Key Highlights:

- Selecting the right forklift ramp requires evaluating specifications such as weight capacity, length, width, and incline angle, adhering to OSHA guidelines.

- Safety features like anti-slip surfaces, guardrails, and edge markers are essential to minimise loading and unloading risks.

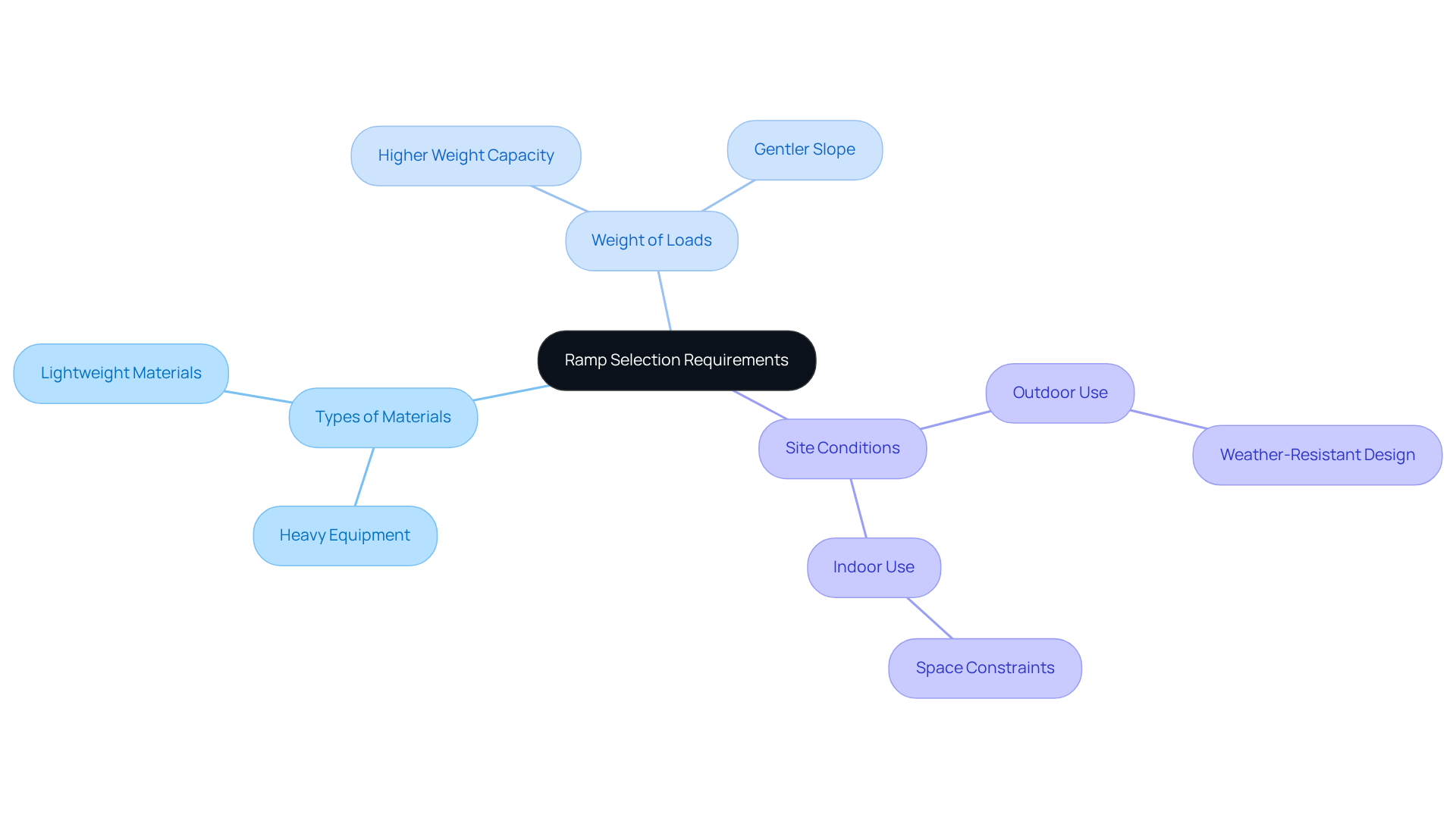

- Project-specific requirements, including the types of materials handled and site conditions, must be assessed for appropriate ramp selection.

- Operators should always orient loads uphill on inclines to maintain stability and prevent tipping incidents.

- Regular training for forklift operators is crucial to ensure they understand ramp features and safe operating procedures.

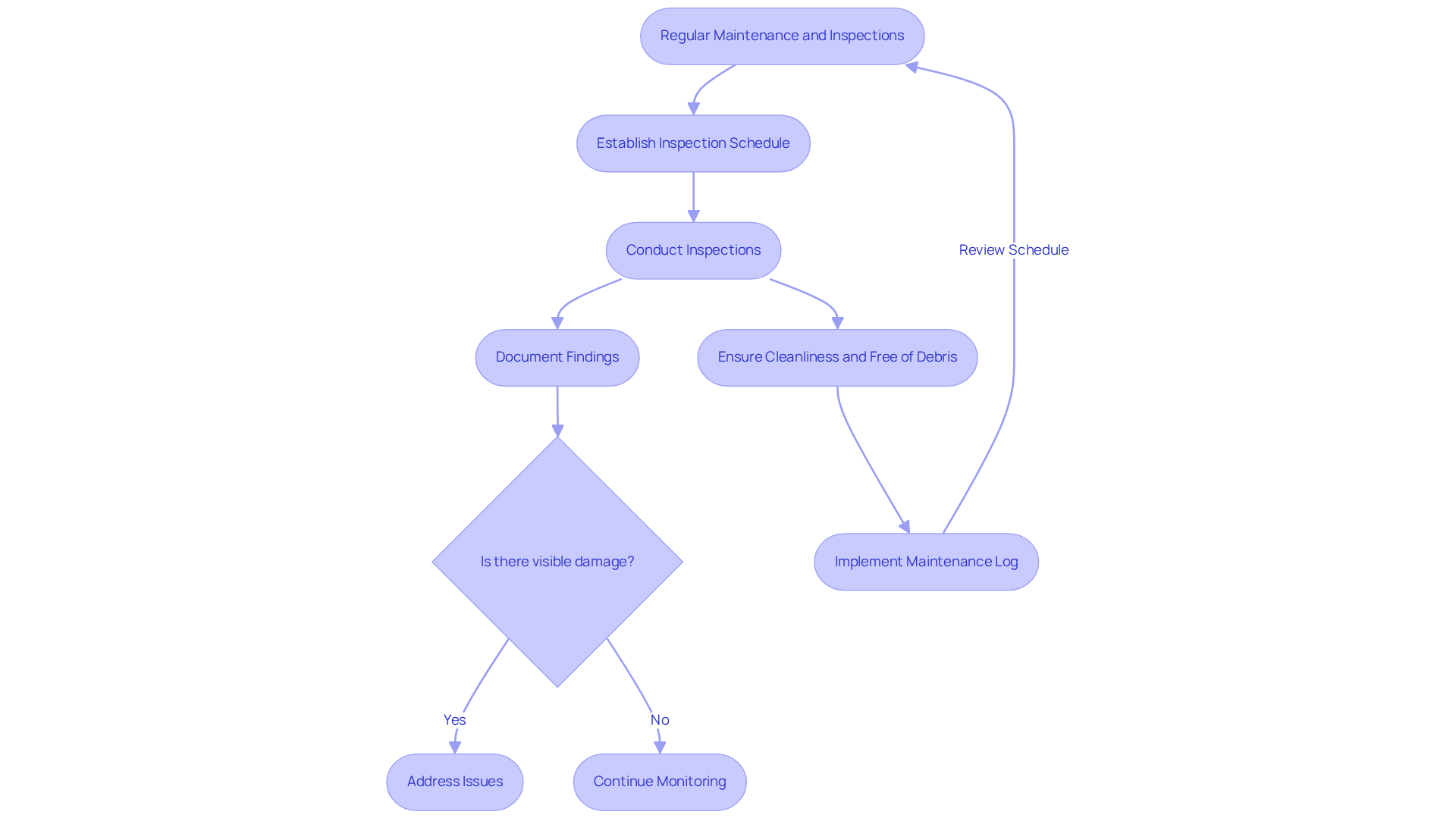

- Routine maintenance and inspections are vital for identifying wear and tear, ensuring ramps are safe and functional.

- A well-structured inspection checklist should cover structural integrity, surface conditions, and safety feature functionality.

Introduction

Selecting the right forklift ramp is not just a matter of convenience; it is a crucial decision that can significantly affect safety and efficiency in any operational environment. Understanding the essential specifications and safety features required for these loading platforms allows operators to reduce the risk of accidents and enhance productivity.

With various project-specific requirements and safety standards to consider, how can one ensure that the chosen ramp meets both operational needs and safety regulations?

This article explores best practices for selecting and using forklift ramps, offering valuable insights to help operators make informed choices that prioritize safety and performance.

Evaluate Ramp Specifications and Safety Features

Selecting the right loading platform requires a careful evaluation of its specifications and safety features. Essential specifications include weight capacity, length, width, and incline angle. The forklift ramp must accommodate a weight capacity that exceeds the total gross moving load (GML) of the forklift and its cargo. In accordance with OSHA guidelines, the incline should not surpass a slope of 1 vertical to 3 horizontal, approximately 20 degrees. Adhering to these standards is vital for ensuring operational safety.

Safety features are crucial in accident prevention. Operators should prioritize inclines that include:

- Anti-slip surfaces

- Guardrails

- Edge markers

These elements help reduce risks associated with loading and unloading. Additionally, structures made from robust materials, such as steel, are preferred for their strength and durability, ensuring they can withstand the demands of regular use.

By focusing on these specifications and safety features of the forklift ramp, operators can significantly decrease the likelihood of accidents, enhance operational efficiency, and create a safer working environment during loading and unloading activities. EZ Equipment Rental offers a diverse selection of well-maintained lifting machines that complement the range of suitable inclines, ensuring clients can find the perfect match for their specific needs. This alignment between loading specifications and the capabilities of the rental lift trucks is essential for achieving optimal performance and safety.

Assess Project-Specific Requirements for Ramp Selection

Selecting the right forklift ramp for a construction project requires a careful assessment of specific project needs. Key considerations include:

- The types of materials being handled

- The weight of the loads

- The conditions of the site

For example, transporting heavy equipment necessitates the use of a forklift ramp that has a higher weight capacity and a gentler slope to ensure safe operations and minimize the risk of accidents.

Environmental factors are also crucial in choosing the appropriate inclines. Forklift ramps designed for outdoor use must be robust and weather-resistant, while those intended for indoor settings should be tailored to fit within limited spaces. By thoroughly analyzing these project-specific requirements, operators can choose inclines that comply with safety standards and enhance overall productivity and efficiency at the job site.

At EZ Equipment Rental, we offer a diverse range of well-maintained lifting machines, ensuring that clients find the perfect fit for their unique needs. Our expert advice and support facilitate a seamless equipment rental experience, reinforcing our commitment to reliability and quality.

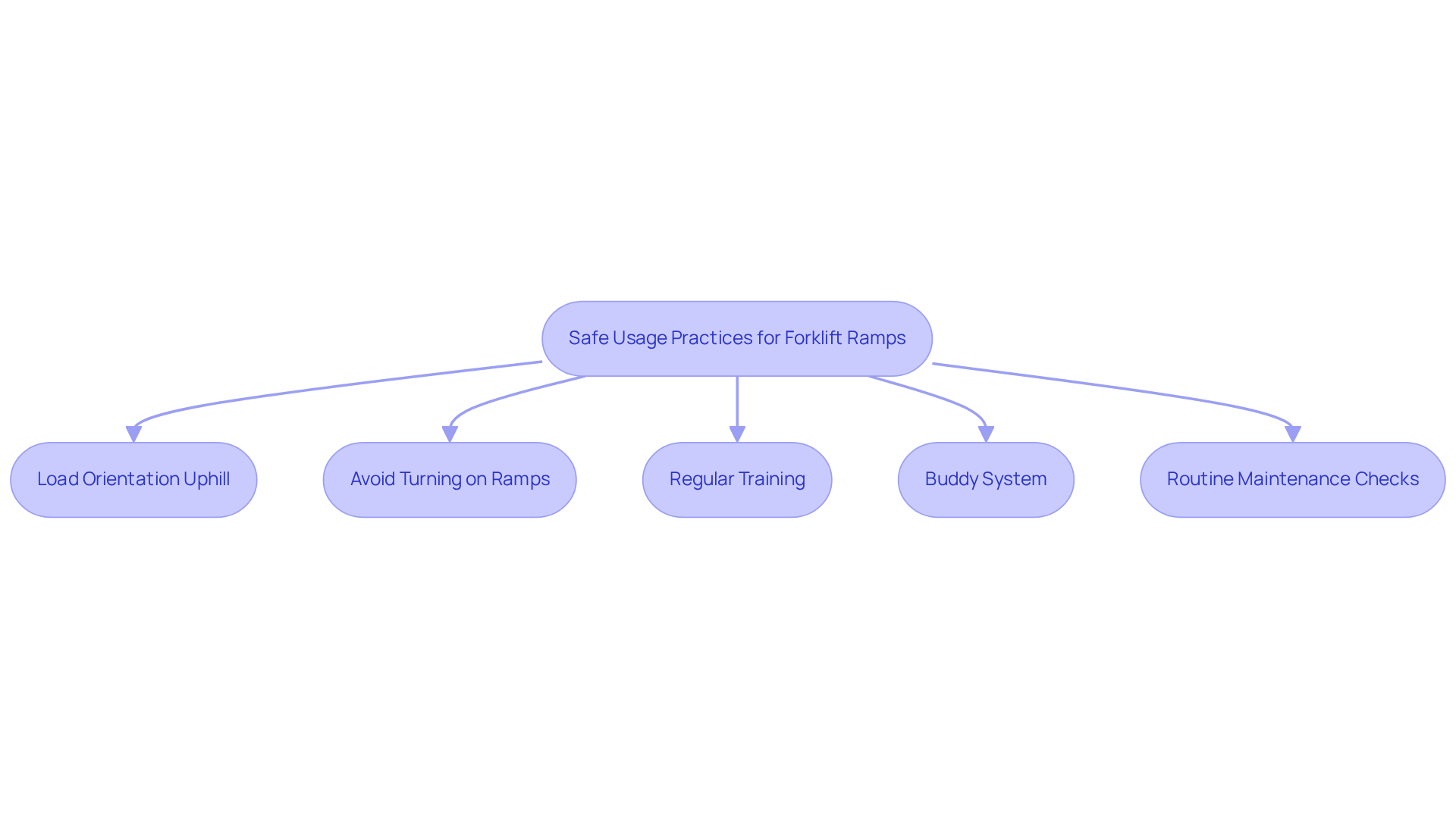

Implement Safe Usage Practices for Forklift Ramps

To ensure the safe usage of lifting platforms, operators must adhere to several best practices. First and foremost, always operate the lift truck with the load oriented uphill when navigating an incline. This practice is essential for maintaining stability and control, as improper driving direction can lead to tipping incidents, which account for a significant percentage of forklift-related injuries. In fact, turn-overs occur when the operator loses control of the forklift's center of gravity, leading to tipping, and are responsible for 42% of all recorded forklift injuries. This statistic underscores the importance of proper driving techniques.

Operators should also avoid turning on ramps; instead, they should make necessary adjustments before reaching the ramp to ensure proper alignment. This simple precaution can prevent accidents caused by loss of control during critical maneuvers.

Regular training for forklift operators is crucial. Operators should be knowledgeable about the specific features and limitations of the ramps they are using, along with general precautionary measures. Establishing a buddy system, where one operator aids another during loading and unloading, can further enhance safety by providing extra oversight and assistance.

Furthermore, routine maintenance checks and inspections of lifting vehicles are essential for guaranteeing safety. These checks help identify potential problems before they result in incidents. By following these safe usage practices, companies can significantly reduce the risk of accidents and injuries related to forklift ramp operations. Investing in comprehensive training programs that emphasize these best practices is vital for fostering a culture of well-being and operational excellence. As noted by safety experts, "Most incidents are preventable through strict adherence to safety standards and ongoing training.

Conduct Regular Maintenance and Inspections

Regular maintenance and inspections of forklift ramps are essential for ensuring their safe and efficient operation. Establishing a routine inspection schedule facilitates the timely identification of wear and tear, such as cracks, rust, or loose components. Promptly addressing these issues is vital to prevent incidents and maintain operational integrity. According to OSHA, effective incident prevention begins with consistent daily practices, underscoring the importance of regular evaluations.

Operators must also ensure that ramps are kept clean and free of debris, as this can create slip hazards. Implementing a maintenance log serves as an effective method to track inspections and repairs, ensuring that all necessary actions are documented and completed in a timely manner. The indirect costs associated with forklift accidents can be four to six times higher than direct costs, emphasizing the financial implications of neglecting maintenance and inspections.

A well-structured inspection checklist should include checks for:

- Structural integrity

- Proper surface conditions

- Functionality of safety features

Safety inspectors recommend that regular assessments not only focus on visible damage but also consider the structure's overall performance under load. This proactive approach fosters a safer working environment and reduces the likelihood of accidents related to the forklift ramp use. Furthermore, it is essential not to overlook less visible areas during inspections, as these can also present significant risks.

Conclusion

Selecting and utilizing the appropriate forklift ramps is crucial for ensuring safety and efficiency in material handling operations. By evaluating ramp specifications, understanding project-specific requirements, and implementing safe usage practices, operators can significantly reduce risks associated with loading and unloading activities.

Key factors such as weight capacity, incline angle, and safety features - like anti-slip surfaces and guardrails - are essential considerations. Regular maintenance and inspections are also necessary to ensure optimal ramp performance. Adhering to these best practices not only creates a safer working environment but also enhances overall operational productivity.

Ultimately, prioritizing safety in forklift ramp selection and usage transcends mere compliance; it fosters a culture of well-being in the workplace. Investing in proper training, routine inspections, and understanding the specific needs of each project can lead to significant reductions in accidents and injuries. By committing to these practices, organizations can promote a safer and more efficient operational landscape, ensuring that every lift is executed with confidence and care.

Frequently Asked Questions

What specifications should be evaluated when selecting a loading platform?

Essential specifications to evaluate include weight capacity, length, width, and incline angle.

What is the recommended weight capacity for a forklift ramp?

The weight capacity of the forklift ramp should exceed the total gross moving load (GML) of the forklift and its cargo.

What are the OSHA guidelines regarding the incline of a forklift ramp?

According to OSHA guidelines, the incline should not surpass a slope of 1 vertical to 3 horizontal, which is approximately 20 degrees.

Why are safety features important for forklift ramps?

Safety features are crucial for accident prevention and help reduce risks associated with loading and unloading.

What safety features should be prioritized for forklift ramps?

Operators should prioritize inclines that include anti-slip surfaces, guardrails, and edge markers.

What materials are recommended for forklift ramps?

Structures made from robust materials, such as steel, are preferred for their strength and durability.

How do proper specifications and safety features impact operational efficiency?

Focusing on the right specifications and safety features can significantly decrease the likelihood of accidents and enhance operational efficiency during loading and unloading activities.

What services does EZ Equipment Rental provide related to forklift ramps?

EZ Equipment Rental offers a diverse selection of well-maintained lifting machines that complement the range of suitable inclines, ensuring clients can find the perfect match for their specific needs.

List of Sources

- Evaluate Ramp Specifications and Safety Features

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- Forklift Ramp Slope Incline Requirements & Safety Guidelines | Bigrentz (https://bigrentz.com/blog/forklift-ramp-slope?srsltid=AfmBOorIZkmdFCjWyFkdDVjjtNe8oyYt6ohtT_snru7-EdGNatXbEGQh)

- Understanding the Economics of Forklift Ramps: Safety, Impact, and Best Practices - Quality Material Handling Inc. (https://qmhinc.com/forklift-ramp-economics?srsltid=AfmBOoq5zR9dHAKhGjV6ZPXwA5a22D3R490zTzvbPxJZvtsWIWM6lRGK)

- Forklift Requirements (2025) – OSHA Certification & Safety Checklist (https://certifyme.net/osha-blog/forklift-ramp-safety-techniques)

- Forklift Ramps: Design and Safety - Quality Material Handling Inc. (https://qmhinc.com/forklift-ramps-design-safety?srsltid=AfmBOorCdkBDOespMyujNAeP82XSixhQdsYVkgu_qMb57QEF26An97zr)

- Assess Project-Specific Requirements for Ramp Selection

- 10 Construction Quotes to Inspire Your Project (https://horstconstruction.com/10-wise-construction-quotes-to-inspire-your-next-project-2)

- 40 Construction Quotes to Motivate Your Team (https://projectmanager.com/blog/construction-quotes)

- Exploring the Dynamics of Forklift Ramp Market: Key Insights and Trends for 2033 (https://linkedin.com/pulse/exploring-dynamics-forklift-ramp-market-key-insights-mpklf)

- United States Forklift Ramp Market Risk, Size & Brands 2026-2033 (https://linkedin.com/pulse/united-states-forklift-ramp-market-risk-size-brands-6rayf)

- Implement Safe Usage Practices for Forklift Ramps

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- Top Forklift Accident Statistics & Prevention Tips for 2025 | CertifyMe (https://certifyme.net/osha-blog/forklift-accidents)

- National Forklift Safety Day Statistics │ MHEDA (https://mheda.org/journal/national-forklift-safety-day-statistics)

- Work Safety: Forklifts - Injury Facts (https://injuryfacts.nsc.org/work/safety-topics/forklifts)

- Conduct Regular Maintenance and Inspections

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Work Safety: Forklifts - Injury Facts (https://injuryfacts.nsc.org/work/safety-topics/forklifts)