Key Highlights:

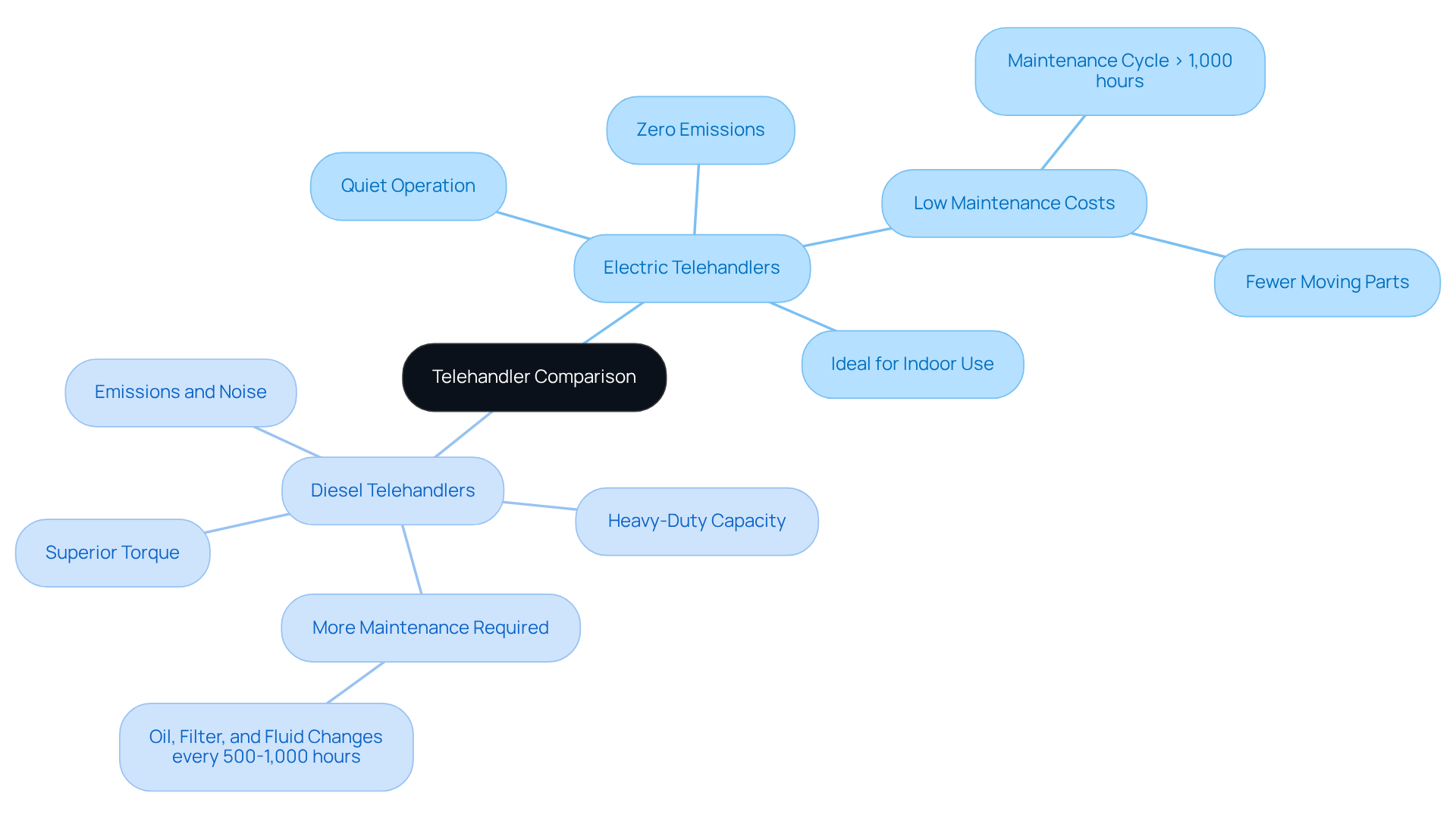

- Electric telehandlers operate on batteries, offering zero emissions and quiet operation, ideal for indoor and urban environments.

- Electric models have lower maintenance costs, with service intervals exceeding 1,000 hours, as they lack fuel filters and oil changes.

- Diesel telehandlers use combustion engines, providing superior torque and lifting capacity for heavy-duty outdoor tasks.

- Diesel models are more robust and can navigate rugged terrains but require more frequent maintenance and produce emissions.

- Electric telehandlers have lower operational costs, with annual charging costs significantly less than diesel fuel costs, promoting long-term savings.

- Limitations of electric telehandlers include restricted operational range due to battery life and higher initial purchase costs.

- Diesel telehandlers are more suitable for outdoor projects needing high lifting capacities and quick refuelling for extended use.

- The choice between electric and diesel telehandlers should consider job site requirements, environmental regulations, and budget constraints.

Introduction

The construction industry stands at a pivotal moment, facing the decision between electric and diesel telehandlers as it strives for a more sustainable future. Each option offers unique advantages and challenges, influencing not only operational efficiency but also environmental compliance and cost-effectiveness. As project managers evaluate their choices, a critical question emerges: which type of telehandler best addresses the diverse needs of contemporary construction sites? This article explores the essential comparisons between electric and diesel telehandlers, providing insights that can inform sound decisions in the dynamic landscape of powered lift equipment.

Understand Key Differences Between Electric and Diesel Telehandlers

Electric lift machines, powered by batteries, offer zero emissions and operate quietly, making them ideal for indoor and urban environments. With a maintenance cycle exceeding 1,000 hours between services, these machines incur lower maintenance costs due to fewer moving parts and the elimination of fuel filters or oil changes.

In contrast, diesel-powered material handlers utilize combustion engines, delivering superior torque and lifting capacity essential for heavy-duty outdoor tasks. These diesel models are generally more robust, capable of navigating rugged terrains without the limitations of battery life. However, they require oil, filter, and fluid changes every 500 to 1,000 hours. Additionally, diesel-powered machines produce emissions and generate more noise, which can be problematic in noise-sensitive areas.

As the construction vehicle market is projected to reach US$150 billion by 2043, the importance of powered lift trucks continues to grow. Ultimately, the choice between electric and diesel machines depends on specific job site requirements, including compliance with environmental regulations and the nature of the tasks involved. Electric lifting machines excel in environments requiring zero tailpipe emissions and minimal noise, reinforcing their advantages in sensitive settings.

Evaluate the Benefits and Drawbacks of Electric Telehandlers

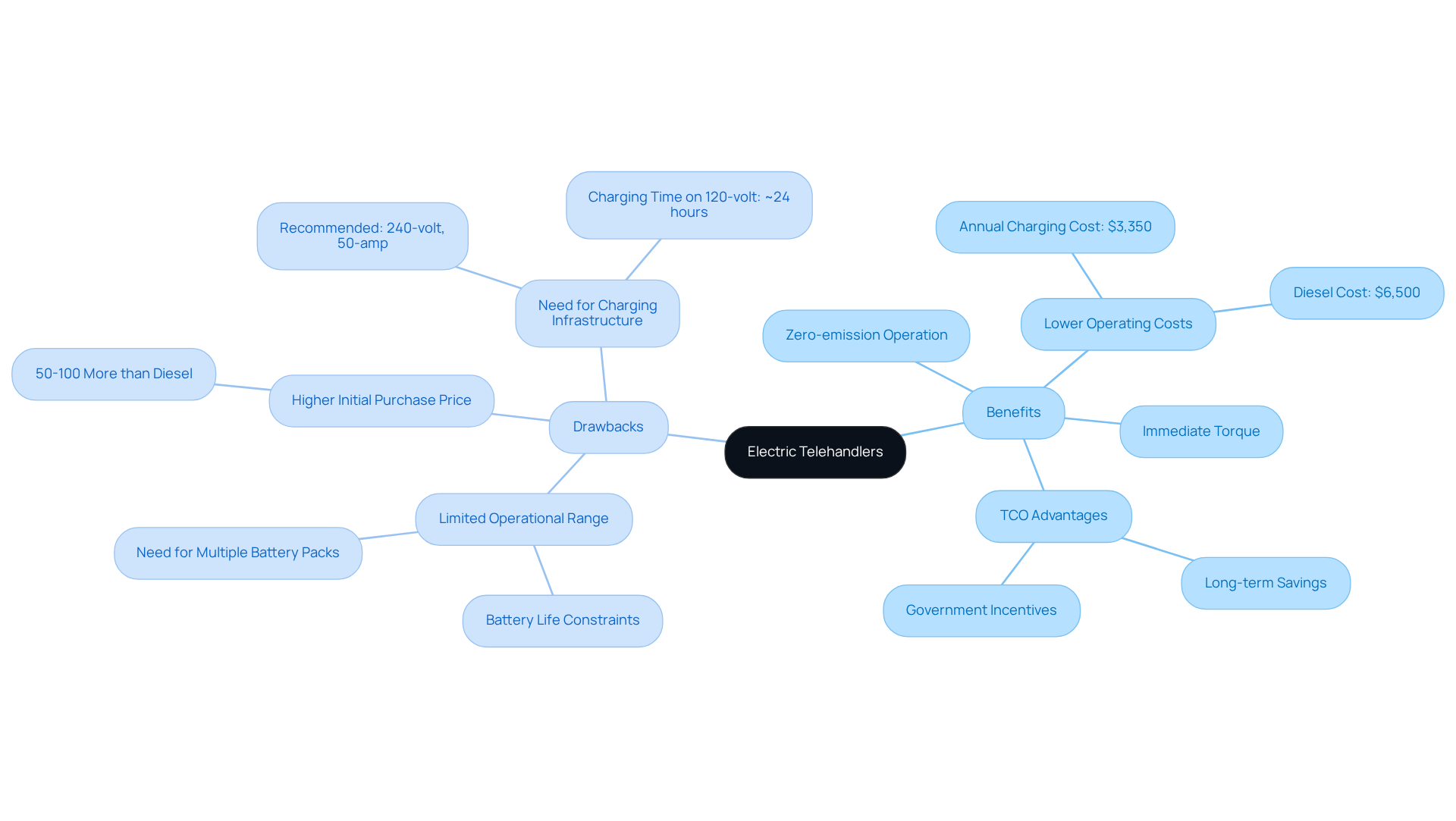

Electric telehandlers offer numerous advantages, especially in urban and indoor job sites where air quality is crucial. Their zero-emission operation not only meets environmental regulations but also improves workplace safety. Operating expenses are significantly lower, as battery-powered models eliminate the need for oil changes and fuel filters, leading to substantial long-term savings. For instance, the annual charging cost for a battery-powered telehandler is approximately $3,350, compared to $6,500 for a diesel counterpart, highlighting a clear financial incentive for extended use. Additionally, the total cost of ownership (TCO) benefits of battery-powered machines are expected to drive their adoption, as industry experts note that these savings can greatly exceed initial investment costs.

Moreover, electric-powered handlers deliver immediate torque, enhancing efficiency in material handling tasks. However, they do have limitations. The operational range is limited by battery life, making them less suitable for larger job sites or extended shifts without careful planning. Contractors may require multiple battery packs for continuous operation, which adds complexity to their use on larger projects. Furthermore, the initial purchase price of battery-powered lifting machines can be 50-100% higher than that of fuel-powered models, which may deter some users despite the potential for lower operational costs.

Experts indicate that while battery-powered machines can match diesel in performance, transitioning to these models necessitates a change in mindset regarding charging infrastructure and usage patterns. A minimum 240-volt, 50-amp charging setup is recommended for optimal operation of battery-powered forklifts. As the industry evolves, the TCO advantages of electric handlers are anticipated to encourage their uptake, particularly as advancements in battery technology continue to enhance their viability for various applications.

Assess the Advantages and Limitations of Diesel Telehandlers

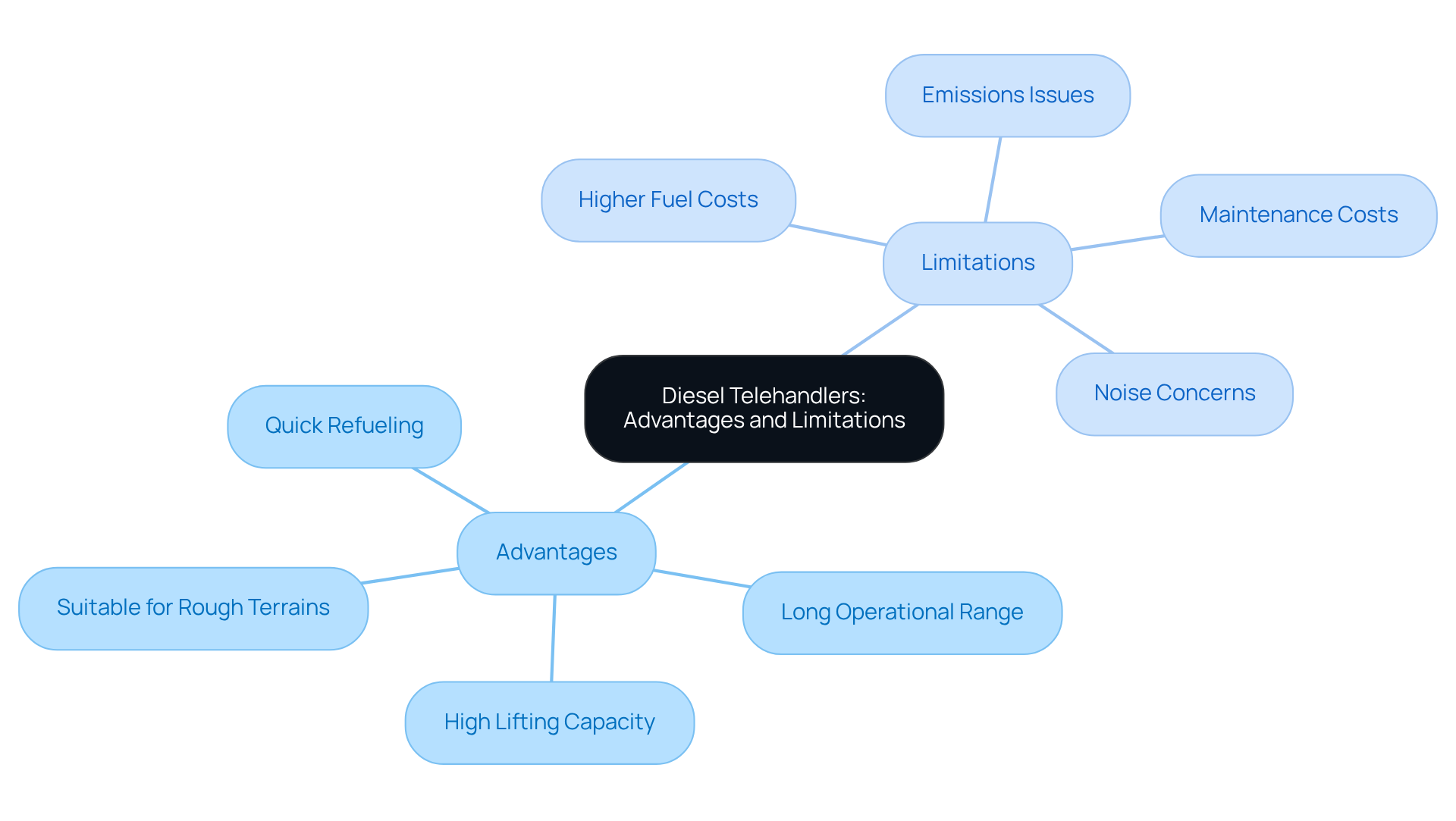

Diesel forklifts are well-regarded for their impressive lifting capacity and torque, making them suitable for heavy-duty applications and outdoor settings. They excel on rough terrains and are less impacted by adverse weather conditions, ensuring reliability in demanding job sites. Additionally, diesel models offer a longer operational range, as they can be refueled quickly, facilitating extended use without interruptions.

However, there are notable drawbacks to consider. Diesel forklifts typically incur higher fuel and maintenance costs, and their emissions may restrict usage in urban or enclosed environments. Furthermore, these diesel-powered material handlers tend to produce more noise, which can be a concern in noise-sensitive areas. Understanding these factors is essential for project managers when selecting the appropriate equipment for their specific needs.

Compare Suitability of Electric vs. Diesel Telehandlers for Construction Projects

When evaluating the suitability of electric versus diesel telehandlers for construction projects, several critical factors must be considered.

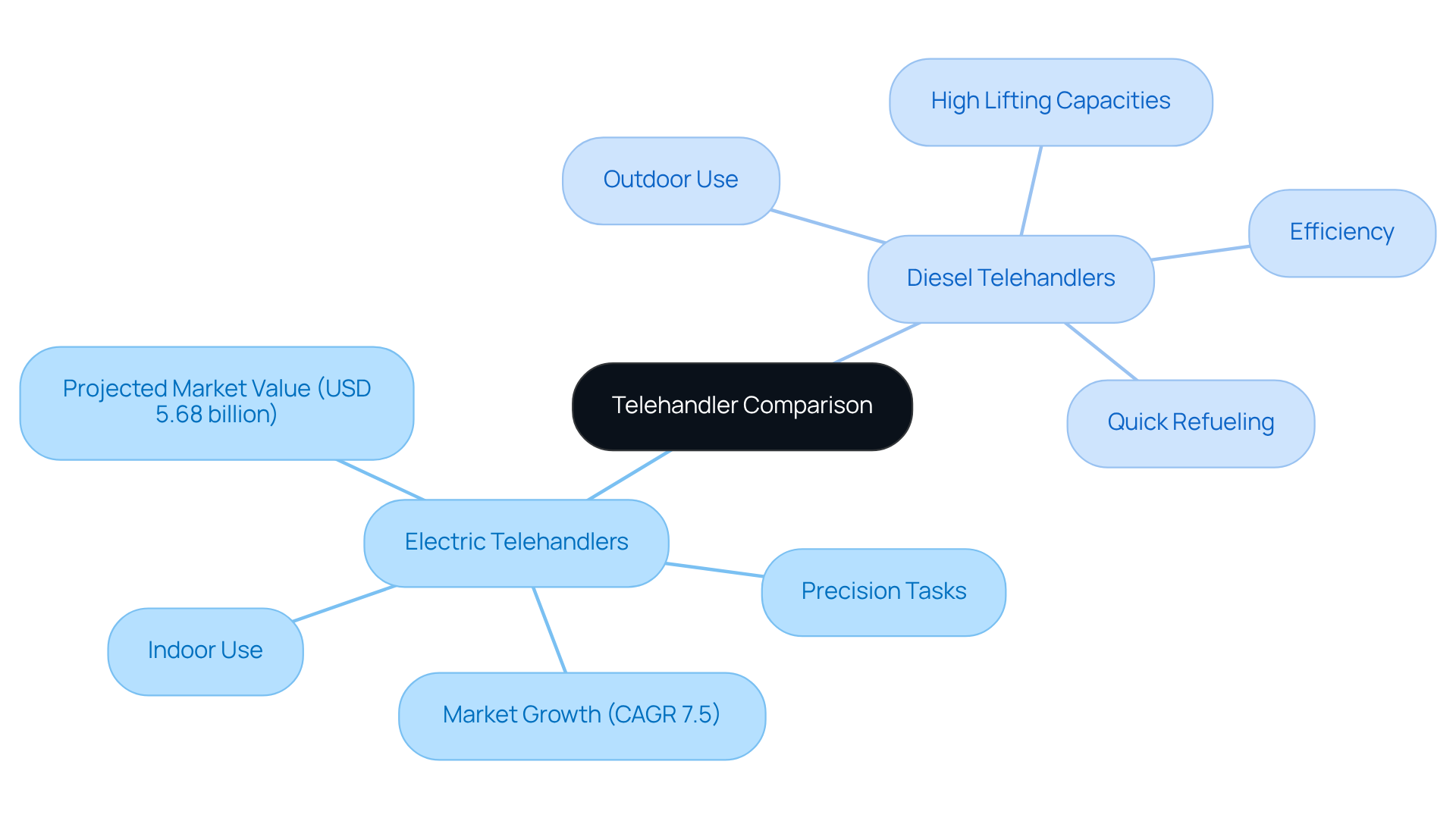

Electric Telehandlers are best suited for indoor applications or urban settings where emissions and noise levels are significant concerns. They are designed for precision tasks and lower lifting capacities, making them ideal for material handling in confined spaces. The market for electric telehandlers is projected to grow at a CAGR of 7.5%, reflecting the increasing demand for sustainable construction solutions. Furthermore, the powered telehandler market is anticipated to reach a value of USD 5.68 billion by 2025.

In contrast, Diesel Telehandlers are the preferred choice for outdoor projects that require high lifting capacities and robust performance in challenging conditions. They excel at handling heavy materials and can operate efficiently over extended hours, making them indispensable on construction sites. Quick refueling is essential for maintaining continuous operation in demanding environments.

Ultimately, the decision regarding a telehandler for rent should be guided by the specific requirements of the project, including environmental considerations, operational demands, and budget constraints. As the telehandler market continues to evolve, understanding these distinctions will empower project managers to make informed choices that enhance productivity and safety on site.

Conclusion

The choice between electric and diesel telehandlers is pivotal for optimizing construction projects, as each type presents unique advantages and challenges. Electric telehandlers excel in urban and indoor settings where noise and emissions are critical concerns, while diesel models are better suited for heavy-duty outdoor applications that demand robust performance and extended operational range.

Key comparisons throughout the article highlight that electric telehandlers offer lower operational costs and zero emissions, positioning them as a sustainable option for specific job sites. Conversely, diesel telehandlers provide superior torque and lifting capacity, which are essential for addressing demanding tasks in rugged terrains. By understanding these distinctions, project managers can make informed decisions about the right equipment tailored to their project's unique requirements.

As the telehandler market continues to evolve and the demand for sustainable solutions grows, making informed choices becomes increasingly vital. Evaluating the suitability of electric versus diesel telehandlers not only boosts productivity and safety on construction sites but also aligns with broader environmental objectives. Ultimately, the future of construction equipment relies on this understanding, fostering a transition towards more efficient and eco-friendly practices.

Frequently Asked Questions

What are the main advantages of electric telehandlers?

Electric telehandlers offer zero emissions, operate quietly, and have a maintenance cycle exceeding 1,000 hours between services, resulting in lower maintenance costs due to fewer moving parts and no need for fuel filters or oil changes.

What are the benefits of diesel telehandlers?

Diesel telehandlers provide superior torque and lifting capacity, making them ideal for heavy-duty outdoor tasks. They are generally more robust and can navigate rugged terrains without the limitations of battery life.

How often do diesel telehandlers require maintenance?

Diesel-powered machines require oil, filter, and fluid changes every 500 to 1,000 hours.

What environmental considerations are associated with diesel telehandlers?

Diesel telehandlers produce emissions and generate more noise, which can be problematic in noise-sensitive areas.

In what environments are electric telehandlers most suitable?

Electric telehandlers are ideal for indoor and urban environments where zero tailpipe emissions and minimal noise are essential.

What factors should be considered when choosing between electric and diesel telehandlers?

The choice depends on specific job site requirements, including compliance with environmental regulations and the nature of the tasks involved.

List of Sources

- Understand Key Differences Between Electric and Diesel Telehandlers

- Electric vs. Diesel Forklifts: Which One Fits Your Business Needs? (https://clarkmhc.com/electric-vs-diesel-forklifts)

- Electric Vehicles in Construction 2023-2043 (https://idtechex.com/en/research-report/electric-vehicles-in-construction/938)

- Telehandler Engine Options: Compare Diesel & Electric (https://telescro.com/telehandler-engine-options)

- Telehlers Market Outlook 2025-2032 (https://intelmarketresearch.com/telehandlers-market-market-16252)

- Electric Telehandler Market Expansion from 2026 to 2033: Growth Trends and 13.1% CAGR Forecast (https://linkedin.com/pulse/electric-telehandler-market-expansion-from-2026-2033-growth-cf3of)

- Evaluate the Benefits and Drawbacks of Electric Telehandlers

- The latest market analysis shows that the Electric Telehandler Market is poised to grow at a CAGR of 6.6% from 2025 to 2032. (https://linkedin.com/pulse/latest-market-analysis-shows-electric-telehandler-poised-lv0ve)

- Electric Construction Equipment vs Diesel Performance | Volvo CE - The Scoop (https://volvoce.com/united-states/en-us/resources/blog/2021/electric-construction-equipment-vs-diesel-performance-comparisons)

- Electric Vehicles in Construction 2024-2044: Technologies, Players, Forecasts (https://idtechex.com/en/research-report/electric-vehicles-in-construction/1022)

- Diesel vs. Electric Telehandlers: Which Is Right for You? (https://lagrangecrane.com/blog/diesel-vs-electric-telehandlers-which-is-right-for-you)

- Assess the Advantages and Limitations of Diesel Telehandlers

- Telehandler Limitations: What Owners Must Know Before Buying (https://telescro.com/telehandler-limitations-what-buyers-miss)

- How Telehandler Innovation at ConExpo 2026 Signals a New Era for Jobsite Efficiency - FULIAN Machinery Parts Official (https://fl-part.com/how-telehandler-innovation-at-conexpo-2026-signals-a-new-era-for-jobsite-efficiency)

- High-capacity telehandlers face test of strength amid economic headwinds (https://internationalrentalnews.com/news/high-capacity-telehandlers-face-test-of-strength-amid-economic-headwinds/8083420.article)

- Telehandler Operation in Confined Spaces (https://dieciaustralia.com.au/blog/telehandler-operation-in-confined-spaces)

- The Benefits and Drawbacks of Using Telehandlers in Construction and A (https://sniperrentals.com/blogs/news/the-benefits-and-drawbacks-of-using-telehandlers-in-construction-and-agriculture?srsltid=AfmBOootVZSdSzKr1uMY8Em8bSrPT5uAsD9mPu6xDPwLfiS5zidrKl5O)

- Compare Suitability of Electric vs. Diesel Telehandlers for Construction Projects

- Telehandler Market Size, Share & Growth | Forecast 2035 (https://expertmarketresearch.com/reports/telehandler-market)

- Electric Telehandler Market Expansion from 2026 to 2033: Growth Trends and 13.1% CAGR Forecast (https://linkedin.com/pulse/electric-telehandler-market-expansion-from-2026-2033-growth-cf3of)

- Telehandler Market Size, Share, Trends, Growth Report 2030 (https://grandviewresearch.com/industry-analysis/telehandler-market-report)

- Telehandler Fuel Consumption: Data, Rates & Cost-Saving Tips (https://telescro.com/telehandler-fuel-consumption)

- Telehandler Market to Reach a value of USD 12.2 bn by 2034 (https://dimensionmarketresearch.com/report/telehandler-market)