Key Highlights:

- Key features of skid steer track tools include traction and stability, durability, weight distribution, and versatility for various applications.

- Leading brands for skid steer tracks are Bobcat, Caterpillar (CAT), John Deere, and Kubota, each known for their reliability and performance.

- Best practises for effective tool usage include conducting pre-operation checks, using proper operation techniques, managing load capacity, and ensuring operator training and safety.

- Maintenance tips for skid steer tracks involve regular cleaning, belt tension adjustment, damage examination, and proper lubrication to extend equipment lifespan.

- Operators should avoid common pitfalls, such as using incorrect cleaning tools, to prevent damage to rubber tracks.

Introduction

Skid steer track tools are essential for operators working in challenging terrains. However, many may overlook the critical features that enhance their effectiveness. By grasping the intricacies of traction, durability, and weight distribution, users can optimize their equipment for a range of applications, from construction to landscaping. Yet, the potential for misuse can lead to accidents and equipment failure.

So, how can operators ensure they are using these powerful tools correctly and safely?

Identify Key Features of Skid Steer Track Tools

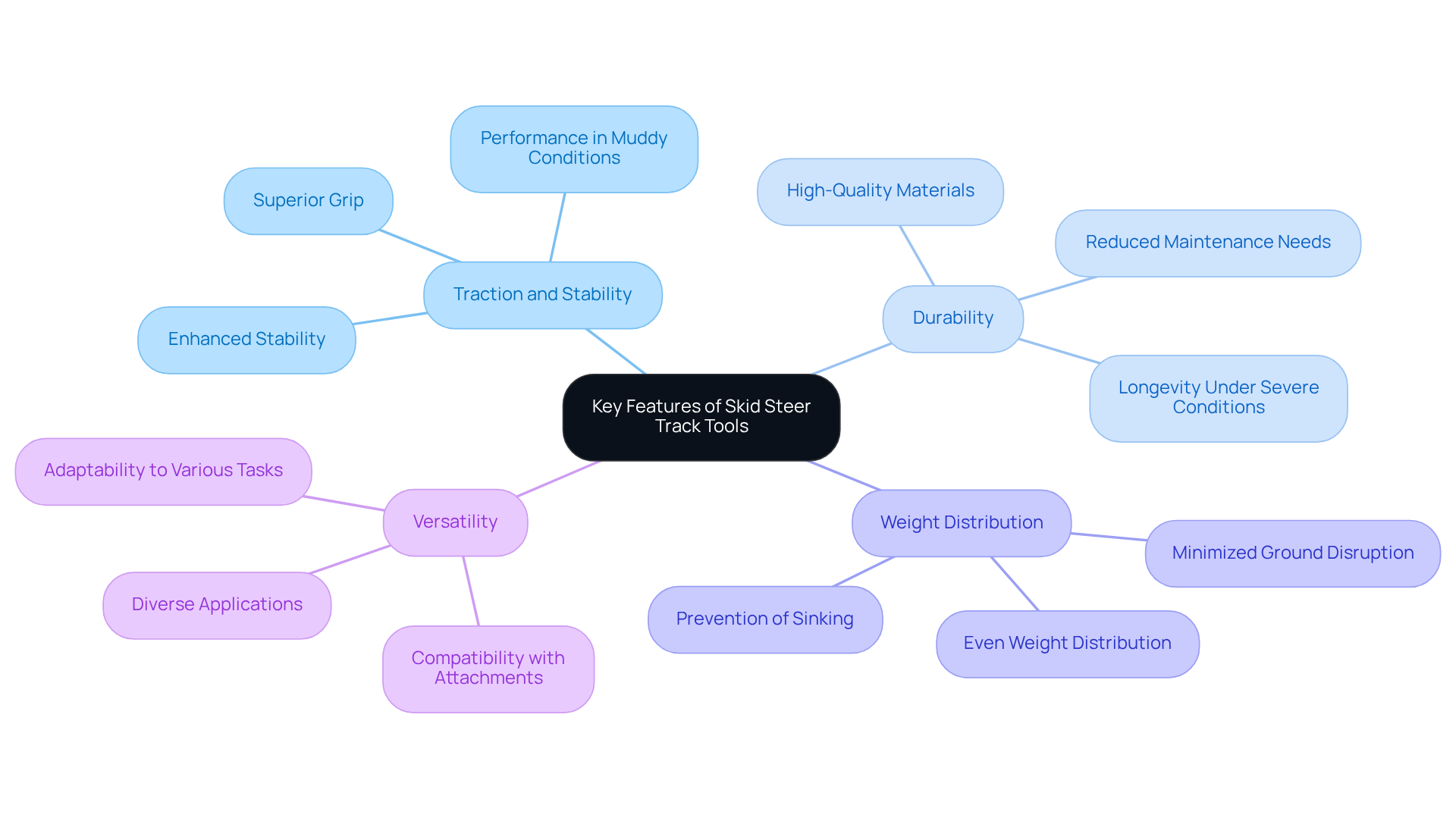

Understanding the key features is essential when selecting skid steer track tools. These features include:

- Traction and Stability: Skid steer tracks provide superior grip on various terrains, enhancing stability during operation. This is particularly important in muddy or uneven conditions.

- Durability: High-quality tracks are designed to endure severe conditions and substantial loads, reducing the need for replacements and maintenance.

- Weight Distribution: Tracks help distribute the vehicle's weight more evenly, minimizing ground disruption and preventing the machine from sinking into soft terrains.

- Versatility: Many compact loader treads are compatible with a variety of attachments, allowing for diverse applications ranging from landscaping to construction.

Understanding these features enables operators to select the right skid steer track tool for their specific needs, ensuring optimal performance and safety on the job site.

Evaluate Leading Brands and Models for Reliability

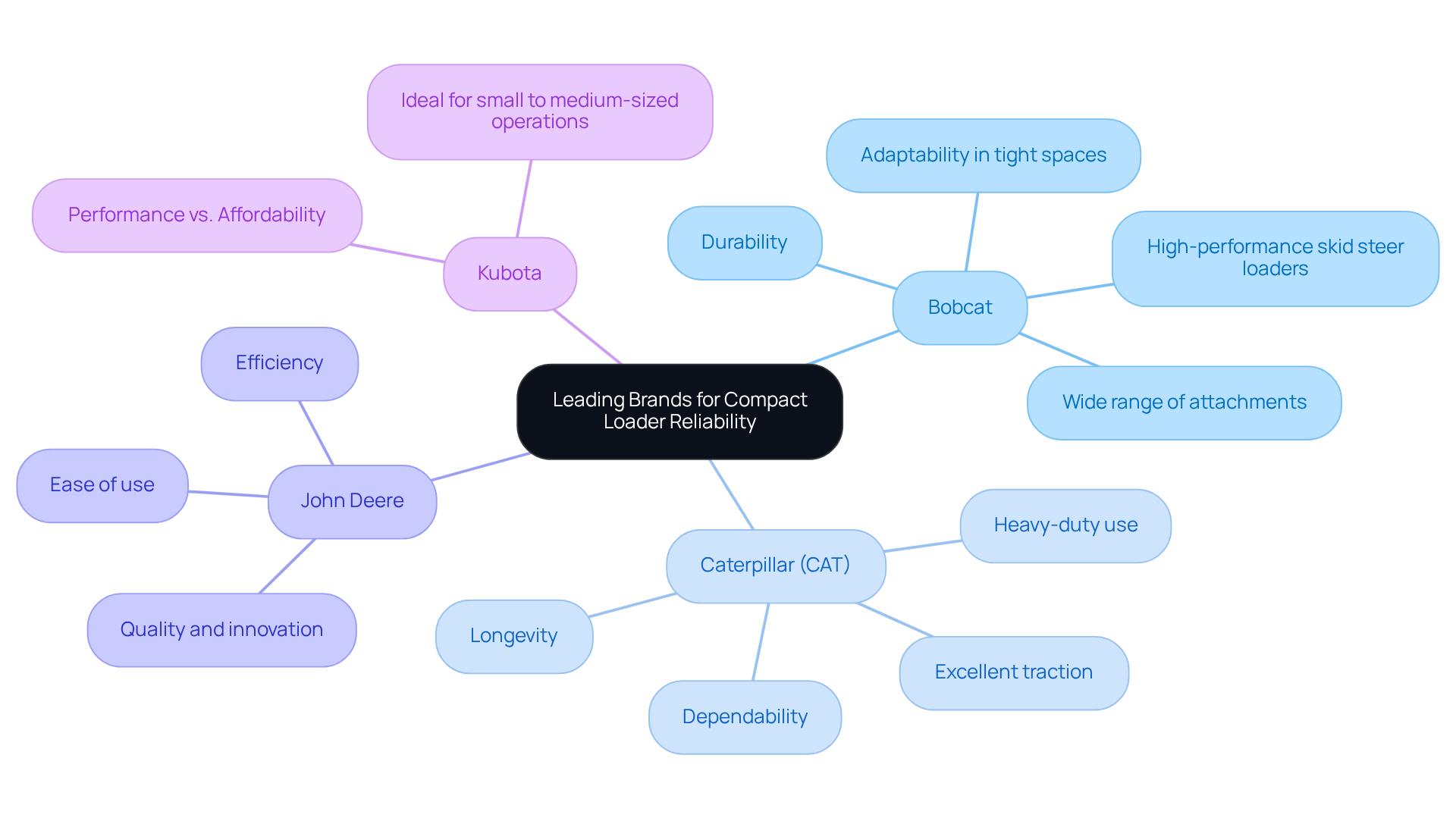

When assessing compact loader equipment, evaluating top brands is crucial for ensuring reliability. Here are some of the leading brands:

- Bobcat: Known for durable and high-performance skid steer loaders, Bobcat offers a range of reliable track options suitable for various applications.

- Caterpillar (CAT): Renowned for robust construction equipment, CAT treads are designed for heavy-duty use, providing excellent traction and longevity.

- John Deere: With a reputation for quality and innovation, John Deere products are engineered for efficiency and ease of use.

- Kubota: Providing a balance of performance and affordability, Kubota treads are favored by small to medium-sized operations.

Researching user reviews and performance ratings can further assist in selecting the best model for specific operational needs.

Implement Best Practices for Effective Tool Usage

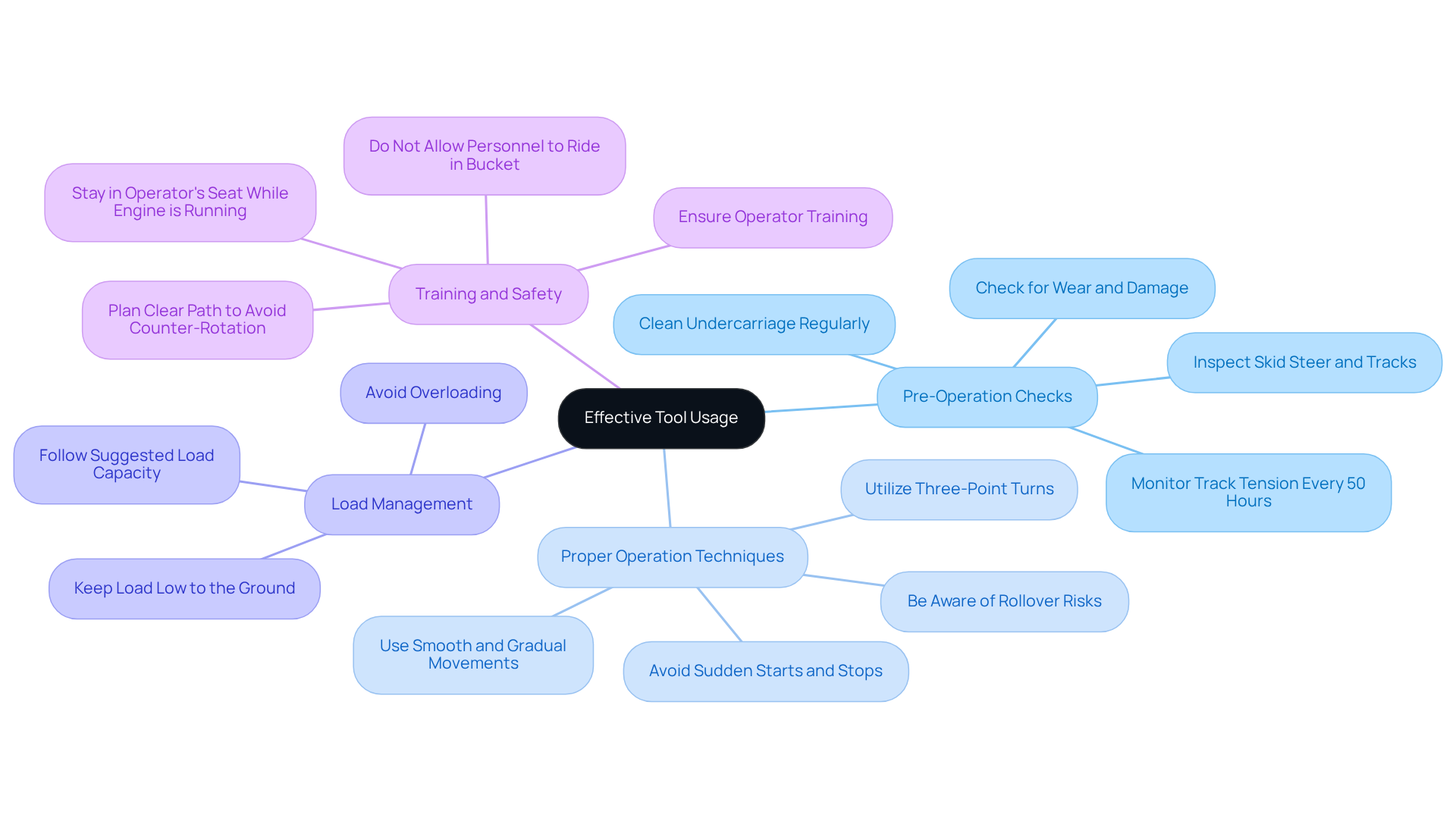

To ensure effective usage of skid steer track tools, operators should adhere to the following best practices:

Pre-Operation Checks: Conduct a thorough inspection of the skid steer and tracks before use. This includes checking for wear, damage, and proper tension. Neglecting these checks can lead to operational issues and increased risk of accidents. Consistent upkeep, including cleaning the undercarriage and monitoring tension, is vital for prolonging rail life and avoiding downtime. It is advised to check the tension of the system every 50 hours to ensure optimal performance.

Proper Operation Techniques: Utilize smooth and gradual movements when operating the machine. Avoid sudden starts and stops, as these can lead to loss of control and potential track damage. For instance, using three-point turns instead of counter-rotations can enhance machine longevity and prevent unnecessary wear. Operators should also be aware that rollovers are a primary cause of injury and death in compact loader operations, making safe operation techniques essential.

Load Management: Follow the suggested load capacity of the vehicle. Overloading increases ground pressure, potentially damaging turf, and heightens the risk of tipping or hydraulic failure. Keeping the load low to the ground enhances stability and safety during operation.

Training and Safety: Ensure all operators are thoroughly trained in the correct use of compact loader equipment and are familiar with safety protocols. This includes understanding the importance of remaining in the operator's seat while the engine is running and never allowing personnel to ride in the bucket or on attachments. Such practices are vital to minimizing risks on the job site, as serious injuries can occur from hitting or crushing someone with moving parts.

Adopting these methods will greatly improve the effectiveness and safety of operations involving compact construction machinery.

Maintain and Care for Skid Steer Track Tools

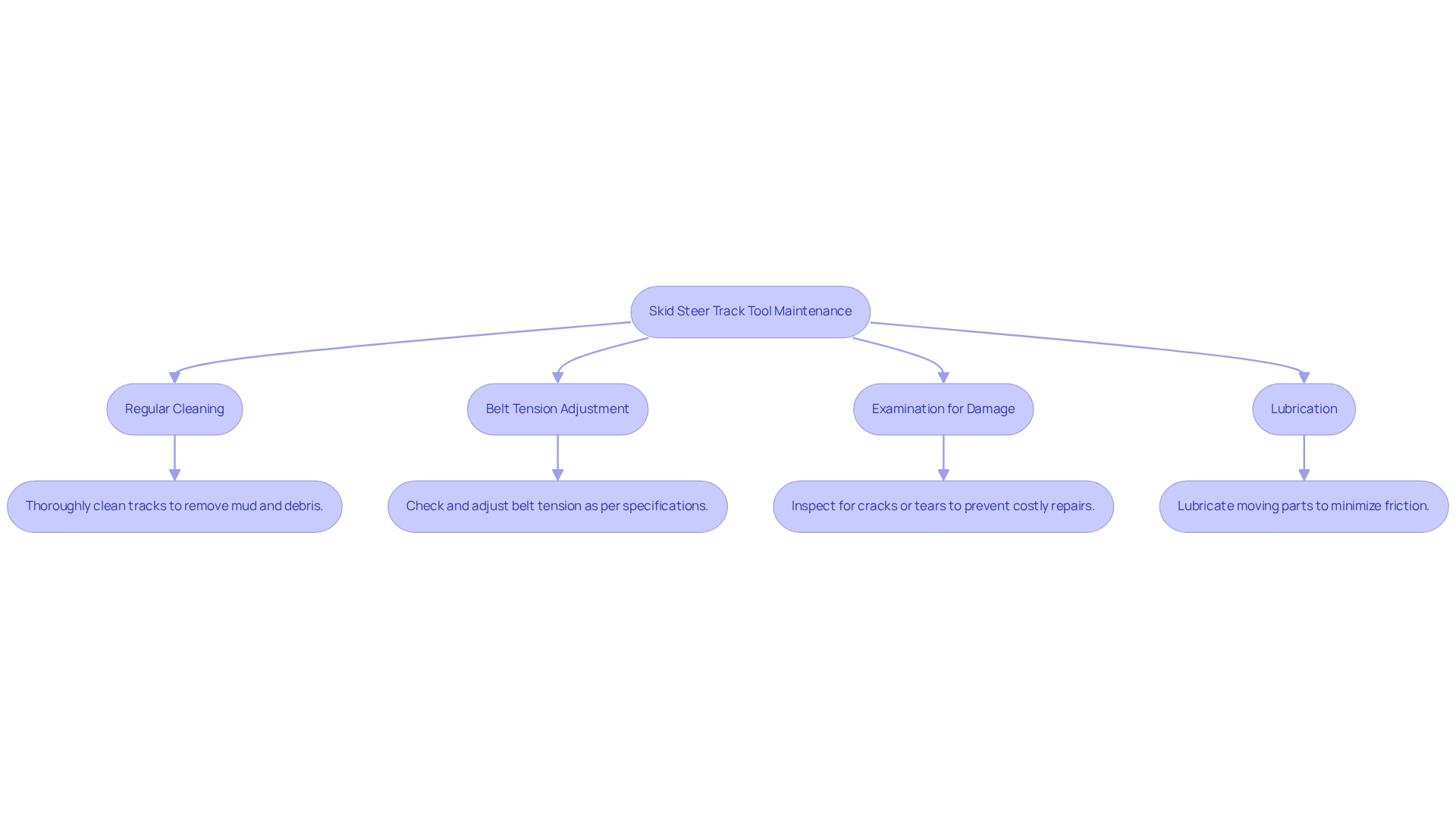

Proper maintenance of the skid steer track tool is essential for ensuring longevity and optimal performance of the equipment. Here are key maintenance tips:

- Regular Cleaning: After each use, thoroughly clean the tracks to remove mud, debris, and contaminants that can accelerate wear. As noted by Inland Truck & Equipment, "Maintaining your rubber treads clean is crucial for avoiding damage." Regular cleaning is vital for preserving the integrity of the pathways.

- Belt Tension Adjustment: Regularly check and adjust the belt tension according to the manufacturer's specifications. Tracks that are too tight can lead to excessive wear, while those that are too loose may derail. Correct tension is crucial for optimal performance and longevity.

- Examination for Damage: Regularly inspect pathways for signs of damage, such as cracks or tears. Routine examination of rubber pathways can prevent costly repairs and interruptions. Early identification of issues can avert further decline, as illustrated in the case study 'Ignoring Small Issues,' which emphasizes the importance of addressing minor rail damage promptly.

- Lubrication: Ensure that all moving parts are adequately lubricated to minimize friction and wear. Follow the manufacturer's guidelines for lubrication intervals to keep equipment in top condition.

By implementing these maintenance practices and using the skid steer track tool, operators can significantly extend the lifespan of their skid steer equipment and ensure optimal performance, ultimately leading to more efficient project execution. Additionally, be mindful of common pitfalls, such as using incorrect cleaning tools, which can damage rubber tracks. Adhering to these guidelines will facilitate effective equipment maintenance.

Conclusion

In conclusion, effectively utilizing skid steer track tools is essential for optimizing performance and ensuring safety on the job site. By concentrating on key features, selecting reputable brands, adhering to best practices, and maintaining equipment diligently, operators can confidently manage a variety of tasks with efficiency and safety.

This article has highlighted critical factors such as traction, durability, and weight distribution of skid steer tracks. It has also stressed the importance of conducting pre-operation checks, employing proper operation techniques, and managing loads to enhance both safety and functionality. Furthermore, the significance of regular maintenance practices - such as cleaning, tension adjustments, and inspections - has been underscored to extend the lifespan of the equipment.

Adopting these best practices not only boosts operational efficiency but also mitigates the risk of accidents and equipment failures. As the construction and landscaping sectors evolve, staying updated on the latest tools and techniques empowers operators to face challenges with assurance. By prioritizing safety and maintenance, individuals can ensure their skid steer track tools perform at their best, ultimately contributing to successful project outcomes.

Frequently Asked Questions

What are the key features of skid steer track tools?

The key features of skid steer track tools include traction and stability, durability, weight distribution, and versatility.

How do skid steer tracks enhance traction and stability?

Skid steer tracks provide superior grip on various terrains, which enhances stability during operation, especially in muddy or uneven conditions.

Why is durability important for skid steer tracks?

Durability is important because high-quality tracks are designed to endure severe conditions and substantial loads, reducing the need for replacements and maintenance.

How do tracks affect weight distribution in skid steers?

Tracks help distribute the vehicle's weight more evenly, minimizing ground disruption and preventing the machine from sinking into soft terrains.

What applications can benefit from the versatility of skid steer tracks?

The versatility of skid steer tracks allows them to be compatible with a variety of attachments, making them suitable for diverse applications ranging from landscaping to construction.

List of Sources

- Identify Key Features of Skid Steer Track Tools

- (https://wickhamtractor.com/blog-posts/how-long-do-skid-steer-tracks-last)

- Future of Skid Steers Discover Top 8 Trends in 2026 (https://skidsteerloader.net/future-of-skid-steers-innovation-in-2026)

- Trendlines: Construction equipment shifts from wheels to tracks (https://powerprogress.com/news/trendlines-construction-equipment-sees-shift-from-wheels-to-tracks/8112491.article)

- The State of Skid Steers and Compact Track Loaders in 2026 (https://compactequip.com/compact-track-loaders/the-state-of-skid-steers-and-compact-track-loaders-in-2026)

- The Benefits of Reliable Skid Steer Tracks for Heavy Tasks (https://gatortrack.com/news/the-benefits-of-reliable-skid-steer-tracks-for-heavy-tasks)

- Evaluate Leading Brands and Models for Reliability

- The State of Skid Steers and Compact Track Loaders in 2026 (https://compactequip.com/compact-track-loaders/the-state-of-skid-steers-and-compact-track-loaders-in-2026)

- Which are the Top 15 Skid Steer Brands to Consider in 2024? (https://hixenmachinery.com/the-top-15-skid-steer-brands-to-consider)

- Implement Best Practices for Effective Tool Usage

- Best Practices for CTL and Skid Steer Operation - Lashley Kubota (https://lashleykubota.com/blog/best-practices-for-ctl-and-skid-steer-operation)

- Experts' Tips: Avoid these track loader mistakes | Landscape Management (https://landscapemanagement.net/experts-tips-avoid-these-track-loader-mistakes)

- Best Practices | Heavy Equipment Best Practices (https://heavymachinesllc.com/6-key-best-practices-for-compact-track-loader-and-skid-steer-operation)

- Maintain and Care for Skid Steer Track Tools

- Rubber Track Maintenance Tips: Keep Your Equipment Running Smoothly (https://inland-group.ca/news-resources/rubber-track-maintenance-tips-keep-your-equipment-running-smoothly)