Key Highlights:

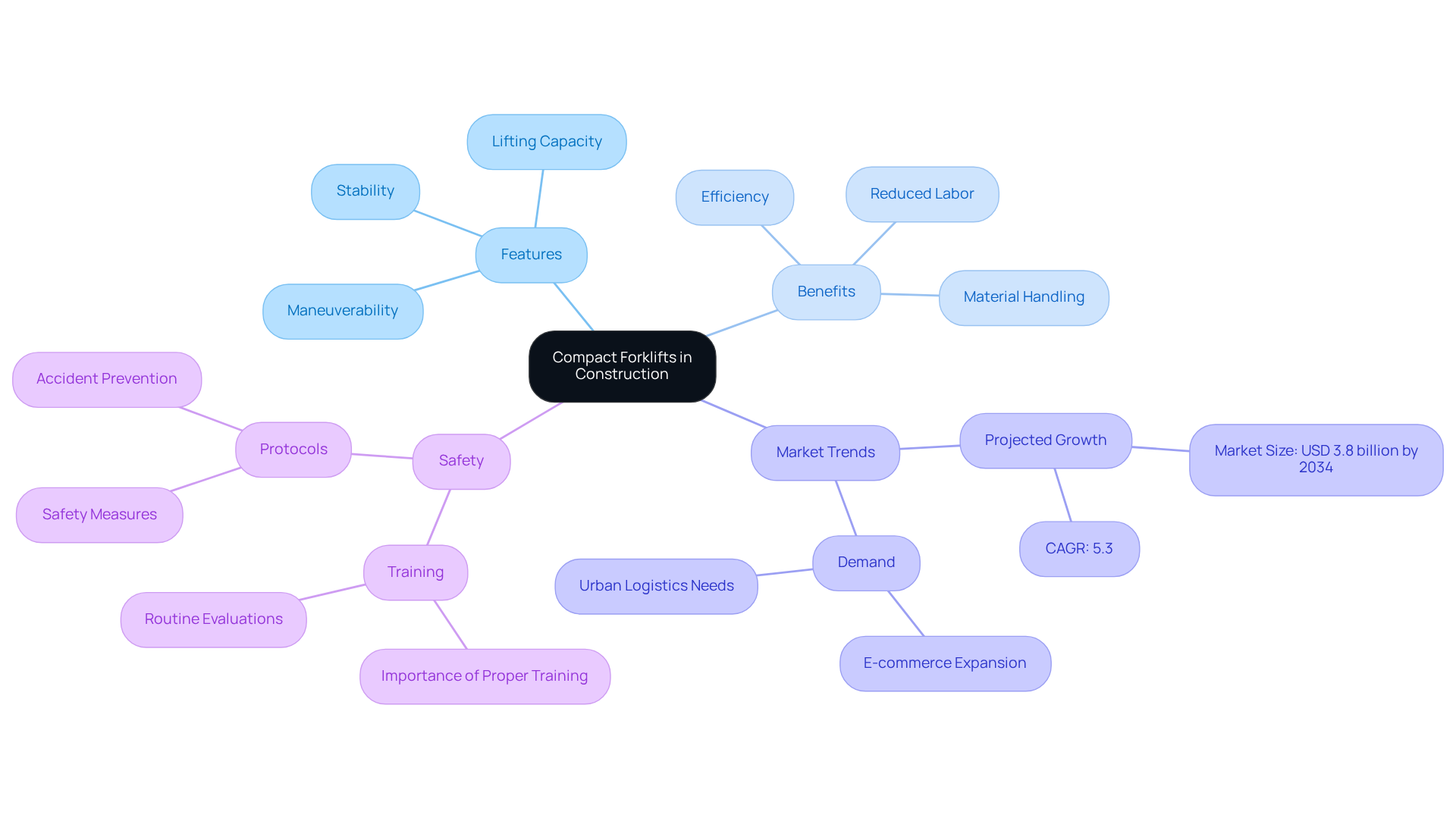

- Compact forklifts are designed for manoeuvrability in tight spaces, making them essential on construction sites.

- They offer increased lifting capacity, stability, and intuitive controls, enhancing material transport efficiency.

- The compact forklift market is projected to grow to USD 3.8 billion by 2034, reflecting rising demand for efficient material handling.

- Compact forklifts can reduce material handling duration by up to 30%, accelerating project timelines.

- Safety is enhanced with compact forklifts, as they are easier to manage, reducing the likelihood of accidents.

- Selecting the right compact forklift involves considering load capacity, lift height, and terrain type for optimal performance.

- Proper training and adherence to safety protocols are crucial, as undertrained operators contribute significantly to forklift accidents.

- Regular maintenance, including daily inspections and scheduled servicing, is vital for optimal performance and equipment longevity.

Introduction

Compact forklifts have become indispensable tools in the construction industry, expertly crafted to navigate the challenges of confined spaces with ease. Their distinctive features not only enhance operational efficiency but also play a crucial role in promoting safety on job sites. However, the effective utilization of these machines relies on a solid understanding of best practices, encompassing:

- Selection

- Operation

- Maintenance

- Safety protocols

What strategies can construction teams adopt to maximize the advantages of compact forklifts while minimizing risks and inefficiencies?

Define Compact Forklifts and Their Role in Construction

Compact forklifts are specialized devices designed for exceptional maneuverability in tight spaces, making them indispensable on construction sites where space is at a premium. With a smaller frame, tighter turning radius, and reduced weight compared to standard models, these machines excel at navigating narrow aisles and congested job sites. This capability allows for the efficient transport of materials and equipment in areas where larger lifting vehicles cannot operate effectively.

At EZ Equipment Rental, we offer a diverse fleet of well-maintained compact forklifts, ensuring clients can find the perfect solution for their specific needs. Our small lifting vehicles feature increased lifting capacity, enhanced stability, and intuitive controls, making them perfect for moving heavy loads and elevating materials to greater heights. By reducing the time and labor associated with manual handling, they streamline operations and contribute to overall project efficiency. As the demand for compact and productive material handling solutions continues to grow, particularly in confined spaces, the role of compact forklifts becomes increasingly essential in addressing the challenges of modern construction environments.

Industry reports project that the small lifting vehicle market will reach USD 3.8 billion by 2034, driven by the need for efficient material handling in confined areas. Additionally, statistics reveal that 23.8% of forklift accidents occur on construction sites, highlighting the importance of proper training and safety measures when operating these machines. This underscores the essential need for safety protocols and training in the effective operation of small lifting machines, a commitment that EZ Equipment Rental upholds to ensure a seamless equipment rental experience.

Highlight Benefits of Compact Forklifts for Project Efficiency

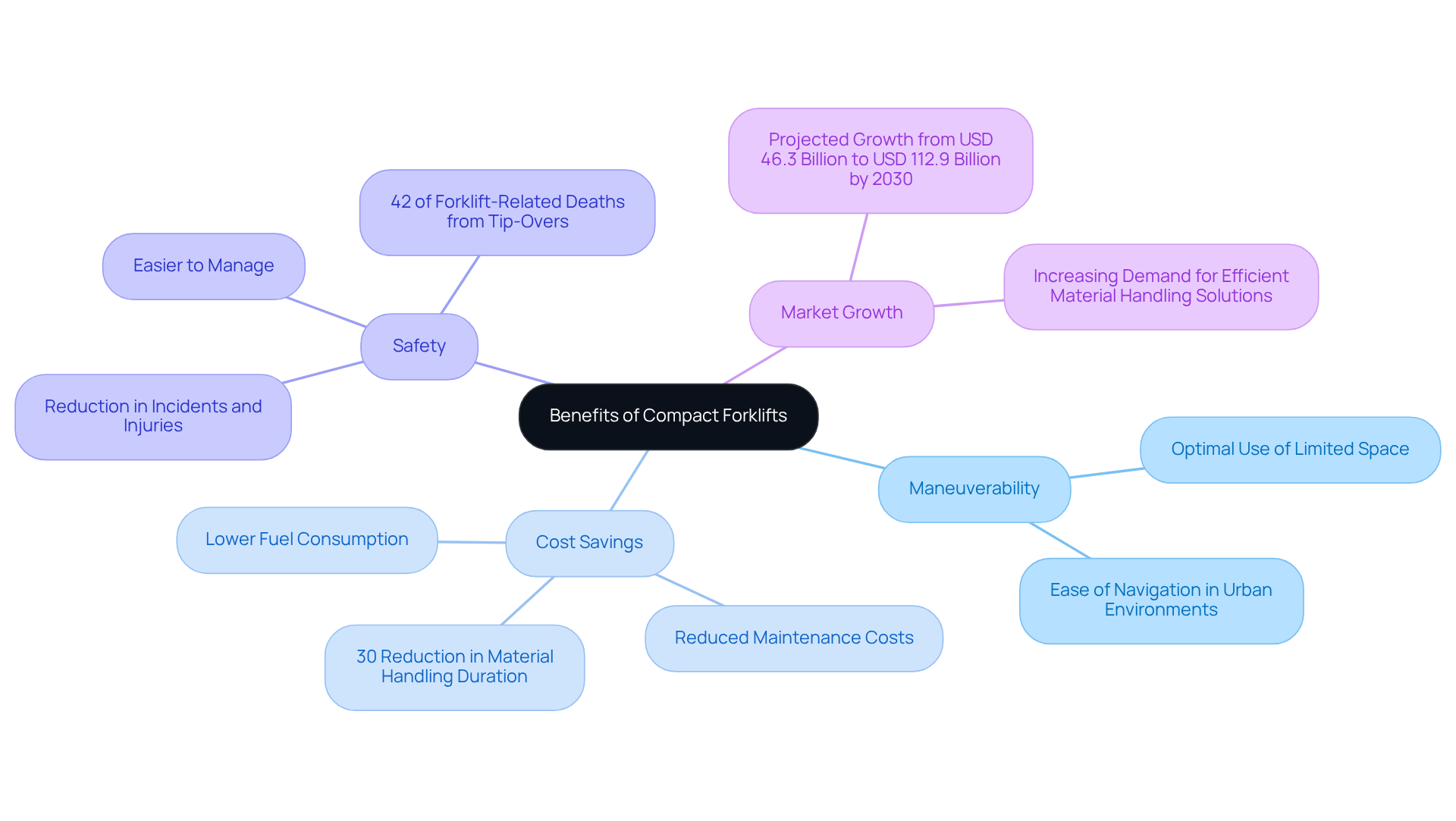

The advantages of compact forklifts significantly enhance project efficiency in construction. Their ability to maneuver in confined spaces allows for optimal use of limited site areas, particularly in urban environments where space is at a premium. This capability simplifies material transport and accelerates project schedules, with research indicating that incorporating small lifting devices can reduce material handling duration by up to 30%. Additionally, their smaller size typically results in lower fuel consumption and maintenance costs, contributing to overall project savings.

Safety is another essential advantage; small lifting vehicles are easier to manage, which reduces the likelihood of incidents and injuries on site. Notably, tip-overs account for 42% of forklift-related deaths, highlighting the importance of using equipment that enhances safety. For instance, a recent construction project in a densely populated area reported a significant improvement in efficiency after adopting a compact forklift, demonstrating its role in boosting productivity while ensuring a safer working environment.

Moreover, the global lift truck market is projected to grow from USD 46.3 billion in 2023 to USD 112.9 billion by 2030, reflecting the increasing demand for efficient material handling solutions. This growth underscores the reliability and quality of compact forklifts, making them a preferred choice in the industry.

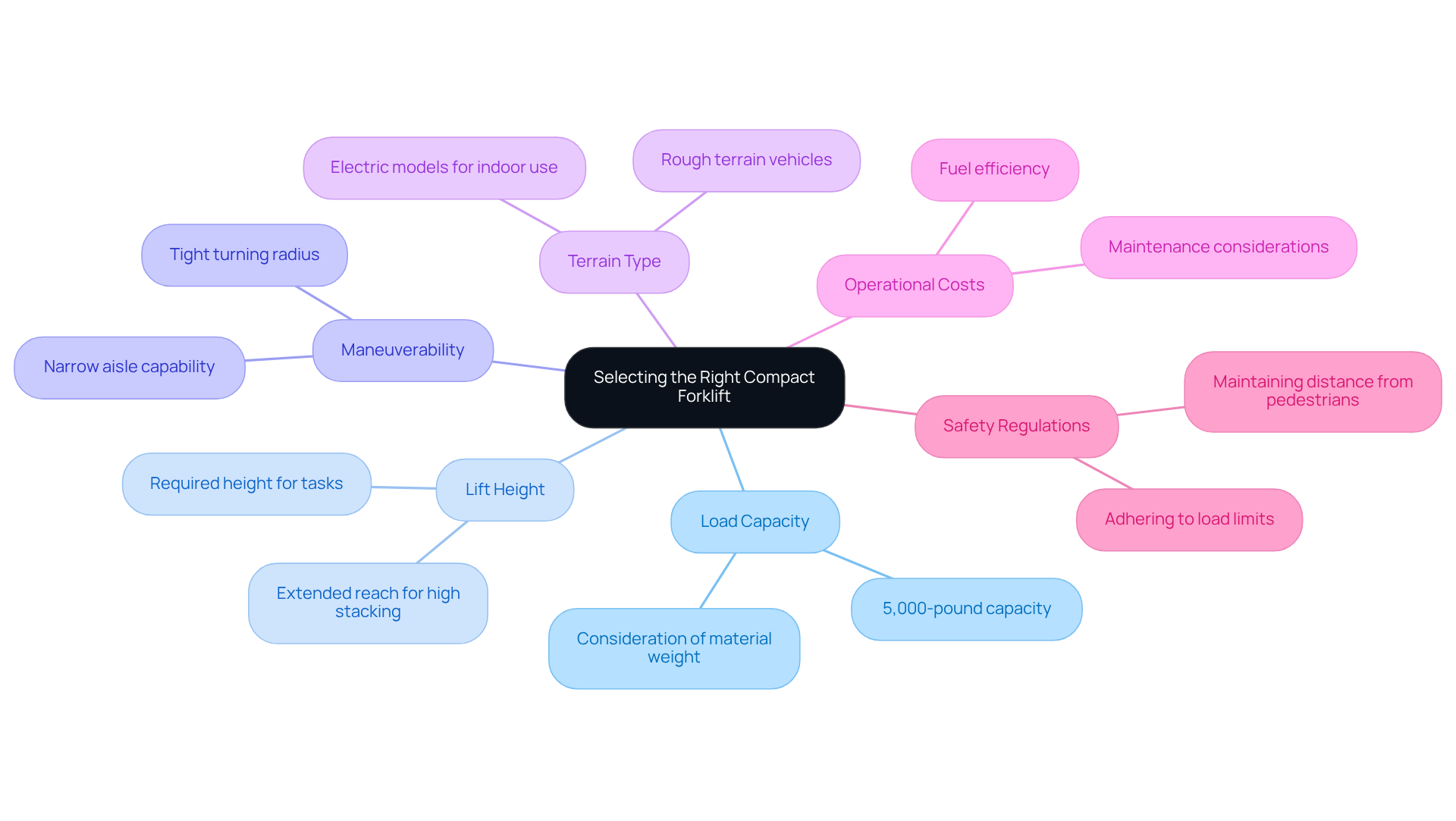

Select the Right Compact Forklift for Specific Tasks

Selecting the right compact vehicle for construction projects requires careful consideration of several key factors, such as load capacity, lift height, and the specific tasks at hand. For projects that involve lifting heavy materials to considerable heights, a vehicle with a higher lift capacity and extended reach is essential. Conversely, tasks that require maneuvering in tight spaces benefit from models with a smaller turning radius. The type of terrain also significantly impacts the choice; rough terrain vehicles are designed for outdoor use on uneven surfaces, while electric models are ideal for indoor environments due to their emission-free operation and lower noise levels.

Moreover, operational costs, including fuel and maintenance, should be factored into the decision-making process to ensure long-term cost-effectiveness. Adhering to safety regulations, such as respecting load limits and maintaining a safe distance from pedestrians, is crucial for creating a secure work environment. For example, a construction site that frequently lifted heavy beams found that opting for a compact forklift with a 5,000-pound capacity significantly enhanced their operational efficiency. Understanding these selection criteria ensures that the chosen lift truck meets the specific requirements of the project, ultimately boosting productivity and safety on site.

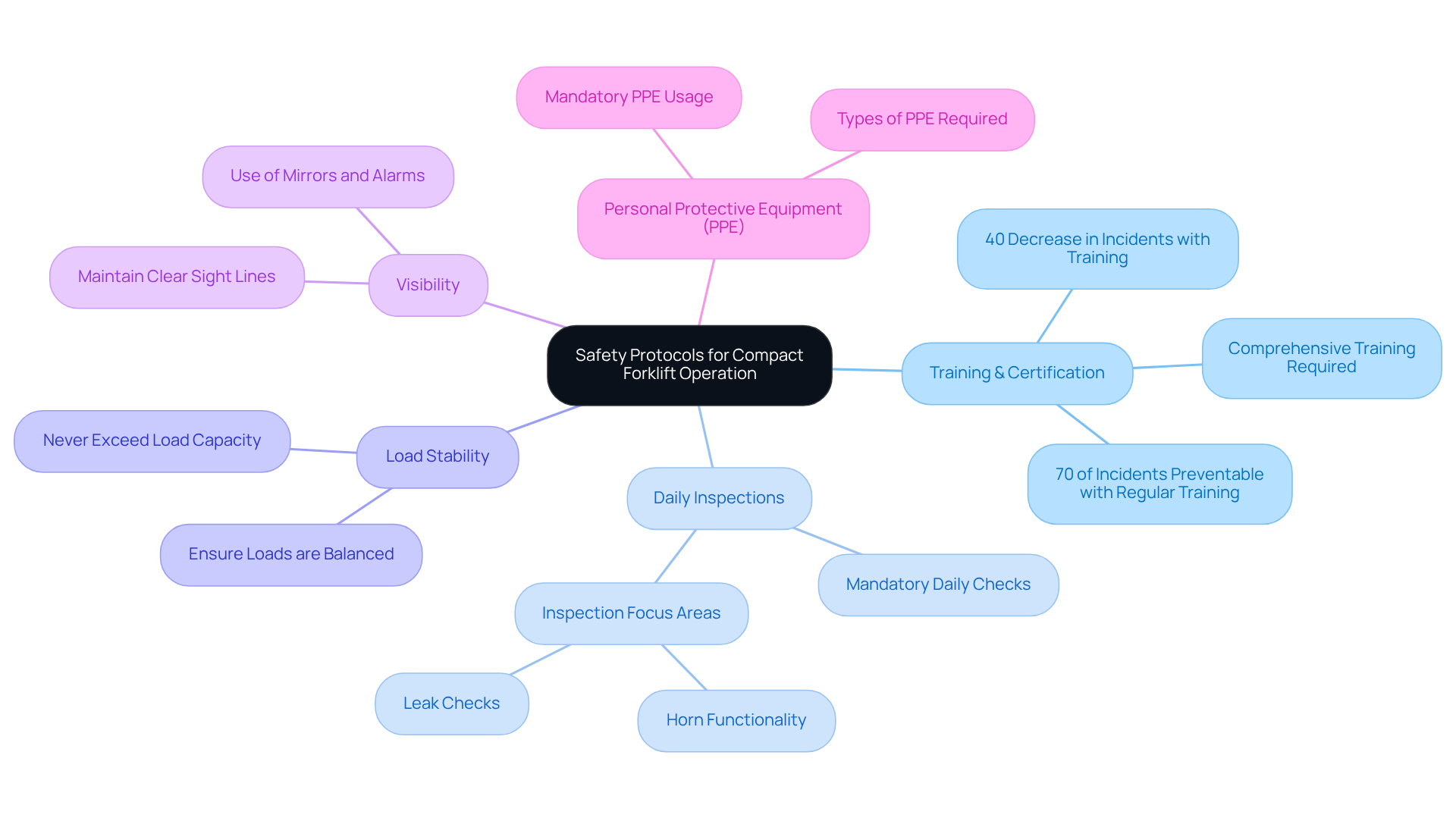

Implement Safety Protocols for Compact Forklift Operation

Strict adherence to operational protocols is essential when operating a compact forklift on construction sites, as it significantly reduces risks. Operators must complete comprehensive training and certification to fully understand the equipment's operational limits and safety features. Key safety practices include:

- Conducting daily inspections before use

- Ensuring loads are stable and balanced

- Maintaining clear visibility while operating

Operators should never exceed the lift's load capacity and must always wear suitable personal protective equipment (PPE).

According to OSHA, a significant number of accidents are attributed to undertrained lift truck operators, underscoring the critical need for effective training. For instance, a construction site that implemented a strict training program experienced a remarkable 40% decrease in forklift-related incidents within a year. Furthermore, studies indicate that 70% of lifting vehicle incidents could be prevented with regular operator instruction, highlighting the direct link between effective training and improved outcomes.

Establish Maintenance Routines for Optimal Performance

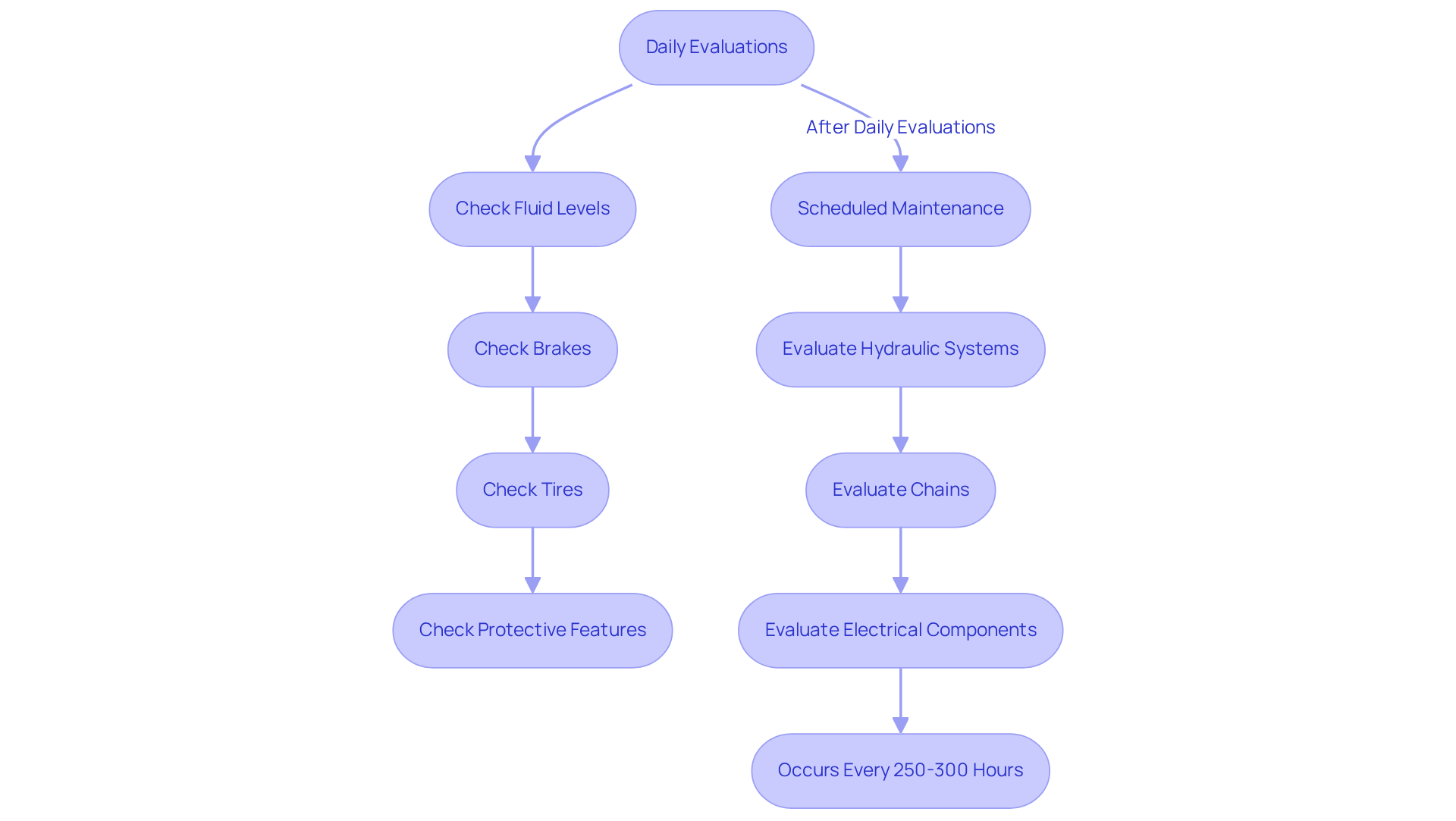

Regular maintenance routines are essential for maximizing the performance of a compact forklift. Operators should conduct daily evaluations that involve checking fluid levels - such as oil and hydraulic fluid - brakes, and tires, while also confirming that all protective features are functional. Scheduled maintenance, typically recommended every 250-300 hours of operation, should include thorough evaluations of hydraulic systems, chains, and electrical components. Incorporating cleaning and lubrication practices into these routines can prevent costly repairs and downtime.

Adhering to a disciplined maintenance schedule not only prevents unexpected breakdowns but also significantly extends the lifespan of the equipment. For instance, a construction company that adopted a proactive maintenance strategy experienced a remarkable 25% reduction in equipment downtime, facilitating smoother project execution and enhancing overall productivity. As noted by industry experts, "Regular inspections and maintenance are critical for ensuring safety and efficiency, ultimately protecting your investment in equipment.

Conclusion

Compact forklifts are essential for enhancing efficiency and safety on construction sites, especially in confined spaces. Their unique design allows for exceptional maneuverability, making them indispensable for transporting materials and equipment effectively. By recognizing their importance, operators can utilize compact forklifts to boost productivity while adhering to safety standards.

This article highlights key practices for effectively using compact forklifts:

- Selecting the appropriate model based on specific project requirements

- Implementing stringent safety protocols

- Establishing regular maintenance routines

Each of these elements contributes to a safer work environment and improved operational efficiency. The insights provided emphasize the necessity of proper training and adherence to safety measures to reduce risks associated with forklift operations.

As the demand for efficient material handling solutions continues to grow, adopting best practices for compact forklift usage becomes increasingly vital. Stakeholders in the construction industry should prioritize training, safety, and maintenance to ensure that compact forklifts remain reliable assets on job sites. By doing so, they not only enhance productivity but also cultivate a culture of safety that ultimately benefits all workers involved.

Frequently Asked Questions

What are compact forklifts and what role do they play in construction?

Compact forklifts are specialized machines designed for exceptional maneuverability in tight spaces, making them essential on construction sites with limited space. They have a smaller frame, tighter turning radius, and reduced weight compared to standard forklifts, allowing for efficient transport of materials and equipment in areas where larger vehicles cannot operate effectively.

What features do compact forklifts offer?

Compact forklifts feature increased lifting capacity, enhanced stability, and intuitive controls, making them ideal for moving heavy loads and elevating materials to greater heights. Their design helps streamline operations and reduce the time and labor associated with manual handling.

Why is there a growing demand for compact forklifts in construction?

The demand for compact forklifts is increasing due to the need for efficient material handling in confined spaces, particularly in urban environments. Industry reports project the small lifting vehicle market will reach USD 3.8 billion by 2034, reflecting this trend.

What safety considerations are associated with compact forklifts?

Safety is a critical advantage of compact forklifts, as they are easier to manage, which reduces the likelihood of incidents and injuries on construction sites. Statistics indicate that 23.8% of forklift accidents occur on construction sites, emphasizing the importance of proper training and safety measures.

How do compact forklifts contribute to project efficiency?

Compact forklifts enhance project efficiency by allowing optimal use of limited site areas, simplifying material transport, and accelerating project schedules. Research shows that using small lifting devices can reduce material handling duration by up to 30%.

What are the cost benefits of using compact forklifts?

The smaller size of compact forklifts typically results in lower fuel consumption and maintenance costs, contributing to overall project savings.

What is the projected growth of the global lift truck market?

The global lift truck market is projected to grow from USD 46.3 billion in 2023 to USD 112.9 billion by 2030, indicating an increasing demand for efficient material handling solutions, including compact forklifts.

List of Sources

- Define Compact Forklifts and Their Role in Construction

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- Small Forklift Market Size, Growth Opportunity 2025-2034 (https://gminsights.com/industry-analysis/small-forklift-market)

- The Role of Forklifts in the Construction Industry - Action Forklift Training (https://actionforklifttraining.com.au/the-role-of-forklifts-in-the-construction-industry)

- Highlight Benefits of Compact Forklifts for Project Efficiency

- Forklift Statistics and Facts (2026) (https://news.market.us/forklift-statistics)

- The Role of Forklifts in the Construction Industry - Action Forklift Training (https://actionforklifttraining.com.au/the-role-of-forklifts-in-the-construction-industry)

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- Boosting Efficiency with Compact and Multi-Directional Forklifts (https://horvertinc.in/boosting-efficiency-with-compact-and-multi-directional-forklifts)

- Forklift Statistics By Market Size, Companies and Facts (https://electroiq.com/stats/forklift-statistics)

- Select the Right Compact Forklift for Specific Tasks

- 9 Common Types of Forklifts: Pros, Cons, & Uses | TRADESAFE (https://trdsf.com/blogs/news/9-common-types-of-forklifts)

- Selecting the Best Forklift for Your Application (https://darrequipment.com/news/selecting-the-best-forklift-for-your-application)

- Implement Safety Protocols for Compact Forklift Operation

- Top 10 Most Common Forklift Accidents [With Statistics] | Conger (https://conger.com/forklift-accidents)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Forklift Injury Statistics 2025 | How to Reduce Forklift Accident Risks (https://certifyme.net/osha-blog/forklift-injuries-key-statistics)

- National Forklift Safety Day Statistics │ MHEDA (https://mheda.org/journal/national-forklift-safety-day-statistics)

- Forklift Tip-Overs [Stats, Causes, Prevention, and Procedures] (https://conger.com/forklift-tip-over)

- Establish Maintenance Routines for Optimal Performance

- The Benefits of Regular Forklift Maintenance for Warehouse Efficiency (https://baconwork.com/blog/the-benefits-of-regular-forklift-maintenance-for-warehouse-efficiency)

- 6 Forklift Maintenance Best Practices to Keep Your Operation Running (https://raymondcorp.com/information/raymond-quick-tips/6-forklift-maintenance-best-practices-to-keep-your-operation-running)

- Top Forklift Maintenance Best Practices for Safety and Efficiency (https://nwforklift.com/post/top-forklift-maintenance-best-practices-for-safety-and-efficiency-1)

- Don’t Get Forked: Why Scheduled Maintenance Is Essential During a Slowing Economy (https://sstlift.com/blog/scheduled-forklift-maintenance-is-essential-during-a-slowing-economy)

- What's the Secret: Understanding Forklift Maintenance Best Practices (https://forkliftselect.com/blogs/news/whats-the-secret-understanding-forklift-maintenance-best-practices)