Overview

The article outlines four essential steps for successful line striping removal equipment rental:

- Researching leasing firms

- Understanding leasing terms

- Examining tools

- Scheduling logistics

By emphasizing the importance of careful evaluation of project needs—such as surface type, marking type, and budget—this guide highlights how thorough preparation can significantly enhance the efficiency and effectiveness of the equipment rental process.

In addition, understanding leasing terms allows for better decision-making and financial planning, ensuring that the rental aligns with project requirements.

Furthermore, examining the tools available ensures that the right equipment is chosen for the specific job, which can lead to improved outcomes and satisfaction.

Ultimately, scheduling logistics effectively ensures that the equipment is available when needed, minimizing downtime and maximizing productivity.

Key Highlights:

- Line striping removal is essential for safety and aesthetics on surfaces like asphalt and concrete.

- Key removal methods include grinding, scarifying, and chemical removal.

- Scarifiers remove up to 1/4 inch of material in one pass, ideal for resurfacing.

- Grinders are effective for precision jobs but may generate fine dust and require multiple passes.

- Water blasters use high-pressure jets to remove markings without damaging the surface.

- Chemical strippers are effective for specific paint types but require careful handling.

- Choosing the right equipment depends on surface type, marking type, project size, budget, and time constraints.

- The line striping machines market is projected to grow at a CAGR of 5.56%.

- To rent equipment, research firms, cheque availability, understand leasing terms, examine tools, schedule delivery, and know the return process.

Introduction

Line striping removal is not merely about erasing marks from asphalt or concrete; it is a vital process that enhances both safety and aesthetics across various environments. With an array of techniques and equipment at your disposal, grasping the nuances of each method can profoundly influence the success of your project. Given the multitude of options and considerations, how can one ensure the selection of the appropriate equipment and approach tailored to specific needs? This article explores essential steps and insights for effectively renting line striping removal equipment, guiding you through the complexities of this critical task.

Understand Line Striping Removal Basics

Line striping removal equipment rental is a critical service that involves erasing existing markings on surfaces such as asphalt or concrete. This process is essential not only for maintaining safety but also for enhancing the aesthetics of parking lots and roadways through line striping removal equipment rental.

Key methods employed in this service include:

- Grinding

- Scarifying

- Utilizing line striping removal equipment rental for chemical removal

Understanding the type of material and the nature of the markings is vital, as different techniques may be required based on these factors. Thorough preparation is crucial; evaluating the condition of the area and selecting the appropriate removal method ensures optimal outcomes without damaging the underlying material.

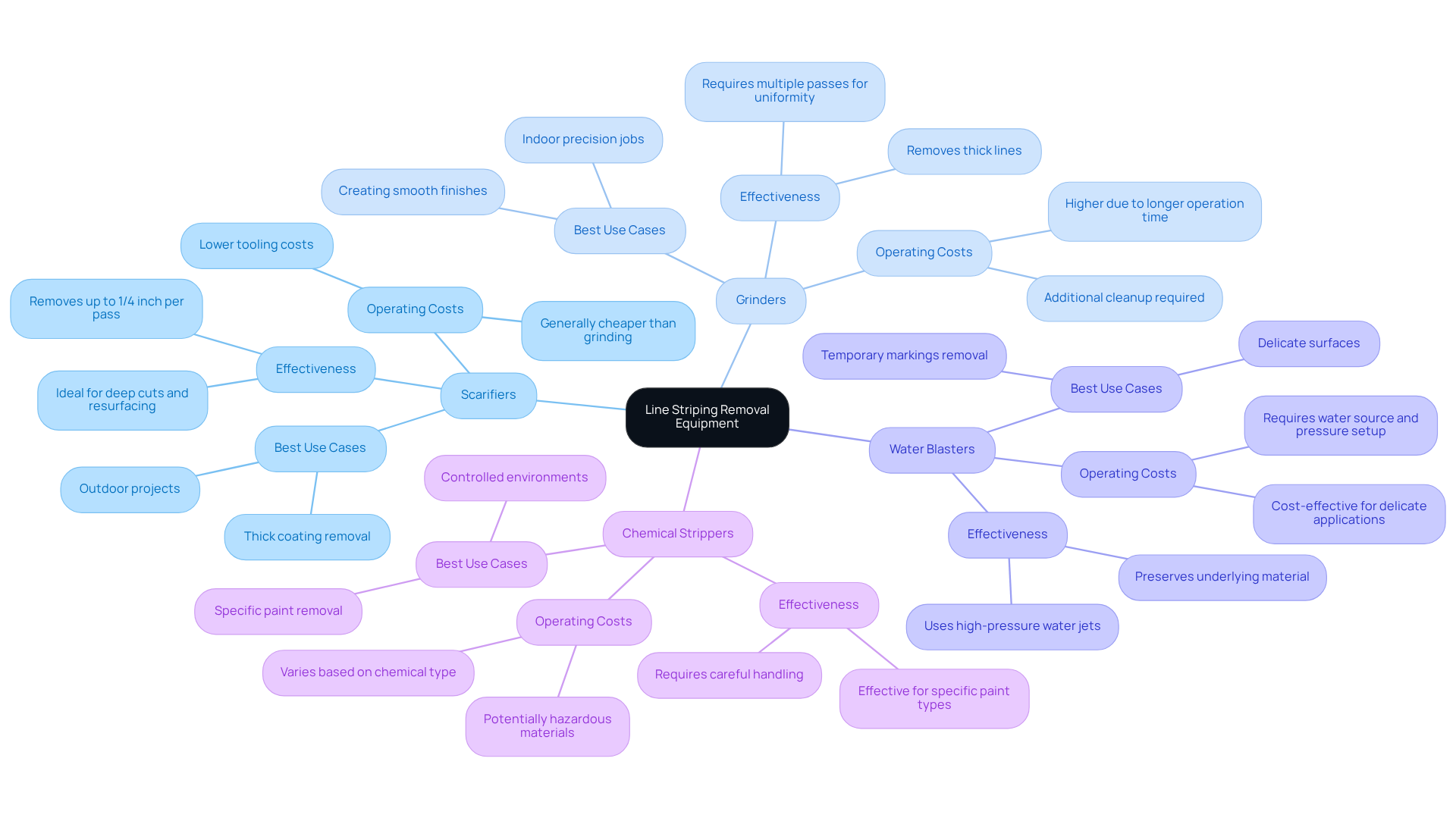

Explore Types of Line Striping Removal Equipment

When it comes to line striping removal, line striping removal equipment rental is essential for achieving optimal results.

-

Scarifiers utilize rotating blades to effectively scrape off markings, making them particularly useful for various surfaces. These machines can remove layers of concrete up to 1/4 inch thick in a single pass and are effective for resurfacing projects requiring cuts deeper than ⅛ of an inch, creating a rough profile that enhances bonding with new coatings.

-

Grinders, known for their heavy-duty capabilities, can swiftly eliminate thick lines. However, they may require additional cleanup due to the fine dust generated during operation. Concrete grinding can take significantly longer than scarifying, increasing operating costs. Grinders are perfect for precision jobs, particularly when a smooth result is needed, but they may require several passes to attain a uniform texture.

-

Water Blasters utilize high-pressure water jets to eliminate markings without harming the underlying material, making them appropriate for delicate applications. Operating at pressures between 15,000 and 30,000 PSI, waterblasting effectively pulverizes temporary markings while preserving the integrity of the pavement.

-

Chemical Strippers are designed for specific types of paint and can be effective but necessitate careful handling and adherence to safety precautions. Determining the kind of paint is essential for choosing the suitable chemical solution, guaranteeing effective removal without harming the material.

Choosing the appropriate line striping removal equipment rental depends on elements like scale, type of material, and the characteristics of the markings that need to be eliminated. For instance, scarifiers are often preferred for outdoor projects requiring deep cuts, while grinders excel in indoor settings where precision is paramount. Utilizing expert services can further improve the efficiency and safety of the paint removal procedure, reducing risks linked to damage and dangerous chemicals. As noted by US Specialty Coatings, "Utilizing expert services reduces risks like unintentional damage to the area or exposure to harmful chemicals.

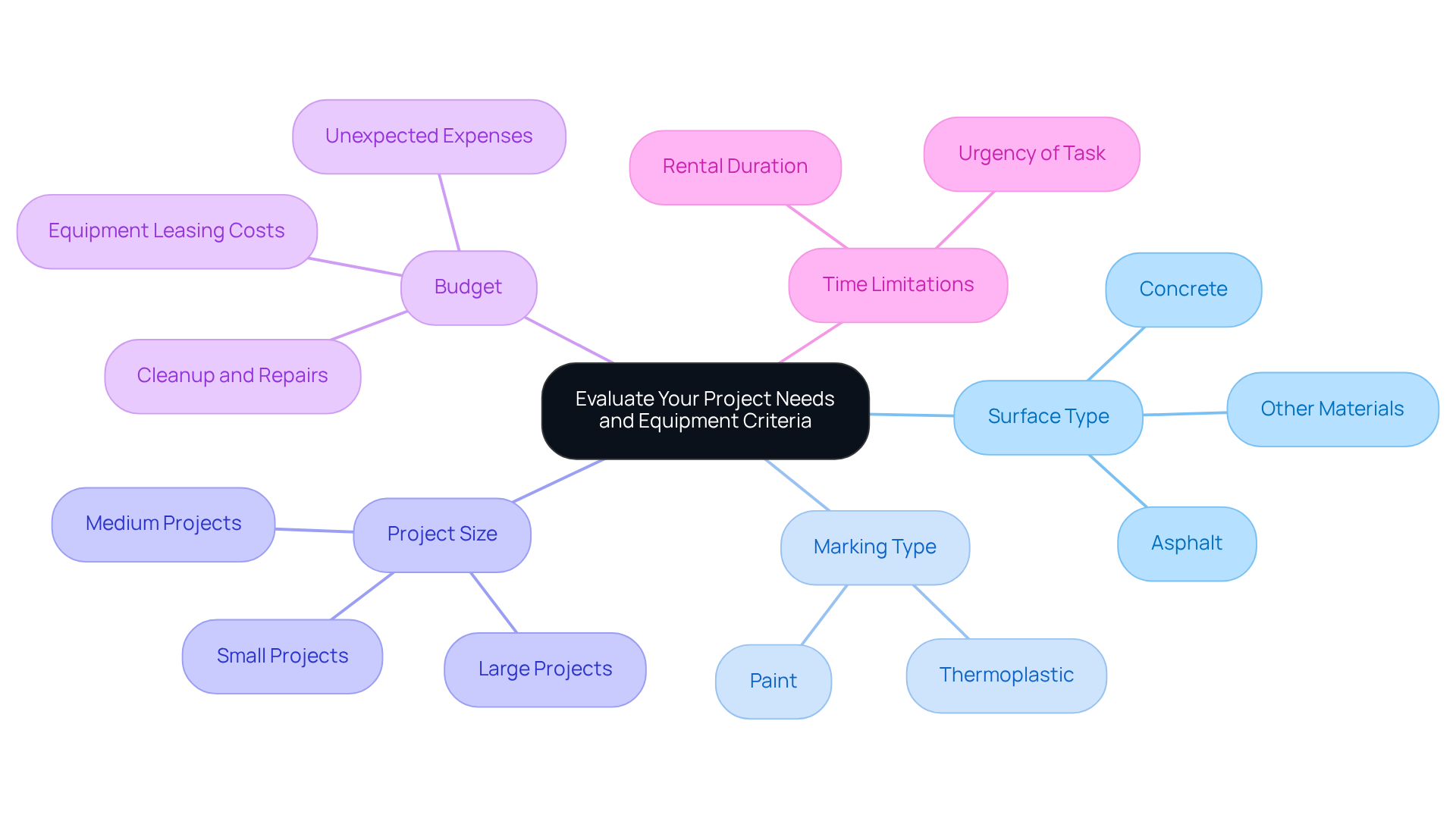

Evaluate Your Project Needs and Equipment Criteria

To effectively evaluate your project needs, consider the following criteria:

- Surface Type: Identify whether the surface is asphalt, concrete, or a different material; this determination significantly impacts your choice of tools.

- Marking Type: Ascertain the type of markings to be removed, such as paint or thermoplastic, to select the most effective removal method.

- Project Size: Assess the area requiring treatment; larger assignments typically necessitate more powerful tools to guarantee efficiency and effectiveness. For instance, successful initiatives like the Head Start Center Lot Project highlight the importance of utilizing appropriate tools for expansive spaces.

- Budget: Develop a comprehensive financial plan for equipment leasing, accounting for potential additional costs related to cleanup or repairs, thereby avoiding unexpected expenses. Notably, well-maintained tools often lead to increased leasing costs due to consistent upkeep and evaluations.

- Time Limitations: Reflect on the urgency of the task, as tight deadlines may dictate the type of equipment selected, influencing both performance and rental duration. Industry specialists emphasize that diligent planning and analysis are crucial for aligning resource requirements with schedule timelines.

By thoroughly assessing these factors, you can ensure the selection of the most suitable tools for your line striping removal equipment rental, ultimately leading to successful outcomes. Incorporating these considerations will not only enhance project efficiency but also align with the growing trend in the line striping machines market, projected to exhibit a CAGR of 5.56%.

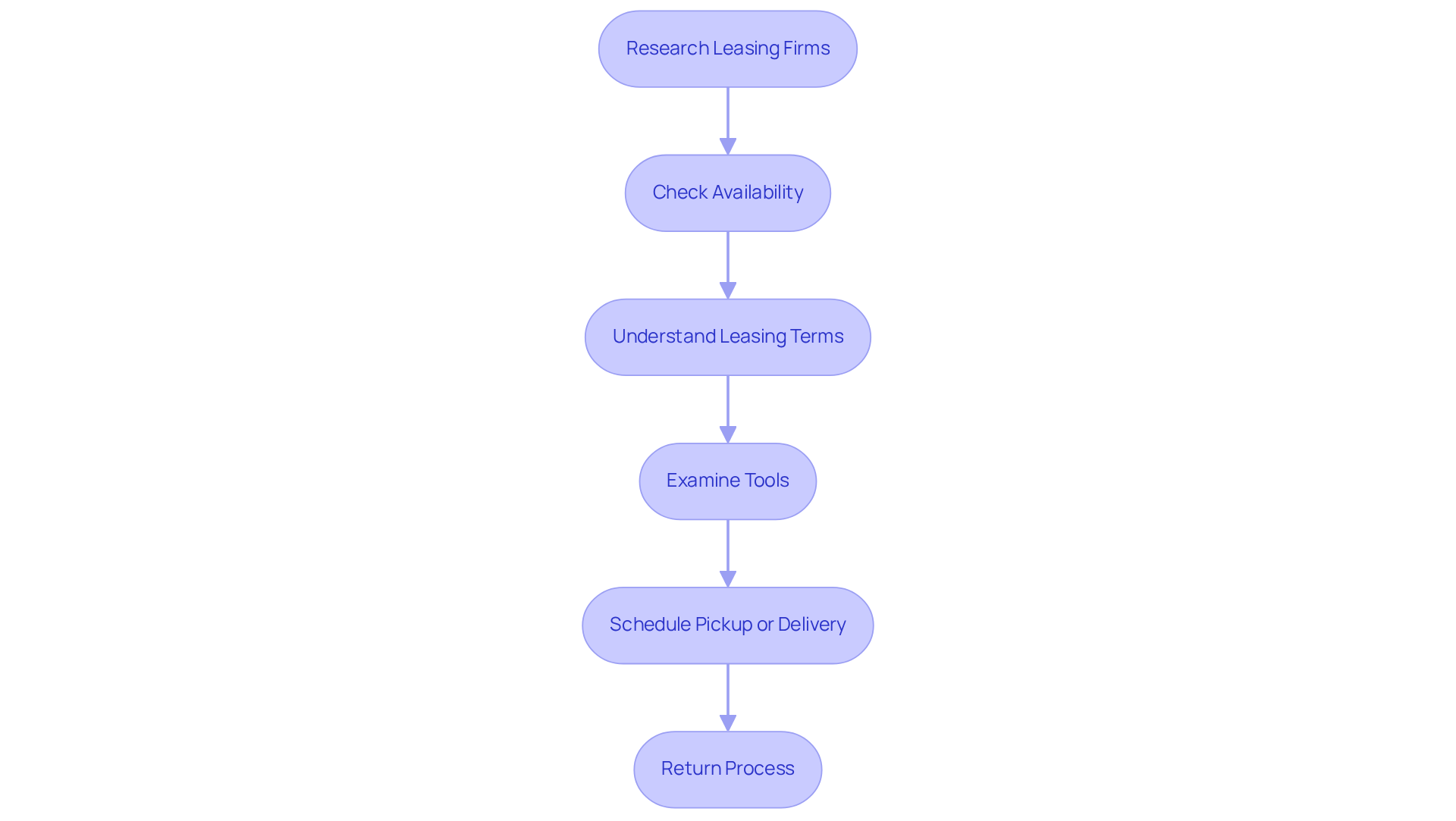

Navigate the Equipment Rental Process

To successfully navigate the equipment rental process, follow these essential steps:

- Research Leasing Firms: Begin by identifying reputable leasing firms in your area, such as EZ Equipment Leasing. This firm is well-known for its specialization in construction tools and its unwavering commitment to customer satisfaction.

- Check Availability: Next, contact the leasing company to confirm the availability of the line striping removal equipment rental you need based on your schedule. This ensures prompt access to the essential instruments necessary for your project.

- Understand Leasing Terms: It is crucial to carefully review the lease agreement, paying close attention to the duration, costs, and any additional fees. A clear understanding of these terms can prevent unexpected expenses and enhance your leasing experience.

- Examine Tools: Prior to concluding the rental, thoroughly examine the tools to ensure they are in proper working order and meet your task requirements. This step is vital for avoiding delays and ensuring the success of your endeavor.

- Schedule Pickup or Delivery: Organize for the items to be collected or delivered to your work location. Confirm that you have the necessary transportation if required, as this can streamline the process and enhance efficiency.

- Return Process: Familiarize yourself with the return process, including any cleaning or maintenance requirements to avoid additional charges. Understanding these details can significantly improve your overall leasing experience.

By adhering to these steps, you can ensure a successful equipment rental experience that effectively meets your project needs.

Conclusion

Successfully managing line striping removal equipment rental requires a comprehensive understanding of the process and the tools involved. This article outlines crucial steps and considerations to ensure the effective removal of markings from surfaces, highlighting the importance of selecting the right equipment tailored to specific project needs.

Key points discussed include the various types of line striping removal equipment, such as:

- Scarifiers

- Grinders

- Water blasters

- Chemical strippers

Each serves distinct purposes based on surface type and marking characteristics. Additionally, evaluating project needs—such as surface type, marking type, project size, budget, and time limitations—plays a vital role in determining the most suitable tools for the job. Navigating the equipment rental process with careful planning and attention to detail further enhances the likelihood of a successful outcome.

In conclusion, understanding the intricacies of line striping removal and the equipment rental process is essential for achieving optimal results. By applying the insights shared in this guide, individuals and businesses can confidently approach their projects. This ensures not only efficiency but also safety and quality in the removal of markings. Embracing these best practices will lead to improved aesthetics and functionality of surfaces, ultimately contributing to a safer and more organized environment.

Frequently Asked Questions

What is line striping removal?

Line striping removal is the process of erasing existing markings on surfaces such as asphalt or concrete, which is essential for maintaining safety and improving the aesthetics of parking lots and roadways.

Why is line striping removal important?

It is important for maintaining safety on roadways and parking lots and for enhancing the visual appeal of these surfaces.

What methods are used for line striping removal?

The key methods for line striping removal include grinding, scarifying, and utilizing chemical removal techniques.

How does the type of material affect line striping removal?

Understanding the type of material and the nature of the markings is vital, as different techniques may be required based on these factors.

Why is preparation important in line striping removal?

Thorough preparation is crucial as it involves evaluating the condition of the area and selecting the appropriate removal method to ensure optimal outcomes without damaging the underlying material.