Key Highlights:

- A crusher bucket is a crushing attachment for excavators that allows on-site material processing, reducing the need for separate crushing equipment.

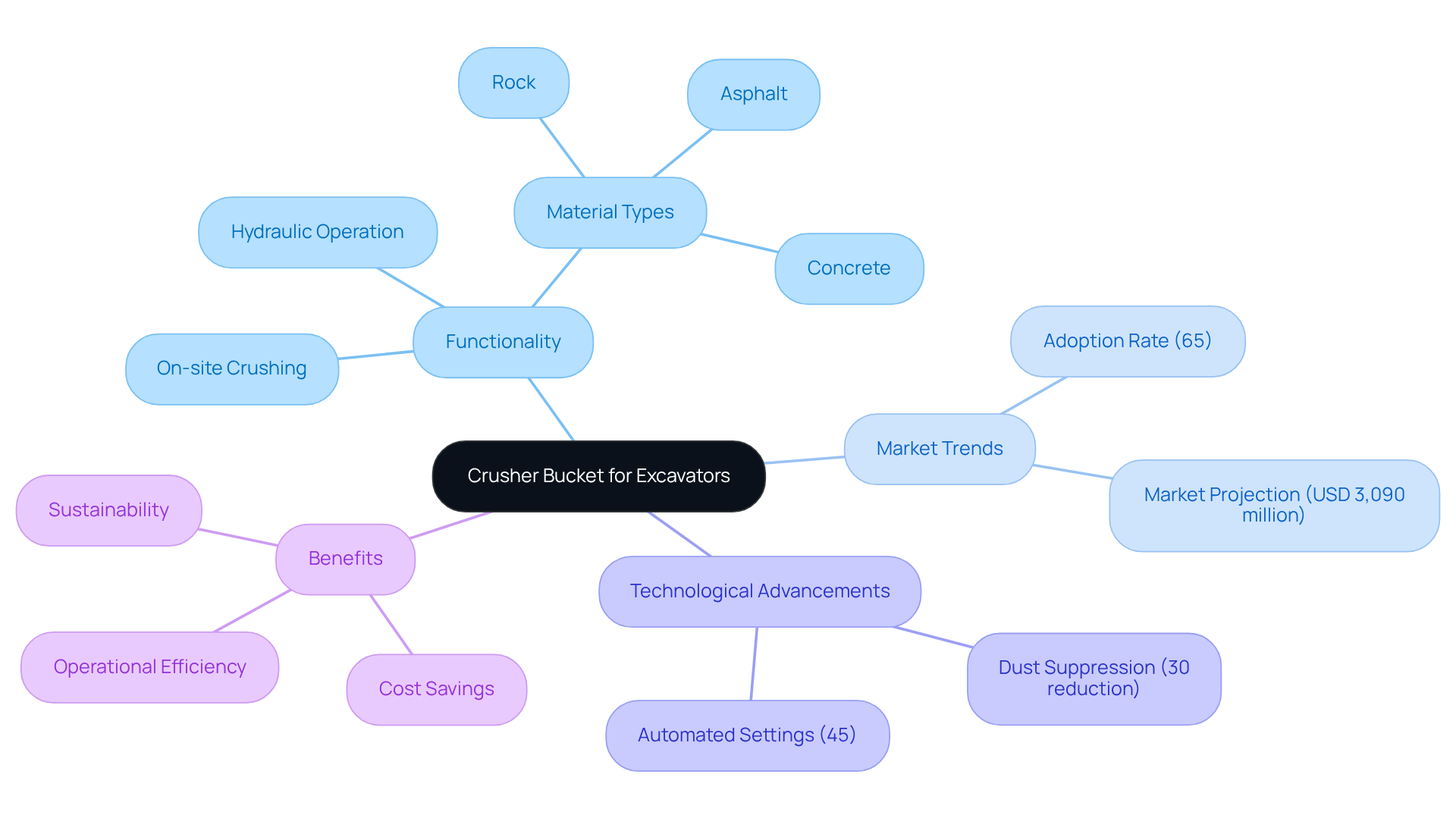

- In 2023, 65% of construction firms adopted crushing attachments, with the global market projected to reach USD 3,090 million by 2031.

- Crusher buckets enhance operational efficiency and sustainability by facilitating on-site recycling of materials, reducing waste and transportation needs.

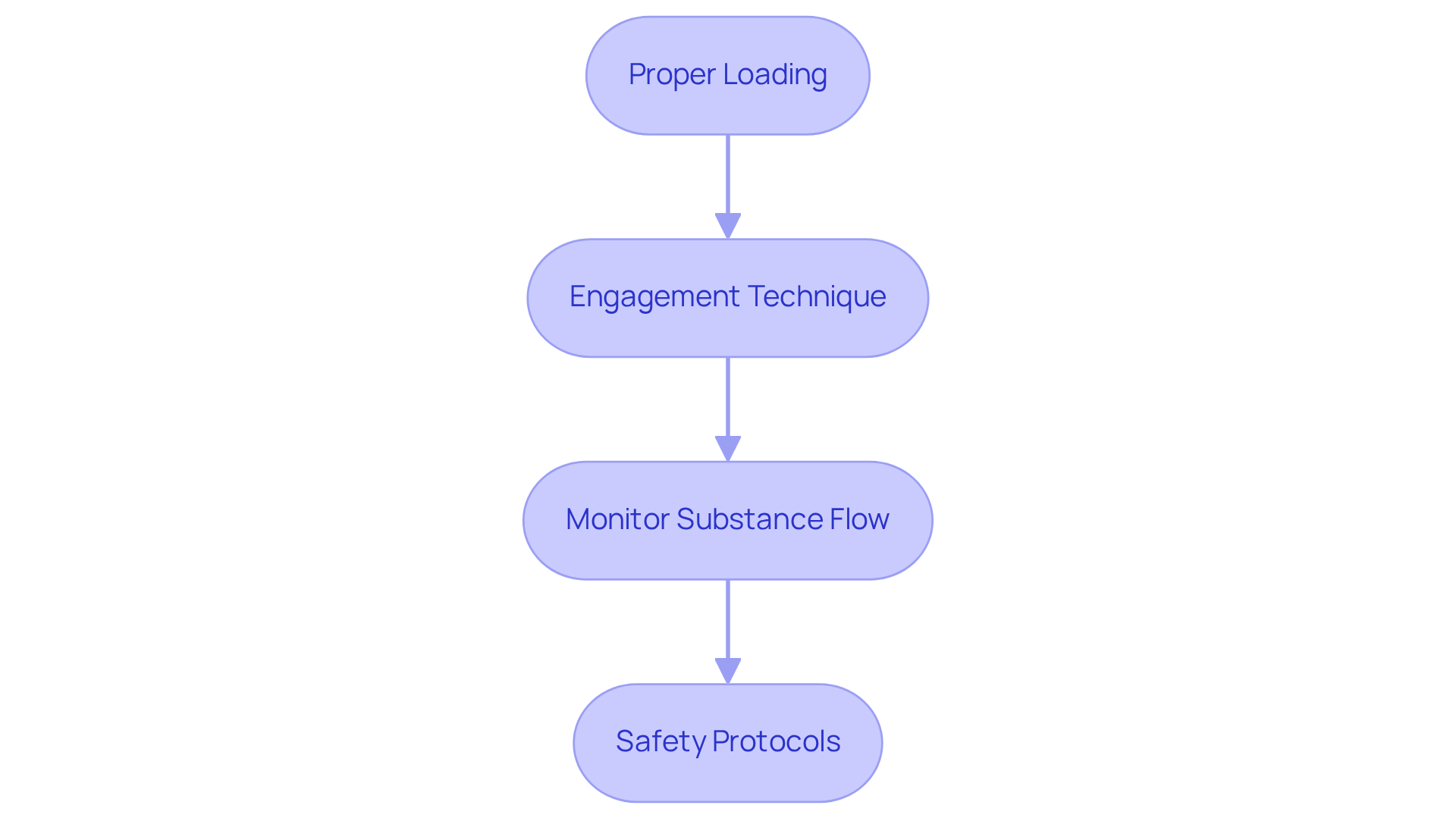

- To operate a crusher bucket effectively, ensure proper loading, engage the technique correctly, monitor substance flow, and follow safety protocols.

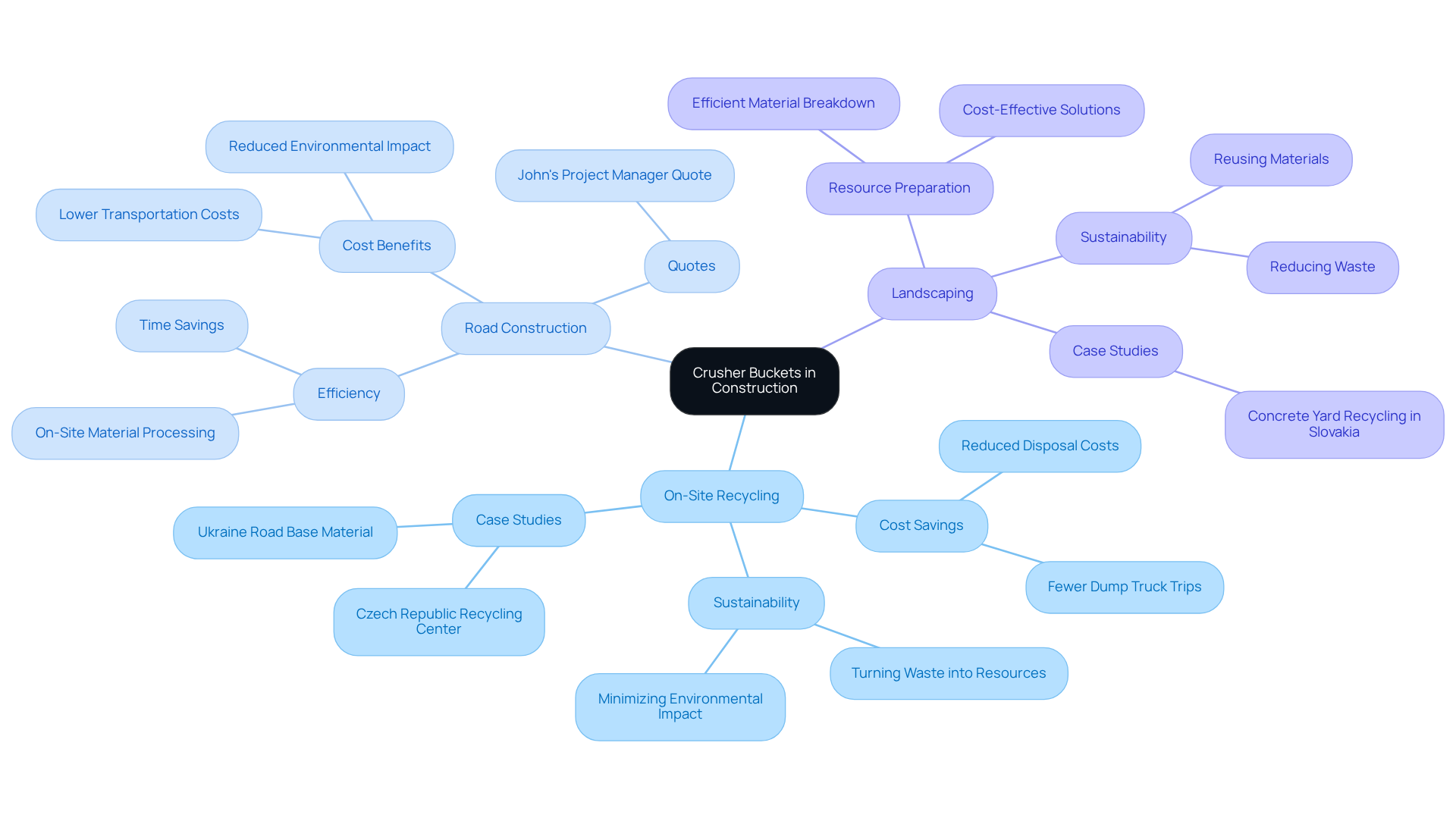

- Key use cases for crusher buckets include on-site recycling of demolition debris, road construction, and landscaping, leading to cost savings and project efficiency.

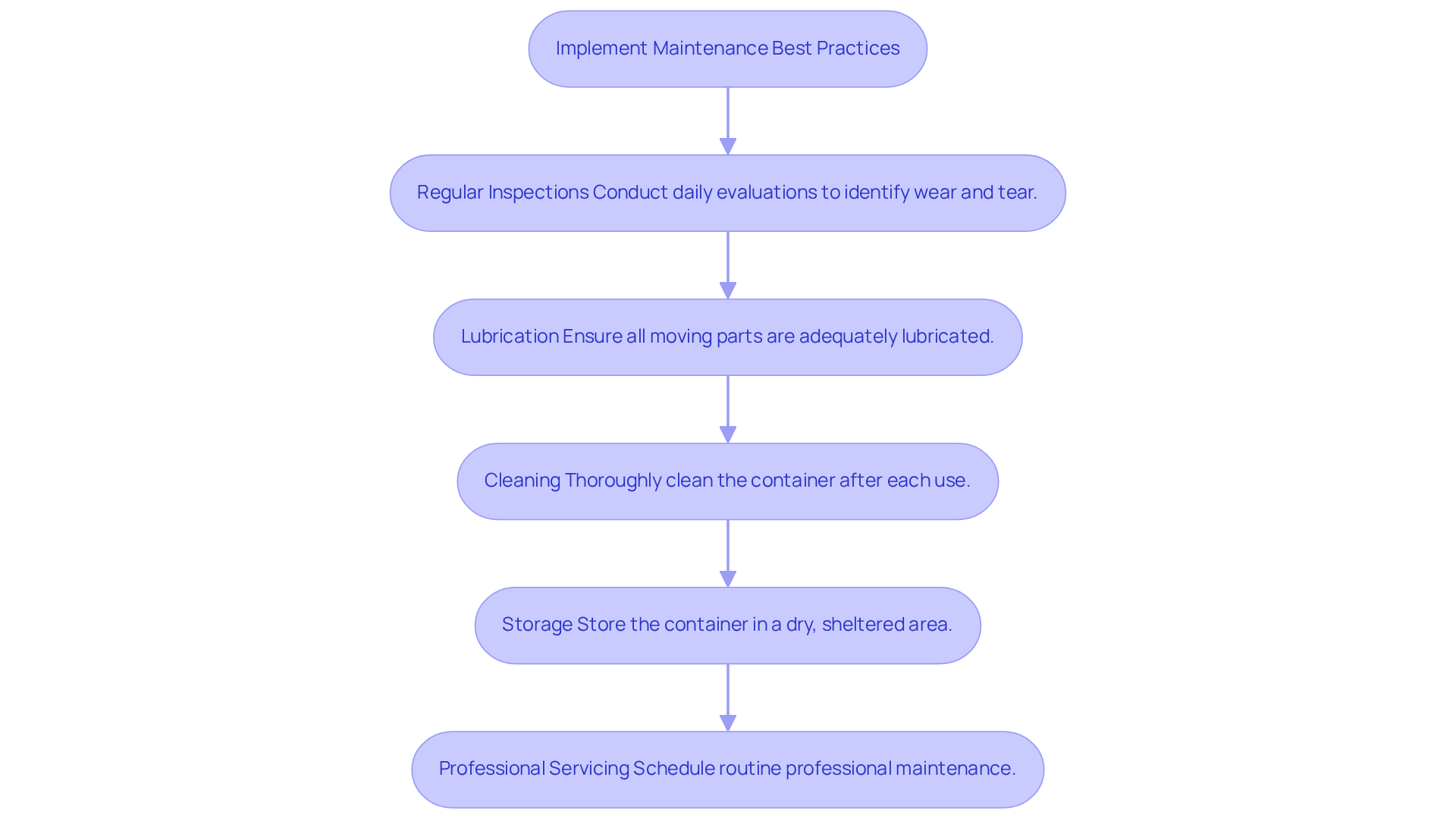

- Maintenance best practises for crusher buckets include regular inspections, lubrication, cleaning, proper storage, and professional servicing to extend equipment lifespan.

- Benefits of using crusher buckets in construction projects include cost savings, time efficiency, reduced environmental impact, versatility, and improved safety.

Introduction

Innovative construction equipment is transforming the industry, and the crusher bucket for excavators stands out as a true game-changer. This powerful attachment streamlines operations by enabling on-site material processing, which not only cuts costs but also minimizes environmental impact. To fully harness the advantages of a crusher bucket, construction professionals must grasp its proper use and maintenance.

How can you maximize the benefits of this versatile tool while ensuring safety and efficiency in your projects? Understanding the nuances of the crusher bucket is essential. By integrating this equipment into your workflow, you can enhance productivity and achieve remarkable results.

In addition, the reliability and quality of the crusher bucket are backed by numerous case studies and testimonials from satisfied customers. These insights reinforce the value of investing in such innovative tools. As you consider your next project, remember that the right equipment can make all the difference.

Take action now - explore the possibilities that the crusher bucket offers and elevate your construction operations to new heights.

Define the Crusher Bucket and Its Functionality

A crusher bucket for excavator is a robust crushing attachment specifically designed for excavators, allowing them to break down materials right on-site. This innovative equipment harnesses the excavator's hydraulic system to operate a set of jaws that efficiently crush various substances, including concrete, asphalt, and rock. The primary goal of a crushing attachment is to reduce the size of these materials, making them easier to handle and transport. By integrating a crusher bucket for excavator into the excavation process, these attachments eliminate the need for separate crushing equipment, streamlining operations and significantly cutting costs.

In 2023, approximately 65% of construction firms adopted crushing attachments, highlighting their growing importance in the industry. The global market for industrial crushing attachments is projected to reach USD 3,090 million by 2031, reflecting the increasing demand for such machinery. These attachments not only enhance operational efficiency but also promote sustainability by reducing waste and facilitating resource recycling. For instance, using a crushing attachment can lead to substantial cost savings by lowering fuel, labor, and raw material expenses.

Recent advancements in excavation tool technology have introduced features like automated settings and real-time performance monitoring, with 45% of new excavation tools in 2023 incorporating these enhancements. Such innovations can boost productivity by as much as 25%. Furthermore, advanced dust suppression systems have been implemented, cutting dust emissions by 30% during operation. Industry leaders emphasize the versatility and efficiency of the crusher bucket for excavator, noting its ability to transform inert materials into reusable aggregates on-site, thus eliminating the need for additional machinery and transport. As Allen Hu, Sales Manager of YC Attachments, aptly states, "One of the most adaptable instruments in contemporary construction is the crushing attachment." This blend of technology and functionality positions these tools as essential components in modern construction projects.

Explain How to Operate a Crusher Bucket Effectively

Maximize Your Crushing Efficiency

To operate a crushing attachment effectively, follow these key steps:

- Proper Loading: Ensure the container is filled with suitably sized substance. Avoid overloading, as this can hinder performance and cause damage.

- Engagement Technique: Activate the crusher attachment by lowering it to the substance and permitting the jaws to crush as you raise. This technique maximizes crushing efficiency.

- Monitor Substance Flow: Keep an eye on the substance flow to prevent blockages. Adjust the feed rate as necessary to maintain a consistent flow.

- Safety Protocols: Always adhere to safety guidelines, including wearing appropriate personal protective equipment (PPE) and ensuring that bystanders are at a safe distance during operation.

By following these steps, you ensure not only the effectiveness of your crushing attachment but also the safety of your operation. Don't hesitate to reach out for more information on our equipment rental services!

Identify Key Use-Cases for Crusher Buckets in Construction

A crusher bucket for excavator is an essential tool that significantly enhances efficiency across various construction scenarios.

-

On-Site Recycling: These attachments allow for immediate recycling of demolition debris, turning waste into reusable aggregate. For instance, a client in the Czech Republic successfully established a compact recycling center using an MB-L160 crusher. This not only reduced disposal costs but also generated profit from recycled materials. Furthermore, the crusher bucket for excavator facilitates the recycling of demolition debris into road base aggregates, underscoring its practicality.

-

Road Construction: Crusher attachments are particularly effective in crushing asphalt and concrete, making them indispensable for road repair and maintenance. Their ability to process materials on-site minimizes transportation needs, leading to substantial cost savings and reduced environmental impact. As John, a Project Manager, noted, "We utilized a crushing attachment to break down concrete and rocks during a highway expansion project. It saved us time and money by reusing the resources on-site and lowering transportation expenses."

-

Landscaping: In landscaping, crushing attachments efficiently break down rocks and other materials, providing a cost-effective solution for resource preparation. This versatility allows contractors to reuse materials that would otherwise require disposal, enhancing project sustainability.

During excavation projects, utilizing a crusher bucket for excavator significantly reduces the volume of material that must be removed from the site. This not only saves time but also cuts hauling costs, as demonstrated in a highway expansion project where on-site recycling led to early completion.

Technological advancements have also contributed to a 20% increase in equipment longevity, highlighting the long-term benefits of investing in crushing attachments. By enabling on-site recycling, these aggregate handling tools promote sustainable construction practices, allowing contractors to minimize waste and optimize resource utilization while boosting overall project efficiency.

Implement Maintenance Best Practices for Longevity

Maximize the lifespan of your crusher bucket by implementing these essential maintenance practices:

-

Regular Inspections: Conduct daily evaluations to identify wear and tear, particularly on the excavator's teeth and hydraulic components. This proactive approach catches issues early, preventing costly repairs and downtime. In fact, aging equipment is nearly three times more likely to cause unplanned downtime than operator error, highlighting the urgency of these inspections.

-

Lubrication: Ensure all moving parts are adequately lubricated according to the manufacturer's specifications. Proper lubrication minimizes friction and wear, enhancing operational efficiency and potentially reducing repair costs by up to 40%.

-

Cleaning: After each use, thoroughly clean the container to eliminate debris and prevent corrosion. Regular cleaning not only maintains performance but also extends the lifespan of the container. Neglecting maintenance can lead to increased wear and higher repair costs.

-

Storage: When not in use, store the container in a dry, sheltered area to protect it from environmental elements. Proper storage conditions significantly reduce wear and prolong the lifespan of the container.

-

Professional Servicing: Schedule routine professional maintenance to address potential issues before they escalate. Regular servicing ensures that all components function optimally, reducing the likelihood of unexpected breakdowns. For example, a site manager who noticed wear on a crushing attachment and arranged maintenance saved the company thousands of dollars by avoiding significant repairs.

By following these practices, you can enhance the longevity and efficiency of your excavation tool, ultimately leading to increased productivity and lower operational expenses.

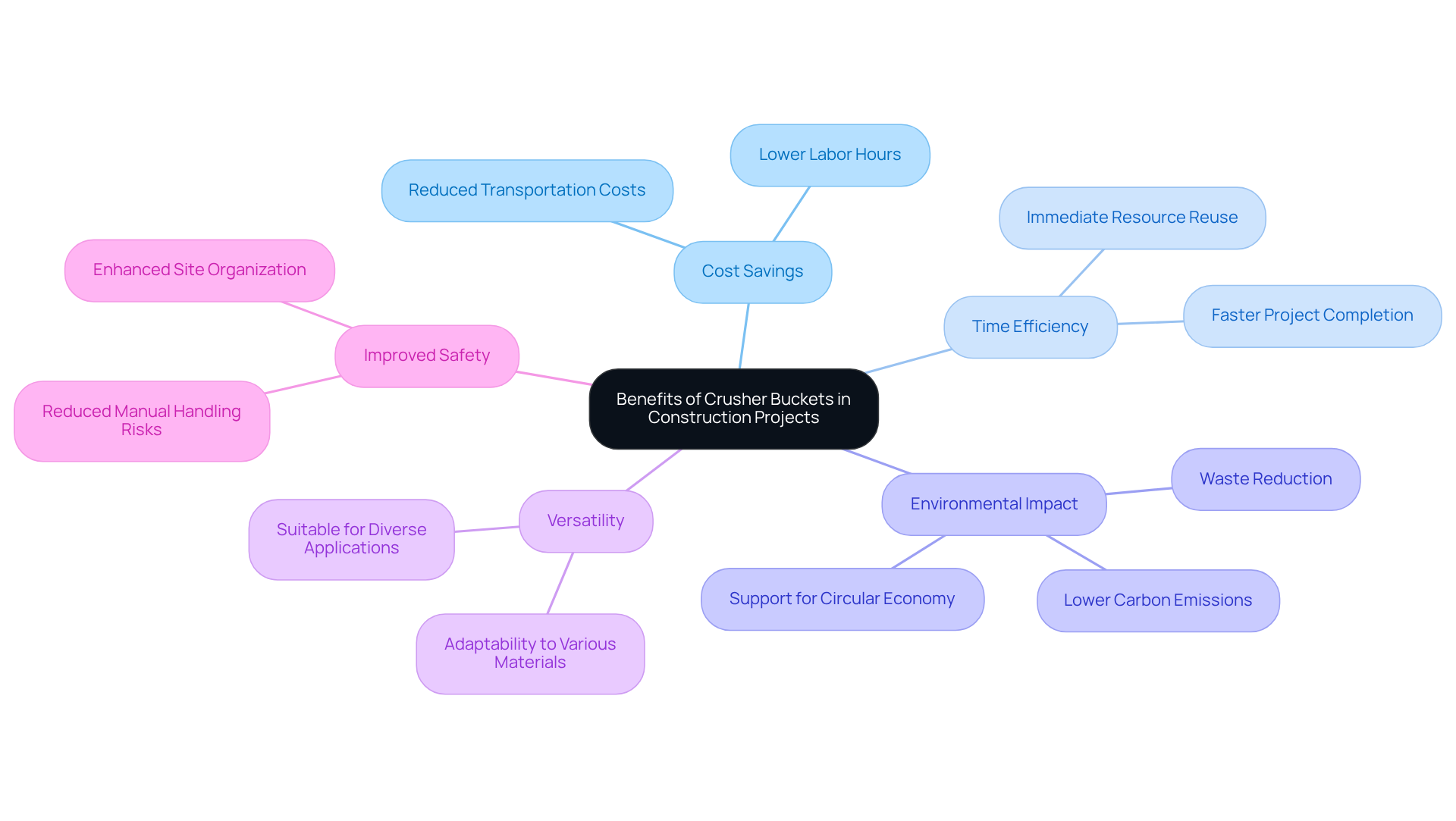

Highlight Benefits of Using Crusher Buckets in Projects

Unlock the Benefits of Crusher Buckets in Construction Projects

Using crusher buckets in construction projects brings a wealth of advantages that can transform your operations.

-

Cost Savings: By minimizing the need for transportation and separate crushing equipment, projects can significantly cut operational costs. For instance, using a crusher bucket for excavator for on-site processing can lead to substantial savings in labor hours spent on loading and unloading materials.

-

Time Efficiency: On-site crushing allows for the immediate reuse of resources, which accelerates project timelines. The quick availability of recycled aggregate has been shown to save an estimated three weeks, preventing delays during regional shortages.

-

Environmental Impact: The construction industry is responsible for over one-third of all waste in many developed countries. The use of a crusher bucket for excavator facilitates recycling and waste reduction, promoting sustainable construction practices. By utilizing a crusher bucket for excavator, they help decrease the need for external transport, lower carbon emissions, and support eco-friendly initiatives.

-

Versatility: The crusher bucket for excavator can handle a variety of materials, making it suitable for diverse applications across different projects. This adaptability enables efficient processing of concrete, asphalt, and other materials right on-site.

-

Improved Safety: By reducing the need for manual handling of heavy materials, crusher buckets help lower the risk of workplace injuries. On-site recycling enhances safety by properly sorting and managing resources, which mitigates common hazards on construction sites.

Incorporating a crusher bucket for excavator not only boosts project efficiency but also aligns with the increasing focus on sustainability in the construction sector. As industry professionals emphasize, "On-site recycling offers significant environmental benefits by keeping materials in use at their original location."

Take Action Now: Embrace the advantages of a crusher bucket for excavator in your next construction project and experience the difference in efficiency, safety, and sustainability.

Conclusion

Using a crusher bucket for excavators marks a pivotal shift in construction efficiency and sustainability. This innovative equipment streamlines operations by enabling on-site material processing, leading to significant cost savings and a commitment to environmental responsibility. By integrating a crusher bucket into excavation projects, contractors can convert waste into reusable aggregates, boosting productivity and reducing the carbon footprint linked to transportation and disposal.

Key insights emphasize the necessity of effective operation and maintenance practices to maximize the advantages of crusher buckets:

- Proper loading techniques

- Vigilant monitoring of substance flow

- Strict adherence to safety protocols

These practices are crucial for ensuring optimal performance. Furthermore, regular inspections, lubrication, and professional servicing can greatly extend the lifespan of these valuable attachments, enhancing their cost-effectiveness and reliability.

Embracing crusher buckets goes beyond mere efficiency; it signifies a commitment to sustainable practices within the construction industry. As the demand for eco-friendly solutions grows, utilizing these attachments positions contractors as leaders in responsible construction. By prioritizing on-site recycling and resource optimization, professionals can contribute to a more sustainable future while enjoying the myriad benefits that crusher buckets provide.

Frequently Asked Questions

What is a crusher bucket for an excavator?

A crusher bucket for an excavator is a robust attachment designed to allow excavators to break down materials on-site, utilizing the excavator's hydraulic system to operate jaws that crush substances like concrete, asphalt, and rock.

What are the main functions of a crusher bucket?

The primary function of a crusher bucket is to reduce the size of materials, making them easier to handle and transport, while streamlining operations and cutting costs by eliminating the need for separate crushing equipment.

How prevalent are crushing attachments in the construction industry?

In 2023, approximately 65% of construction firms adopted crushing attachments, indicating their growing importance in the industry.

What is the projected market value for industrial crushing attachments by 2031?

The global market for industrial crushing attachments is projected to reach USD 3,090 million by 2031.

What are the benefits of using a crusher bucket?

Benefits include enhanced operational efficiency, cost savings by reducing fuel, labor, and raw material expenses, and promoting sustainability by reducing waste and facilitating resource recycling.

What recent advancements have been made in excavation tool technology?

Recent advancements include automated settings and real-time performance monitoring, with 45% of new excavation tools in 2023 incorporating these enhancements, potentially boosting productivity by up to 25%.

How do advanced dust suppression systems improve the operation of crusher buckets?

Advanced dust suppression systems have been implemented to cut dust emissions by 30% during operation, improving the working environment.

What are the key steps to operate a crusher bucket effectively?

Key steps include proper loading of suitably sized substances, engaging the attachment technique by lowering it and allowing the jaws to crush as you raise, monitoring substance flow to prevent blockages, and adhering to safety protocols.

What safety measures should be followed when operating a crusher bucket?

Safety measures include wearing appropriate personal protective equipment (PPE) and ensuring that bystanders are at a safe distance during operation.