Overview

This article presents four essential steps for successfully renting underground boring tools, highlighting the critical need to understand tool types, evaluate selection criteria, compare rental options, and review terms before finalizing any agreements.

It details specific tools such as:

- Horizontal Directional Drills

- Auger Boring Machines

Alongside key considerations like soil conditions and operator skill level. This ensures that contractors can make informed decisions that align with their project requirements and budget constraints.

By following these guidelines, contractors can confidently navigate the rental process, ensuring they select the most suitable equipment for their needs.

Key Highlights:

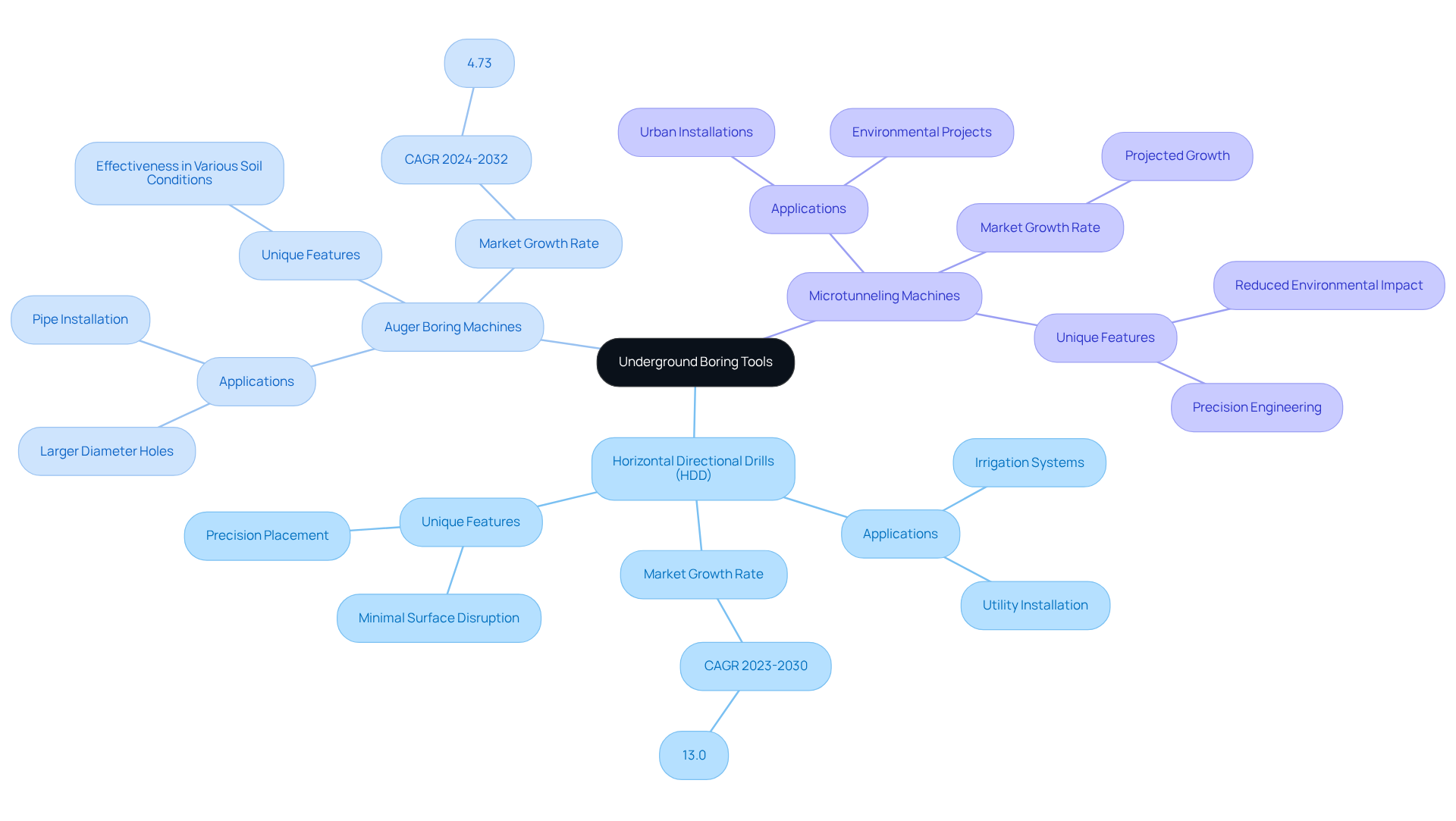

- Underground boring tools are essential for construction and utility installation, with key types including Horizontal Directional Drills (HDD), Auger Boring Machines, and Microtunneling Machines.

- The HDD market is projected to grow at a CAGR of 13.0%, reaching USD 18.70 billion by 2030, driven by infrastructure investments and urbanisation.

- Auger Boring Machines are ideal for larger diameter holes, while Microtunneling Machines are favoured for precise underground installations in urban areas.

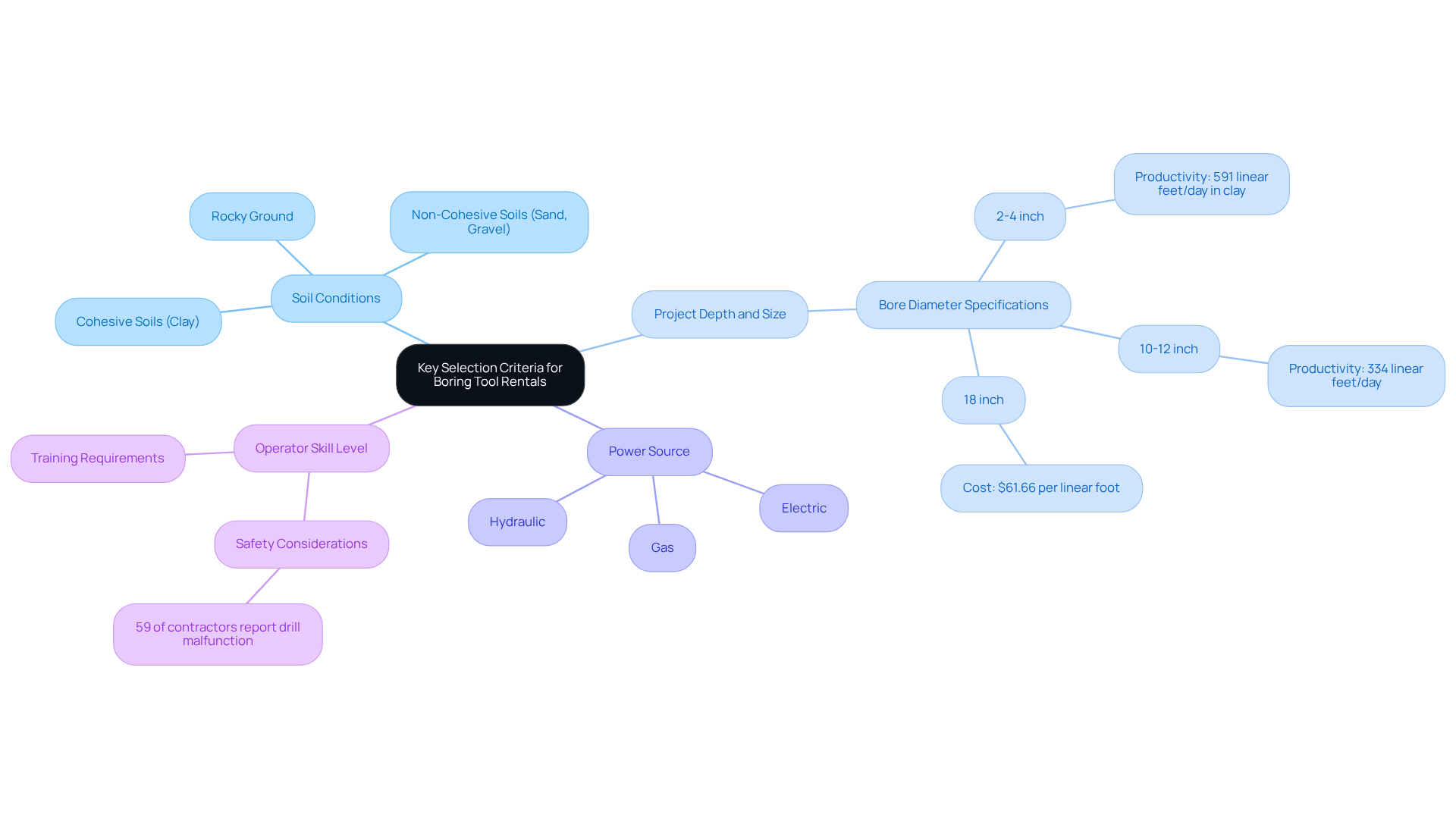

- Key selection criteria for boring tool rentals include soil conditions, project depth and size, power source, and operator skill level.

- Understanding soil types influences equipment choice; for example, clay may require different strategies than rocky soil.

- The median installation cost for a 10-inch diameter bore is approximately $12.00 per linear foot, while an 18-inch diameter installation costs about $61.66 per linear foot.

- Rental process steps include investigating local leasing firms, requesting estimates, comparing tool features, and checking for duration discounts.

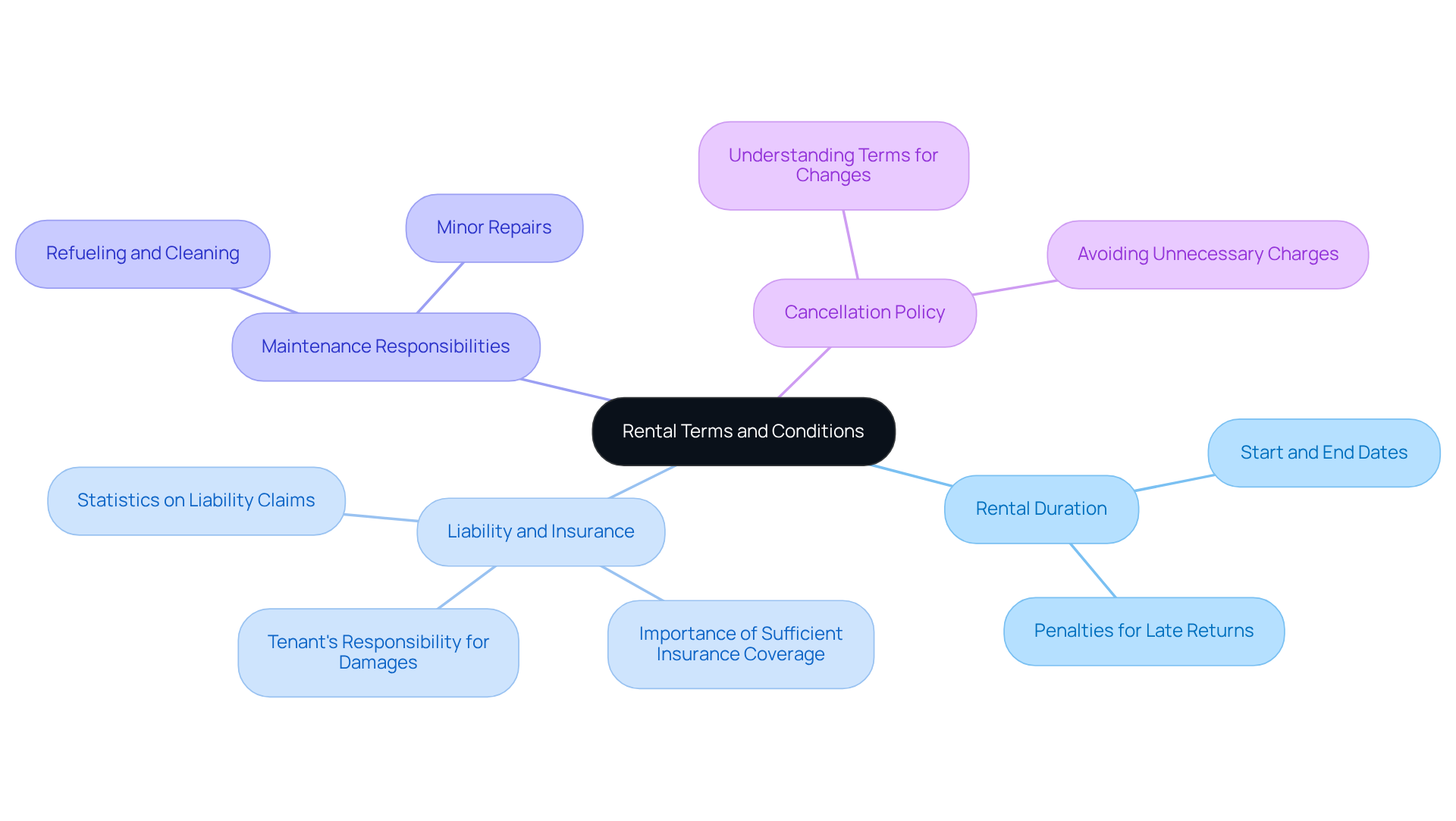

- Before finalising a rental, review terms regarding rental duration, liability and insurance, maintenance responsibilities, and cancellation policies.

Introduction

Understanding the intricacies of underground boring tool rentals is essential for any construction project aiming for efficiency and minimal disruption. The market for these specialized tools is projected to grow significantly, presenting contractors with a unique opportunity to enhance their operations by mastering the rental process. However, navigating the selection criteria, comparing pricing options, and reviewing rental terms can often lead to confusion and costly mistakes. To ensure a successful rental experience that aligns with project needs and budget constraints, it is crucial to follow key steps.

Understand Underground Boring Tools and Their Applications

Subsurface drilling instruments are pivotal in various construction and utility installation projects. The primary types include:

- Horizontal Directional Drills (HDD): These machines excel at installing utilities beneath obstacles such as roads and rivers, facilitating minimal surface disruption. The HDD market is projected to experience significant growth, with a compound annual growth rate (CAGR) of 13.0% from 2023 to 2030. This growth is driven by increasing investments in infrastructure and urbanization. By 2030, the market value of HDD is expected to reach USD 18.70 billion, underscoring its critical role in modern construction practices.

- Auger Boring Machines: Specifically designed for creating larger diameter holes in soil, auger boring machines are ideal for installing pipes and conduits. Their effectiveness across various soil conditions renders them a preferred choice among contractors.

- Microtunneling Machines: Engineered for precise underground installations, especially in urban settings where minimizing surface disruption is crucial, microtunneling technology is gaining traction. Its efficiency and reduced environmental impact compared to traditional methods make it an attractive option.

Understanding these instruments and their specific applications is vital for selecting the appropriate equipment for your project, whether it involves utility installation, landscaping, or construction work.

For example, if you need to install irrigation pipes under a driveway, a Horizontal Directional Drill would be the most effective choice. This method not only minimizes surface disruption but also allows for precise placement of the pipes, ensuring the integrity of the surrounding area remains intact. As the demand for efficient and environmentally friendly solutions grows, the adoption of HDD technology continues to rise, solidifying its status as a key player in modern construction practices.

Evaluate Key Selection Criteria for Boring Tool Rentals

When considering underground boring tool rental, several key selection criteria must be evaluated to ensure project success.

- Soil Conditions: Understanding the soil type—whether cohesive like clay or non-cohesive such as sand or gravel—is essential. Each type influences the selection of implement and bit. For example, clay might require a different strategy compared to rocky ground, which demands more durable equipment with specialized bits.

- Project Depth and Size: Clearly defining the required depth and size of the bore is crucial. Tasks requiring an 18-inch wide bore will have different tool specifications compared to those requiring a 4-inch wide. The typical productivity for 2-4 inch wide installations in clay can reach up to 591 linear feet daily, while for 10-12 inch widths, it averages about 334 linear feet per day. Furthermore, the median price for 10" product diameter installation is roughly $12.00 per linear foot, offering insight into cost implications associated with depth and diameter.

- Power Source: The selection between electric, gas, or hydraulic-powered equipment should depend on job site accessibility and available power sources. Hydraulic equipment, for instance, may be more appropriate for larger projects needing substantial power.

- Operator Skill Level: Ensure that the chosen implement can be operated safely and effectively by the available personnel. The intricacy of the device should align with the expertise of the operators to avert accidents and guarantee efficiency. Significantly, 59% of contractors indicate that drill malfunction is a frequent issue, highlighting the importance of choosing equipment that matches operator skill levels to alleviate such problems.

For instance, if your project involves boring through rocky soil, opting for a heavy-duty tool with specialized bits designed for such conditions is advisable, rather than using a standard auger. This approach not only enhances efficiency but also minimizes the risk of equipment failure, which is a common issue reported by contractors. Moreover, taking into account the typical expense for 18" product diameter installation at $61.66 per linear foot can offer a clearer financial context for the decision-making process concerning equipment selection. Furthermore, employing HDD with underground boring tool rental can result in savings of 50% to 70% in comparison to micro-tunneling, making it an attractive choice when choosing the appropriate boring equipment.

Compare Rental Options and Pricing for Boring Tools

To identify the most advantageous rental options for underground boring tools, follow these essential steps:

- Investigate Local Leasing Firms: Begin by searching for in your vicinity. EZ Equipment Lease, for instance, is well-regarded for its extensive selection of machinery tailored to various construction needs, including boom lifts, excavators, and mini excavators.

- Request Estimates: Reach out to several leasing firms to gather quotes for the specific equipment required. Be sure to inquire about any additional costs, such as delivery fees or insurance, to gain a comprehensive understanding of the total expense involved.

- Compare Features: Evaluate the features of the tools offered by different companies. Pay close attention to their condition, power sources, and any accessories included that may enhance functionality.

- Check Duration Discounts: Don’t forget to ask about potential discounts for extended use. Many companies provide reduced rates for weekly or monthly agreements, which can lead to significant savings.

Practical Example: For instance, if one company offers a competitive daily rate but adds extra charges for delivery, while another includes delivery in their pricing, choosing the latter could be more cost-effective. This approach not only saves money but also simplifies logistics, facilitating a smoother execution of tasks.

Review Rental Terms and Conditions Before Finalizing Your Choice

Before finalizing your rental choice, it is crucial to thoroughly review the following terms and conditions:

- Rental Duration: Clearly understand the start and end dates of the rental period, as well as any penalties for late returns. Late fees can accumulate quickly, impacting your project budget.

- Liability and Insurance: Clarify who is accountable for damages or incidents that occur during the underground boring tool rental period. Numerous lease contracts specify that the tenant is responsible for any damages, making it crucial to have sufficient insurance coverage for underground boring tool rental. Statistics suggest that equipment leasing companies frequently encounter substantial liability claims. In fact, the U.S. equipment leasing market is anticipated to expand to $54.7 billion by 2025, highlighting the necessity for thorough protection.

- Maintenance Responsibilities: Be aware of your maintenance obligations during the lease period. This may include tasks such as refueling, cleaning, or performing minor repairs related to underground boring tool rental. Comprehending these responsibilities can avert unforeseen fees at the conclusion of the lease.

- Cancellation Policy: Familiarize yourself with the cancellation policy for the underground boring tool rental in case your project timeline changes. Understanding the terms of your underground boring tool rental can protect you from facing unnecessary charges if you need to modify your leasing plans.

Practical Example: If the lease agreement specifies that you are liable for any damages incurred during the duration of the lease, ensure you have adequate insurance coverage, especially if using an underground boring tool rental, to protect yourself from unexpected costs. As Abhishek Kataria notes, 'The necessity of underground boring tool rental has become evident for all sizes of construction companies,' highlighting the importance of being prepared for potential liabilities. This proactive approach can safeguard your finances and ensure a smoother rental experience.

Conclusion

The successful rental of underground boring tools represents a multifaceted process that relies on a deep understanding of the equipment, careful evaluation of key selection criteria, and a thorough comparison of rental options alongside a meticulous review of rental terms. By comprehensively grasping the specific applications and functions of various boring tools—such as Horizontal Directional Drills, Auger Boring Machines, and Microtunneling Machines—contractors can make informed decisions that significantly enhance project efficiency and effectiveness.

Key insights from this guide underscore the critical importance of assessing:

- Soil conditions

- Project depth

- Power sources

- Operator skill level

when selecting boring tools. Furthermore, comparing rental options, including cost, features, and duration discounts, is vital for securing the most advantageous deal available. A meticulous review of rental agreements ensures clarity regarding responsibilities, liability, and potential penalties, thereby safeguarding against unexpected challenges.

Ultimately, understanding the underground boring tool rental process not only streamlines construction projects but also fosters a proactive approach to equipment management. By implementing these strategies, contractors can optimize their operations, reduce costs, and ensure successful project outcomes. Embracing these steps leads to a more efficient and cost-effective approach to underground boring, reinforcing the essential role these tools play in modern construction and utility installation.

Frequently Asked Questions

What are the primary types of underground boring tools?

The primary types of underground boring tools include Horizontal Directional Drills (HDD), Auger Boring Machines, and Microtunneling Machines.

What is the main advantage of Horizontal Directional Drills (HDD)?

HDD machines excel at installing utilities beneath obstacles like roads and rivers with minimal surface disruption, making them ideal for various construction projects.

What is the projected growth of the HDD market?

The HDD market is projected to grow at a compound annual growth rate (CAGR) of 13.0% from 2023 to 2030, with an expected market value of USD 18.70 billion by 2030.

What are Auger Boring Machines used for?

Auger Boring Machines are specifically designed for creating larger diameter holes in soil, making them ideal for installing pipes and conduits across various soil conditions.

How do Microtunneling Machines differ from other boring tools?

Microtunneling Machines are engineered for precise underground installations, particularly in urban settings where minimizing surface disruption is crucial, and they offer reduced environmental impact compared to traditional methods.

Why is it important to understand different underground boring tools?

Understanding these instruments and their specific applications is vital for selecting the appropriate equipment for projects involving utility installation, landscaping, or construction work.