Overview

Successful welding tool rental is contingent upon:

- Selecting the appropriate welding method

- Comprehending rental agreements

- Thoroughly inspecting equipment

- Fostering clear communication with rental providers

These steps are not merely suggestions; they are essential to ensuring project efficiency, safety, and cost-effectiveness. Proper tool selection and meticulous inspections can significantly mitigate delays and unforeseen expenses, reinforcing the reliability and quality of the rental process.

Key Highlights:

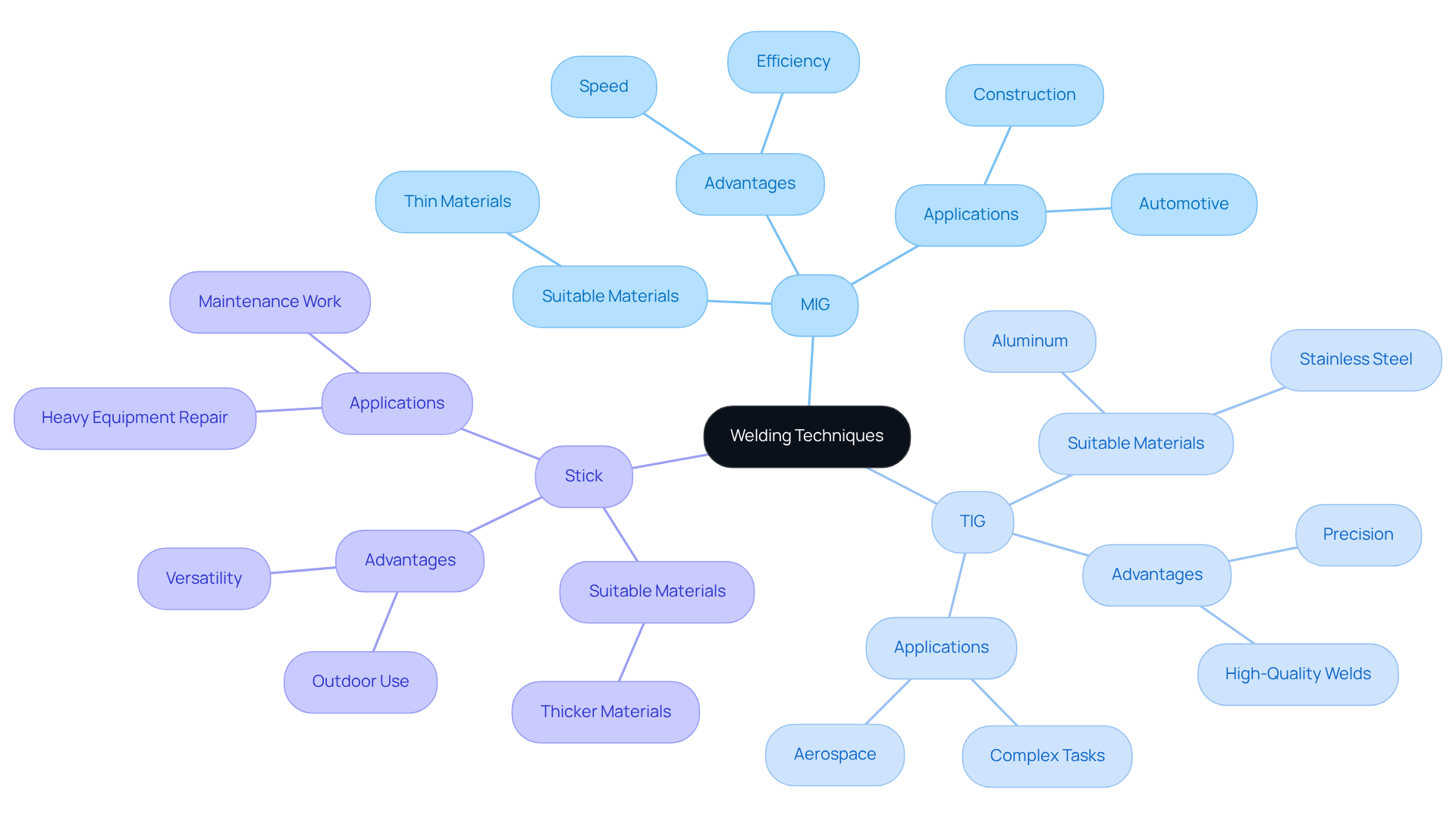

- Choosing the right welding method (MIG, TIG, Stick) is crucial for project success, as each method requires specific tools.

- MIG welding is efficient for thin materials, while TIG welding offers precision for complex tasks, especially with stainless steel and aluminium.

- Understanding material requirements helps in selecting the appropriate welding tool; for example, TIG is preferred for aluminium.

- Investigating rental agreements is essential, focusing on lease duration, payment terms, and maintenance responsibilities to avoid unforeseen costs.

- Conducting thorough inspections and tests of rental equipment is vital for safety and efficiency, preventing delays and hazards.

- Effective communication with rental providers ensures clarity on project needs, maintenance responsibilities, and available support, enhancing the leasing experience.

Introduction

Navigating the world of welding tool rentals can indeed be a challenging endeavor, particularly when the success of your project relies heavily on the right equipment. Selecting the appropriate tools transcends mere convenience; it profoundly influences efficiency, safety, and the quality of the final product.

As the demand for skilled welding continues to surge, grasping the intricacies of rental agreements, conducting thorough equipment inspections, and fostering effective communication with providers becomes essential.

How can one ensure they are making the most informed choices in a landscape teeming with options and potential pitfalls?

It’s time to explore the key factors that will empower you to make confident decisions.

Choose the Right Welding Tools for Your Project

Choosing the appropriate tools is vital for the success of any undertaking. Begin by assessing the specific technique required—MIG, TIG, or Stick—as each method necessitates distinct equipment. MIG fabrication excels with thin materials and is recognized for its speed, making it suitable for tasks that prioritize efficiency. In contrast, TIG joining is favored for its precision, especially when handling complex tasks or materials such as stainless steel and aluminum, where high-quality welds are crucial.

Understanding the materials involved is equally important. For instance, if your project involves aluminum, a TIG welder is often the best choice due to its capability to produce clean and precise welds. On the other hand, Stick techniques may be more suitable for thicker materials or outdoor uses where wind can impact the joining process.

Investigating the capabilities of each joining tool will enable you to make informed choices. Examine case studies where contractors effectively employed welding tool rental agreements for MIG or TIG to satisfy task requirements. For example, a recent initiative emphasized how access to a diverse welding tool rental fleet enabled a stadium construction team to adhere to strict timelines while upholding high safety standards. This initiative not only conserved considerable time but also showcased the efficiency advantages of choosing the appropriate tools, as illustrated by the refinery endeavor that saved 10-12 days of turnaround time through effective utilization. By matching your tool selection with assignment criteria, you can enhance performance and attain excellent outcomes.

Additionally, remember that EZ Equipment Rental's commitment to quality and reliability ensures that you are renting tools that meet high standards, further enhancing your project's success.

Understand Rental Terms and Conditions

Before concluding your lease, it is essential to thoroughly examine the terms and conditions related to the apparatus. Key aspects to consider include:

- Lease duration

- Payment terms

- Potential fees for late returns or damages

Furthermore, clarify maintenance responsibilities during the leasing period; some agreements may stipulate that you return the equipment in the same condition it was received, which could involve cleaning or minor repairs. Familiarizing yourself with these details not only helps avoid unforeseen expenses but also guarantees a seamless leasing experience. Transparency about fees, including delivery and setup charges, is essential to minimize misunderstandings. By understanding your obligations and the specifics of the rental agreement, you can make informed decisions that enhance your overall rental experience.

Inspect and Test Equipment Before Rental

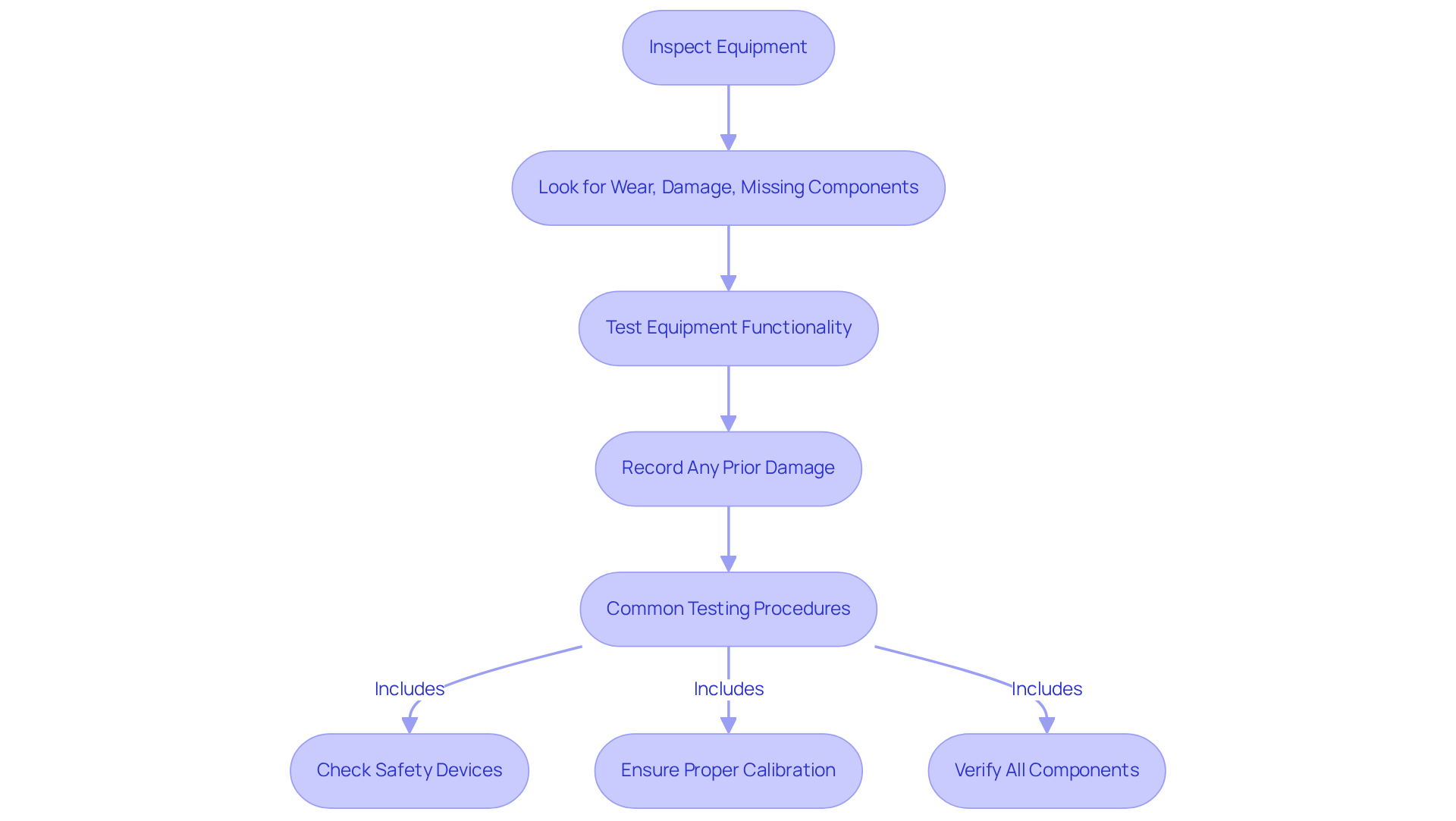

Before engaging in welding tool rental, it is essential to conduct a comprehensive inspection to ensure optimal working condition. Look for visible signs of wear, damage, or missing components. Testing the equipment, if feasible, is crucial to confirm its proper operation. This proactive step helps prevent delays and safety hazards during your project, especially when utilizing a welding tool rental. For example, identifying a gas leak in a welding machine or a malfunctioning trigger before the welding tool rental can save significant time and frustration.

Recording any prior damage is also crucial to prevent disagreements when returning the items; neglecting this can result in confusion and possible expenses. Regular inspections not only improve efficiency but also align with safety best practices, as emphasized by safety experts who advocate for thorough equipment testing to reduce risks. According to statistics, 21 percent of deaths occur in the construction industry, underscoring the critical need for thorough inspections. Remember, a well-kept property can be the difference between a successful endeavor and expensive setbacks.

Additionally, common testing procedures include:

- Checking the functionality of safety devices

- Ensuring proper calibration

- Verifying that all components are operational

Integrating these practices will enhance the protection of your initiative and team.

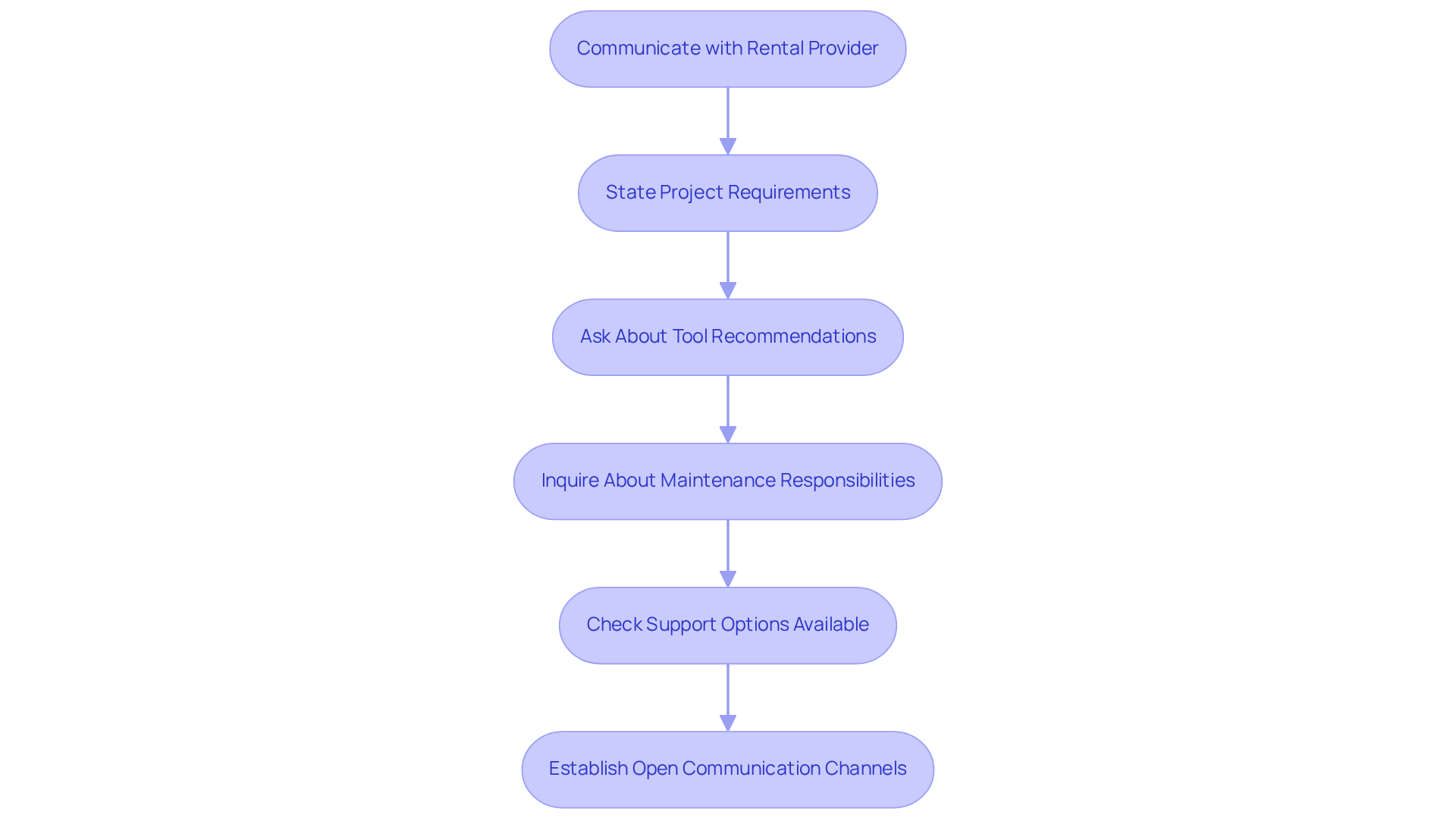

Communicate Clearly with Rental Providers

Effective communication with your provider is paramount for a successful tool leasing experience. Clearly articulate your project requirements, specifying the type of welding you will undertake and any essential features needed in the welding tool rental. It is crucial to ask relevant questions about the leasing process, including maintenance responsibilities and the assistance available during the lease period. For example, if you require help with setup or operation, inquire whether the provider offers training or technical support. Maintaining open communication channels facilitates swift resolution of any issues, ensuring you possess the essential resources to accomplish your task effectively.

Furthermore, consider inquiring about customer satisfaction ratings for providers in Texas, as this can provide insight into their dependability and service quality. Questions to pose might include:

- What specific welding tool rental do you recommend for my project?

- How do you manage upkeep of tools during the leasing duration?

- What support options are available if I encounter issues with the equipment?

By addressing these aspects, you can foster a productive relationship with your rental provider and enhance your project's success.

Conclusion

Selecting the right welding tools and comprehending the rental process are essential for the success of any welding project. By meticulously assessing the specific techniques required, grasping rental terms, inspecting equipment, and maintaining clear communication with rental providers, individuals can significantly enhance their project outcomes. These practices not only lead to improved efficiency but also help in avoiding costly setbacks.

Key insights underscore the significance of choosing the appropriate welding method—be it MIG, TIG, or Stick—tailored to the project at hand, alongside the necessity of thoroughly understanding the rental agreement to avert unexpected fees. Moreover, inspecting and testing equipment prior to rental can prevent safety hazards and operational delays, while effective communication with rental providers cultivates a more productive working relationship.

Ultimately, embracing these essential tips for successful welding tool rental empowers individuals to approach their projects with confidence and clarity. By prioritizing informed decisions and proactive measures, the journey toward achieving high-quality welds and project success becomes more accessible, paving the way for a safer and more efficient working environment.

Frequently Asked Questions

Why is choosing the right welding tools important for a project?

Choosing the appropriate tools is vital for the success of any welding project, as different techniques require distinct equipment tailored to the specific needs of the task.

What are the main types of welding techniques mentioned in the article?

The main types of welding techniques mentioned are MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and Stick welding.

What are the advantages of MIG welding?

MIG welding excels with thin materials and is recognized for its speed, making it suitable for tasks that prioritize efficiency.

When is TIG welding preferred?

TIG welding is favored for its precision, especially when handling complex tasks or materials such as stainless steel and aluminum, where high-quality welds are crucial.

What type of welding is best for aluminum projects?

For projects involving aluminum, a TIG welder is often the best choice due to its capability to produce clean and precise welds.

Which welding technique is more suitable for thicker materials or outdoor use?

Stick welding techniques may be more suitable for thicker materials or outdoor uses where wind can impact the joining process.

How can examining case studies help in choosing welding tools?

Investigating the capabilities of each joining tool and examining case studies can provide insights into how contractors effectively employed welding tool rental agreements to meet task requirements and enhance project outcomes.

What benefits did a stadium construction team experience by using a diverse welding tool rental fleet?

The stadium construction team was able to adhere to strict timelines while upholding high safety standards, conserving considerable time and showcasing the efficiency advantages of choosing the appropriate tools.

How does EZ Equipment Rental contribute to project success?

EZ Equipment Rental's commitment to quality and reliability ensures that the tools rented meet high standards, further enhancing the success of welding projects.