Key Highlights:

- Skid steer trenchers feature adjustable depth control, allowing operators to customise trench depths for various applications.

- Depth settings range from 4 to 48 inches with trench widths of 6 to 8 inches, enhancing compliance and minimising errors.

- Modern trenchers, like the Skid Steer Trencher X-TREME, utilise advanced engines for improved efficiency and consistent operator controls.

- Skid steer trenchers are cost-effective, with lower rental costs compared to larger equipment, aiding project supervisors in budget management.

- High-quality hydraulic motors and gearboxes ensure reliable operation and reduce failure rates, crucial for meeting project deadlines.

- Versatile chain configurations allow trenchers to adapt to various soil types, enhancing digging efficiency and reducing equipment wear.

- Regular maintenance is essential for maximising the durability and performance of skid loaders, ensuring reliable operation.

Introduction

Skid steer trenchers have become essential tools for project managers, providing a combination of efficiency, precision, and adaptability in various excavation tasks. With features such as adjustable depth control and versatile chain configurations, these machines streamline operations and significantly lower costs compared to traditional trenching methods.

However, the challenge persists: how can managers ensure they select the right trencher that meets diverse project requirements while maximizing performance and reliability?

This article explores the key features of skid steer trenchers that can enhance project success and optimize resource allocation.

Adjustable Depth Control for Precision Trenching

Skid steer trenchers equipped with adjustable depth control allow operators to customize trench depths according to specific task requirements. This feature is crucial for ensuring that trenches comply with precise standards for utility installations, drainage systems, and landscaping projects. By facilitating accurate depth adjustments, supervisors can minimize costly mistakes and ensure compliance with local regulations.

Modern models, including the skid steer trencher, such as the Skid Steer Trencher X-TREME, provide depth settings from 4 to 48 inches and adjustable trench widths of 6 to 8 inches, effectively catering to various applications and soil conditions. The latest advancements in trenching technology, including the introduction of the new Cummins 121-horsepower engine in the RT125 models, have further enhanced operational efficiency and precision. Consistent operator controls across different models contribute to this improvement, ensuring a reliable user experience.

Moreover, regular maintenance is vital for ensuring the durability and efficiency of skid loaders, enabling project managers to maximize their investment in machinery. As Desirae emphasizes, 'Proper upkeep of your skid loader is essential for its durability and performance.' This underscores the importance of maintenance in achieving optimal equipment reliability.

Efficiency and Budget-Friendly Design

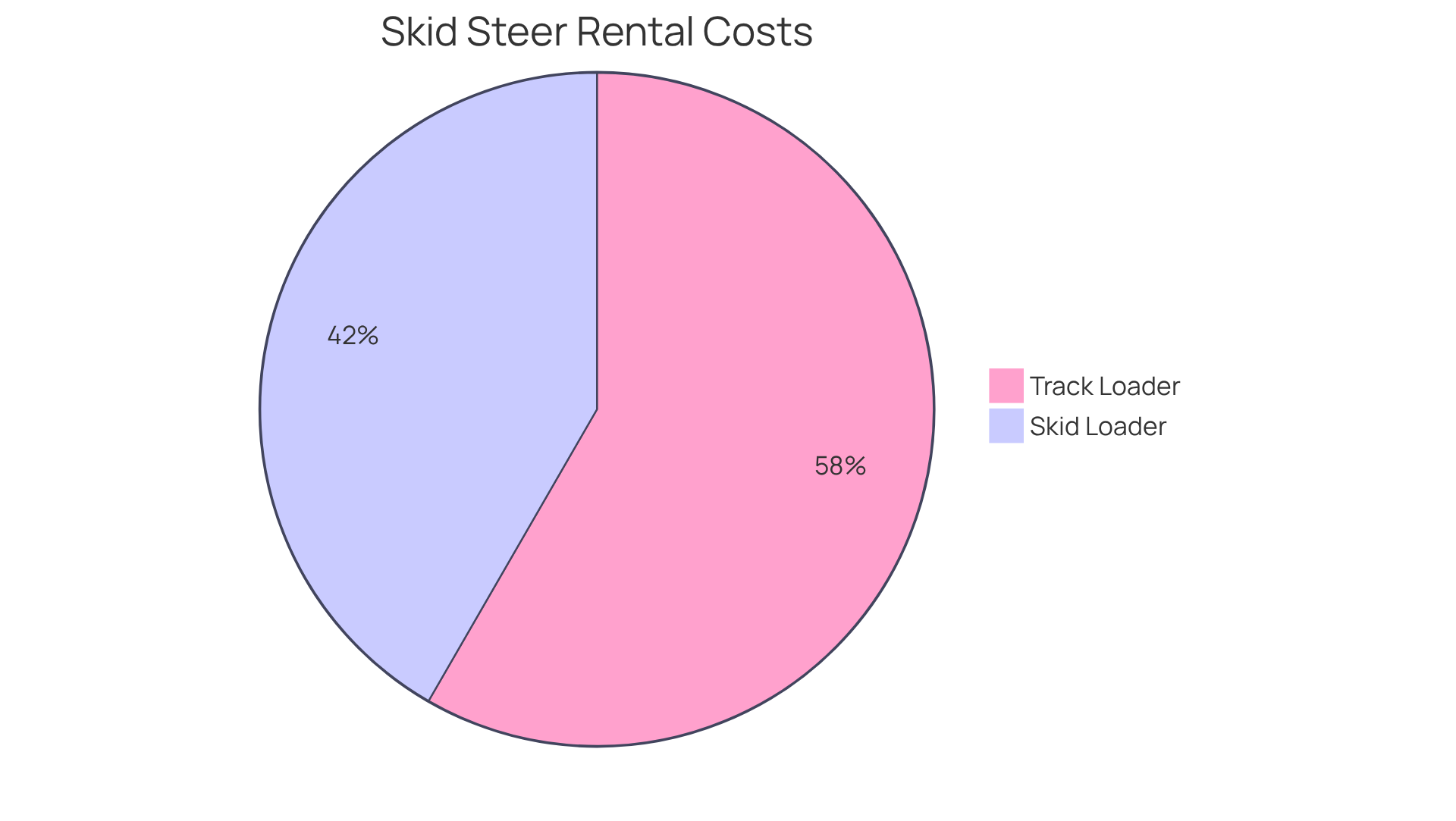

Skid steer trenchers are engineered for optimal efficiency, significantly enhancing trenching operations compared to traditional excavation methods. Their compact design and powerful engines enable them to navigate tight spaces while maintaining high productivity. Notably, these machines typically incur lower rental costs than larger equipment; for instance, a 1,000-pound skid loader is priced at around $250 per day, while a 1,900-pound track loader can exceed $350 daily. This makes them a cost-effective choice for project supervisors. By reducing labor time and minimizing equipment rental expenses, managers can allocate resources more effectively, ultimately boosting profitability.

Furthermore, the versatility of skid loaders, equipped with adjustable tools for various soil types, ensures they meet diverse project requirements without incurring excessive costs. As noted by McLaren Industries:

- "skid loaders are significantly more efficient in accomplishing tasks," highlighting their utility across a range of applications.

High-Quality Motor and Gearbox for Reliability

The effectiveness of a skid steer trencher is fundamentally linked to the quality of its motor and gearbox. High-performance hydraulic motors paired with durable gearboxes are essential for ensuring smooth operation across diverse conditions, delivering consistent power and torque. This reliability is especially crucial for managers facing stringent deadlines.

Machines outfitted with advanced planetary gear systems perform exceptionally well in tough soil conditions, significantly reducing the likelihood of failures and ensuing delays. Investing in high-quality gearboxes not only enhances operational efficiency but also lowers failure rates, ultimately leading to successful project completions. Regular maintenance, including fluid checks and inspections for leaks, is vital for maintaining this reliability.

As noted by industry expert Stefano ‘Stephen’ Leghissa, "This is a smarter machine. Our new control system allows even inexperienced operators to operate the machine, helping it reach optimal performance." By focusing on both quality and upkeep, supervisors can ensure their machines operate dependably, fulfilling deadlines efficiently.

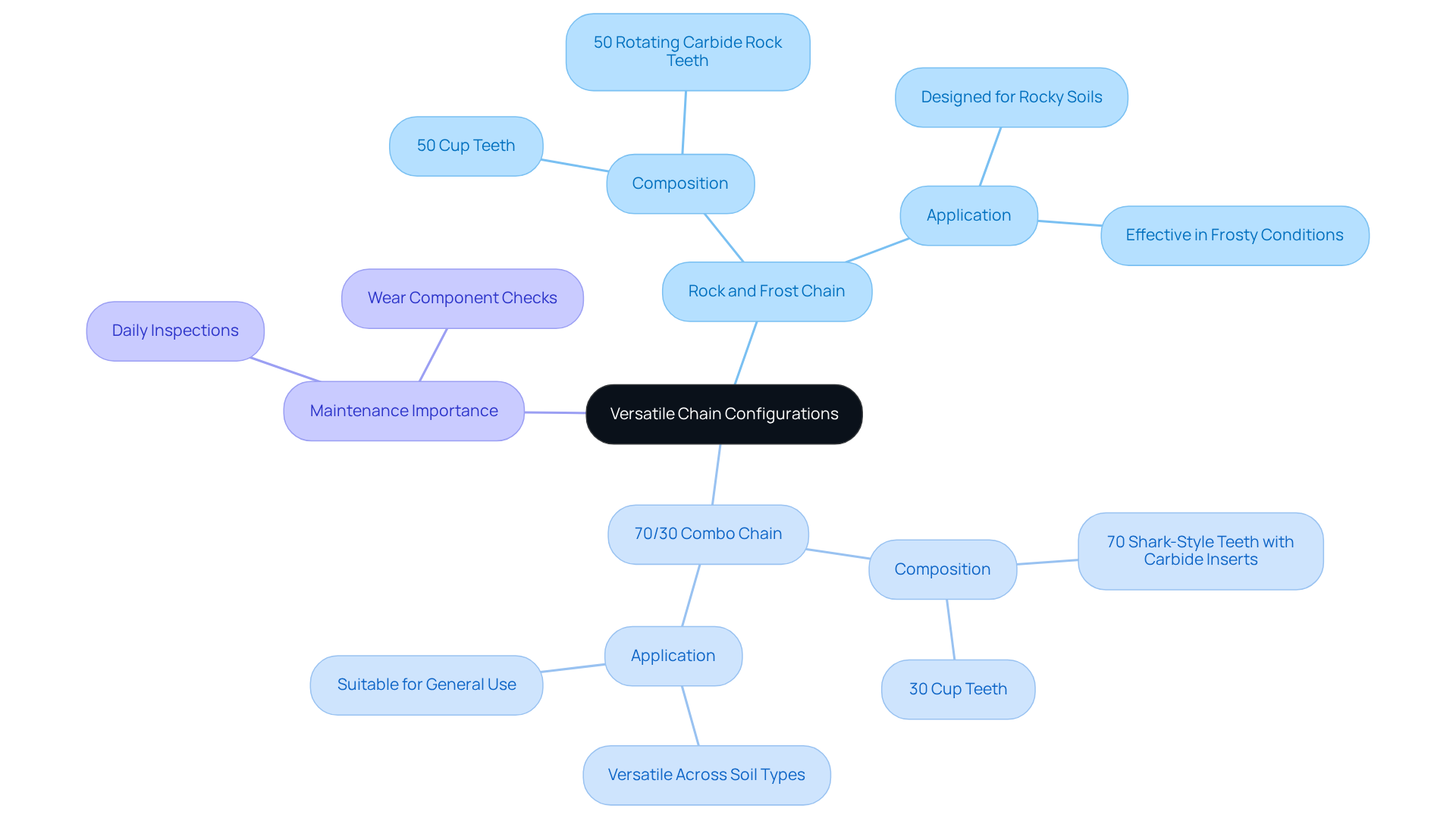

Versatile Chain Configurations for Different Soil Types

Skid steer trenchers are designed with versatile chain configurations that can be customized for different soil types, from soft dirt to rocky terrain. This adaptability is crucial for managers dealing with diverse on-site conditions. For instance, specialized chains are available for specific applications, such as those designed for clay or rocky soils.

- The Rock and Frost chain, which includes 50% cup teeth and 50% rotating carbide rock teeth, excels in challenging environments.

- In contrast, the 70/30 Combo chain, comprising 70% shark-style teeth with carbide inserts and 30% cup teeth, provides versatility across different soil types.

By selecting the appropriate chain configuration for the skid steer trencher, operators can significantly enhance efficiency in digging, minimize equipment wear, and ensure smoother execution. Additionally, regular maintenance, including daily inspections of wear components like chains, is vital for the longevity of excavation machines. This strategic approach not only boosts productivity but also extends the trencher's lifespan, making it a prudent investment for any construction project.

Conclusion

Skid steer trenchers are essential tools for project managers aiming for efficiency and precision in trenching operations. Their adjustable depth control, high-quality motors, versatile chain configurations, and cost-effective design not only boost productivity but also ensure adherence to project specifications. By grasping these critical features, managers can make informed choices that enhance both performance and cost-effectiveness.

Key arguments emphasize the significance of:

- Adjustable depth control for accurate trenching

- The efficiency and affordability of skid steer trenchers compared to traditional methods

- The reliability offered by high-quality motors and gearboxes

- The adaptability of chain configurations for different soil types

Each of these factors contributes to a smoother workflow and minimizes the risk of costly delays, highlighting the importance of selecting the right equipment for specific project requirements.

Ultimately, leveraging the advantages of skid steer trenchers can lead to more successful project outcomes. Project managers should prioritize these features when choosing trenching equipment, as this not only improves operational efficiency but also ensures timely project completion within budget. Investing in reliable and versatile trenchers empowers teams to address diverse challenges, paving the way for increased productivity and profitability in construction projects.

Frequently Asked Questions

What is adjustable depth control in skid steer trenchers?

Adjustable depth control allows operators to customize trench depths according to specific task requirements, ensuring compliance with precise standards for utility installations, drainage systems, and landscaping projects.

What are the benefits of using adjustable depth control in trenching?

This feature minimizes costly mistakes and ensures compliance with local regulations by facilitating accurate depth adjustments.

What are the depth and width settings available in modern skid steer trenchers?

Modern skid steer trenchers, such as the Skid Steer Trencher X-TREME, provide depth settings from 4 to 48 inches and adjustable trench widths of 6 to 8 inches.

How have advancements in technology improved skid steer trenchers?

The introduction of the new Cummins 121-horsepower engine in the RT125 models has enhanced operational efficiency and precision, along with consistent operator controls across different models.

Why is regular maintenance important for skid loaders?

Regular maintenance is vital for ensuring the durability and efficiency of skid loaders, helping project managers maximize their investment in machinery and achieve optimal equipment reliability.

List of Sources

- Adjustable Depth Control for Precision Trenching

- The Advantages of Owning a Skid Steer Trencher Attachment (https://mclarenindustries.com/us/en/news-and-resources/articles/322/the-advantages-of-owning-a-skid-steer-trencher-attachment)

- Modern Trenchers Offer Productivity, Versatility (https://utilitycontractormagazine.com/modern-trenchers-offer-productivity-versatility)

- A Case Study: Trench Stabilization Using Cutter Soil Mixing - New Zealand Geotechnical Society (https://nzgs.org/libraries/a-case-study-trench-stabilization-using-cutter-soil-mixing)

- Trenching Tech Advancements Coming to the Jobsite (https://theutilityexpo.com/news/trenching-tech-advancements-coming-to-the-jobsite)

- The Best Trencher for Skid Steer: A Comprehensive Guide (https://theredbarnguy.com/best-trencher-for-skid-steer)

- Efficiency and Budget-Friendly Design

- The Advantages of Owning a Skid Steer Trencher Attachment (https://mclarenindustries.com/us/en/news-and-resources/articles/322/the-advantages-of-owning-a-skid-steer-trencher-attachment)

- How Much Does a Skid Steer Rental Cost? - Rentalex (https://rentalex.com/how-much-does-a-skid-steer-rental-cost)

- How Much Does It Cost to Rent a Skid Steer? | BigRentz (https://bigrentz.com/blog/how-much-does-it-cost-to-rent-skid-steer?srsltid=AfmBOoqQpiAFB-NQAATog5iNMGJAydnpzNv9FRo9ybKXwrcYGCCnXyTT)

- What Does It Cost to Rent Heavy Equipment | Cat Rentals (https://catrentalstore.com/en_US/blog/cost-to-rent-heavy-equipment.html)

- Maximize Efficiency with Skid Steer Trencher Attachment (https://skidsteerloader.online/maximize-efficiency-with-skid-steer-trencher-attachment)

- High-Quality Motor and Gearbox for Reliability

- Tesmec’s ‘Trenchtronic’ technology takes trenchers towards full automation (https://globalhighways.com/news/tesmecs-trenchtronic-technology-takes-trenchers-towards-full-automation?page=17)

- Trencher Maintenance Guide: Preventive and Scheduling Best Practices - FieldInsight (https://fieldinsight.com/blog/trencher-maintenance)

- Case Studies - Learn How Our Team Helped Improve Performance and Reduce Costs (https://cat.com/en_US/articles/ci-articles/case-studies-fleet-monitoring.html)

- Wind turbine Gearbox failure rate statistics - Find China manufacturer and supplier - HZPT Blog (https://manufacturer.hzpt.com/wind-turbine-gearbox-failure-rate-statistics)

- Versatile Chain Configurations for Different Soil Types

- Improving Trencher Versatility with Attachments (https://theutilityexpo.com/news/improving-trencher-versatility-with-attachments)

- What to Look for in Choosing a Trencher for Skid Steers or Mini Skid Steers - Virnig Manufacturing (https://virnigmfg.com/trencher-for-skid-steers-or-mini-skid-steers)

- Modern Trenchers Offer Productivity, Versatility (https://utilitycontractormagazine.com/modern-trenchers-offer-productivity-versatility)

- Your Guide to Skid Steer Trencher Attachments (https://skidsteersolutions.com/inside-the-cab-skid-steer-solutions/your-guide-to-skid-steer-trencher-attachments?srsltid=AfmBOopeVsE0lrHCoCNOHR3mYHYPo69Nqt7gHyTMe26oTNMxaut8XQk0)