize yourself with OSHA standards related to forklift operations. This includes understanding operator training requirements, inspection procedures, and necessary protective measures.

-

Establish Safety Procedures: Create and communicate clear protocols for lifting vehicle operations. This should encompass speed limits, load handling procedures, and designated travel paths within the warehouse to ensure a safe working environment.

-

Regular Safety Gatherings: Conduct regular meetings to discuss safety protocols, share updates on regulations, and address any concerns raised by employees. These gatherings foster a culture of safety and continuous improvement.

-

Encourage Reporting: Cultivate an environment where employees feel comfortable reporting unsafe conditions or practices without fear of retaliation. This proactive approach can help identify and mitigate risks before they lead to accidents. Research shows that organizations with strong reporting cultures experience a significant reduction in incidents.

As we approach 2026, it is crucial for warehouses to emphasize protective procedures. Statistics indicate that approximately 30% of facilities still do not fully comply with OSHA standards for warehouse forklifts. Forklift accidents result in an average of 16 missed workdays per event, underscoring the importance of effective protective measures. Implementing robust protection protocols not only safeguards employees but also enhances overall productivity and operational efficiency.

Utilize Personal Protective Equipment (PPE) Effectively

Efficient use of personal protective equipment (PPE) is crucial for ensuring the safety of personnel operating warehouse forklifts in warehouse environments. Here are key considerations for effective PPE implementation:

- Identify Required PPE: Assess and determine the necessary PPE for forklift operators, which typically includes hard hats, safety glasses, high-visibility vests, gloves, and steel-toed boots. Ensure that all PPE meets industry standards to provide adequate protection.

- Training on PPE Use: Implement comprehensive training programs that educate operators on the correct use and maintenance of PPE. Operators must understand when and how to use each piece of equipment to enhance their protection and effectiveness. According to OSHA, "employers must take reasonable steps to ensure a safe workplace and prevent harm."

- Regular Inspections: Conduct routine inspections of PPE to verify its condition. Promptly replace any broken or worn-out equipment to maintain safety standards and avoid potential hazards. Research indicates that workplaces with strict PPE enforcement policies achieve compliance rates as high as 90%.

- Encourage Compliance: Foster a safety-first culture where wearing PPE is non-negotiable. Regular reminders about the importance of PPE can reinforce its role in preventing injuries and ensuring adherence to regulations. Notably, proper use of PPE can prevent 37.6% of occupational injuries and diseases, significantly reducing the risk of accidents.

By prioritizing the effective use of PPE, organizations can substantially reduce the risk of injuries, thereby creating a safer working environment for those operating a warehouse forklift. The PPE market is projected to grow from $73.82 billion in 2026 to $92.86 billion in 2027, reflecting the ongoing emphasis on health and safety measures across various industries.

Conclusion

Implementing effective practices for safe warehouse forklift operations is not merely a regulatory obligation; it is essential for ensuring the safety and efficiency of material handling processes. By prioritizing comprehensive training, daily inspections, adherence to safety protocols, and the effective use of personal protective equipment, organizations can establish a robust framework that significantly mitigates the risk of accidents and enhances overall workplace safety.

This article highlights four key practices:

- Comprehensive forklift operator training

- Daily inspections

- Adherence to OSHA compliance

- Effective use of PPE

Each of these components is crucial in fostering a safe working environment. Comprehensive training equips operators with the necessary skills and knowledge, while daily inspections help identify potential hazards before they escalate into incidents. Adhering to safety protocols ensures that all operations comply with established regulations, thereby promoting a culture of safety. Finally, the proper use of PPE safeguards workers from potential injuries, underscoring the importance of a proactive approach to safety.

In conclusion, the importance of implementing these best practices cannot be overstated. By committing to thorough training programs and regular inspections, organizations not only meet OSHA standards but also prioritize the well-being of their employees. As the landscape of warehouse operations continues to evolve, embracing these safety measures will be crucial in minimizing risks and fostering a culture of safety. It is imperative for all stakeholders to take action, ensuring that safety remains a priority in warehouse forklift operations for years to come.

Frequently Asked Questions

Why is comprehensive forklift operator training important?

Comprehensive forklift operator training is essential to ensure safe operations of warehouse forklifts, significantly reducing the risk of accidents and injuries related to material handling operations.

What key components should be included in a forklift training program?

A forklift training program should include theoretical knowledge about various types of forklifts and their safety features, hands-on training under experienced supervision, certification for operators, and regular refresher courses.

What is the significance of theoretical knowledge in forklift training?

Theoretical knowledge is crucial as it helps operators understand the different types of forklifts, their specific functions, and the safety features they possess, which is foundational for safe equipment operation.

How does hands-on training benefit forklift operators?

Hands-on training allows operators to gain real-world experience in a controlled environment, and effective training has been shown to lead to a 70% reduction in injuries.

What is the role of certification in forklift operation?

Certification ensures that operators are skilled in managing forklifts and adhere to safety standards. It is required by OSHA before operators can operate forklifts independently.

How often should refresher courses be conducted for forklift operators?

Regular refresher courses should be arranged to keep operators informed about protocols and changes in regulations, with OSHA recommending these courses every three years or sooner after incidents.

What are the consequences of insufficient forklift training?

Insufficient forklift training can lead to serious accidents and fatalities, as evidenced by incidents like the fatal injuries suffered by a lift operator in Elm Mott, Texas, due to inadequate training.

What statistics highlight the importance of forklift training?

Statistics indicate that 70% of lifting equipment accidents are preventable through adequate training, and 79 workers lost their lives to forklift-related incidents in a single year, underscoring the critical need for effective training.

List of Sources

- Implement Comprehensive Forklift Operator Training

- Forklift Injury Statistics 2025 | How to Reduce Forklift Accident Risks (https://certifyme.net/osha-blog/forklift-injuries-key-statistics)

- National Forklift Safety Day Statistics │ MHEDA (https://mheda.org/journal/national-forklift-safety-day-statistics)

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- OSHA Top 10 Citations for 2024 (https://forklifttraining.com/osha-top-10-citations-2024)

- Forklift Training: Essential for Workplace Safety and Productivity | Active Safety Training and Consulting (https://activetrainingconsultants.com/2025/08/29/forklift-training-essential-for-workplace-safety-and-productivity)

- Conduct Daily Forklift Inspections

- Top Forklift Accident Statistics & Prevention Tips for 2025 | CertifyMe (https://certifyme.net/osha-blog/forklift-accidents)

- Forklift Injury Statistics 2025 | How to Reduce Forklift Accident Risks (https://certifyme.net/osha-blog/forklift-injuries-key-statistics)

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- Work Safety: Forklifts - Injury Facts (https://injuryfacts.nsc.org/work/safety-topics/forklifts)

- National Forklift Safety Day Statistics │ MHEDA (https://mheda.org/journal/national-forklift-safety-day-statistics)

- Adhere to Safety Protocols and OSHA Compliance

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Forklift Injury Statistics 2025 | How to Reduce Forklift Accident Risks (https://certifyme.net/osha-blog/forklift-injuries-key-statistics)

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- Warehouse Safety Statistics 2026: Injury Rates, Risks and Prevention Tips (https://blog.oshaonlinecenter.com/warehouse-safety-statistics)

- Work Safety: Forklifts - Injury Facts (https://injuryfacts.nsc.org/work/safety-topics/forklifts)

- Utilize Personal Protective Equipment (PPE) Effectively

- PPE's Role in Preventing Industrial Accidents | Horton Mendez (https://hortonmendez.com/what-is-the-purpose-of-ppe)

- Personal Protective Equipment (PPE) Statistics To Know In 2025 (https://oshagear.com/blog/ppe-statistics)

- Work Safety: Forklifts - Injury Facts (https://injuryfacts.nsc.org/work/safety-topics/forklifts)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)