Overview

Renting welding trucks effectively necessitates meticulous attention to specific welding needs, truck specifications, rental agreements, and comprehensive equipment inspections. It is essential to identify the appropriate welding processes and evaluate truck capabilities.

Understanding lease terms and conducting thorough pre-rental checks are critical steps to ensure successful and safe project execution. By following these guidelines, you can ensure that your rental experience meets the highest standards of reliability and quality.

Key Highlights:

- Identify specific welding processes needed for projects, such as MIG, TIG, or Stick, each suited for different applications.

- Assess materials like steel and aluminum to determine appropriate joining methods and tools.

- Evaluate project size to select suitable equipment; larger projects may require more durable tools.

- Consider enhancements like spool guns for aluminum or specialized torches for different techniques.

- Decide between mobile fabrication vehicles or fixed equipment; rental trucks are crucial for on-site welding in construction.

- Evaluate truck specifications including payload capacity (3,000 to 7,000 lbs), engine power (300-450 hp), and towing capacity (10,000 to 30,000 lbs).

- Review rental agreements carefully, focusing on lease duration, fees, maintenance responsibilities, and insurance clauses.

- Inspect rental equipment for damage, perform functional tests, and document any issues to avoid disputes.

- Statistics show 30% of rental items fail safety inspections, highlighting the need for thorough pre-rental checks.

Introduction

In the dynamic world of welding, selecting the right equipment and ensuring optimal performance are pivotal to project success. Identifying specific welding needs, evaluating truck specifications, and understanding rental agreements are essential steps that streamline operations.

As construction projects increasingly demand on-site capabilities, the significance of mobile welding solutions continues to rise. This article explores crucial factors to consider when renting welding trucks, from equipment inspections to comprehending contractual obligations. By addressing these elements, professionals can confidently tackle any challenge that comes their way.

Identify Your Welding Needs

- Determine the specific joining process required for your project, such as MIG, TIG, or Stick methods. Each method boasts distinct advantages tailored to different applications; for instance, MIG is favored for its speed and ease of use, while TIG excels in precision for thinner materials.

- Assess the materials you will be working with, including common options like steel and aluminum. Understanding the characteristics of these substances is essential, as they dictate the appropriate joining method and tools necessary.

- Evaluate the size of your project to gauge the energy and capability required. Larger projects may necessitate more durable equipment, whereas smaller tasks can often be managed with portable options.

- Consider any specific characteristics or attachments that may enhance your work, such as spool guns for aluminum or specialized torches for various techniques.

- Assess whether a mobile fabrication vehicle or fixed equipment is more suitable for your work site. Welding trucks for rent are becoming increasingly vital, with a significant portion of construction projects now requiring on-site metal joining capabilities to boost efficiency and minimize downtime. In fact, the welders segment is anticipated to command the largest market share and demonstrate the highest CAGR during the forecast period, underscoring the growing importance of this process in construction. As noted by All-State Career School, 'If you enjoy hands-on work and creating products or infrastructure used every day, this profession could be the right career choice.' Furthermore, advanced joining methods, such as friction stir bonding and laser techniques, are gaining traction, highlighting the necessity for project managers to stay informed about current trends in this field.

Evaluate Truck Specifications and Features

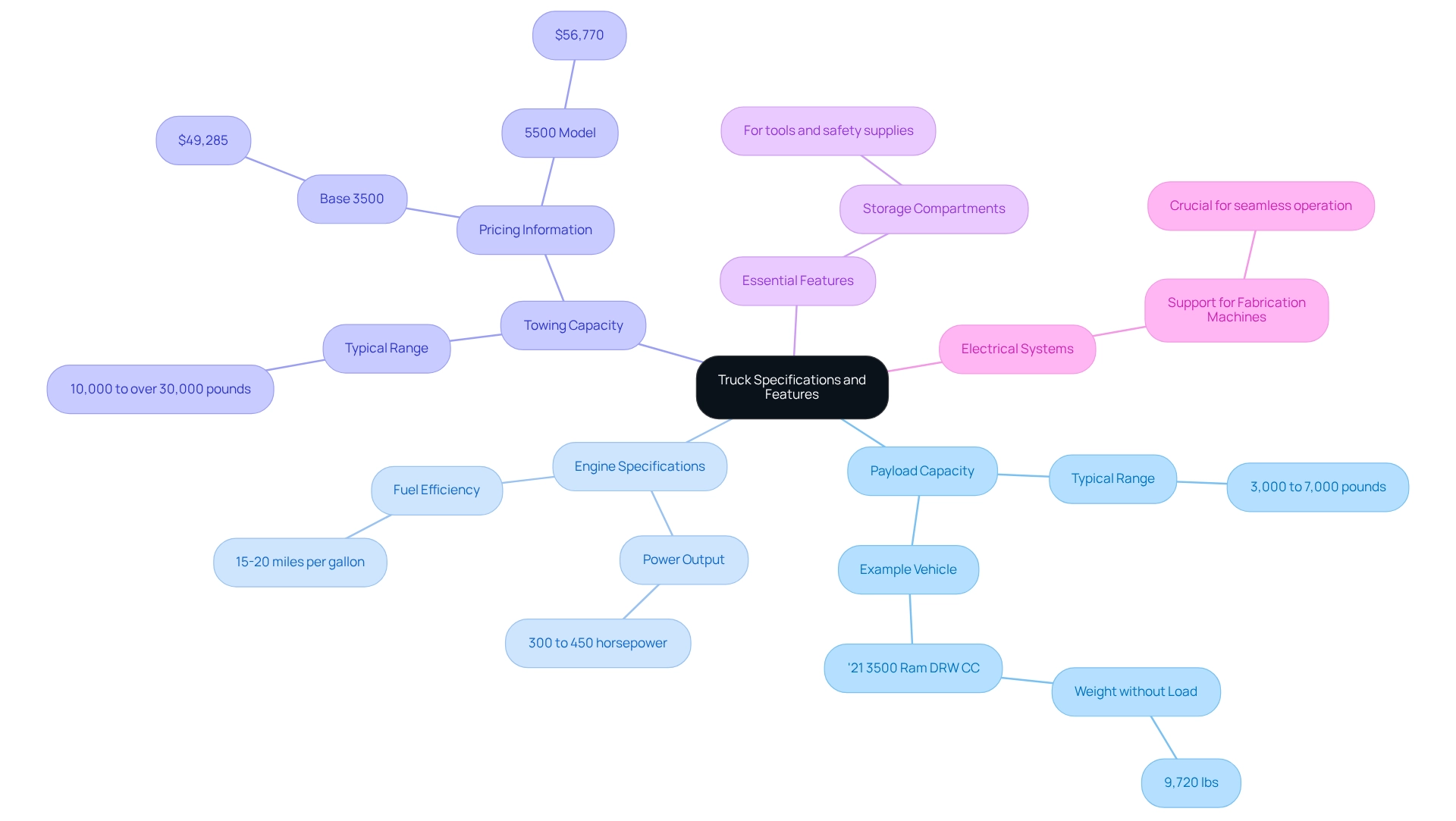

- Assess the vehicle's payload capacity to ensure it can accommodate the necessary tools and materials effectively. The typical payload capacity of fabrication vehicles available today ranges from 3,000 to 7,000 pounds, depending on the model and configuration. For example, the '21 3500 Ram DRW CC has a weight of 9,720 lbs without any load, which is critical for understanding payload considerations.

- Review engine specifications with a focus on power output and fuel efficiency. In 2025, many service vehicles are equipped with engines delivering between 300 to 450 horsepower, while fuel efficiency ratings are improving to approximately 15-20 miles per gallon.

- Evaluate the vehicle's towing capacity, especially if additional gear needs to be transported. Chassis cab vehicles can feature towing capacities that range from 10,000 to over 30,000 pounds, making them suitable for heavy-duty tasks. It is vital to recognize that the costs for chassis cab vehicles vary, with the base 3500 priced at $49,285 and the 5500 model at $56,770, which should be factored into your budget planning.

- Look for essential features such as storage compartments for tools and safety supplies, which play a significant role in keeping everything organized and accessible on job sites.

- Ensure the vehicle is equipped with adequate electrical systems to support fabrication machines and other tools, as this is crucial for seamless operation during projects. Additionally, consider the challenges outlined in the case study titled 'Personal Experiences with Heavy Towing,' which highlights the issues faced while towing welding trucks for rent and underscores the importance of selecting the right tools.

Review Rental Agreements and Terms

Carefully review the lease agreement to fully comprehend all terms and conditions. Pay particular attention to the lease duration, associated fees, and any additional costs, such as fuel and maintenance. It is essential to clarify responsibilities regarding device maintenance and repairs throughout the leasing period. Ensure that the agreement includes provisions for insurance and liability coverage. Additionally, look for clauses that address damage, wear and tear, and penalties for late returns.

A well-structured lease contract is crucial for preventing misunderstandings. Regular assessments of lease agreements can help uphold compliance with legal standards, ensuring that all parties are aware of their responsibilities. For instance, utilizing templates for equipment leasing agreements can simplify the drafting process, provided they are updated to reflect current legal requirements. A case study on this topic underscores the importance of keeping templates current to avoid legal pitfalls. In the construction sector, the average leasing period for welding trucks for rent typically spans from a few days to several weeks, depending on project requirements. Furthermore, common extra costs associated with renting welding trucks for rent may include fuel surcharges and maintenance fees, which can significantly impact project budgets. Additionally, using leasing management software can further streamline the handling of agreements and terms, making the process more efficient. If you have any questions or need further assistance, do not hesitate to contact Sniper Rentals at 432-788-9900.

Conduct Equipment Inspection Before Rental

- Begin by inspecting the welding machine for any visible signs of damage or wear; this can indicate potential issues that may affect performance. Thoroughly check all cables, hoses, and connections for integrity and safety, ensuring they are free from fraying or leaks that could lead to accidents. Confirm that all safety features, including emergency shut-offs, are fully operational to protect users during operation.

- Carry out a functional test of the apparatus to confirm that it operates properly before departing the leasing facility. This action is vital for avoiding future issues. Document any existing damage thoroughly to avoid disputes upon return; this practice not only safeguards your interests but also encourages accountability in the leasing process.

- Statistics indicate that approximately 30% of rental items fail safety inspections, underscoring the necessity of thorough pre-rental checks. Expert recommendations emphasize that safety should be viewed as an investment rather than a cost, reinforcing the importance of diligent inspections to ensure both worker safety and equipment reliability. As Aidan O’Shannessy wisely stated, "If you don’t know, ask. Working with people is far better than working against them — always bring together all the people and information available to you!" This highlights the value of consulting with knowledgeable personnel during the inspection process.

Conclusion

Selecting the right welding truck is not just a choice; it is a critical element for success in the welding industry. By understanding the unique needs of each project—from the type of welding process to the materials involved—professionals lay the foundation for informed decision-making. Evaluating truck specifications, such as payload capacity and engine performance, ensures that the chosen equipment can effectively handle the demands of the job.

Furthermore, comprehending rental agreements is essential to avoid unexpected costs and liabilities. A thorough review of terms and conditions, coupled with clear communication regarding maintenance and responsibilities, can prevent misunderstandings and protect all parties involved. Conducting diligent equipment inspections prior to rental is equally vital, safeguarding against potential issues that may arise during operation.

In conclusion, the welding industry is evolving, and so too are the demands for mobile solutions that enhance efficiency on construction sites. By focusing on key areas—identifying welding needs, evaluating truck specifications, understanding rental agreements, and performing thorough inspections—professionals can confidently navigate the complexities of welding projects. This proactive approach not only streamlines operations but also fosters a safer and more productive working environment, ultimately leading to project success.

Frequently Asked Questions

What joining processes should I consider for my welding project?

You should determine whether to use MIG, TIG, or Stick methods. MIG is favored for its speed and ease of use, while TIG is best for precision work on thinner materials.

Why is it important to assess the materials I will be working with?

Assessing the materials, such as steel and aluminum, is crucial because their characteristics dictate the appropriate joining method and tools needed for your project.

How does the size of my project influence my equipment choice?

The size of your project affects the energy and capability required; larger projects may need more durable equipment, while smaller tasks can often be handled with portable options.

What specific characteristics or attachments should I consider for my welding tasks?

You may want to consider using spool guns for aluminum or specialized torches for different welding techniques to enhance your work.

Should I use a mobile fabrication vehicle or fixed equipment for my work site?

It depends on your project needs; welding trucks for rent are increasingly important as many construction projects require on-site metal joining to improve efficiency and reduce downtime.

What is the market trend for welding in construction?

The welders segment is expected to hold the largest market share and show the highest compound annual growth rate (CAGR) during the forecast period, indicating the growing importance of welding in construction.

Are there any advanced joining methods I should be aware of?

Yes, advanced methods such as friction stir bonding and laser techniques are gaining popularity, making it important for project managers to stay informed about current trends in the field.