Key Highlights:

- Telescopic forklifts, or reach trucks, feature an extendable boom for enhanced material handling at various heights and distances.

- Key functionalities include an extendable boom, versatile attachments, and the ability to navigate rough terrain, making them suitable for construction and agricultural tasks.

- Operator training and adherence to OSHA standards are crucial for safe operation, alongside pre-operation inspections and the use of personal protective equipment (PPE).

- Common applications of telescopic forklifts include construction sites, agricultural operations, and landscaping projects, where they effectively lift and transport heavy materials.

- Operators must avoid pitfalls such as overloading, improper terrain use, and neglecting visibility to enhance safety.

- Regular maintenance practises, including daily inspections, fluid checks, lubrication, and scheduled servicing, are essential for ensuring equipment longevity and operational efficiency.

Introduction

Telescopic forklifts are renowned for their impressive reach and versatility, making them essential tools across various industries, especially in construction and agriculture. As their usage continues to grow, it becomes increasingly important for operators to understand best practices for safe and effective operation. This knowledge is crucial for maximizing productivity while minimizing risks associated with these powerful machines. With numerous functionalities and potential pitfalls, operators must consider:

- How can they fully harness the capabilities of telescopic forklifts without compromising safety?

Understand Telescopic Forklifts: Definition and Functionality

A reach truck, commonly referred to as a telehandler, is a highly versatile piece of equipment designed to raise, move, and place heavy materials at various heights and distances. Unlike traditional forklifts that primarily lift items vertically, telescopic forklifts have an extendable boom that enhances operators' reach and versatility in material handling. This capability is particularly advantageous on construction sites, in agricultural settings, and in other environments where a telescopic forklift is essential for transporting heavy items. Key functionalities include:

- Extendable Boom: The boom's ability to extend and retract allows operators to efficiently access high or distant loads, significantly boosting productivity and ensuring secure working environments. This exceptional reach is vital for tasks that require lifting materials to elevated positions.

- Versatile attachments for the telescopic forklift can accommodate a variety of equipment, such as forks, buckets, and platforms, broadening their operational capabilities and enabling diverse applications, making them indispensable for construction and maintenance tasks.

- Many models of telescopic forklifts are specifically engineered to navigate rough terrain, making them ideal for outdoor construction sites where conditions can be challenging.

Understanding these functionalities is crucial for operators aiming to optimize both efficiency and safety in their operations. For example, case studies have shown that the design of extending lifting machines, featuring a base support frame and independent corner arms, allows for precise control over load height and travel direction, thereby enhancing productivity in busy environments. Furthermore, the telescopic forklift's ability to reach heights that conventional lifting equipment cannot access underscores its importance in construction. As the market for telescopic forklifts continues to grow, driven by increasing demand in construction and logistics, operators must prioritize safety and compliance, including obtaining the necessary OSHA certification to ensure secure operation. Additionally, utilizing load charts to determine safe lifting capacities is essential for preventing accidents and ensuring operational security. At EZ Equipment Rental, we offer a diverse selection of specialized lifting machines tailored to meet your specific needs, enhancing productivity and safety on your job site.

Implement Safety Protocols: Training and Operational Guidelines

Implementing comprehensive precautionary protocols is essential to operate a telescopic forklift securely. Key practices include:

- Operator Training: All operators must undergo formal training and certification, adhering to OSHA standards. This training should encompass the operation of the telescopic forklift, load handling, and safety protocols.

- Pre-Operation Inspections: Conduct thorough inspections before each use, checking for mechanical issues, fluid levels, and the functionality of protective equipment.

- Use of Personal Protective Equipment (PPE): Operators should wear appropriate PPE, including hard hats, protective eyewear, and high-visibility clothing, to minimize injury risks.

- Establish Clear Communication: Utilize hand signals or radios to maintain communication among team members, particularly in busy environments.

- Load Management: Always adhere to the load capacity chart for the telescopic forklift and ensure that loads are stable and secure before lifting. Avoid exceeding the machine's rated capacity to prevent tipping or accidents.

Implementing these protocols not only enhances safety but also fosters a culture of responsibility and awareness on job sites.

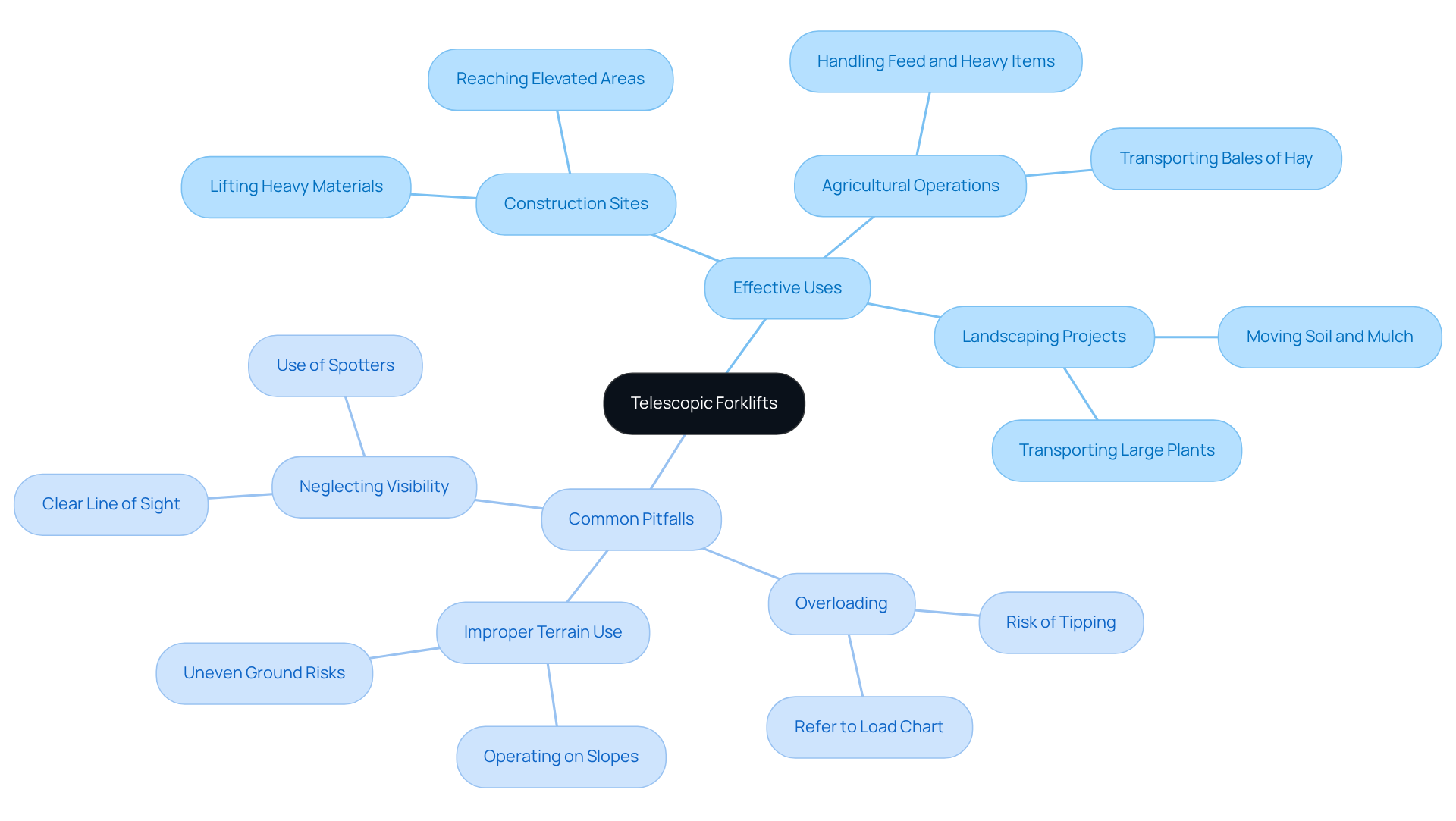

Identify Suitable Applications: Effective Uses and Common Pitfalls

Telescopic forklifts are highly versatile and serve a range of applications effectively. Here are some notable uses:

- Construction Sites: These machines excel at lifting heavy materials to elevated areas, such as beams and trusses, where traditional forklifts may face challenges.

- Agricultural Operations: They are particularly useful for transporting bales of hay, feed, and other heavy items across uneven terrain.

- Landscaping Projects: Telescopic lifts can assist in moving soil, mulch, and large plants to hard-to-reach areas.

While these machines offer significant advantages, operators must be mindful of common pitfalls:

- Overloading: Exceeding the weight limit can result in tipping and accidents. Always refer to the load chart for guidance.

- Improper Terrain Use: Operating on slopes or uneven ground without appropriate precautions can heighten the risk of accidents.

- Neglecting Visibility: Poor visibility can lead to mishaps. Operators should ensure a clear line of sight and utilize spotters when necessary.

By understanding both the effective applications and potential drawbacks, operators can enhance their efficiency and safety when using telescopic forklifts.

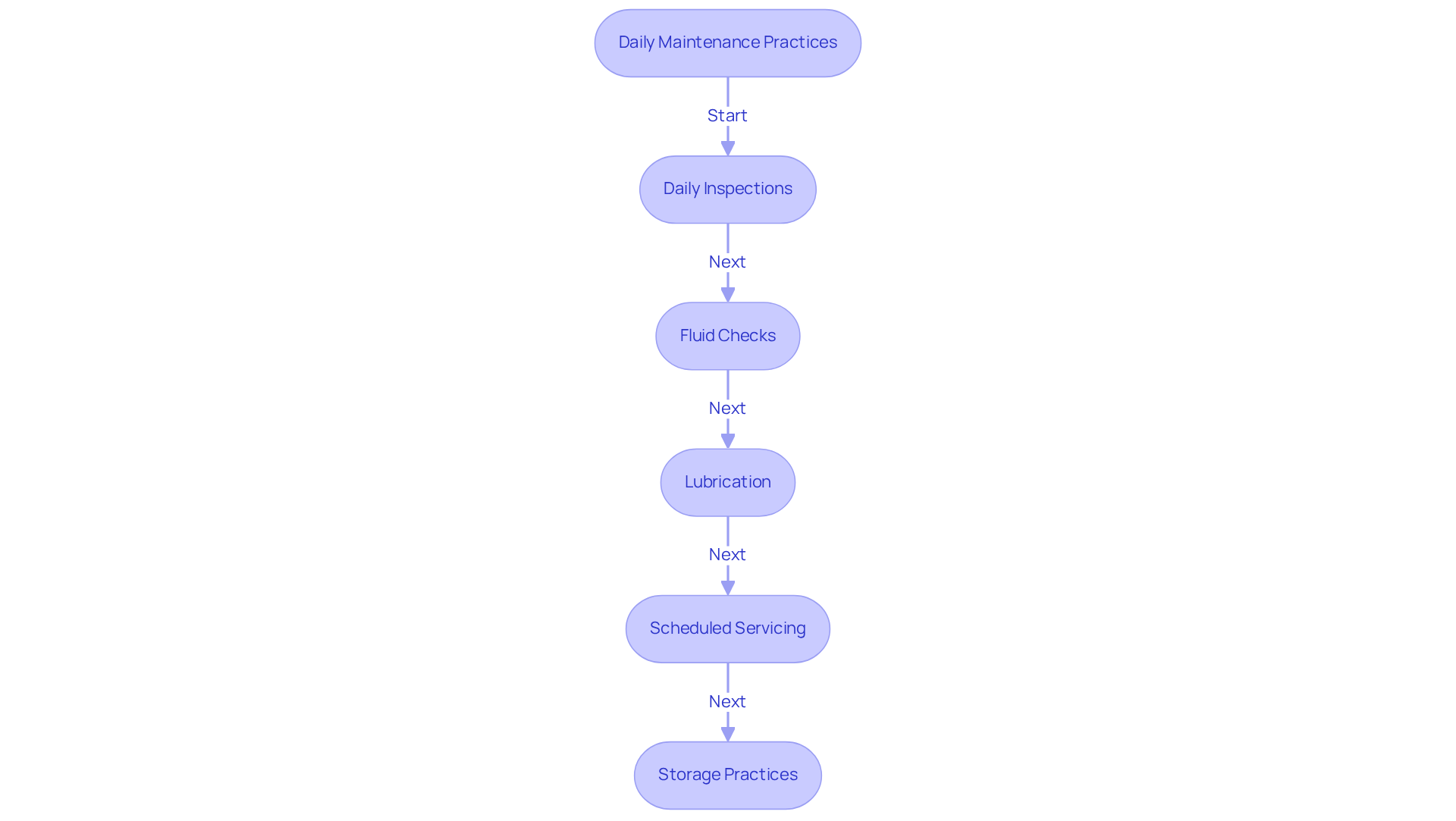

Maintain Equipment: Best Practices for Longevity and Efficiency

Regular maintenance is essential for the safe and efficient operation of a telescopic forklift. Renting from a reputable company like EZ Equipment Rental guarantees well-maintained equipment, which significantly enhances both longevity and performance. By adhering to best practices, you can further improve reliability:

- Daily Inspections: Conduct thorough pre-operation checks each day. Inspect the boom, forks, hydraulic systems, and tire conditions for any signs of wear or damage. Daily inspections help identify potential issues early, reducing the risk of accidents and downtime.

- Fluid Checks: Consistently monitor and maintain fluid levels, including hydraulic oil, coolant, and fuel. Proper fluid levels are crucial for optimal performance and can prevent operational failures.

- Lubrication: Follow the manufacturer's recommendations for lubricating moving parts. Regular lubrication minimizes friction and wear, contributing to smoother operation and extending the equipment's lifespan.

- Scheduled Servicing: Adhere to a regular servicing schedule based on usage hours, including timely replacement of filters and fluids. This is vital for maintaining the efficiency and reliability of the telescopic forklift. Additionally, EZ Equipment Rental offers professional inspection services that can detect issues regular checks might miss, further minimizing downtime.

- Storage Practices: Store the telehandler in a clean, dry environment to prevent rust and corrosion. Ensure it is parked on a level surface with the boom lowered to maintain stability and security.

Implementing these maintenance practices not only prolongs the lifespan of the equipment but also enhances its operational efficiency, ensuring it remains a reliable asset on the job site. Regular maintenance is crucial, as neglecting to maintain a telescopic forklift can lead to costly repairs and safety hazards. The maintenance and repair industry faces a fatal injury rate of 13 per 100,000 workers, underscoring the importance of diligent upkeep.

Conclusion

Effectively operating a telescopic forklift requires a thorough understanding of its functionality, safety protocols, and maintenance practices. This versatile equipment not only boosts productivity across various job sites but also necessitates a strong commitment to safe operation. By prioritizing training, adhering to operational guidelines, and following maintenance schedules, operators can ensure both efficiency and safety when using these powerful machines.

Key insights highlight the significance of operator training and pre-operation inspections, which are vital for minimizing risks and preventing accidents. A solid grasp of the machine's capabilities and limitations, including load management and terrain considerations, is essential for effective usage. Furthermore, regular maintenance practices, such as daily inspections and fluid checks, are crucial for extending the lifespan of telescopic forklifts and maintaining their operational efficiency.

In conclusion, the effective use of telescopic forklifts relies on a combination of knowledge, safety practices, and diligent maintenance. As industries increasingly depend on this equipment, operators must adopt these best practices to cultivate a culture of safety and efficiency. By doing so, they not only safeguard themselves and their teams but also contribute to a safer and more productive work environment.

Frequently Asked Questions

What is a telescopic forklift?

A telescopic forklift, also known as a reach truck or telehandler, is a versatile piece of equipment designed to raise, move, and place heavy materials at various heights and distances using an extendable boom.

How does a telescopic forklift differ from a traditional forklift?

Unlike traditional forklifts that primarily lift items vertically, telescopic forklifts have an extendable boom that enhances the operator's reach and versatility in material handling, allowing for more efficient access to high or distant loads.

What are the key functionalities of telescopic forklifts?

Key functionalities include an extendable boom for accessing high or distant loads, versatile attachments such as forks, buckets, and platforms for diverse applications, and the ability to navigate rough terrain, making them ideal for outdoor construction sites.

Why is it important for operators to understand the functionalities of telescopic forklifts?

Understanding these functionalities is crucial for optimizing efficiency and safety in operations, as it allows operators to utilize the equipment effectively and reduce the risk of accidents.

What safety measures should operators take when using telescopic forklifts?

Operators should prioritize safety by obtaining necessary OSHA certification, utilizing load charts to determine safe lifting capacities, and ensuring compliance with operational security protocols to prevent accidents.

In what environments are telescopic forklifts particularly advantageous?

Telescopic forklifts are particularly advantageous in construction sites, agricultural settings, and other environments where heavy items need to be transported at various heights and distances, especially in challenging outdoor conditions.

How does the design of telescopic forklifts enhance productivity?

The design features, such as a base support frame and independent corner arms, allow for precise control over load height and travel direction, thereby enhancing productivity in busy environments.

What type of equipment can be attached to a telescopic forklift?

Telescopic forklifts can accommodate a variety of attachments, including forks, buckets, and platforms, broadening their operational capabilities for different tasks.

List of Sources

- Understand Telescopic Forklifts: Definition and Functionality

- Telescopic Boom Forklift Truck Market Growth Analysis by 2031 (https://alliedmarketresearch.com/telescopic-boom-forklift-truck-market)

- What is a Telescopic Forklift? - CFE Equipment Corporation (https://cfeequipment.com/what-is-a-telescopic-forklift)

- Advantages of Telescopic Lifts by OshaEducationCenter.com (https://oshaeducationcenter.com/why-choose-telescopic-forklift-equipment)

- Telescopic Forklift Market’s Consumer Insights and Trends (https://datainsightsmarket.com/reports/telescopic-forklift-32641)

- An Overview of Telescopic Forklifts - NovaLift Equipment Inc (https://novaliftequipment.com/everything-you-need-to-know-about-telescopic-forklifts)

- Implement Safety Protocols: Training and Operational Guidelines

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- 5 Common Forklift Accidents and How to Prevent Them - OSHA.com (https://osha.com/blog/5-most-common-forklift-accidents-and-how-to-prevent-them)

- Work Safety: Forklifts - Injury Facts (https://injuryfacts.nsc.org/work/safety-topics/forklifts)

- Forklift Injury Statistics 2025 | How to Reduce Forklift Accident Risks (https://certifyme.net/osha-blog/forklift-injuries-key-statistics)

- Identify Suitable Applications: Effective Uses and Common Pitfalls

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Telescopic Forklift Market Size, Trends, Growth | 2033 Report (https://globalgrowthinsights.com/market-reports/telescopic-forklift-market-111215)

- Telehandler Market Size, Share & Growth | Forecast 2035 (https://expertmarketresearch.com/reports/telehandler-market)

- Telescopic Forklift: 13 Ways to Use It and 5 Mistakes to Avoid - Bobcat of North Texas (https://bobcatofnorthtexas.com/knowledge-center/telescopic-forklift-13-ways-to-use-it-and-5-mistakes-to-avoid)

- Maintain Equipment: Best Practices for Longevity and Efficiency

- The Transformative Impact of Preventive Maintenance in Construction (https://maintworld.com/Asset-Management/The-Transformative-Impact-of-Preventive-Maintenance-in-Construction)

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- Telehandler Forklift Maintenance Tips (https://wollongongforklift.com.au/blog/essential-maintenance-tips-for-equipment-when-hiring-a-telehandler-forklift)

- 30 Key Maintenance Statistics & Facts Highlighting 2026 Trends (https://coastapp.com/blog/maintenance-metrics-statistics-facts)

- 4 Tips For Maintaining Telehandlers | JLG (https://jlg.com/en/directaccess/4-tips-for-maintaining-telehandlers)