Overview

The article presents four effective solutions for addressing equipment-related issues in construction projects. These solutions include:

- Implementing preventive maintenance

- Utilizing digital management tools

- Enhancing team training

- Improving communication practices

Notably, evidence supports the claim that regular maintenance can prevent costly delays, while digital tools and comprehensive training programs significantly reduce operator errors and enhance overall project efficiency.

Implementing preventive maintenance ensures that equipment remains in optimal condition, thereby minimizing the risk of unexpected breakdowns. In addition, utilizing digital management tools streamlines operations, allowing for real-time tracking and efficient resource allocation. Furthermore, enhancing team training equips operators with the necessary skills, fostering a safer and more productive work environment.

Improving communication practices facilitates better collaboration among team members, which is essential for timely project completion. By integrating these solutions, construction projects can achieve higher levels of efficiency and reliability. The combination of regular maintenance, advanced tools, skilled personnel, and effective communication creates a robust framework for success in the equipment rental industry.

To experience these benefits firsthand, consider implementing these strategies in your next project. Engage with us today to explore how our services can elevate your operations and ensure project success.

Key Highlights:

- Common equipment-related issues in construction include mechanical failures, inadequate tool availability, operator errors, and neglect of maintenance.

- Equipment failures contribute to significant project delays, costing the U.S. construction industry $11.5 billion annually in injuries.

- Preventive maintenance and regular servicing are crucial to avoid downtime and repair costs.

- A structured assessment of equipment management practises involves inventory assessment, utilisation analysis, cost evaluation, feedback collection, and compliance checks.

- Digital solutions like asset management software, telematics systems, and predictive maintenance tools can enhance equipment management efficiency.

- Training programmes and clear communication channels are essential for minimising operator errors and improving project outcomes.

- Regular workshops and feedback mechanisms foster a culture of continuous learning and innovation within construction teams.

Introduction

Construction projects are intricate undertakings where every detail counts. However, equipment-related issues often emerge as significant obstacles. Mechanical failures can halt progress, while inadequate tool availability may lead to costly delays. The stakes are high in this environment. This article explores four effective solutions that can revolutionize how construction teams manage equipment, ensuring smoother operations and enhanced safety. With the ever-evolving landscape of technology and training, it is crucial for teams to stay ahead of the curve and mitigate the risks associated with equipment management.

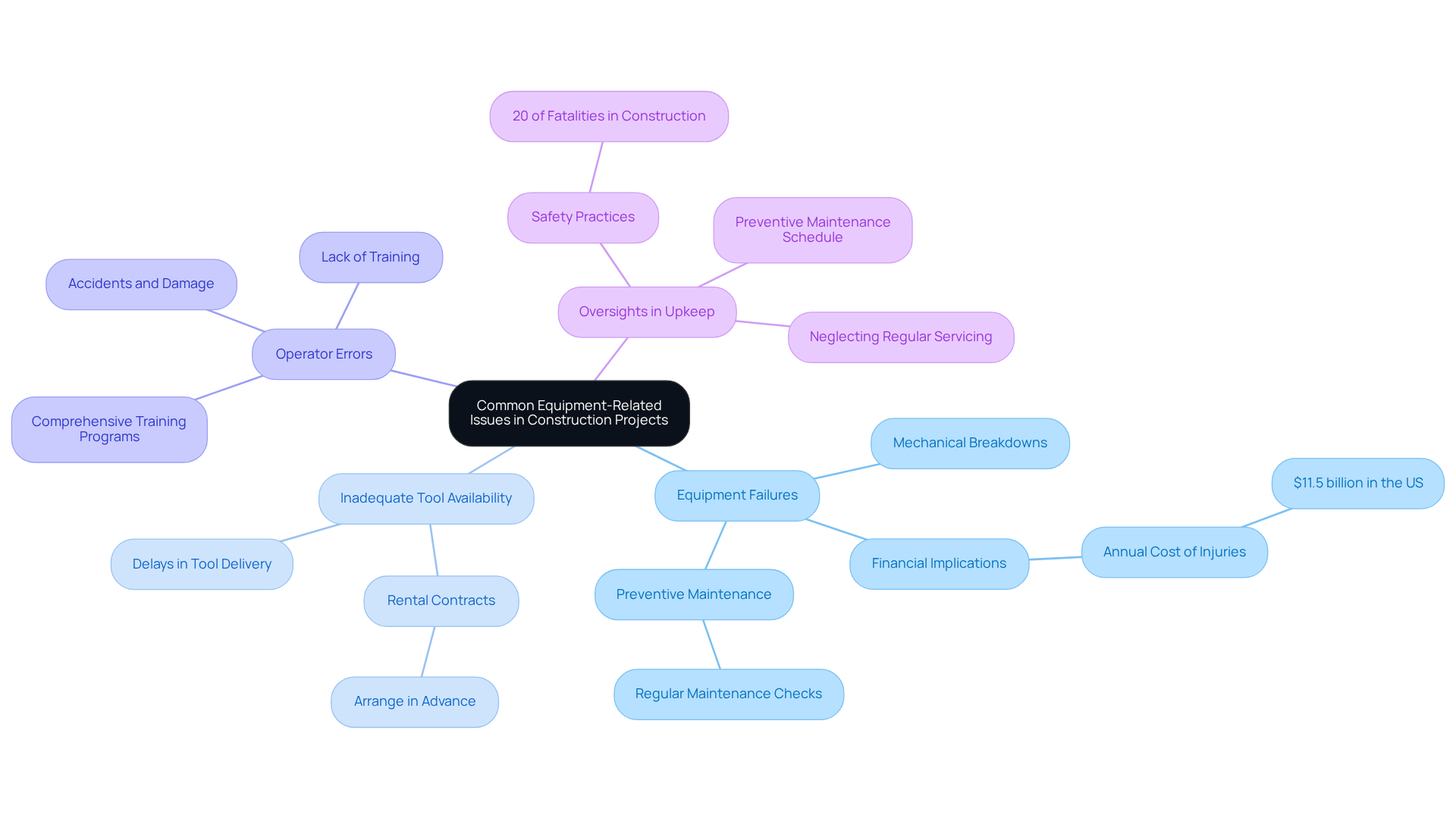

Identify Common Equipment-Related Issues in Construction Projects

To effectively address solutions for equipment-related issues in construction projects, it is essential to identify the most common challenges that may arise. These include:

- Equipment Failures: Mechanical breakdowns can significantly impede progress, with statistics revealing that equipment failures contribute to substantial project delays. In fact, construction injuries result in an annual expense of $11.5 billion for the United States, underscoring the financial implications of machinery problems. Regular maintenance checks are vital in preventing these failures and ensuring seamless operations.

- Inadequate Tool Availability: Delays in tool delivery or insufficient quantities can lead to costly project setbacks. To mitigate this risk, it is crucial to arrange rental contracts in advance, ensuring prompt access to essential tools.

- Operator Errors: Lack of training can lead to improper equipment use, resulting in accidents or damage. As David Auton, Senior Reliability Engineering Director, noted, "Investing in preventive care actually saves money." Implementing a comprehensive training program for all operators is essential to minimize these risks and enhance on-site safety.

- Oversights in Upkeep: Neglecting regular servicing can exacerbate machinery issues, leading to increased downtime and repair costs. Establishing a preventive maintenance schedule is crucial to keeping machinery in optimal condition and avoiding unnecessary interruptions. The importance of maintenance is further highlighted by the fact that 20% of all fatalities in the private sector occur in the construction industry, emphasizing the need for stringent safety practices.

By recognizing and addressing these prevalent solutions for equipment-related issues in construction projects, construction teams can better prepare their resources and strategies to effectively tackle challenges.

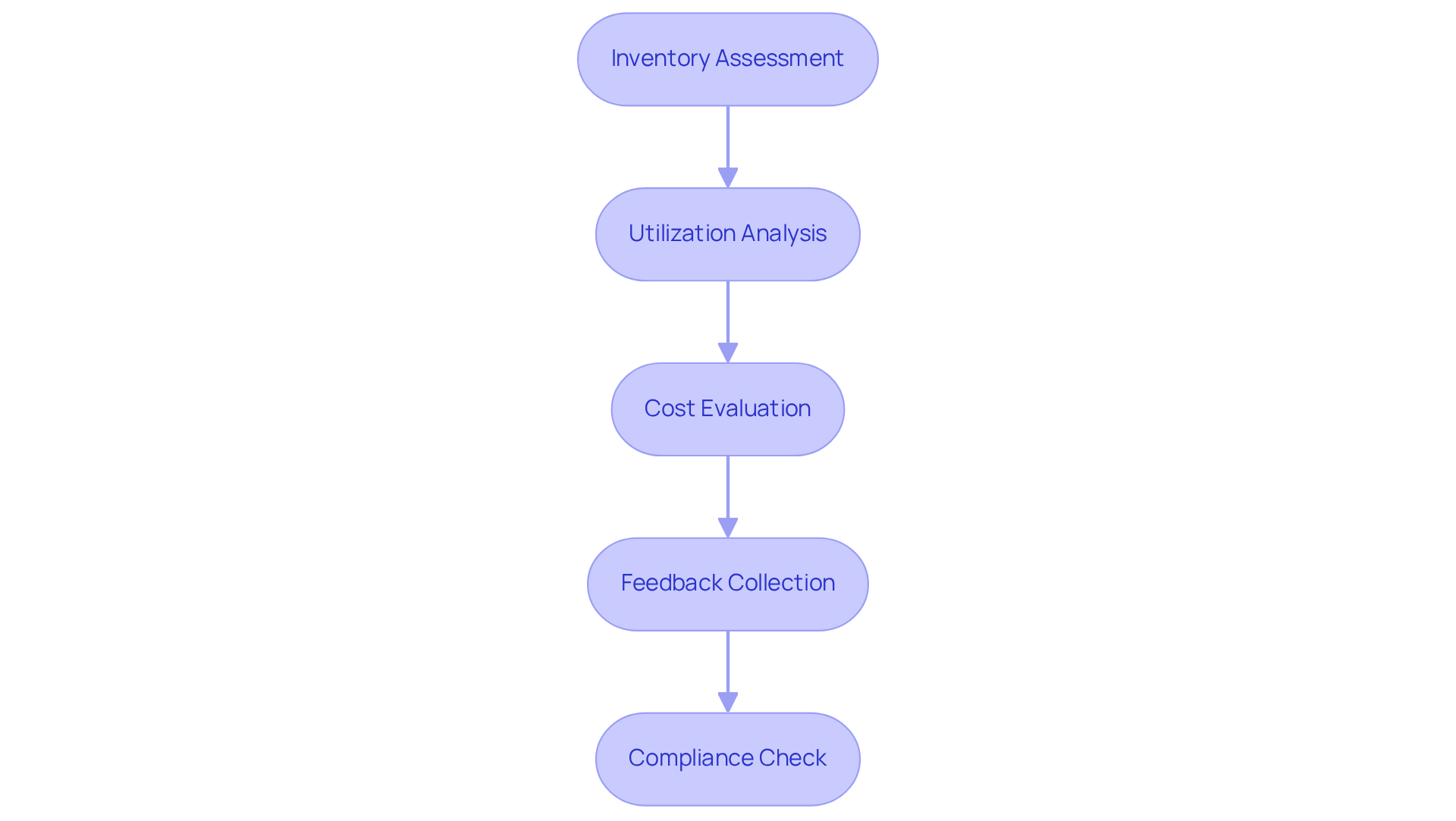

Assess Current Equipment Management Practices

To enhance your equipment management practices, conduct a thorough assessment by following these steps:

-

Inventory Assessment: Begin with a comprehensive inventory of all operational tools, detailing their condition, usage frequency, and maintenance history. This foundational step is essential for understanding your current assets. As Paul Tournier wisely noted, "A goal without a plan is just a wish," underscoring the significance of structured assessments.

-

Utilization Analysis: Next, evaluate the usage rates of each item. Identify underutilized assets that could be leased or sold; nearly 30% of construction machinery often remains inactive due to breakdowns, maintenance, or inefficiencies, necessitating solutions for equipment-related issues in construction projects. Addressing these underutilized assets is vital for optimizing resource allocation.

-

Cost Evaluation: Examine the financial implications of each asset, including maintenance, repairs, and downtime costs. Unscheduled downtime is projected to cost manufacturers as much as $50 billion annually, which highlights the necessity of solutions for equipment-related issues in construction projects. This analysis will help pinpoint which items are financially viable and which may be draining resources.

-

Feedback Collection: Solicit input from operators and management regarding performance and any challenges faced. This feedback is crucial for addressing practical issues and enhancing overall efficiency.

-

Compliance Check: Finally, ensure that all devices comply with safety and regulatory standards. Aging machinery is nearly three times more likely to cause unplanned downtime than operator errors, making solutions for equipment-related issues in construction projects essential for maintaining operational integrity and avoiding substantial fines and project delays.

By implementing this structured assessment, you will gain a clearer understanding of your management landscape, enabling you to identify areas that require immediate attention and optimize your operations effectively.

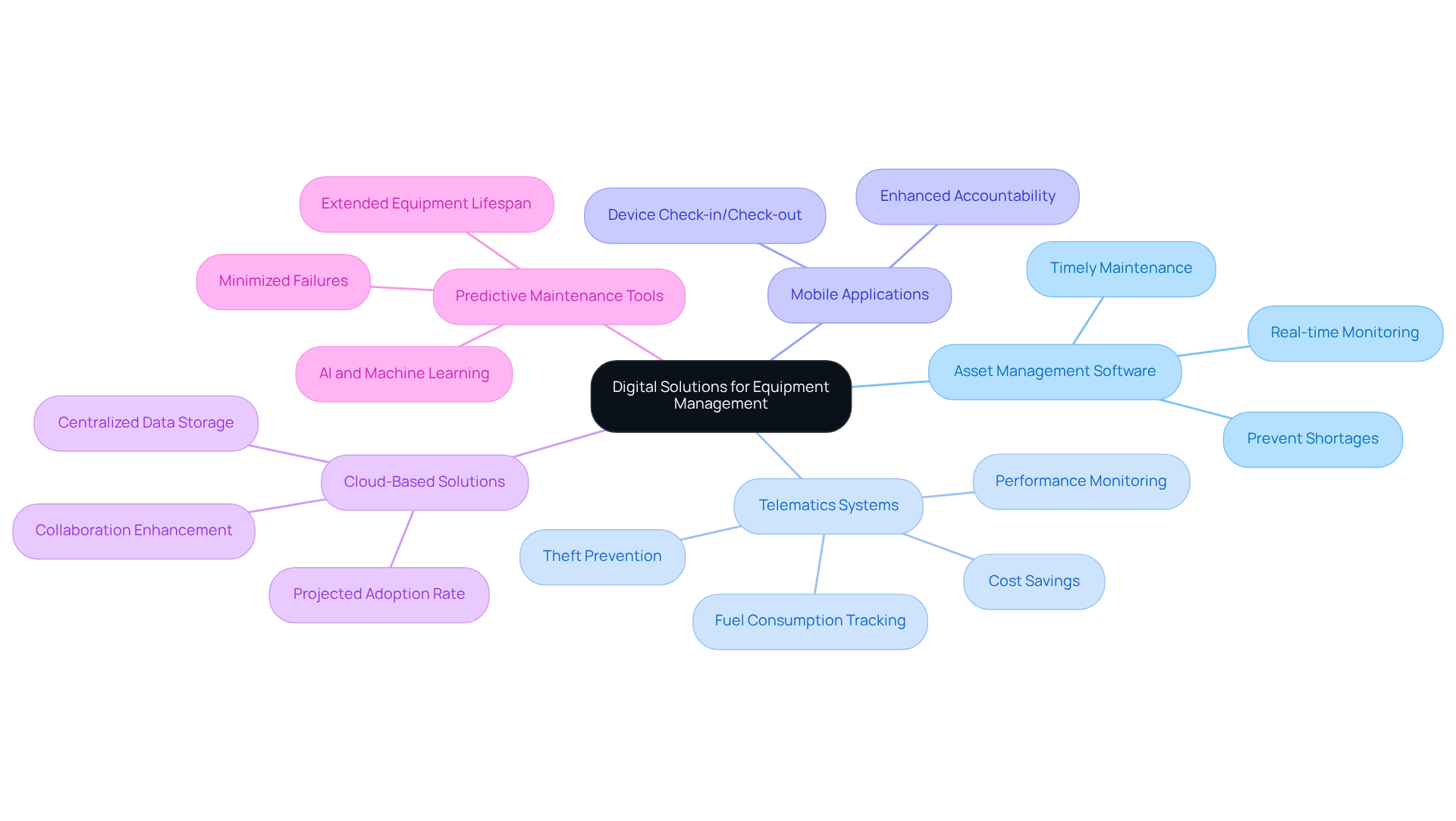

Implement Digital Solutions for Equipment Management

To modernize your equipment management practices, consider implementing the following digital solutions:

-

Asset Management Software: Leverage software that enables real-time monitoring of asset usage, upkeep schedules, and inventory levels. This proactive approach can prevent shortages of tools and ensure timely maintenance, ultimately enhancing project efficiency.

-

Telematics Systems: Installing telematics devices on heavy machinery facilitates the monitoring of performance metrics, fuel consumption, and location. This information not only signals maintenance needs but also optimizes machinery usage, resulting in significant cost savings. Studies show that telematics can improve ROI on heavy machinery by maximizing usage and minimizing unnecessary rentals. Furthermore, telematics systems can alert users when machinery is not operating at peak performance, which is crucial for predictive maintenance and operational efficiency. They also play a critical role in theft prevention and recovery of high-value portable assets, addressing a major concern in construction.

-

Mobile Applications: Implement mobile apps for device check-in/check-out processes, making it easier to track tools across job sites. This enhances accountability and reduces the risk of loss or misplacement of tools.

-

Cloud-Based Solutions: Adopt cloud-based platforms for centralized data storage and access, enabling team members to collaborate and share information effortlessly. By 2025, it is anticipated that 60% of construction firms will utilize cloud-based software for project management, reflecting the industry's shift towards digital transformation.

-

Predictive Maintenance Tools: Employ AI and machine learning tools to predict when machinery will require maintenance based on usage patterns. This proactive strategy minimizes unexpected failures and extends the lifespan of your machinery, ultimately leading to improved operational efficiency.

By incorporating solutions for equipment-related issues in construction projects, you can enhance your asset management efficiency and significantly reduce operational risks.

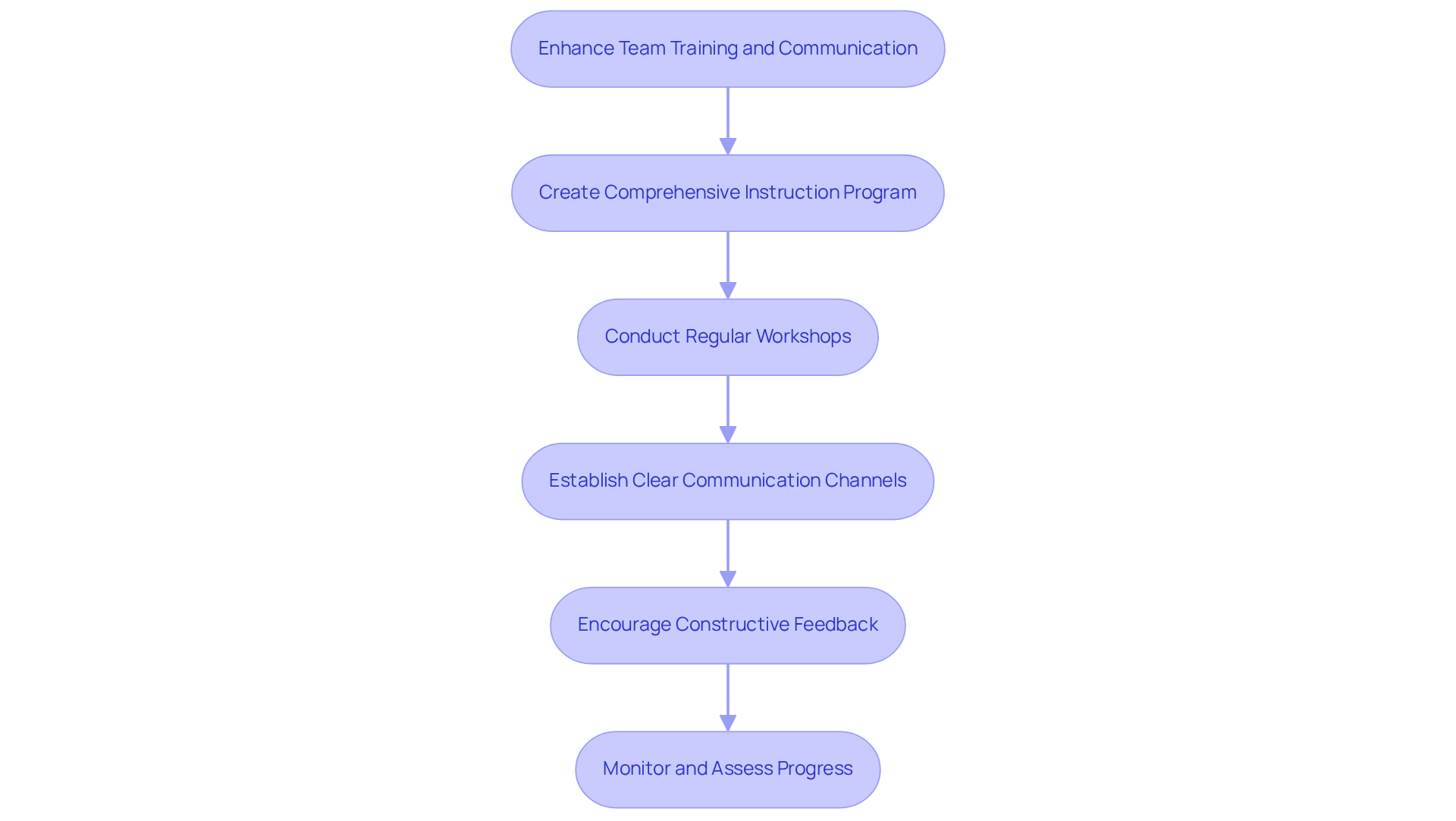

Enhance Team Training and Communication for Effective Implementation

To ensure the successful implementation of your equipment management strategies, it is imperative to prioritize enhancing team training and communication.

-

Create a Comprehensive Instruction Program: Establish a robust instructional program that encompasses machinery operation, maintenance procedures, and safety protocols. It is essential that all team members complete training before operating any machinery, as this foundational knowledge is crucial for both safety and efficiency.

-

Conduct Regular Workshops: Organize frequent workshops to keep the team updated on new tools, emerging technologies, and best practices in management. These sessions not only enhance skills but also foster a culture of continuous learning, leading to improved team performance and reduced accident rates.

-

Establish Clear Communication Channels: Create clear communication protocols for reporting equipment issues, scheduling maintenance, and sharing updates. Employ regular team gatherings and digital communication tools to enable prompt information sharing, which is crucial for reducing downtime and improving coordination. Notably, poor communication causes 48-52% of rework in construction projects, underscoring the critical need for effective communication.

-

Encourage Constructive Feedback: Cultivate an environment where team members feel at ease sharing insights on tool performance and management practices. This open dialogue can lead to continuous improvement and innovation in equipment handling, ultimately enhancing safety and productivity. As Cathy Spears observed, "In construction, where the stakes are high, and the margins for error are slim, mastering the art of communication can be the difference between a task’s success or failure."

-

Monitor and Assess Progress: Regularly evaluate the effectiveness of educational and communication efforts. Utilize metrics such as completion rates and incident reports to guide modifications to programs, ensuring they address the changing requirements of the team and initiative. Observing accident and injury rates before and after instruction can reveal a decrease in figures, signifying the effectiveness of the education.

By prioritizing training and communication, you can build a cohesive team that is well-equipped to provide solutions for equipment-related issues in construction projects effectively, leading to improved project outcomes and enhanced safety standards.

Conclusion

Addressing equipment-related issues in construction projects is paramount for ensuring efficiency, safety, and overall project success. Recognizing common challenges—such as equipment failures, inadequate tool availability, operator errors, and neglect in upkeep—enables construction teams to proactively implement solutions that mitigate risks and enhance operational effectiveness.

Key strategies encompass:

- Conducting thorough assessments of current equipment management practices

- Adopting digital solutions like asset management software and telematics systems

- Prioritizing comprehensive training and communication among team members

These approaches not only streamline operations but also foster a safer work environment, significantly reducing the potential for accidents and costly delays.

Ultimately, the emphasis on effective equipment management transcends mere machinery maintenance; it cultivates a culture of safety, accountability, and continuous improvement within the construction industry. By investing in proper training, leveraging technology, and maintaining open lines of communication, construction teams can confidently navigate equipment-related challenges, ensuring that projects are completed on time and within budget. Embracing these practices will lead to more resilient operations and a stronger foundation for future success in construction endeavors.

Frequently Asked Questions

What are common equipment-related issues in construction projects?

Common issues include equipment failures, inadequate tool availability, operator errors, and oversights in upkeep.

How do equipment failures impact construction projects?

Equipment failures can significantly impede progress and contribute to substantial project delays, resulting in financial implications, with construction injuries costing the U.S. $11.5 billion annually.

What can be done to prevent equipment failures?

Regular maintenance checks are vital in preventing equipment failures and ensuring seamless operations on construction sites.

What risks are associated with inadequate tool availability?

Delays in tool delivery or insufficient quantities can lead to costly project setbacks. Arranging rental contracts in advance can mitigate this risk.

How can operator errors be minimized?

Implementing a comprehensive training program for all operators is essential to minimize risks associated with improper equipment use.

Why is regular maintenance important for construction machinery?

Regular servicing helps avoid increased downtime and repair costs, ensuring machinery remains in optimal condition and preventing unnecessary interruptions.

What safety statistics highlight the importance of maintenance in construction?

The construction industry accounts for 20% of all fatalities in the private sector, emphasizing the need for stringent safety practices and regular maintenance.