Key Highlights:

- Preventive maintenance is crucial for reducing unexpected forklift breakdowns, potentially decreasing downtime by up to 30%.

- Regular checks of fluid levels, tyres, and battery health are essential components of a preventive maintenance programme.

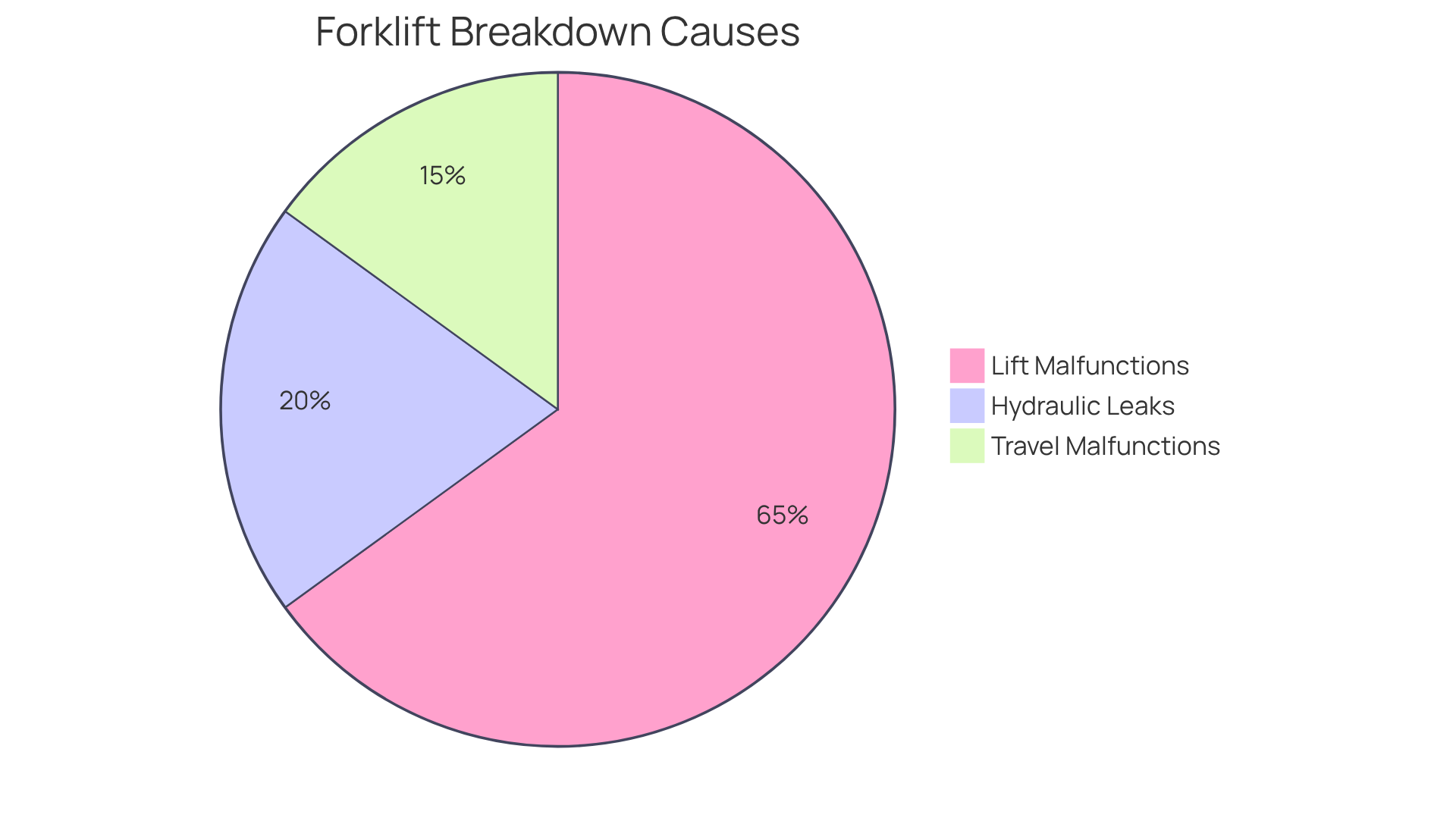

- Hydraulic leaks cause about 20% of forklift breakdowns, while travel and lift malfunctions account for 15% of service calls.

- Maintaining detailed service logs helps identify recurring issues and facilitates timely interventions.

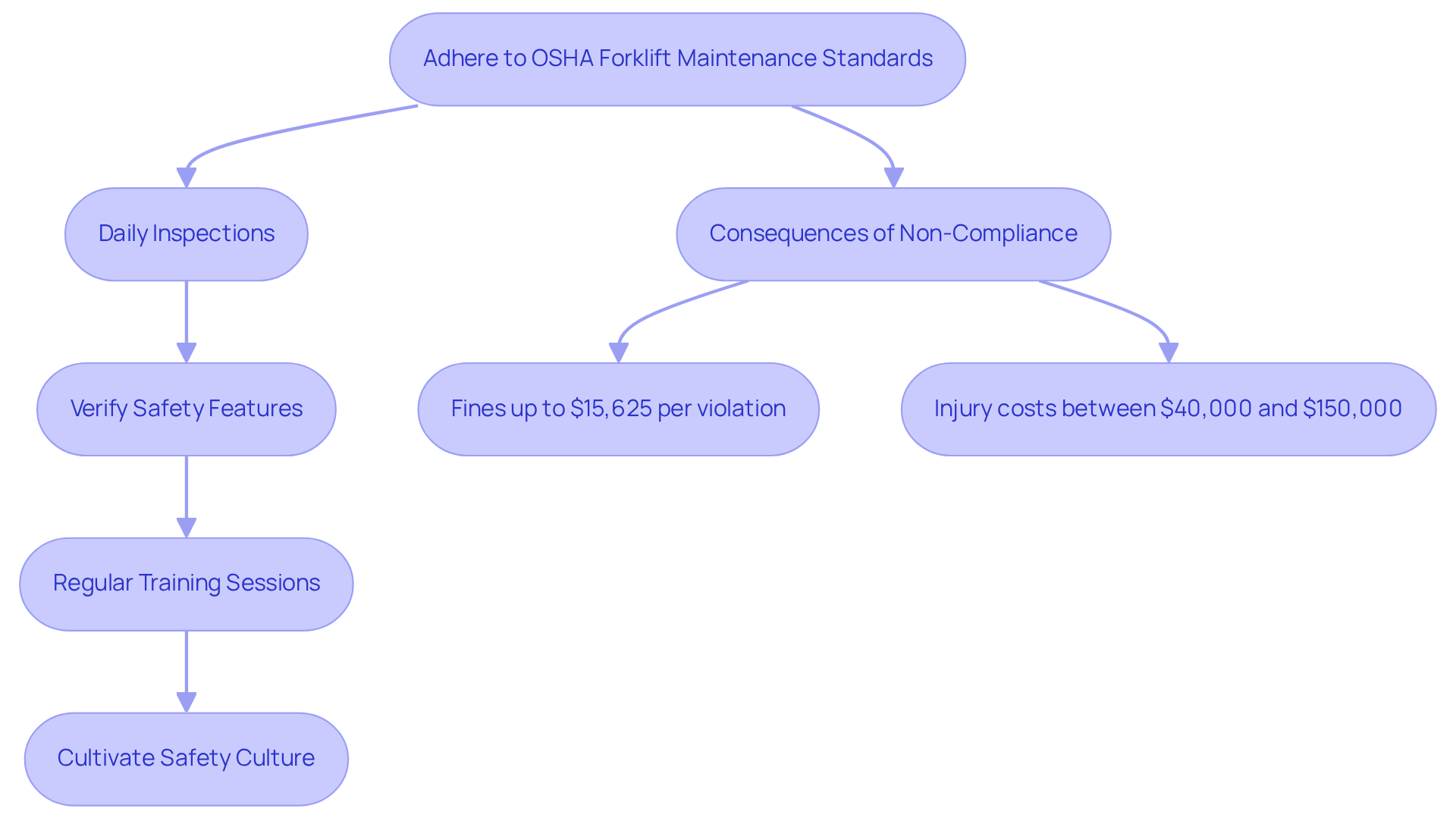

- Adhering to OSHA standards requires daily inspections of lifting machines to ensure operational safety features are functional.

- In 2021, there were 7,290 injuries related to lifting machines, highlighting the need for stringent safety measures.

- Cost of forklift service injuries can range from $40,000 to $150,000, emphasising the financial impact of non-compliance.

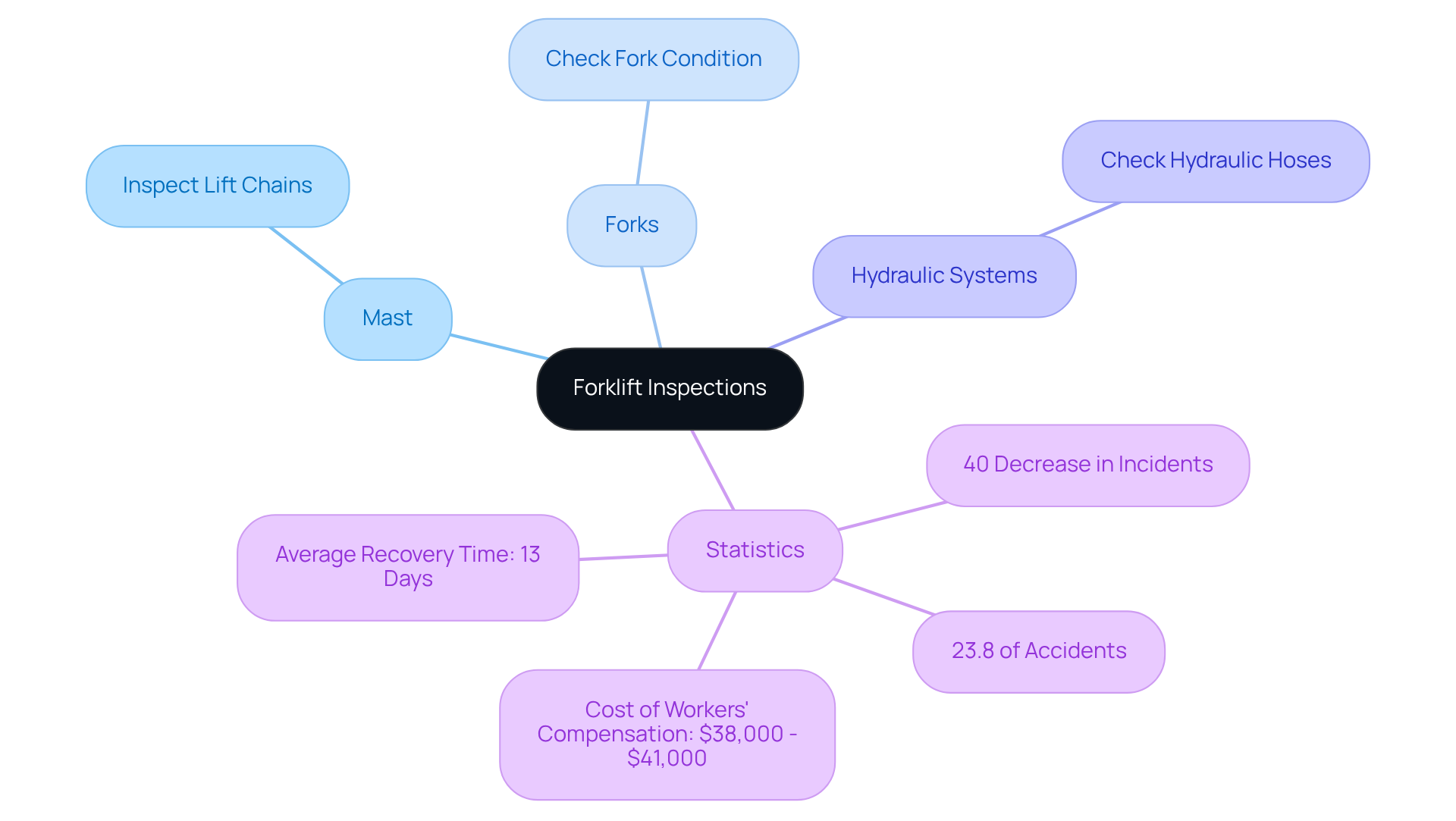

- Routine evaluations of key components, like the mast and hydraulic systems, are vital for safe operations and can reduce incidents by 40%.

- The average recovery time for forklift injuries is 13 days, compared to 8 days for other injuries, underscoring the severity of neglecting inspections.

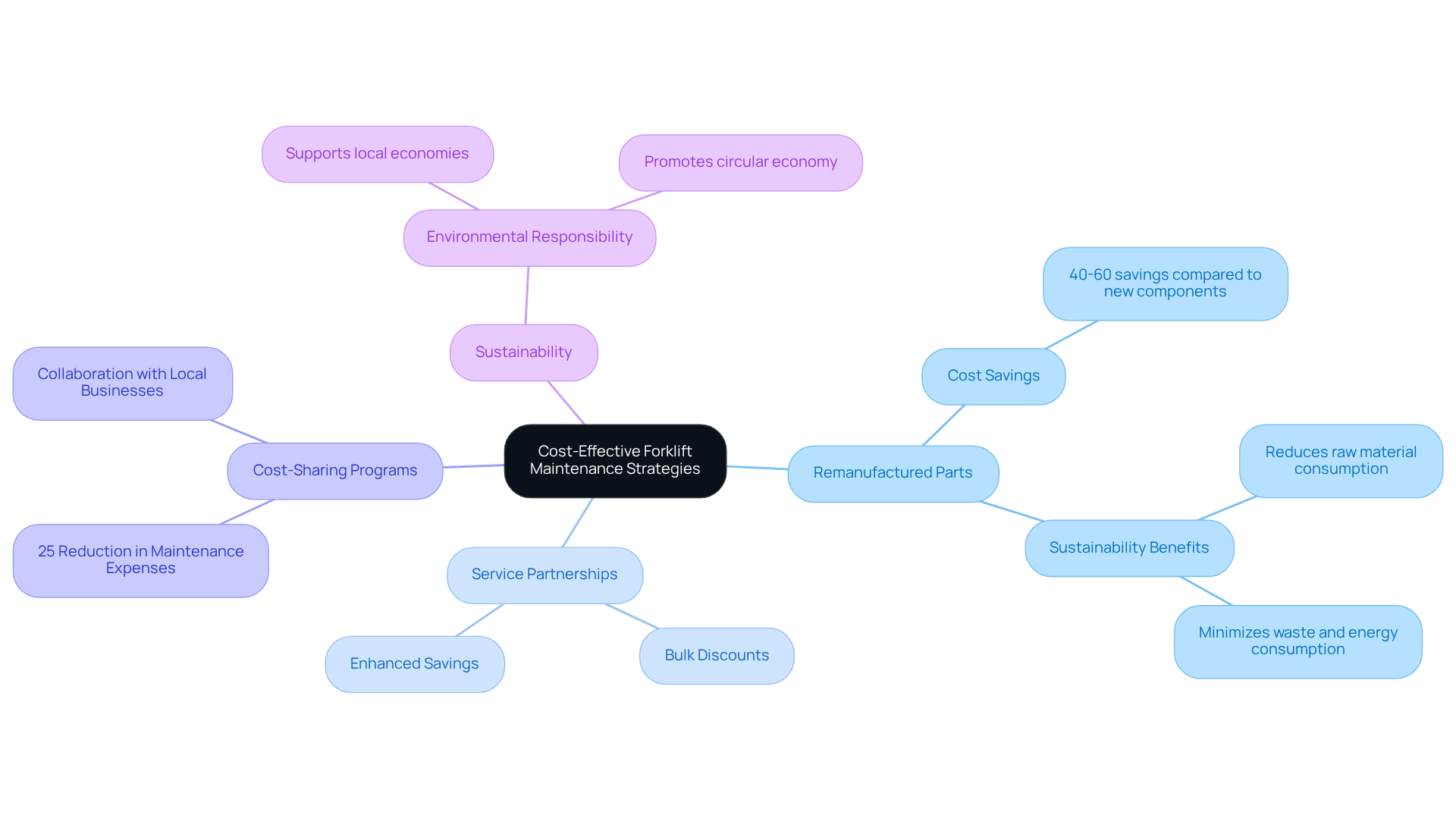

- Using remanufactured parts for repairs can save 40-60% compared to new components, enhancing financial performance.

- Engaging in cost-sharing maintenance programmes can lead to a 25% reduction in overall expenses.

Introduction

Effective management of forklift operations is crucial in the construction industry, where safety and efficiency are essential. Project managers can significantly benefit from implementing key forklift service practices that enhance equipment reliability while protecting their workforce and budgets. However, the complexities of maintenance standards present a challenge in identifying the most effective strategies to prevent costly breakdowns and accidents.

What practices can transform forklift management from a mere obligation into a powerful tool for operational excellence? By focusing on essential service protocols, managers can not only ensure compliance but also foster a culture of safety and efficiency that resonates throughout their projects.

Prioritize Preventive Maintenance for Forklifts

Preventive upkeep serves as the cornerstone of effective forklift service management, enabling project managers to reduce the risk of unexpected breakdowns. Establishing a routine for forklift service is essential, which includes regular checks of fluid levels, tire conditions, and battery health. For instance, construction sites that implement a preventive upkeep program can reduce equipment downtime by up to 30%, as supported by various industry studies. Additionally, hydraulic leaks account for approximately 20% of lifting equipment breakdowns, while travel and lift malfunctions contribute to about 15% of service calls.

Maintaining detailed logs of forklift service history is equally vital, as it helps identify recurring issues and enables timely interventions before they escalate into significant problems. As noted by Total Warehouse, 'Insufficient maintenance of lifting equipment can lead to insurance claims, regulatory breaches, and higher premium expenses.' This proactive approach not only enhances the reliability of lifting equipment but also ensures smoother operations on construction sites, ultimately safeguarding productivity and safety.

Adhere to OSHA Forklift Maintenance Standards

Adherence to OSHA standards is crucial for any construction project involving material handling equipment. Project managers must ensure that all lifting machines undergo daily inspections, as mandated by OSHA. This includes verifying operational safety features such as brakes, lights, and horns. In 2021, there were 7,290 injuries related to lifting machines, highlighting the urgent need for stringent safety measures. Regular training sessions for operators on these standards, including refresher training every three years, can significantly enhance safety and compliance.

For instance, a construction firm that diligently follows OSHA guidelines not only safeguards its workforce but also reduces the risk of incurring costly fines, which can amount to $15,625 per violation, along with potential legal issues. Forklift service injuries typically impose costs on businesses ranging from $40,000 to $150,000, underscoring the financial ramifications of non-compliance. By cultivating a culture of safety and adhering to these protocols, project managers can effectively maintain project timelines and budgets while ensuring the well-being of all stakeholders.

Conduct Regular Inspections of Key Forklift Components

Routine evaluations of vital forklift components, including the mast, forks, and hydraulic systems, are essential for safe operations on construction sites, emphasizing the need for forklift service, where 23.8% of forklift accidents occur. Project managers should implement a structured checklist that encompasses daily pre-shift assessments and more comprehensive weekly evaluations. For instance, inspecting lift chains for wear and ensuring hydraulic hoses are intact can significantly reduce the risk of accidents and minimize costly repairs.

Safety experts emphasize that daily pre-shift evaluations are not merely a regulatory requirement; they are a critical practice that enhances operational safety and efficiency, just like forklift service does. A notable case study from a leading construction firm revealed that adopting a rigorous review schedule resulted in a 40% decrease in incidents related to forklift service, highlighting the effectiveness of proactive safety measures. Furthermore, the average recovery time for lift truck injuries is 13 days, compared to 8 days for other types of injuries, underscoring the serious consequences of neglecting these checks.

The direct cost of a workers' compensation claim for a forklift injury typically ranges from $38,000 to $41,000, reinforcing the economic rationale for conducting routine evaluations. Project managers must be vigilant about common pitfalls associated with neglecting inspections, such as overlooking critical components, which can lead to severe accidents.

Implement Cost-Effective Forklift Maintenance Strategies

Implementing cost-effective upkeep strategies is essential for improving a project's financial performance. Project managers should consider using remanufactured parts for forklift service repairs, as they can provide significant savings - often 40-60% less than new components - without compromising safety or reliability. As Matt Beinlich, Senior Director of Remanufacturing Business, notes, "Remanufactured components are a much more cost-competitive option compared to new ones because fewer raw materials are required." Establishing a service partnership with a dependable provider for forklift service can further enhance these savings, potentially leading to bulk discounts on components and services.

For example, a construction project that engaged in a cost-sharing maintenance program with neighboring businesses achieved a notable 25% reduction in overall maintenance expenses. Additionally, utilizing remanufactured parts supports sustainability by minimizing waste and energy consumption, aligning with the increasing focus on environmental responsibility in construction. By prioritizing these cost-effective strategies, project managers can sustain operational efficiency while adhering to budget constraints.

Conclusion

Prioritizing effective forklift service practices is essential for project managers who seek to improve safety, efficiency, and cost-effectiveness on construction sites. By implementing preventive maintenance, adhering to OSHA standards, conducting regular inspections, and utilizing cost-effective strategies, project managers can significantly reduce risks associated with forklift operations and ensure smooth project execution.

This article emphasizes four key practices:

- The importance of preventive maintenance in minimizing unexpected breakdowns.

- The necessity of compliance with OSHA regulations to protect workers.

- The value of routine inspections for critical forklift components to avert accidents.

- The potential savings from adopting cost-effective maintenance strategies.

Each of these practices not only enhances workforce safety but also contributes to the overall financial health of the project.

In conclusion, the importance of diligent forklift service cannot be overstated. Project managers are encouraged to embrace these best practices to cultivate a culture of safety and efficiency, ultimately leading to improved project outcomes. By taking proactive measures today, the long-term benefits of reduced downtime, enhanced compliance, and lower maintenance costs will resonate throughout the lifespan of any construction project.

Frequently Asked Questions

What is the importance of preventive maintenance for forklifts?

Preventive maintenance is crucial for effective forklift service management as it helps reduce the risk of unexpected breakdowns and enhances the reliability of lifting equipment.

What should be included in a routine forklift service?

A routine forklift service should include regular checks of fluid levels, tire conditions, and battery health.

How can preventive maintenance impact equipment downtime?

Implementing a preventive maintenance program can reduce equipment downtime by up to 30%, according to various industry studies.

What are the common causes of forklift breakdowns?

Common causes of forklift breakdowns include hydraulic leaks, which account for approximately 20% of issues, and travel and lift malfunctions, contributing to about 15% of service calls.

Why is it important to maintain detailed logs of forklift service history?

Maintaining detailed logs of forklift service history is vital as it helps identify recurring issues and enables timely interventions before they escalate into significant problems.

What are the consequences of insufficient maintenance of lifting equipment?

Insufficient maintenance can lead to insurance claims, regulatory breaches, and higher premium expenses, as noted by Total Warehouse.

How does preventive maintenance contribute to construction site operations?

A proactive maintenance approach ensures smoother operations on construction sites, ultimately safeguarding productivity and safety.

List of Sources

- Prioritize Preventive Maintenance for Forklifts

- The Importance of Preventive Maintenance in Forklifts: 3 Key Benefits | JYC EQUIPMENT (https://jycequipment.com/blog/865-the-importance-of-preventive-maintenance-in-forklifts-3-key-benefits)

- The Strategic Importance of Proactive Forklift Repair & Maintenance (https://totalwarehouse.com/blogs/the-strategic-importance-of-proactive-forklift-repair-maintenance)

- Preventive Maintenance Schedules and Daily Inspections: The Foundation of Forklift Safety and Efficiency | NorthPennNow (https://northpennnow.com/news/2025/oct/15/preventive-maintenance-schedules-and-daily-inspections-the-foundation-of-forklift-safety-and-efficiency)

- Contact Us | Outside US & Canada | Damotech (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- Adhere to OSHA Forklift Maintenance Standards

- Forklift Injury Statistics 2025 | How to Reduce Forklift Accident Risks (https://certifyme.net/osha-blog/forklift-injuries-key-statistics)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Forklift Accidents: 2025 Stats, Top Causes & OSHA Rules (https://damotech.com/blog/forklift-accidents-causes-and-prevention)

- Forklift Accident Costs: Hidden Dangers That Could End Your Business | CertifyMe.net (https://certifyme.net/osha-blog/the-hidden-costs-of-forklift-accidents)

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- Conduct Regular Inspections of Key Forklift Components

- Occupational Injuries, Illnesses, and Fatalities Involving Forklifts (https://bls.gov/iif/factsheets/fatal-occupational-injuries-forklifts-2017.htm)

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Implement Cost-Effective Forklift Maintenance Strategies

- Benefits of Investing in Remanufactured Truck Parts - Big Truck (https://bigtruckequipment.com/benefits-of-investing-in-remanufactured-truck-parts)

- Cost analysis and ROI of forklift optimization initiative... (https://eoxs.com/new_blog/cost-analysis-and-roi-of-forklift-optimization-initiatives)

- Remanufacturing And It's Importance To The Heavy Duty Parts Industry (https://fleetconceptsinc.com/remanufacturing-and-its-importance-to-the-heavy-duty-parts-industry)

- Remanufactured parts and components could help decrease your machinery’s total cost of ownership, promote profitability (https://constructionpublications.com/remanufactured-parts)