Key Highlights:

- Transit laser levels are precision instruments used in construction and surveying to establish horizontal and vertical planes accurately.

- These tools minimise human error, enhancing project success and safety by providing precision that traditional methods cannot match.

- Rotary optical devices are popular for their 360-degree alignment capabilities, achieving precision within ±1/16 inch at 100 feet.

- The construction equipment market was valued at over $2.5 billion USD in 2022, with a projected growth rate exceeding 4% through 2032.

- Choosing the right transit laser level involves considering factors like range, precision, and features tailored to specific project needs.

- Models like the Topcon RL-H5A are ideal for large outdoor projects, while compact models suit smaller indoor tasks.

- Regular calibration and maintenance are crucial for ensuring the accuracy and reliability of transit laser levels.

- Best practises for operating these tools include verifying calibration, maintaining stability during use, and avoiding instrument movement once set up.

Introduction

Transit laser levels have transformed the construction and surveying industries by providing unmatched precision in establishing horizontal and vertical planes. As projects increase in complexity and scale, it becomes essential for professionals to understand how to effectively utilize these tools to enhance accuracy and efficiency. However, despite their importance, many users encounter common pitfalls that can undermine their effectiveness. To ensure optimal performance and reliability when using transit laser levels, it is crucial to adopt best practices that address these challenges.

Understand Transit Laser Levels: Definition and Importance

Transit laser levels are essential precision instruments in construction and surveying, designed to establish both horizontal and vertical planes with remarkable accuracy. By projecting a light beam, these tools enable users to measure and align structures with a level of precision that traditional leveling techniques cannot achieve. Their role in modern construction practices is significant, as they substantially minimize human error, a critical factor in project success.

For instance, rotary optical devices, which dominate the market, are known for their 360-degree continuous alignment capability, making them indispensable for various applications, from grading to interior construction. Expert assessments indicate that the precision of optical measuring tools can reach within ±1/16 inch at 100 feet, highlighting their reliability in meeting safety and quality standards.

The construction equipment market was valued at over $2.5 billion USD in 2022 and is expected to grow at a compound annual growth rate exceeding 4% from 2023 to 2032, reflecting the rising demand for precision tools in the industry. Additionally, a projected 9.2% increase in contractor activity in 2024 underscores the growing importance of the transit laser level in future projects.

As the construction sector evolves, the integration of advanced optical technology continues to enhance productivity and efficiency, making the transit laser level vital for professionals aiming for accuracy in their work. However, it is essential for users to receive adequate training to prevent misapplication, ensuring these tools are utilized to their fullest potential.

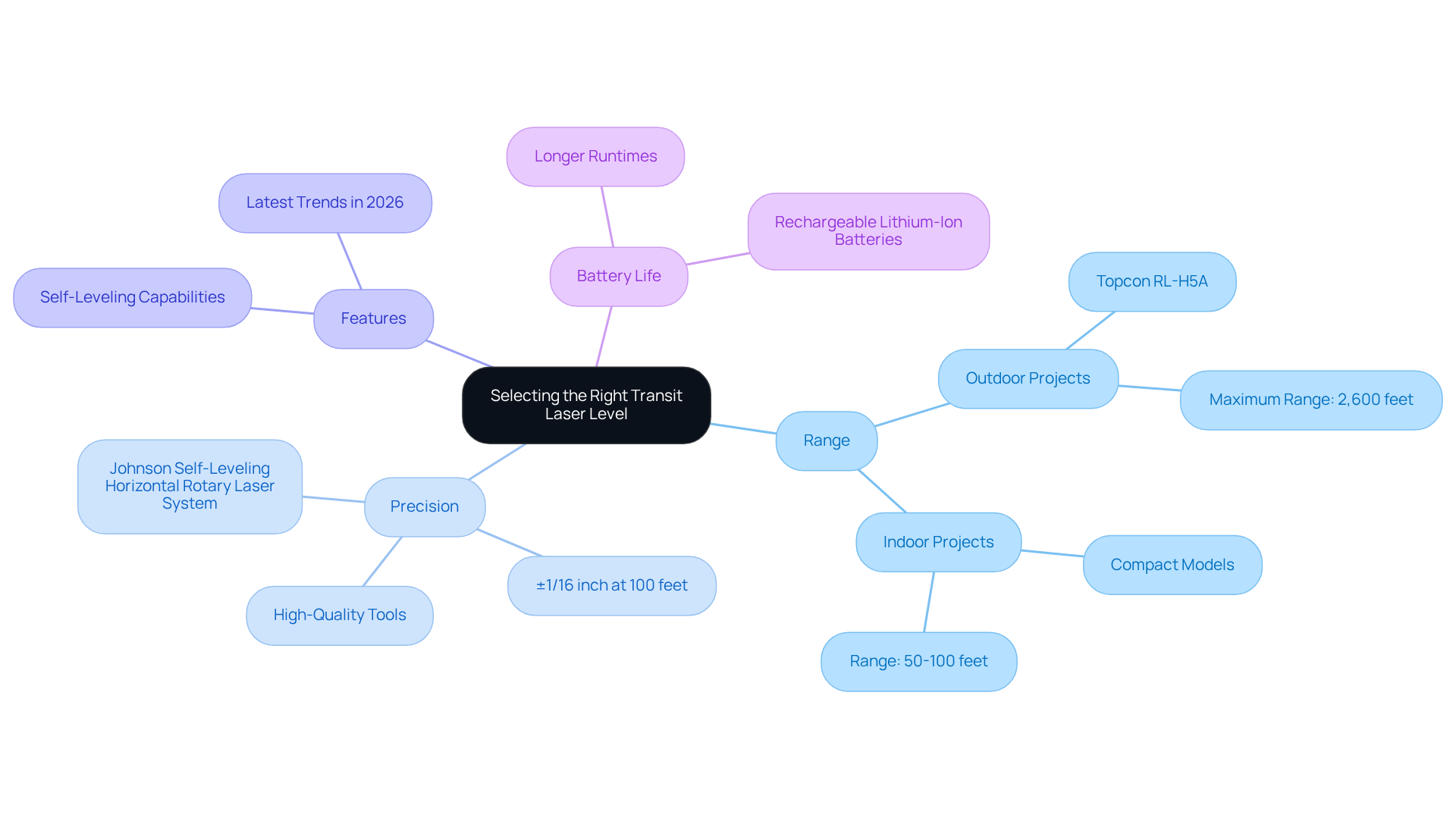

Select the Right Transit Laser Level for Your Project Needs

It is essential to choose the right transit laser level for the success of your project. Key factors to consider include range, precision, and specific features tailored to your needs. For larger outdoor projects, models with an extended range, such as the Topcon RL-H5A, are ideal, reaching up to 2,600 feet in diameter to ensure visibility across expansive sites. In contrast, compact models are better suited for smaller indoor tasks, where a range of 50 to 100 feet is sufficient.

Precision is another critical requirement; a high-quality tool, such as a transit laser level, should achieve a precision of ±1/16 inch at 100 feet, which is vital for accurate tasks. For instance, the Johnson Self-Leveling Horizontal Rotary Laser System offers a precision of ±1/8 inch at 50 feet, making it a reliable choice for various applications. Additionally, consider the latest features available in 2026, such as self-leveling capabilities that correct for bumps and disturbances, typically self-leveling within 4 to 5 degrees, enhancing usability on active job sites.

Construction experts emphasize the importance of selecting a precise tool, like a transit laser level, that aligns with task specifications. As one specialist noted, "Choosing the right tool can significantly impact the effectiveness and accuracy of your work, especially in grading and layout tasks." Furthermore, manufacturers like DeWalt stress that battery life and type are crucial considerations, as rechargeable lithium-ion batteries can provide longer runtimes and lower ongoing costs. Understanding these specifications and trends will empower you to select a tool that not only meets your project's demands but also optimizes time and resource management.

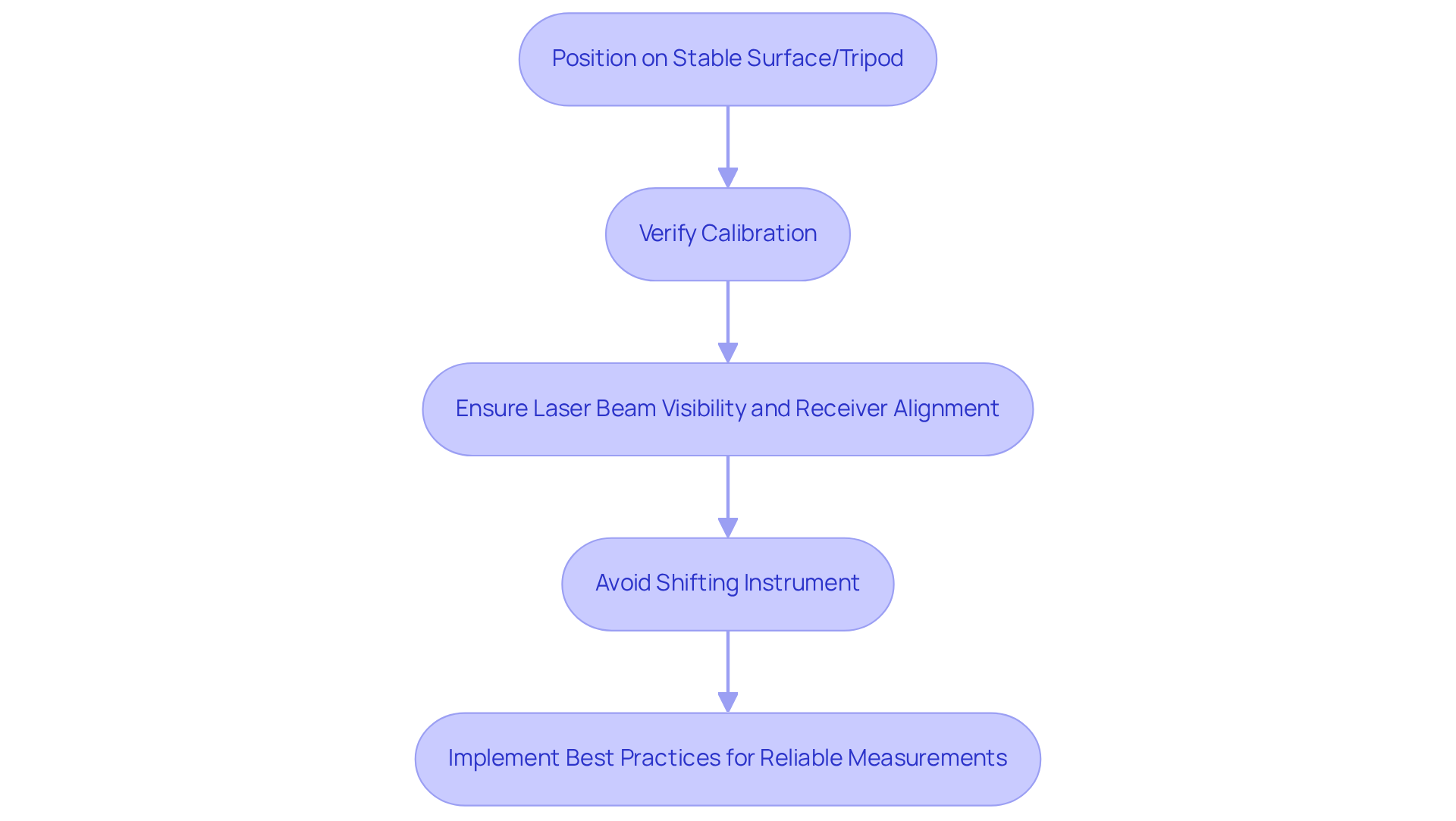

Implement Best Practices for Operating Transit Laser Levels

To operate the transit laser level effectively, position the device on a stable surface or tripod to ensure optimal precision. Before use, verify the calibration, as even minor misalignments can lead to significant measurement errors. Calibration is an ongoing process that requires regular checks to maintain precision. When taking measurements, ensure that the transit laser level's laser beam is clearly visible and that the receiver is correctly aligned.

It is crucial to avoid shifting the instrument once it is set up, as this can disturb the alignment and compromise accuracy. Neglecting calibration can lead to serious consequences, including inaccurate measurements that may result in costly rework or safety hazards on the job site.

By implementing these best practices, you will enhance the reliability and precision of your measurements throughout the project, ultimately contributing to successful outcomes.

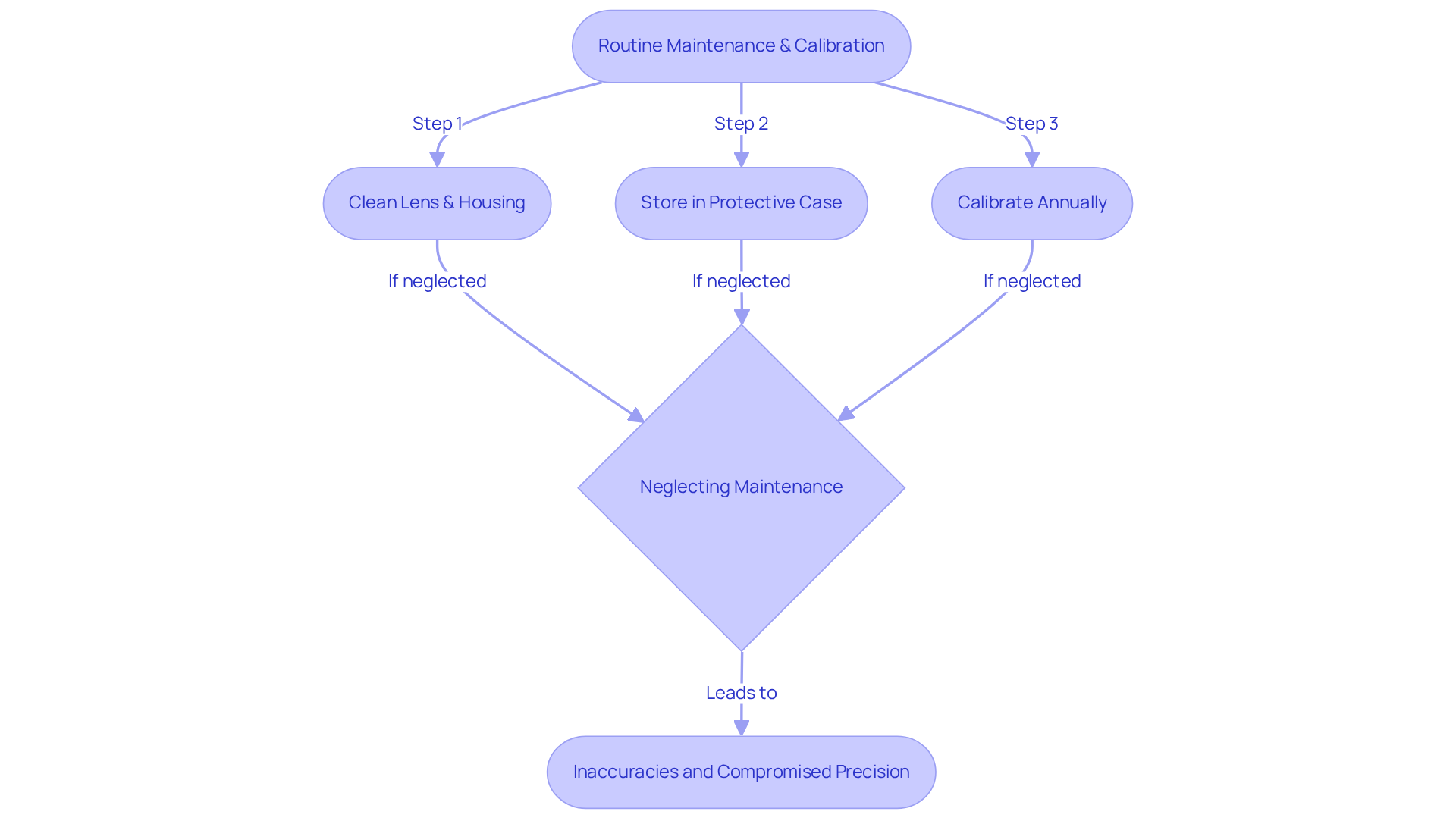

Maintain and Calibrate Transit Laser Levels for Optimal Performance

To ensure optimal performance of the transit laser level devices, implementing a routine maintenance and calibration schedule is essential. Regular cleaning of the lens and housing with a soft, lint-free cloth prevents dust and debris from compromising accuracy. Additionally, storing the equipment in a protective case safeguards it from potential damage. Calibration should occur at least annually, or more frequently for tools subjected to heavy use. Industry experts recommend that "calibration should occur at least once a year, especially when the item is a high-use piece of equipment." This process involves verifying the level against established benchmarks and making necessary adjustments to maintain precision.

Neglecting these practices can lead to significant inaccuracies, jeopardizing quality and adherence to industry standards. Several case studies emphasize that failing to carry out regular calibration can cause instruments to go out of calibration, leading to compromised precision that influences results. By adhering to these maintenance protocols, you enhance the reliability of your transit laser level, ultimately improving the outcomes of your construction projects.

Conclusion

Transit laser levels are essential tools in the construction and surveying industries, offering unparalleled precision in establishing horizontal and vertical planes. Their capacity to reduce human error and improve accuracy is vital for achieving successful project outcomes. As the construction sector evolves, it becomes increasingly important for professionals to understand how to effectively utilize these instruments to meet safety and quality standards.

This article outlines best practices for using transit laser levels, including:

- Selecting the right model based on project requirements

- Implementing effective operating procedures

- Maintaining calibration for optimal performance

Key factors such as range, precision, and the latest features must be carefully considered to ensure the appropriate tool is chosen for specific tasks. Furthermore, regular maintenance and calibration are crucial to prevent inaccuracies that could compromise project integrity.

Incorporating these best practices not only enhances the reliability of measurements but also contributes to the overall success of construction projects. By prioritizing the proper usage and maintenance of transit laser levels, professionals can significantly improve their work quality and efficiency. Embracing these insights empowers users to leverage the full potential of transit laser levels, ensuring they remain at the forefront of precision in construction and surveying.

Frequently Asked Questions

What are transit laser levels?

Transit laser levels are precision instruments used in construction and surveying to establish horizontal and vertical planes with high accuracy by projecting a light beam.

Why are transit laser levels important in construction?

They significantly minimize human error and enhance precision in measuring and aligning structures, which is crucial for the success of construction projects.

What is the accuracy of optical measuring tools like transit laser levels?

Optical measuring tools can achieve precision within ±1/16 inch at 100 feet, making them reliable for meeting safety and quality standards.

What is the market value of construction equipment, including transit laser levels?

The construction equipment market was valued at over $2.5 billion USD in 2022 and is expected to grow at a compound annual growth rate of over 4% from 2023 to 2032.

What is the projected increase in contractor activity for 2024?

There is a projected 9.2% increase in contractor activity in 2024, highlighting the growing importance of transit laser levels in future construction projects.

How does the integration of advanced optical technology impact the construction sector?

The integration of advanced optical technology enhances productivity and efficiency in construction, making transit laser levels vital for professionals seeking accuracy.

Is training necessary for using transit laser levels?

Yes, adequate training is essential to prevent misapplication and ensure that users can utilize transit laser levels to their fullest potential.

List of Sources

- Understand Transit Laser Levels: Definition and Importance

- Construction Laser Market- Global Growth Insights (https://aptella.com/news/construction-laser-market-global-growth-insights)

- Construction Lasers Market Size | Growth & CAGR of 6.97% (https://industryresearch.biz/market-reports/construction-lasers-market-107993)

- Construction Lasers Market Share and Growth Statistics 2035 (https://factmr.com/report/construction-lasers-market)

- Construction Laser Market Size, Share & Industry Trends – 2032 (https://gminsights.com/industry-analysis/construction-laser-market)

- Laser Levels for Construction Market Size, Share & Growth Trends Analysis by 2034 (https://reportsanddata.com/report-detail/laser-levels-for-construction-market)

- Select the Right Transit Laser Level for Your Project Needs

- Choosing The Right Tool | LevelPedia | Laser Level | Torpedo Levels | Tape Measure | Squares | Levels | Johnson Level & Tool Mfg Company (https://johnsonlevel.com/LevelPedia34)

- Laser Level Buying Guide | How to Choose & Use (https://lightyx.com/post/guide-to-laser-levels-what-to-know-before-you-buy)

- The Best Rotary Laser Levels, Tested and Reviewed (https://bobvila.com/articles/best-rotary-laser-levels)

- Laser Comparison Charts (https://contractors-tools.com/laser-comparison-charts?srsltid=AfmBOophNzCzkNkG9WPGBkCEw-ETX1dQoMon-Vcqh3LUP7D3PuFoKufU)

- Construction Level: Buying Guide (https://engineersupply.com/Construction-level-Buying-Guide.aspx?srsltid=AfmBOoofuAVRiCXYU8uI4zD2326zz7vy42HD-iEAZ_bXibbE-IF1PUUV)

- Implement Best Practices for Operating Transit Laser Levels

- Why Calibration of Measuring Instruments Is Crucial for Accuracy (https://prismcalibration.com/importance-of-calibrating-measuring-instruments)

- Why Calibration Matters in Manufacturing | ATS (https://advancedtech.com/blog/why-manufacturers-should-care-about-calibration)

- Measurement Accuracy in Construction: Why It Matters (https://perfectmeasuringtape.com/blog/uncategorized/measurement-accuracy-in-construction-why-it-matters)

- The Importance of Instrument Calibration: Ensuring Accuracy and Precision in Every Measurement - Calibration Lab (https://ips-us.com/the-importance-of-instrument-calibration-ensuring-accuracy-and-precision-in-every-measurement)

- Maintain and Calibrate Transit Laser Levels for Optimal Performance

- 7 Reasons to Calibrate Your Laser Tracker Today (https://apimetrology.com/7-reasons-to-calibrate-your-laser-tracker-today)

- Why you should calibrate your measurement system (https://easylaser.com/en-us/about-easy-laser/blog/why-you-should-calibrate-your-measurement-system)

- Laser Level Tool Maintenance Tips for Accuracy & Long-Term Performance (https://omadatools.com/blogs/media-and-updates/laser-level-tool-maintenance-tips?srsltid=AfmBOore7Q8e3FQK2HagZWJlluV_DHjMW5gWKGW8kPe3Z_8_CNsZYC69)

- The Impact of Regular Calibration on the Performance of Laboratory Instruments (https://rootsmetrology.com/blog/the-impact-of-regular-calibration-on-the-performance-of-laboratory-instruments)