Key Highlights:

- The Grove RT760E is a 60 tonne rough terrain crane designed for heavy lifting in challenging environments.

- Key specifications include a maximum hoisting capacity of 60 tonnes and a boom length of up to 30.1 metres, allowing heights of 166 feet.

- Understanding the crane's capacity chart is crucial for safe operations, ensuring operators do not exceed lifting limits.

- Features like all-wheel drive and high ground clearance enhance mobility on uneven terrain.

- The PAT I-Flex 5 LMI system provides real-time load monitoring, emphasising safety in hoisting operations.

- Conducting thorough site assessments is essential, including evaluating terrain stability and identifying overhead hazards.

- Improper outrigger use is a leading cause of crane incidents; therefore, extending outriggers correctly is critical for stability.

- Operators must maintain vertical elevation during lifts to prevent swinging and utilise tag lines for load management.

- Ongoing training and effective communication among team members are vital for enhancing operational safety and efficiency.

- A culture of safety and teamwork contributes to successful project completion and protects personnel.

Introduction

Understanding the complexities of operating a 60-ton rough terrain crane is crucial for maximizing safety and efficiency on any job site. Take the Grove RT760E, for instance; this powerful machine can truly shine when operators master its specifications, conduct thorough site assessments, and implement effective practices for setup and load management. But here’s the challenge: how can operators ensure they’re not just compliant with safety regulations but also proficient in using advanced equipment? This article explores four best practices that can elevate crane operations, reduce risks, and cultivate a culture of continuous improvement in the field.

Understand the Specifications and Capabilities of a 60 Ton Rough Terrain Crane

The Grove RT760E is a robust 60 ton rough terrain crane designed for heavy lifting in demanding environments. Its sturdy framework and advanced hydraulic systems make it a reliable choice for operators who need to navigate challenging job sites. Understanding key specifications is crucial; operators must be well-versed in maximum hoisting capacity, boom length, and operational radius. For instance, the impressive 60 ton rough terrain crane, Grove RT760E, boasts an average hoisting capacity of 60 tons, with boom lengths reaching up to 30.1 meters, allowing for heights of up to 166 feet.

Grasping the machine's capacity chart is essential for safe operations. This chart outlines secure lifting limits based on boom length and weight distance, ensuring operators remain within safe thresholds. As industry specialists emphasize, "Comprehending weight charts is crucial for ensuring security and efficiency on the job site." Furthermore, the crane's mobility features, including all-wheel drive and high ground clearance, enhance its ability to traverse uneven terrain, making it an invaluable asset on any project.

The Grove RT760E also integrates advanced protective features, such as the PAT I-Flex 5 LMI system, which provides real-time load monitoring. This highlights the importance of safety in hoisting operations. Additionally, boom lifts offer exceptional vertical and horizontal reach, enabling workers to access elevated areas and maneuver around obstacles with ease-essential for tasks like painting, repairs, or construction work.

Knowledge of these specifications not only boosts operational efficiency but also significantly reduces the risk of accidents. This underscores the critical role of safety in hoisting operations. By understanding the capabilities and features of the Grove RT760E, operators can ensure that they are equipped to handle their tasks effectively and safely.

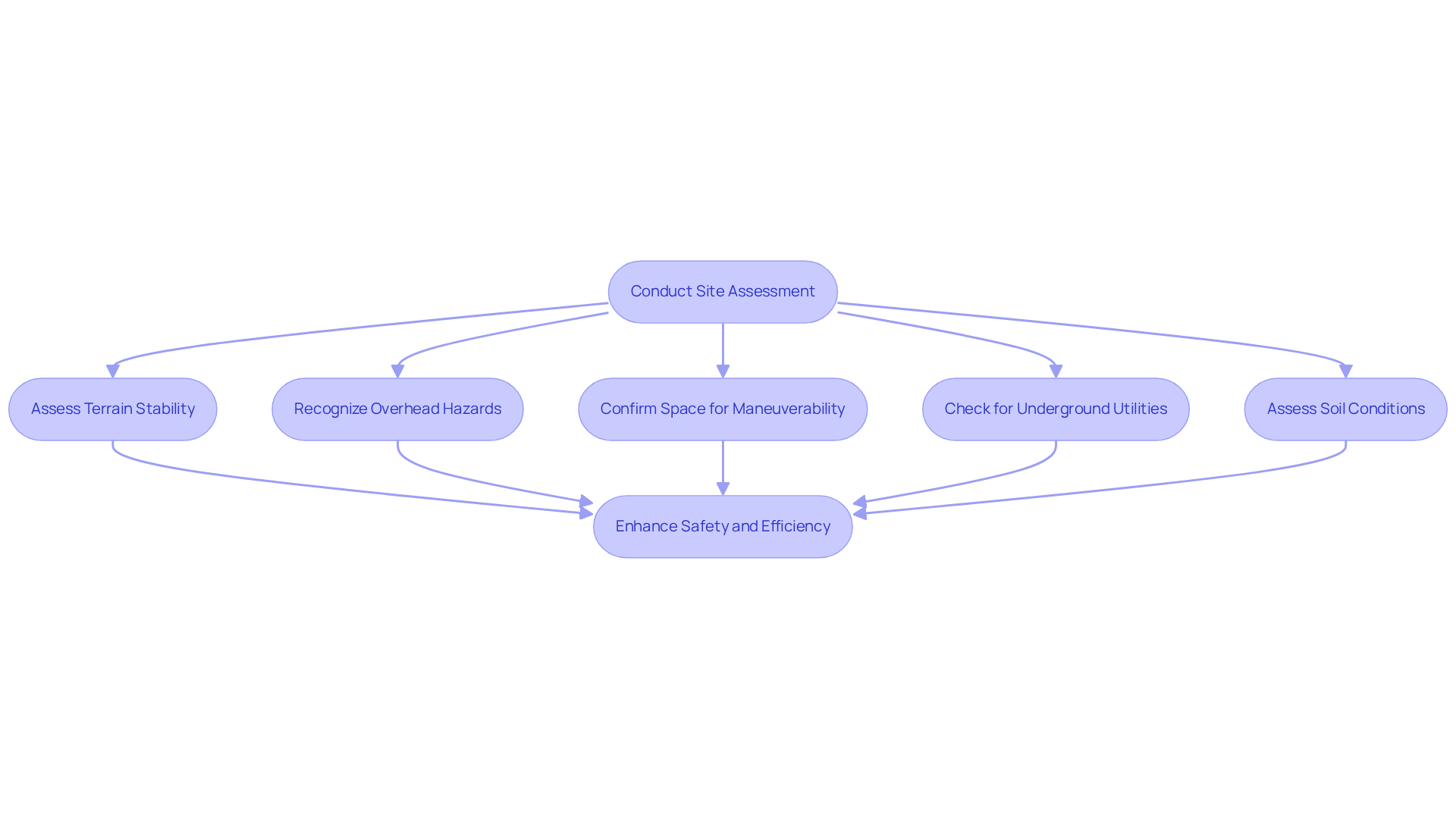

Conduct a Thorough Site Assessment for Safe Crane Operation

Before operating a 60 ton rough terrain crane, conducting a thorough site assessment is essential for ensuring safety and operational efficiency. This evaluation must encompass:

- Assessing terrain stability

- Recognizing overhead hazards like power lines

- Confirming there is adequate space for equipment maneuverability

- Checking for underground utilities

- Assessing soil conditions to determine load-bearing capacity

High moisture levels can lead to softer ground, increasing the risk of instability.

Utilizing tools like site maps and performing detailed walk-throughs can help identify potential risks, such as uneven ground or moisture levels that may compromise stability. According to the U.S. Bureau of Labor Statistics, an average of 44 people die in crane-related accidents in the U.S. each year, highlighting the critical need for thorough site evaluations. Furthermore, the Inspection and Certification Bureau states that nearly 90% of lifting equipment accidents stem from human error, often exacerbated by inadequate site assessments.

OSHA mandates that a worker inspect each hoisting device component prior to lifting material into the air. By addressing these factors proactively, operators can significantly enhance safety and efficiency on the job site. Don't leave safety to chance - ensure your site assessments are thorough and effective.

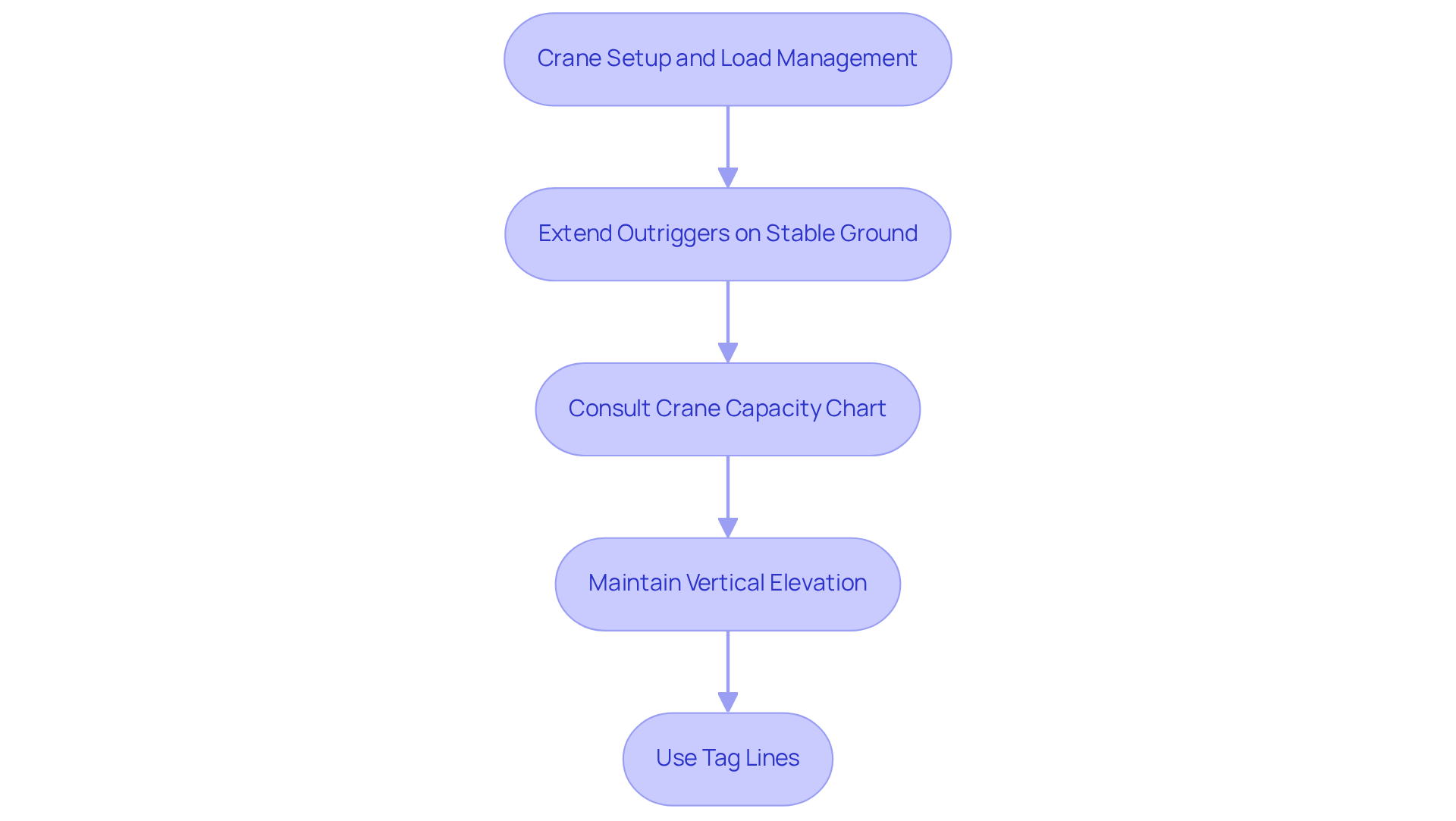

Implement Best Practices for Crane Setup and Load Management

To ensure safe and effective machinery operations, operators must adhere to best practices during setup and load management. Properly extending outriggers on stable ground is essential for maximizing stability and preventing tipping. In fact, improper outrigger use is a leading cause of incidents involving lifting equipment. Statistics reveal that 43% of deadly work injuries involving hoisting equipment occurred in the private construction industry, highlighting the high-risk nature of operations in this sector.

Furthermore, human error, poor communication, inadequate rigging practices, and power line contact have significantly contributed to lifting equipment incidents from 2021 to 2024. This underscores the importance of proper outrigger use. Operators should always consult the crane's capacity chart to determine suitable weight limits based on boom length and radius. Exceeding these limits can lead to structural failure, which is a risk no operator should take.

During lifting, maintaining a vertical elevation is crucial to avoid swinging, which can destabilize the item. Employing tag lines is a practical method for managing the cargo's movement during transport, further enhancing security. Frequent evaluations of rigging tools and load securing techniques are essential to maintain standards and avert accidents. As specialists in protective measures emphasize, "Just because it can lift it, doesn’t mean it should." This statement reinforces that extending outriggers correctly is not merely a suggestion but an essential step for ensuring stability and preventing tipping occurrences.

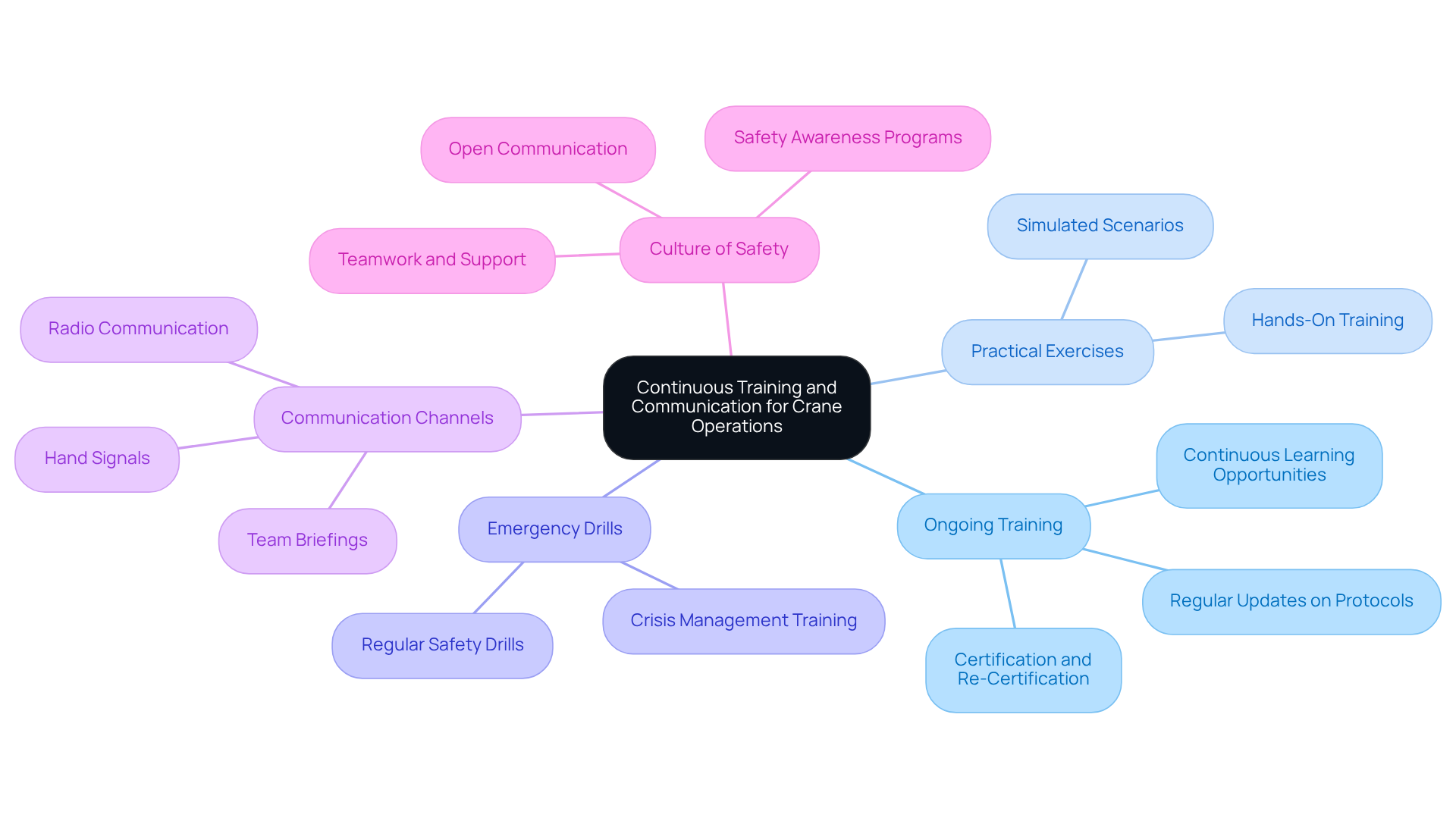

Foster Continuous Training and Communication for Crane Operations

Ongoing training is essential for operators to stay informed about protocols, equipment management, and regulatory standards. Regular training sessions should include practical exercises, emergency drills, and updates on new technologies or procedures. This approach not only enhances skills but also ensures that operators are prepared for any situation that may arise.

Furthermore, fostering open communication among team members is vital for ensuring that everyone understands their roles and responsibilities during crane operations. Establishing clear communication channels, such as hand signals or radio communication, can significantly reduce the risk of accidents. By prioritizing effective communication, teams can work more cohesively and efficiently, ultimately leading to safer operations.

Encouraging a culture of safety and teamwork will enhance overall operational effectiveness and project success. When operators feel supported and informed, they are more likely to perform at their best. This commitment to safety and collaboration not only protects personnel but also contributes to the successful completion of projects.

Conclusion

Understanding how to effectively operate a 60-ton rough terrain crane, particularly the Grove RT760E, is crucial for ensuring safety and operational efficiency. By mastering the specifications, conducting thorough site assessments, implementing best practices for setup and load management, and fostering continuous training and communication, operators can significantly elevate their performance on the job site.

Key insights underscore the necessity of knowing the crane's capabilities, such as its hoisting capacity and boom length, which are vital for safe operations. Thorough site assessments help identify potential hazards, ensuring operators are well-prepared for the challenges posed by uneven terrain. Furthermore, adhering to best practices during setup and load management - like proper outrigger use and maintaining vertical elevation during lifts - is essential to prevent accidents. Continuous training and open communication among team members cultivate a culture of safety, ultimately leading to more successful project outcomes.

In conclusion, operating a 60-ton rough terrain crane effectively goes beyond merely understanding the machinery; it requires a comprehensive approach that prioritizes safety, efficiency, and teamwork. By embracing these best practices, operators can minimize risks and maximize productivity, ensuring that every lift is executed with confidence and precision. Prioritizing these strategies not only protects personnel but also contributes to the overall success of construction projects. Take action now - implement these practices and watch your project outcomes improve.

Frequently Asked Questions

What is the Grove RT760E?

The Grove RT760E is a robust 60 ton rough terrain crane designed for heavy lifting in demanding environments.

What are the key specifications of the Grove RT760E?

The Grove RT760E has an average hoisting capacity of 60 tons, a boom length reaching up to 30.1 meters, and can achieve heights of up to 166 feet.

Why is it important to understand the capacity chart of the crane?

Understanding the capacity chart is essential for safe operations as it outlines secure lifting limits based on boom length and weight distance, ensuring operators remain within safe thresholds.

What mobility features does the Grove RT760E have?

The Grove RT760E features all-wheel drive and high ground clearance, which enhance its ability to traverse uneven terrain.

What safety features are integrated into the Grove RT760E?

The crane integrates advanced protective features such as the PAT I-Flex 5 LMI system, which provides real-time load monitoring to enhance safety during hoisting operations.

How does the crane assist in tasks like painting or construction work?

The boom lifts of the Grove RT760E offer exceptional vertical and horizontal reach, enabling workers to access elevated areas and maneuver around obstacles with ease.

How does knowledge of the crane's specifications impact operational efficiency?

Knowledge of the specifications boosts operational efficiency and significantly reduces the risk of accidents, highlighting the critical role of safety in hoisting operations.