Key Highlights:

- Evaluate existing tools before selecting machinery for construction projects to ensure they meet specific project requirements.

- Identify project tasks and necessary tools, such as cranes for heavy lifting, to enhance efficiency and safety.

- Assess site conditions, including terrain and accessibility, to determine the need for specialised equipment.

- Consult with stakeholders like project managers and site supervisors to gather diverse insights on machinery needs.

- 94% of construction firms value data collection for informed decision-making, highlighting the need for structured assessments.

- Develop a capital expenditure (CapEx) plan that includes budgeting for purchases, rentals, maintenance, and training costs.

- Prioritise tool requirements and consider future project needs to avoid delays and additional expenses.

- Conduct a cost-benefit analysis to compare expenses and benefits of equipment options for informed decision-making.

- Consider logistics such as accessibility, transportation, storage, and supplier coordination to ensure timely availability of equipment.

Introduction

Selecting the right production equipment is a critical decision that can significantly impact the success of construction projects. As the construction industry increasingly relies on advanced technologies and data-driven strategies, understanding best practices for equipment selection becomes essential. This knowledge not only enhances productivity but also ensures safety on site. However, navigating the myriad of options available while balancing budget constraints and project requirements presents a significant challenge.

Construction professionals must effectively assess their equipment needs to make informed choices that align with both immediate tasks and future demands. By focusing on reliable equipment and service quality, they can enhance project outcomes and maintain operational efficiency. The ability to make strategic decisions in equipment selection is vital for achieving long-term success in the competitive construction landscape.

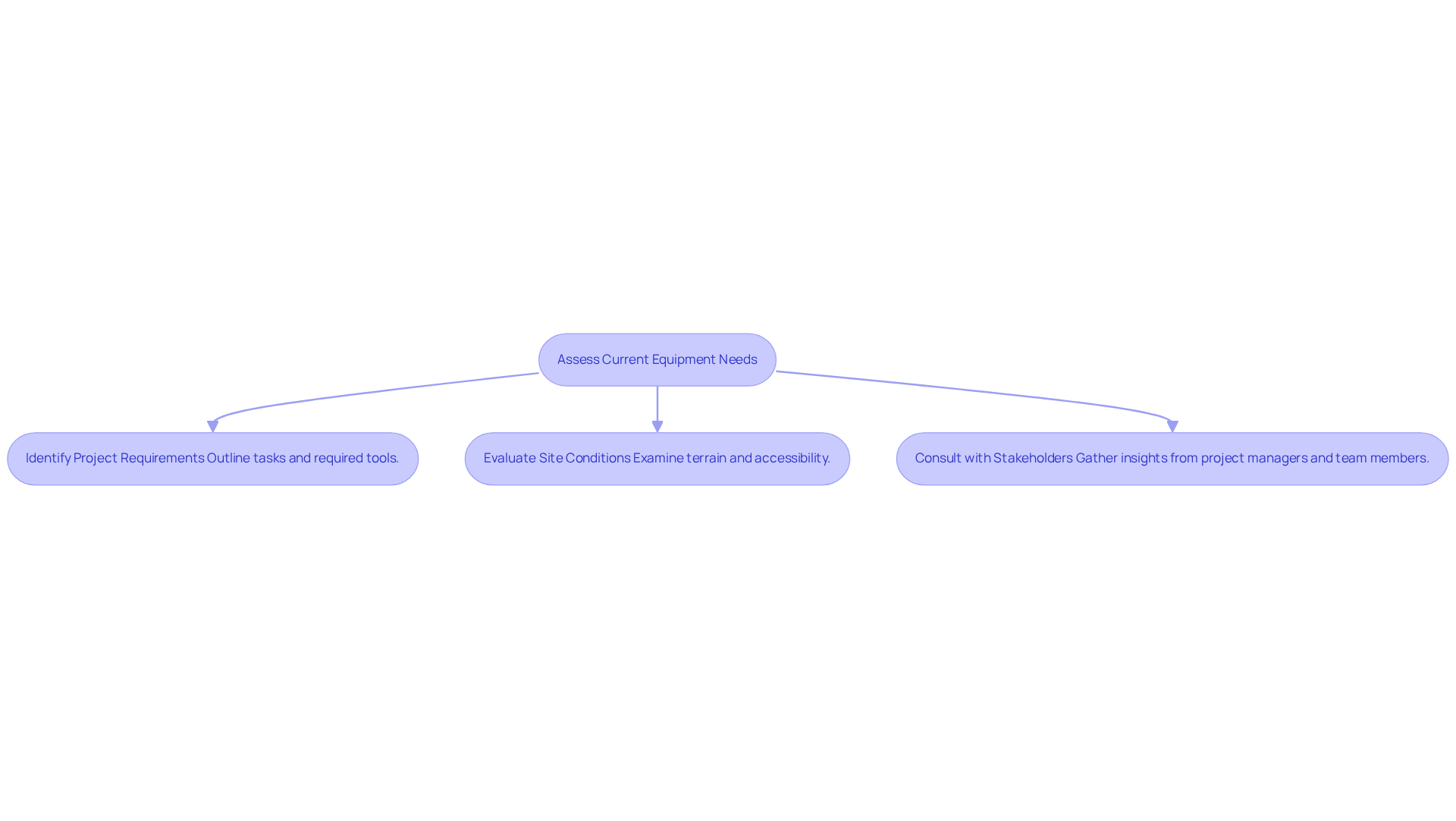

Assess Current Equipment Needs

A thorough evaluation of existing tools is crucial before selecting any machinery for a construction project. This assessment should be tailored to the specific requirements of the initiative, taking into account the scope of work, types of tasks, conditions at the job site, and the production equipment needed.

- Identify Project Requirements: Clearly outline the tasks to be completed and the tools required for their execution. For example, tasks that involve heavy lifting should consider cranes or forklifts, as these are essential for both efficiency and safety.

- Evaluate Site Conditions: Examine the terrain, accessibility, and environmental factors that could affect machinery performance. In instances of rough terrain, specialized equipment like all-terrain forklifts may be necessary to ensure effective operations.

- Consult with Stakeholders: Collaborate with project managers, site supervisors, and team members to gather insights on machinery needs and preferences. This inclusive approach not only ensures that various perspectives are considered but also enhances the quality of decision-making.

Statistics indicate that 94% of construction firms recognize the value of data collection and analysis for informed decision-making, underscoring the importance of a structured approach to tool assessment. Furthermore, case studies reveal that 70% of contractors believe advanced technologies can significantly enhance productivity and safety, highlighting the necessity for a comprehensive evaluation of resource needs to effectively leverage these advantages.

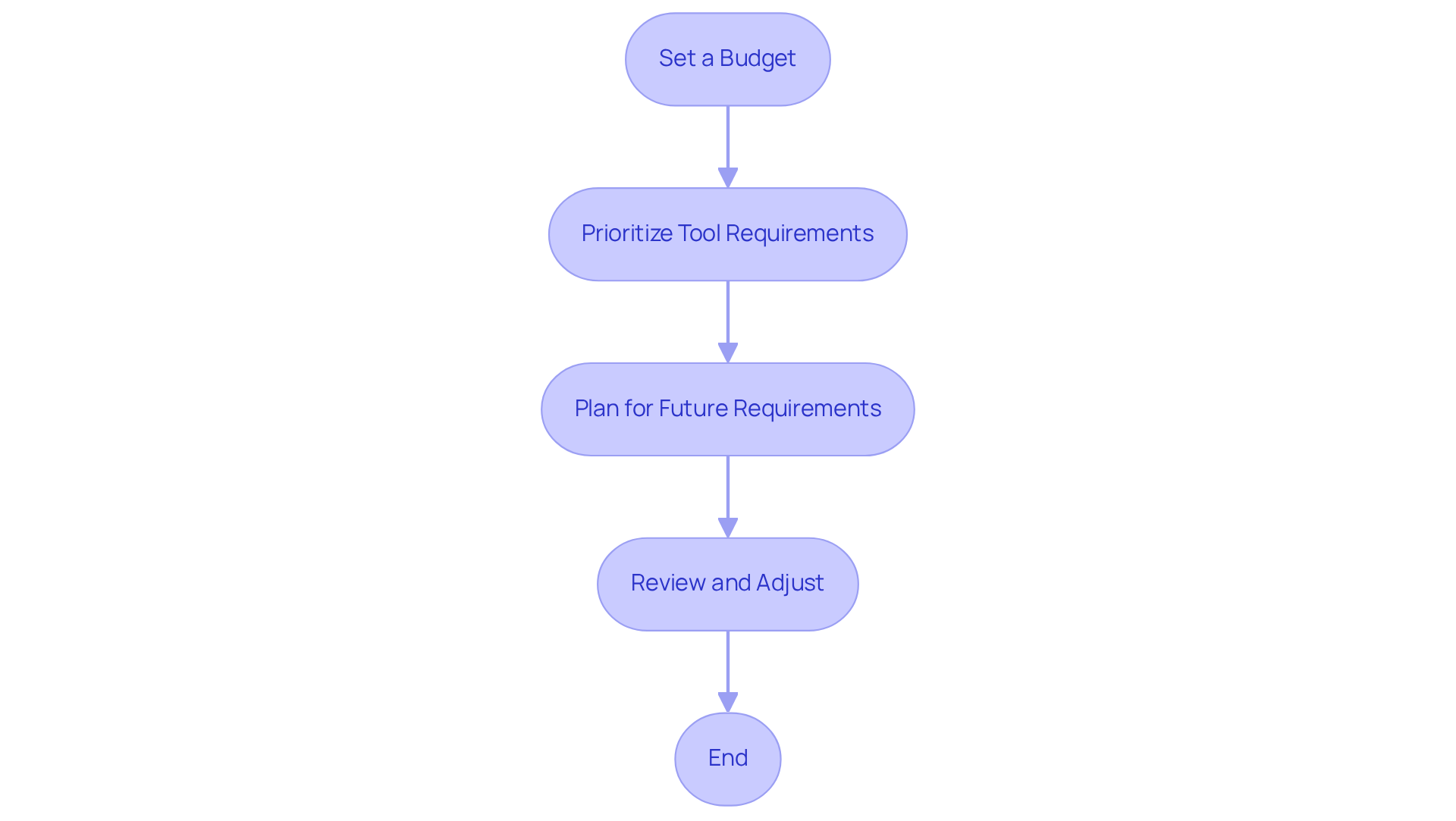

Develop a Capital Expenditure Plan

Developing a capital expenditure (CapEx) plan is crucial for effectively managing the financial aspects of production equipment selection in construction projects. Here are key steps to create an effective CapEx plan:

-

Set a Budget: Establish the total budget for purchases or rentals. This should encompass not only the costs of the items but also maintenance, operational expenditures, and potential training fees. Renting tools from EZ Equipment Rental can significantly lower these ongoing costs by eliminating the need for maintenance and storage associated with ownership.

-

Prioritize Tool Requirements: Assess current tool needs and prioritize essential resources for the task at hand. Focus on acquiring high-impact production equipment, including forklifts and earthmoving machinery, that enhance productivity. Renting from EZ Equipment Rental offers the flexibility to adapt to changing requirements without the burdens of ownership.

-

Plan for Future Requirements: Anticipate future projects and potential tool needs. Allocating resources for tools that may be necessary down the line can prevent delays and additional expenses, ensuring that projects remain on schedule and within budget. With EZ Equipment Rental, you can easily modify your equipment rental solutions to meet future demands without the complications of long-term commitments.

-

Review and Adjust: Regularly evaluate the CapEx plan to ensure it aligns with project progress and financial performance. Adjustments may be required to accommodate evolving project needs or unforeseen expenses. By leveraging EZ Equipment Rental's services, you can adapt your tool strategy as necessary, ensuring that your CapEx plan remains effective and responsive.

By following these steps, construction project managers can develop a robust CapEx plan that facilitates effective tool selection and sound financial management regarding production equipment.

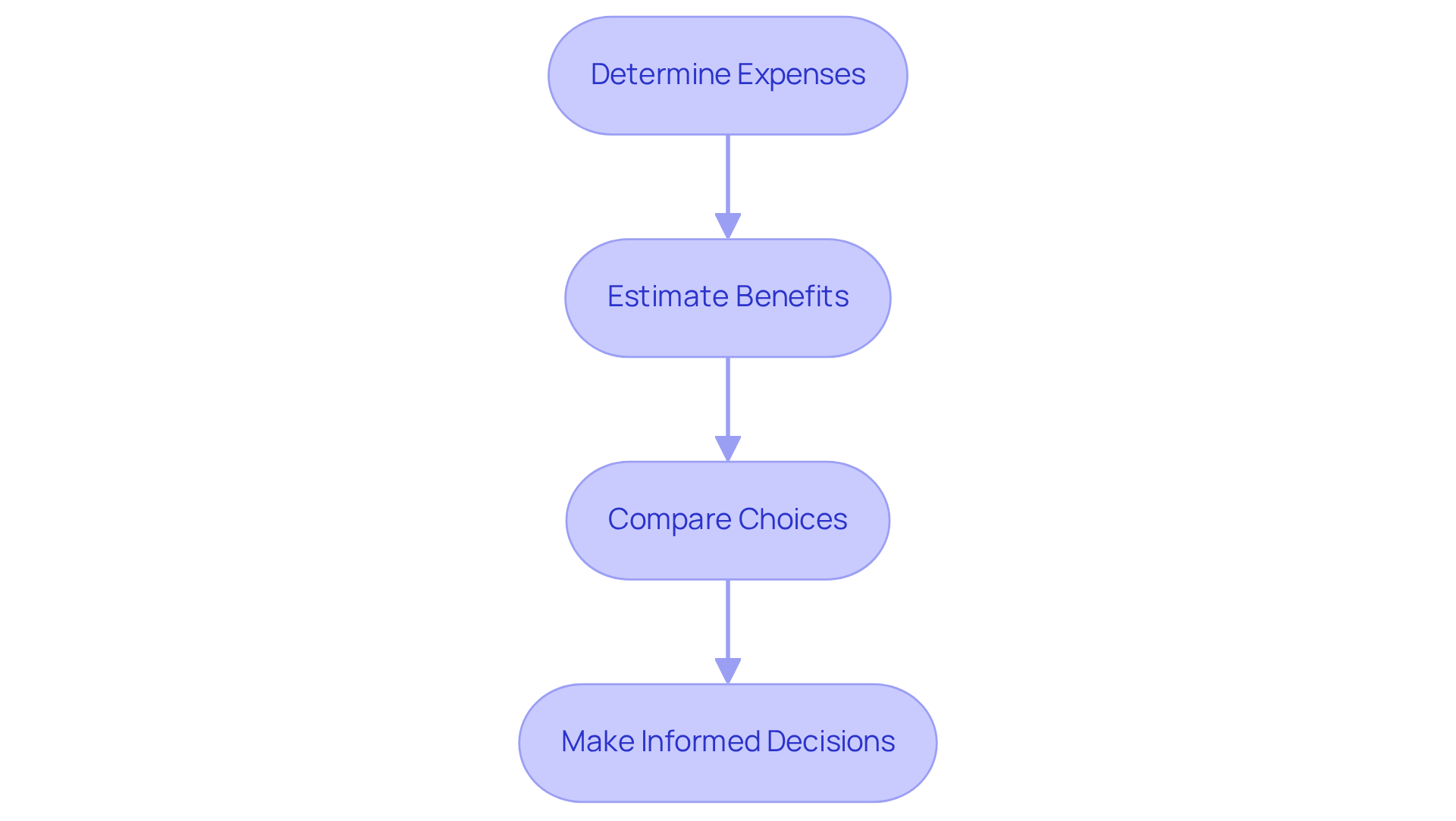

Conduct a Cost-Benefit Analysis

A cost-benefit analysis (CBA) serves as a systematic method for evaluating the financial implications of various options. Conducting a thorough CBA involves several key steps:

- Determine Expenses: Begin by listing all expenses associated with the equipment, including purchase price, maintenance, operational costs, and potential downtime expenses.

- Estimate Benefits: Next, assess the expected advantages of utilizing the equipment, such as increased productivity, reduced labor costs, and improved project timelines.

- Compare Choices: Evaluate different equipment options by contrasting the total expenses against the anticipated benefits. This comparison will help identify which option offers the best return on investment.

- Make Informed Decisions: Finally, use the insights gained from the CBA to inform your choice of equipment. Select the production equipment that provides the most favorable balance of costs and benefits while ensuring alignment with project objectives and budget constraints.

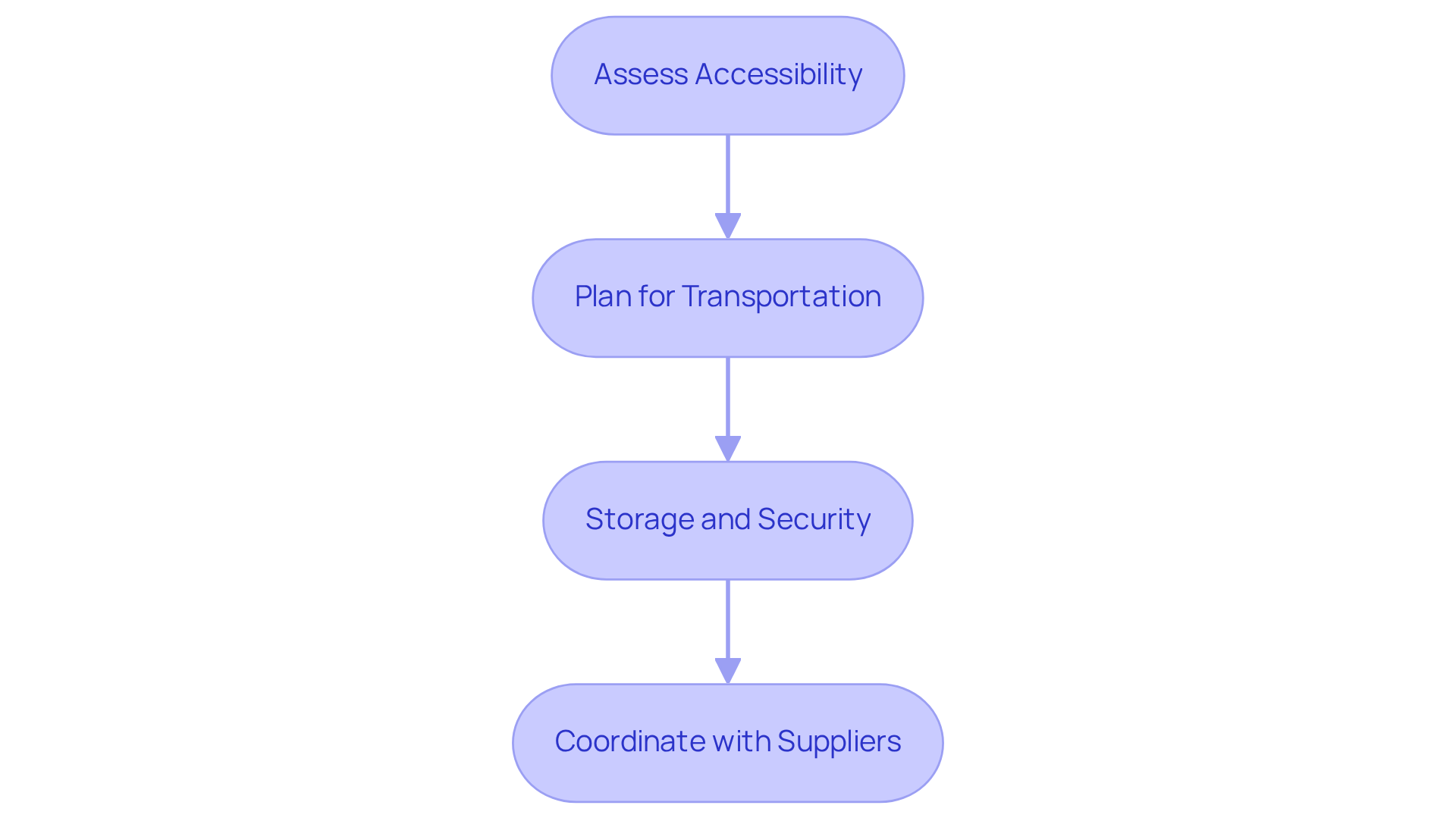

Consider Physical Location and Logistics

The physical position of a construction area significantly influences machinery selection and logistics. Here are essential considerations:

-

Assess Accessibility: Evaluate the ease of delivering tools to the location by examining road conditions, layout, and potential obstacles that could hinder access. Proper access is crucial; insufficient access can lead to increased risks and delays, ultimately impacting project timelines.

-

Plan for Transportation: Strategize the logistics of moving tools to and from the site. This involves analyzing transportation costs, expected timeframes, and the availability of suitable transport vehicles. Effective transportation planning minimizes delays and ensures that tools arrive when needed.

-

Storage and Security: Ensure adequate on-site storage space for devices when not in use. Implement security measures to protect valuable assets from theft or damage, as construction sites can be vulnerable to such risks.

-

Coordinate with Suppliers: Foster open communication with providers to guarantee timely delivery and availability. This coordination is vital for preventing delays and ensuring that the right equipment is on-site precisely when required, thus maintaining project momentum and efficiency.

Conclusion

Selecting the right production equipment is crucial for effective construction project management. By understanding the specific needs of a project, developing a solid capital expenditure plan, conducting a thorough cost-benefit analysis, and considering logistical factors, construction professionals can make informed decisions that enhance efficiency and productivity.

Key points include:

- Assessing current equipment needs tailored to project requirements

- The necessity of a well-structured CapEx plan for effective financial resource management

- The role of a cost-benefit analysis in evaluating equipment options

- The significance of logistics and site conditions in the selection process, as these factors can greatly influence project timelines and overall success

In conclusion, careful selection of production equipment impacts not only the immediate efficiency of construction projects but also contributes to long-term financial health and safety. By adhering to these best practices, construction managers can optimize their equipment choices, adapt to evolving project demands, and drive their projects to successful completion. Embracing these strategies fosters a proactive approach to equipment management, ensuring that construction firms remain competitive and effective in an ever-changing industry landscape.

Frequently Asked Questions

Why is it important to assess current equipment needs before selecting machinery for a construction project?

Assessing current equipment needs is crucial to ensure that the selected machinery aligns with the specific requirements of the project, including the scope of work, types of tasks, site conditions, and production equipment needed.

What factors should be considered when identifying project requirements for machinery?

When identifying project requirements, it is important to clearly outline the tasks to be completed and the tools required for their execution. For instance, tasks involving heavy lifting should consider using cranes or forklifts for efficiency and safety.

How do site conditions affect the selection of machinery?

Site conditions, such as terrain, accessibility, and environmental factors, can significantly impact machinery performance. For example, in rough terrain, specialized equipment like all-terrain forklifts may be necessary to ensure effective operations.

Who should be consulted when evaluating equipment needs for a construction project?

It is beneficial to consult with project managers, site supervisors, and team members to gather insights on machinery needs and preferences. This collaborative approach enhances decision-making by incorporating various perspectives.

What does the statistic about data collection and analysis in construction firms indicate?

The statistic that 94% of construction firms recognize the value of data collection and analysis highlights the importance of a structured approach to tool assessment for informed decision-making.

What do contractors believe about the impact of advanced technologies on construction projects?

According to case studies, 70% of contractors believe that advanced technologies can significantly enhance productivity and safety, emphasizing the need for a comprehensive evaluation of resource needs to leverage these advantages effectively.

List of Sources

- Assess Current Equipment Needs

- Construction Equipment Market Size, Share, Industry Analysis [2024-2030] (https://marketsandmarkets.com/blog/AT/construction-equipment-market)

- Assessing Factors Affecting Construction Equipment Productivity Using Structural Equation Modeling | MDPI (https://mdpi.com/2075-5309/13/2/502)

- Construction Equipment Market Size & Share, Growth Analysis 2038 (https://researchnester.com/reports/construction-equipment-market/1425)

- Construction Equipment Market Share, Size, & Growth Report By 2030 (https://marknteladvisors.com/research-library/global-construction-equipment-market.html)

- 100+ Construction Industry Statistics | Autodesk (https://autodesk.com/blogs/construction/construction-industry-statistics)

- Develop a Capital Expenditure Plan

- 2024 Capital Spending Survey: Spending Levels Off (https://assemblymag.com/articles/98930-2024-capital-spending-survey-spending-levels-off)

- 7 Must-Know Statistics About Equipment Rentals (https://gocodes.com/construction/equipment-rentals-statistics)

- Equipment Rental Industry: Growth, Trends, Challenges, and Future Scope (https://yo-rent.com/blog/equipment-rental-market-growth-trends-opportunities)

- Construction Equipment Rental Market Statistics 2025-2034 (https://statifacts.com/outlook/us-construction-equipment-rental-market)

- Construction Equipment Market 2025–2032: Infrastructure Expansion, Urbanization, and Technology-Driven Equipment Modernization | MMR Statistics (https://mmrstatistics.com/reports/641062/construction-equipment-market)

- Conduct a Cost-Benefit Analysis

- Cost-Benefit Analysis: Renting vs. Buying Excavator Attachments (https://hammerhire.com.au/the-cost-benefit-analysis-of-renting-vs-buying-excavator-attachments)

- Construction Equipment Costs You Must Consider - Tenna (https://tenna.com/equipment-tracking-guide/construction-equipment-costs)

- (PDF) The Benefits of Cost-Benefit Analysis in Construction Projects (https://researchgate.net/publication/373576114_The_Benefits_of_Cost-Benefit_Analysis_in_Construction_Projects)

- Estimating Construction Equipment Costs: Key Factors & Tips (https://anterratech.com/blog/estimate-construction-equipment-costs)

- TOP 7 COST BENEFIT ANALYSIS QUOTES | A-Z Quotes (https://azquotes.com/quotes/topics/cost-benefit-analysis.html)

- Consider Physical Location and Logistics

- Effect of site access and working space on building costs (https://bcis.co.uk/insight/effect-of-site-access-and-working-space-on-building-costs)

- The Importance of Proper Site Access in Construction Planning | NPK (https://npki.com/resources/the-importance-of-proper-site-access-in-construction-planning)

- Logistics Statistics 2025 — 50 Key Figures (https://procurementtactics.com/logistics-statistics)

- (PDF) Review of Logistics Challenges within the Construction Industry (https://researchgate.net/publication/392342446_Review_of_Logistics_Challenges_within_the_Construction_Industry)

- The 4 Most Common Challenges in Construction Logistics (https://caliber.global/blog/construction-logistics-challenges-supply-chain)