Overview

The essential practices for safe 40 lift operation are critical to ensuring a secure work environment. Understanding the equipment, conducting thorough pre-operational checks, adhering to load limits, utilizing personal protective equipment (PPE), and ensuring comprehensive training and maintenance are paramount. These practices are not merely recommendations; they are vital components that can significantly reduce the risk of accidents.

In the construction industry, where aerial platforms are a common concern, the implementation of proper knowledge and safety protocols can help mitigate the notable fatalities associated with lift operations.

Take action now to prioritize safety and ensure that all operational practices are adhered to meticulously.

Key Highlights:

- Understanding the basic components and functions of a 40 lift is crucial for safe operation.

- Operators must familiarise themselves with controls, load capacity, and stability features.

- Aerial platforms contribute to 2-3% of construction fatalities, highlighting the need for safety measures.

- Pre-operational checks should include assessments for damage and ensuring stable positioning.

- Personal Protective Equipment (PPE) is essential to minimise injury risks when operating at heights.

- Strict adherence to load limits is necessary to maintain operational safety.

- Emergency procedures must be well understood to handle potential power failures or malfunctions.

- Comprehensive training and certification for operators are vital for safe operation, including operational techniques and emergency response.

- Regular maintenance and inspections, including daily checks and scheduled servicing, are essential to prevent malfunctions.

- Documentation of inspections and maintenance activities is important for regulatory compliance and performance monitoring.

Introduction

Operating a 40 lift presents significant challenges, particularly when evaluating the associated risks. Aerial platforms contribute to a notable percentage of construction fatalities, making it essential to grasp the critical practices for safe operation. This article explores vital safety protocols, training requirements, and maintenance strategies that not only bolster operator safety but also enhance overall efficiency.

What key practices can be implemented to prevent accidents and ensure compliance in this high-stakes environment?

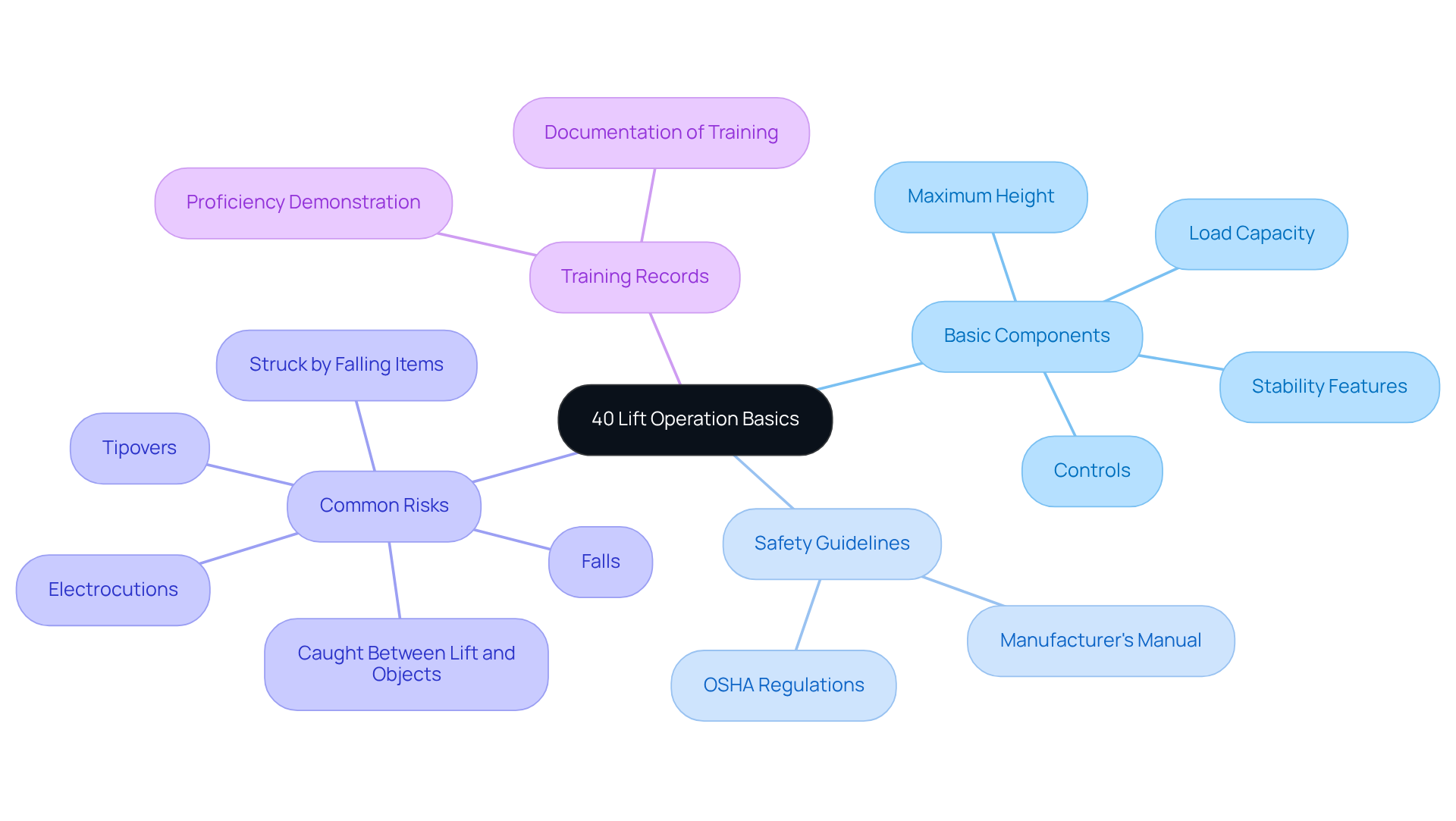

Understand the Basics of 40 Lift Operation

Before operating a 40 lift, it is essential to understand its basic components and functions. Familiarize yourself with the elevator's controls, including steering, raising, and emergency functions. Operators must also be aware of the device's maximum height, load capacity, and stability features. Understanding these factors will assist in making informed choices during operation and ensure that the apparatus is utilized within its intended parameters.

Furthermore, personnel should examine the manufacturer's manual for specific operational guidelines and safety features unique to the model being utilized. This fundamental understanding is the initial phase in fostering a secure working environment when operating a 40 lift elevating platform. Notably, aerial platforms account for 2 to 3% of all construction fatalities, with around 26 construction workers losing their lives annually due to aerial platform incidents.

Moreover, keeping records of training for aerial equipment users is crucial for adherence to OSHA regulations. Operators must also be aware of common pitfalls, such as the risks of being caught between the elevator and objects or struck by falling items, to ensure a safer operational environment. By prioritizing safety and understanding the equipment, operators can significantly reduce risks and enhance overall productivity.

Implement Safety Protocols for 40 Lift Use

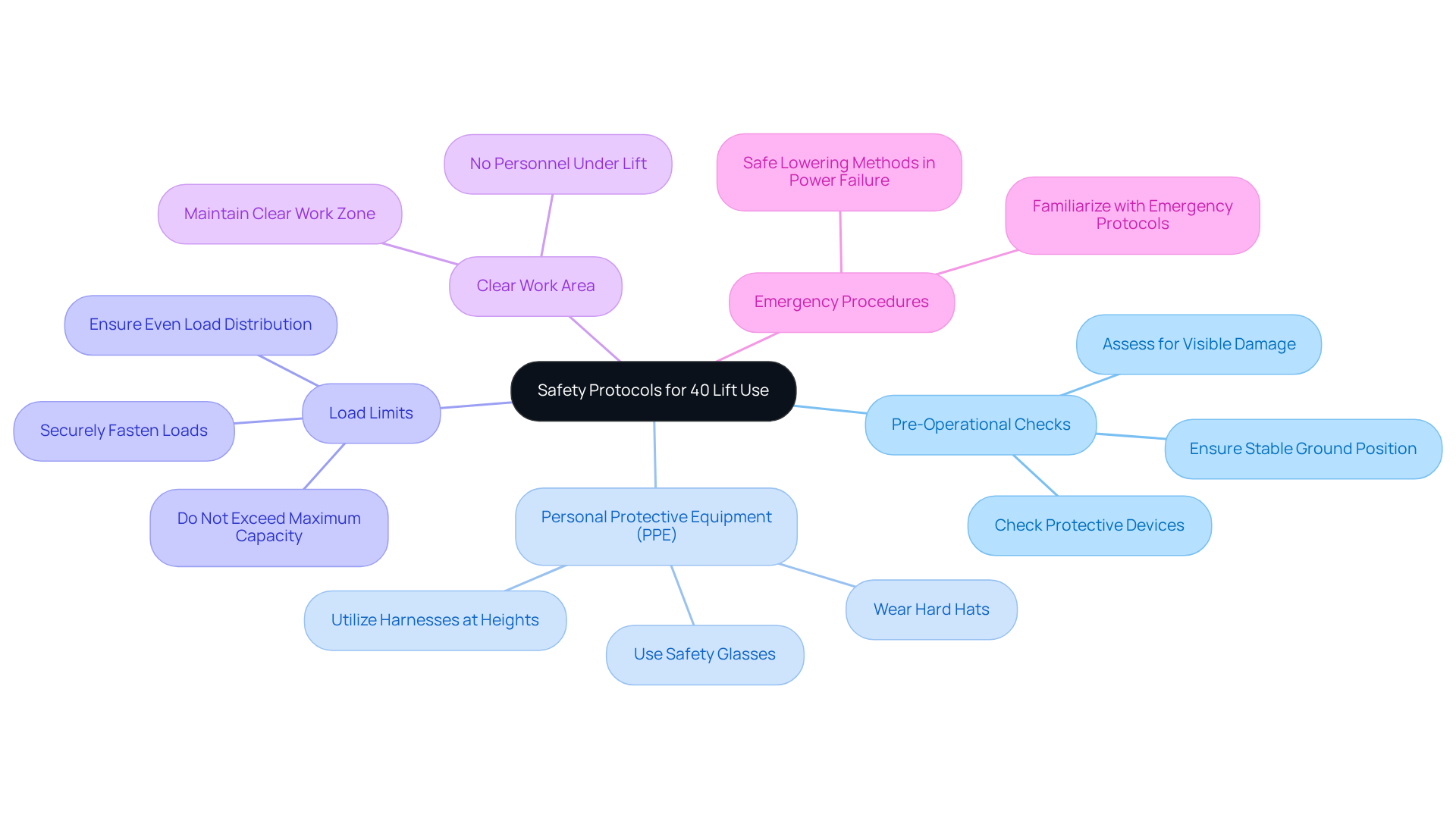

To ensure the safe operation of a 40 lift, it is essential for operators to adhere to safety protocols.

Pre-Operational Checks are crucial. Conduct comprehensive assessments before usage, examining for any visible damage, ensuring protective devices are functional, and confirming that the platform is positioned on stable ground. These checks are foundational to safe operations of the 40 lift.

Personal Protective Equipment (PPE) is non-negotiable. Always wear appropriate PPE, including hard hats, safety glasses, and harnesses when working at heights. This equipment is vital for minimizing injury risks.

Load Limits must be strictly observed. Never exceed the hoist's maximum load capacity. Ensure that all loads are evenly distributed and securely fastened. Adhering to these limits is essential for operational safety when operating the 40 lift.

Clear Work Area protocols should be implemented. Maintain a clear work zone around the hoist to prevent accidents. Ensure that no personnel are standing beneath the elevator while it is in operation. This practice significantly reduces the risk of injury.

Emergency Procedures are critical for safety. Familiarize yourself with emergency protocols, including the proper methods for safely lowering the platform in the event of a power failure. By following these protocols, operators can greatly mitigate the risk of accidents.

Ensure Proper Training and Certification for Operators

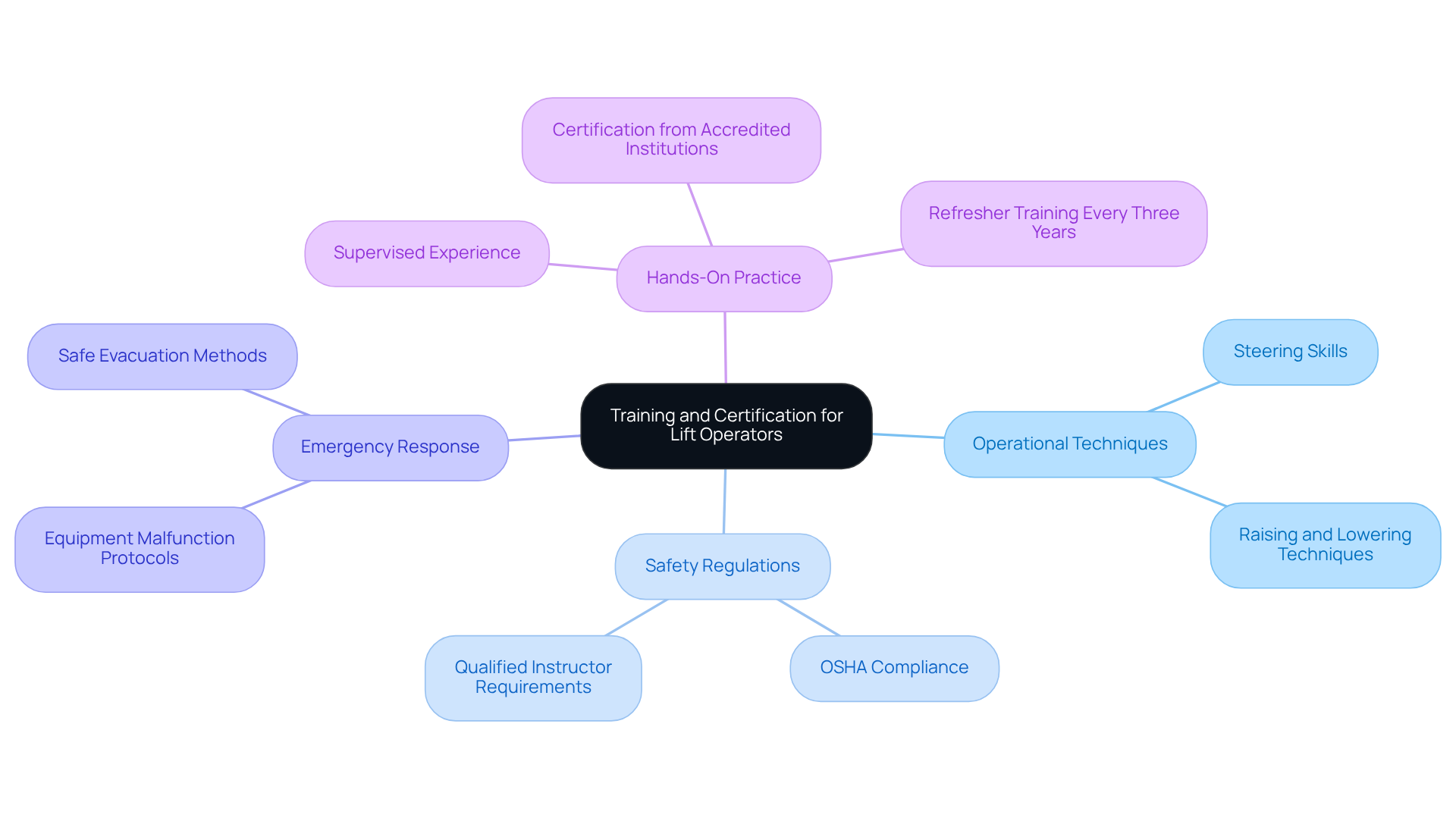

Ensuring the safe operation of a 40 lift requires comprehensive training and certification for all operators. This training must encompass several key areas:

-

Operational Techniques: Operators must master essential skills for maneuvering the apparatus, including precise steering, raising, and lowering techniques. This foundational knowledge is crucial for safe operation.

-

Safety Regulations: A thorough understanding of safety regulations, particularly those established by OSHA, is vital. OSHA mandates that employers provide instruction to ensure operators are skilled and certified for the specific types of lifts they will operate. A qualified instructor should hold a recognized degree, certificate, or professional status, enhancing the credibility of the development process.

-

Emergency Response: Operators should be well-versed in emergency response protocols, including procedures for handling equipment malfunctions and safe evacuation methods. This preparation is critical for minimizing risks during unexpected situations.

-

Hands-On Practice: Practical exercises are essential, enabling individuals to acquire supervised experience in real-world scenarios. Certification should be obtained from accredited educational institutions to verify that individuals meet industry standards. Furthermore, refresher training for forklift operators is necessary at least every three years to maintain skills and keep knowledge current.

Neglecting appropriate preparation can result in significant hazard risks, as data indicates that 25% of forklift incidents stem from insufficient instruction. Additionally, the economic benefits of hazard training are notable; for instance, insurance companies may reduce workers' compensation expenses with proof of hazard training. By investing in thorough development programs, employers not only enhance safety but also improve operational efficiency and minimize liability. New associates must receive proper training on the equipment they will use to ensure a safe working environment.

Conduct Regular Maintenance and Inspections

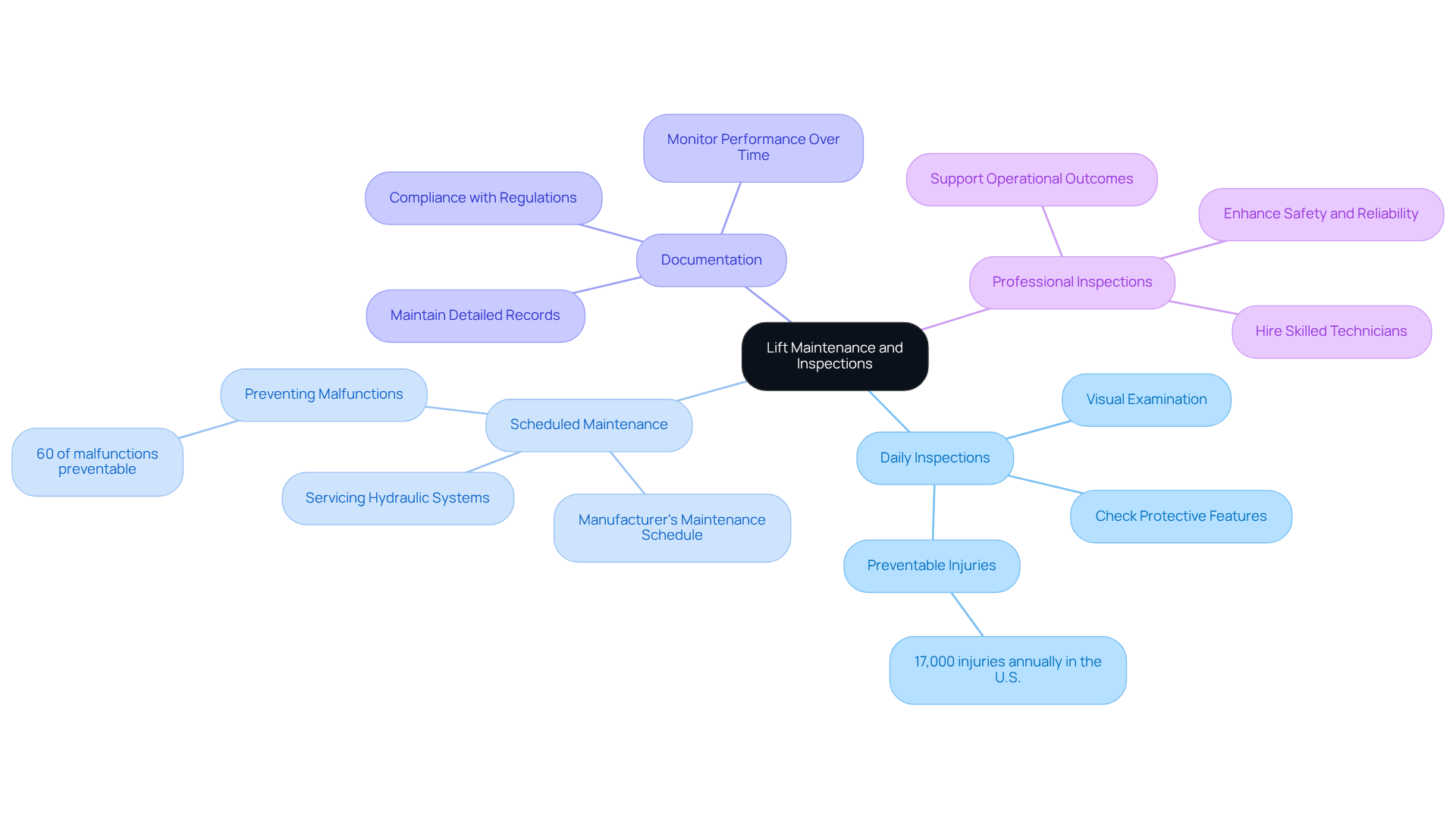

To ensure the safety and functionality of a 40 lift, operators must implement a comprehensive maintenance and inspection schedule that includes:

-

Daily Inspections: Operators should conduct a visual examination prior to each use, meticulously looking for indications of wear or damage and verifying that all protective features are functional. This practice is essential; approximately 17,000 people in the U.S. suffer elevator-related injuries annually, with many incidents preventable through diligent inspections.

-

Scheduled Maintenance: Adhering to the manufacturer's recommended maintenance schedule is crucial. This typically involves servicing hydraulic systems, inspecting electrical components, and replacing worn parts. Regular maintenance can significantly reduce the likelihood of unexpected breakdowns—studies indicate that about 60% of malfunctions in 40 lift systems could be prevented through consistent care.

-

Documentation: It is vital to maintain detailed records of all inspections and maintenance activities. This documentation is crucial for compliance with regulatory requirements and for monitoring the elevator's performance over time, ensuring that operators can demonstrate adherence to regulations.

-

Professional Inspections: Hiring skilled technicians for regular professional assessments is essential to ensure that the lift complies with all standards and regulations. Regular professional evaluations not only enhance safety but also improve the reliability and efficiency of the equipment, ultimately supporting better operational outcomes.

Conclusion

Understanding and implementing essential practices for safe 40 lift operation is crucial for minimizing risks and ensuring a secure working environment. By prioritizing safety protocols, operators can navigate the complexities of 40 lift usage while safeguarding themselves and their colleagues.

Key practices include:

- A thorough understanding of the equipment

- Adherence to safety protocols

- Comprehensive training and certification for operators

- Regular maintenance and inspections

These elements collectively contribute to a culture of safety that not only protects workers but also enhances operational efficiency. Recognizing the significance of each practice can lead to a substantial decrease in accidents and injuries associated with aerial platforms.

Ultimately, fostering a commitment to safety should be a top priority for all organizations utilizing 40 lifts. By investing in training, adhering to safety guidelines, and maintaining equipment diligently, employers can create a safer workplace while also complying with regulations. Embracing these best practices not only protects lives but also promotes a more productive and responsible approach to lift operation.

Frequently Asked Questions

What should operators understand before using a 40 lift?

Operators should understand the basic components and functions of the 40 lift, including its controls for steering, raising, and emergency functions, as well as its maximum height, load capacity, and stability features.

Why is it important to familiarize oneself with the manufacturer's manual?

Familiarizing oneself with the manufacturer's manual is important because it provides specific operational guidelines and safety features unique to the model being utilized, which is essential for safe operation.

What is the significance of understanding the risks associated with aerial platforms?

Understanding the risks associated with aerial platforms is significant because it helps operators avoid common pitfalls, such as being caught between the elevator and objects or struck by falling items, thereby ensuring a safer operational environment.

How do aerial platforms relate to construction fatalities?

Aerial platforms account for 2 to 3% of all construction fatalities, with approximately 26 construction workers losing their lives annually due to incidents involving aerial platforms.

Why is it necessary to keep training records for aerial equipment users?

Keeping training records for aerial equipment users is necessary for adherence to OSHA regulations, ensuring that operators are properly trained and compliant with safety standards.

What can operators do to enhance safety and productivity when using a 40 lift?

Operators can enhance safety and productivity by prioritizing safety, understanding the equipment thoroughly, and being aware of the potential risks involved in operating the lift.