Overview

The seven benefits of using a remote control sheepsfoot roller are compelling:

- Enhanced efficiency

- Improved safety

- Cost savings

- Versatility in applications

- Low maintenance requirements

- Advanced technology features

- Eco-friendliness

These rollers not only streamline compaction processes but also reduce labor costs by up to 14%, making them an attractive option for modern construction projects. Furthermore, they enhance safety by minimizing operator exposure to hazards, which is crucial in today’s work environments.

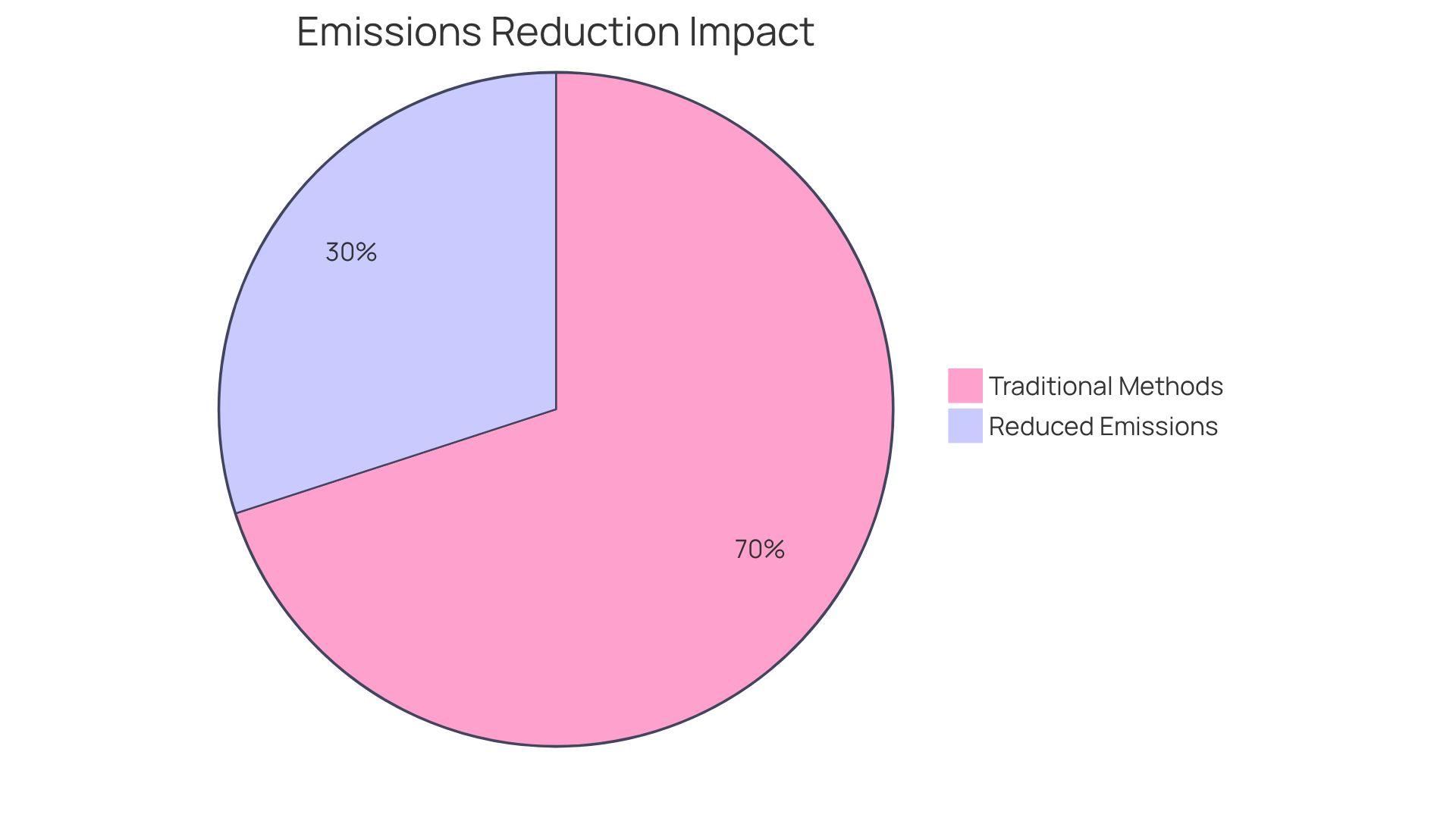

In addition to safety, these rollers contribute to environmental sustainability by lowering emissions by as much as 30%. This eco-friendliness positions them as a smart investment for contractors looking to balance productivity with environmental responsibility. The advanced technology features incorporated into these machines further enhance their reliability and efficiency, ensuring that projects are completed on time and within budget.

Ultimately, the combination of these benefits makes remote control sheepsfoot rollers an essential tool in the construction industry. Their versatility and low maintenance requirements mean they can adapt to various project needs while providing consistent performance. Investing in this equipment not only boosts operational efficiency but also contributes to a safer and more sustainable work environment.

Key Highlights:

- EZ Equipment Rental is a leading provider of remote control sheepsfoot roller rentals in Dallas, TX, catering to diverse construction needs.

- The equipment rental market is projected to grow to USD 200.85 billion by 2032, driven by increased construction activities.

- Remote control sheepsfoot rollers enhance efficiency, allowing precise compaction in challenging terrains, which is crucial for stable foundations.

- Safety is improved with remote operation, reducing worker exposure to hazards and contributing to fewer workplace injuries.

- Utilising remote control technology can lead to a 30% reduction in compaction time and improve project productivity.

- The versatility of remote control sheepsfoot rollers makes them suitable for various projects, including road development and utility installations.

- The technology offers cost savings in labour and time, with reported reductions of up to 14% in labour costs.

- Advanced features such as automated compaction settings and real-time monitoring improve usability and performance.

- Remote control sheepsfoot rollers require minimal maintenance, reducing downtime and operational costs for contractors.

- The use of this technology supports eco-friendly practises by reducing fuel consumption and emissions by up to 30%.

Introduction

The construction industry is experiencing a transformative shift as advanced machinery becomes increasingly essential for efficient operations. Among these innovations, remote control sheepsfoot rollers emerge as a standout solution, delivering a range of benefits that significantly enhance project outcomes and streamline workflows.

As construction professionals strive to improve safety, precision, and cost-effectiveness, a critical question arises: how can the integration of remote control technology into compaction processes fundamentally alter project execution?

This article explores the multifaceted advantages of utilizing remote control sheepsfoot rollers, revealing their potential to revolutionize construction practices.

EZ Equipment Rental: Premier Remote Control Sheepsfoot Roller Rentals in Dallas, TX

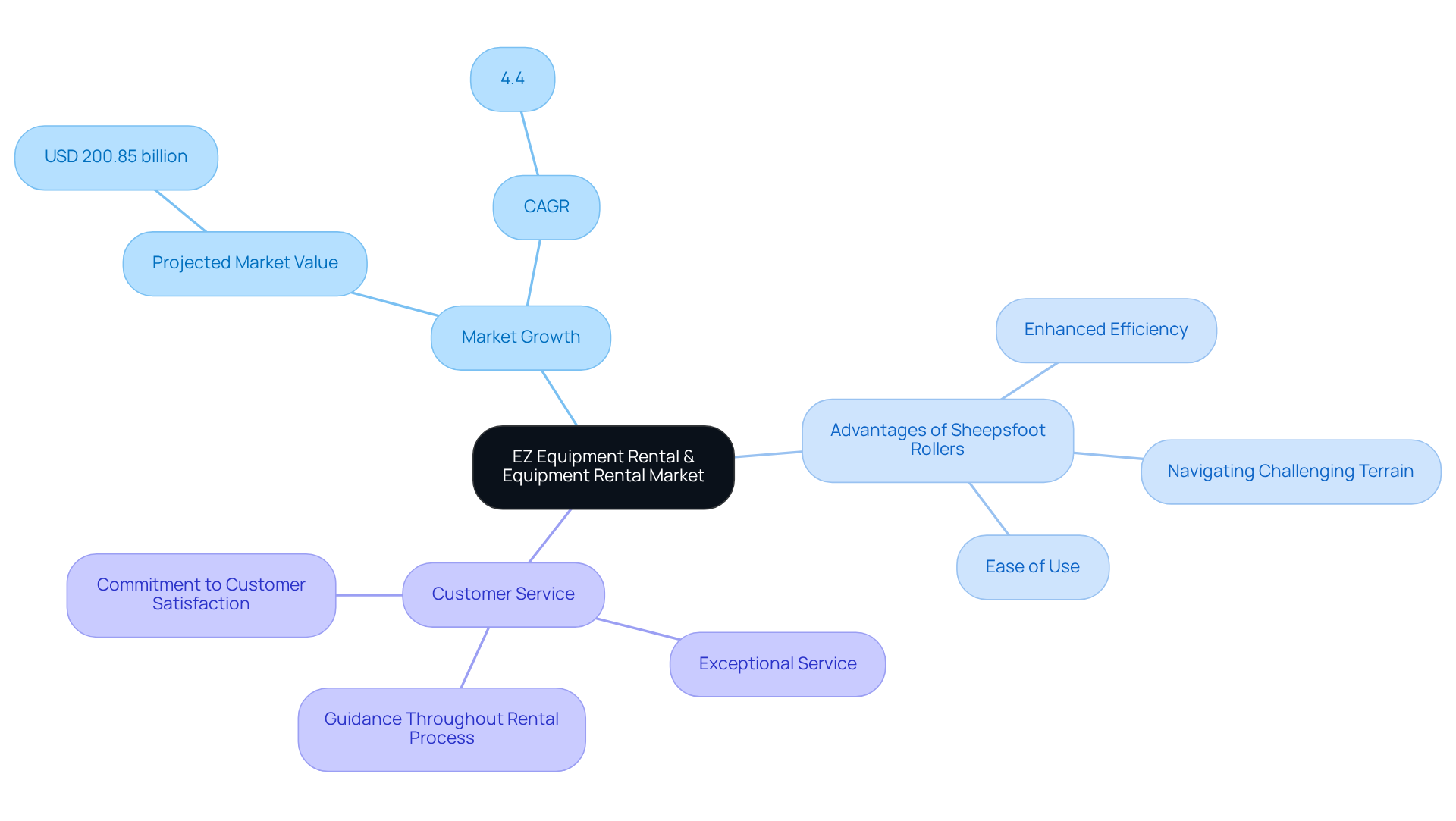

EZ Equipment Rental stands as the premier supplier of remote control sheepsfoot roller rentals in Dallas, TX, offering an extensive selection of high-quality equipment tailored to meet diverse building requirements. With the equipment rental market projected to reach USD 200.85 billion by 2032, growing at a CAGR of 4.4% until 2034, the demand for specialized machinery such as sheepsfoot rollers is on the rise. This trend is particularly evident in Texas, where the equipment rental industry is experiencing significant growth, driven by increased construction activities and urban development.

At EZ Equipment Rental, our seasoned team is dedicated to delivering exceptional service, guiding clients throughout the rental process to ensure they select the right equipment for their projects. Our unwavering commitment to excellence and customer satisfaction distinguishes us in the competitive Dallas-Fort Worth area. Leasing a remote control sheepsfoot roller provides numerous advantages, including enhanced efficiency, ease of use, and the ability to navigate challenging terrain, making it an ideal choice for construction professionals aiming to elevate their project outcomes.

As industry leaders emphasize, 'The growing use of rental equipment in multiple sectors is a crucial factor in market expansion,' highlighting the importance of utilizing advanced machinery such as remote control sheepsfoot rollers. By choosing EZ Equipment Rental, you are not only investing in top-tier equipment but also ensuring that your projects are executed with precision and reliability.

Improved Precision: Achieve Accurate Compaction with Remote Control Sheepsfoot Rollers

Remote control sheepsfoot rollers are engineered to deliver exceptional accuracy during compaction activities. By allowing operators to control the machine from a distance, these rollers excel in achieving precise compaction, even in challenging terrains and confined spaces. This precision is vital for ensuring that soil density meets specifications, which is essential for creating stable and durable foundations.

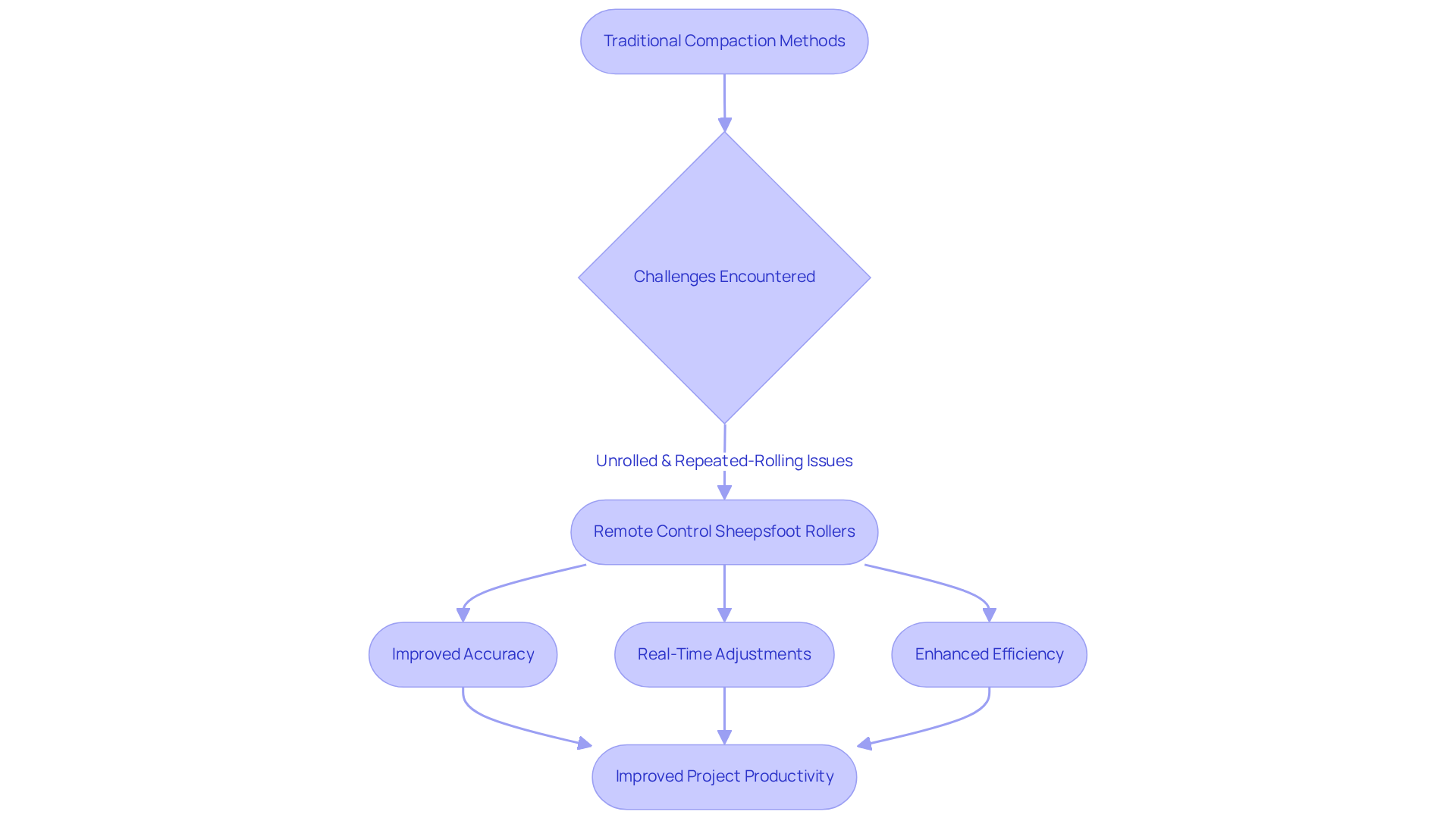

Traditional compaction methods often depend heavily on operators, leading to issues such as unrolled and repeated-rolling problems, as highlighted by civil engineer Qinglong Zhang. The ability to make real-time adjustments to compaction settings significantly enhances the efficiency of these machines, making them indispensable for industry experts. Research indicates that utilizing advanced equipment such as a remote control sheepsfoot roller can improve outcomes by minimizing rework and ensuring compliance with density standards.

Furthermore, machinery management technology has been shown to boost project productivity by 30-50%, ultimately resulting in safer and more efficient building processes. This combination of precision, efficiency, and productivity positions the remote control sheepsfoot roller as a crucial asset in modern construction, encouraging industry professionals to consider its integration into their projects.

Enhanced Safety: Reduce On-Site Risks with Remote Operation

Remote control sheepsfoot rollers greatly improve safety on building sites by allowing operators to operate machinery from a safe distance. This capability effectively reduces exposure to common hazards such as vibrations, excessive noise, and potential accidents, particularly in confined or hazardous environments. By minimizing the presence of workers in dangerous areas, these machines not only contribute to a safer worksite but also ensure effective compaction results. Statistics reveal that falls accounted for 40% of fatalities in the building industry, with falls, slips, and trips leading to 423 deaths in 2022, underscoring the critical need for enhanced safety protocols.

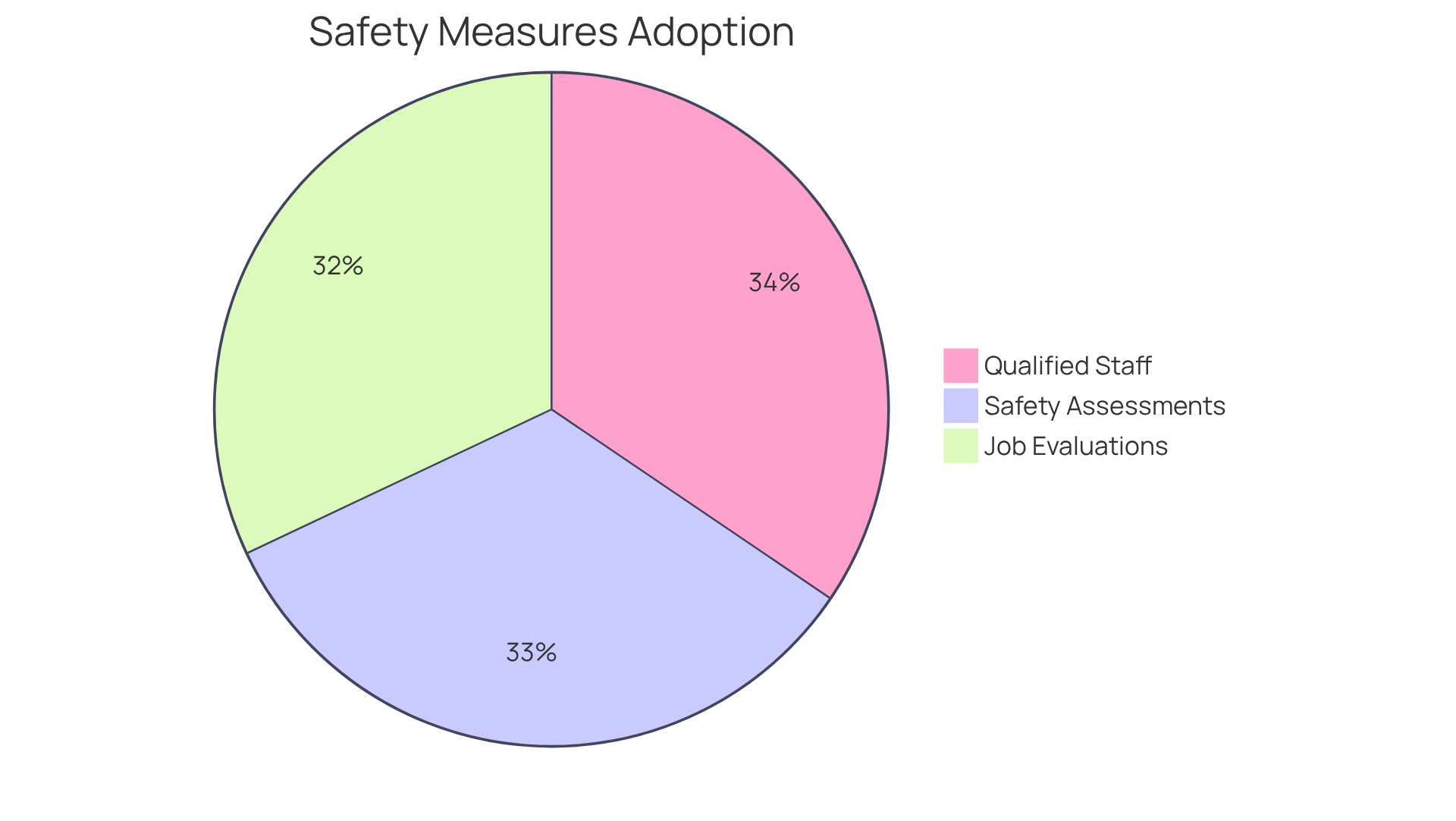

Moreover, remote operation technology aligns with the sector's commitment to improved safety measures. Currently:

- 70% of firms assign qualified project safety staff

- 68% conduct regular job safety assessments

- 65% perform ongoing job hazard evaluations

Safety professionals assert that integrating remote-controlled machinery can significantly mitigate risks associated with heavy equipment operation, ultimately leading to fewer workplace injuries and fatalities. As one expert noted, "Controlling unsafe behavior is crucial to reducing accidents on construction sites." For example, companies utilizing remote operation have reported a marked decrease in incidents, showcasing the effectiveness of this technology in enhancing overall site safety.

Additionally, with the average OSHA penalty per inspection being $4,018 and the annual cost of construction-related deaths reaching $5 billion, investing in remote operation technology is not merely a safety measure but also a financially sound decision. Embrace the future of construction safety by considering remote control sheepsfoot rollers for your next project.

Increased Efficiency: Streamline Compaction Processes with Remote Control

Remote control sheepsfoot rollers are transforming compaction processes by significantly enhancing efficiency. Operators can manage the remote control sheepsfoot roller from a distance, which eliminates the need to frequently enter and exit the cab. This not only reduces downtime but also streamlines workflow. Such capabilities enable rapid adjustments in response to changing site conditions, culminating in faster project completion.

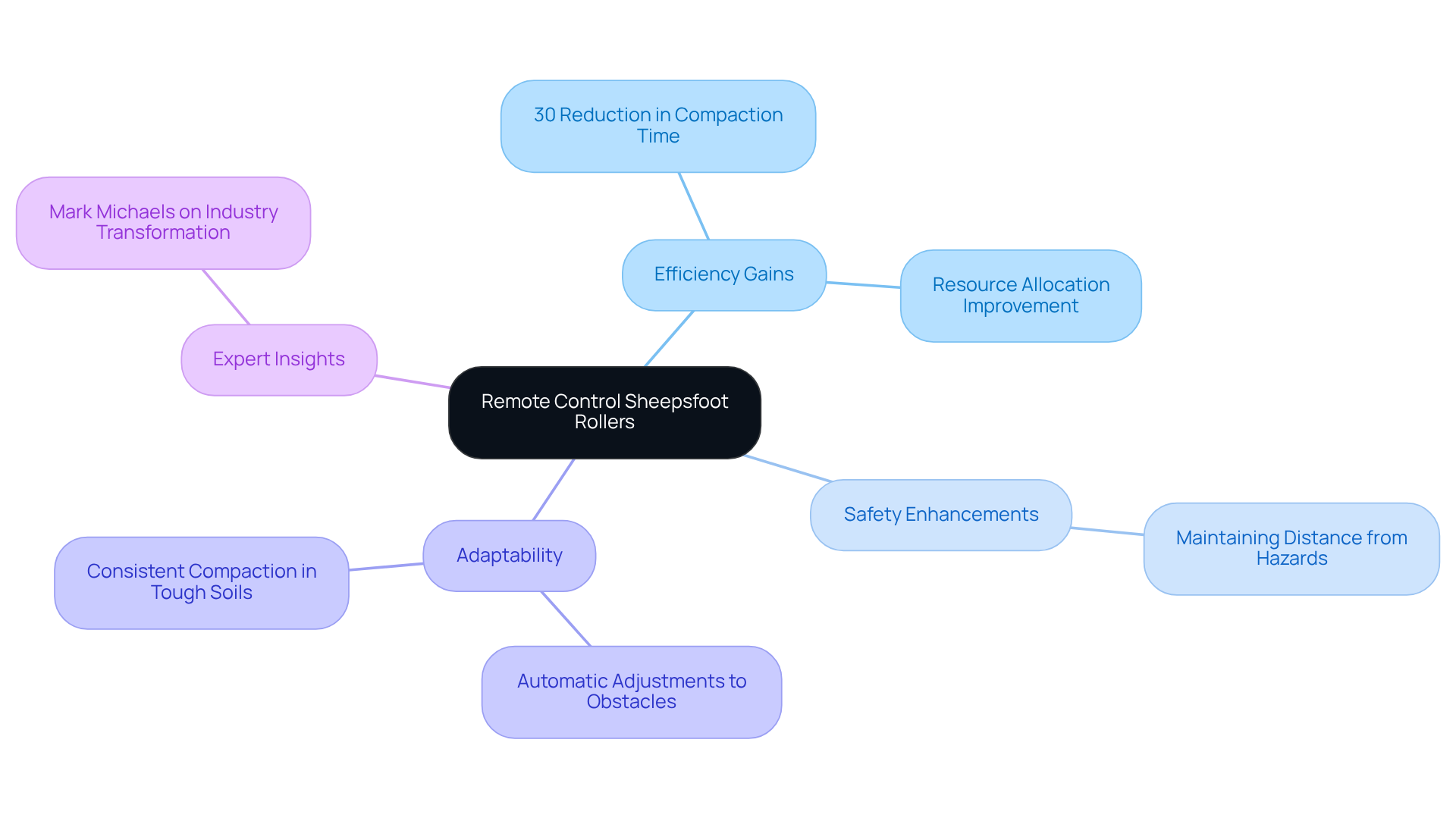

Statistics indicate that projects utilizing a remote control sheepsfoot roller experience notable efficiency gains, with reports highlighting up to a 30% reduction in compaction time. For instance, in a recent pipeline development project, the deployment of remote control sheepsfoot rollers allowed the team to allocate resources more effectively, thereby boosting overall productivity on the job site.

Project managers have observed that the remote control sheepsfoot roller not only accelerates the compaction process but also fosters a safer working environment by allowing operators to maintain a safe distance from moving parts and potential hazards. As Mark Michaels, Senior Director of Product Management at Husqvarna Construction North America, articulates, 'The remote control sheepsfoot roller technology is transforming the industry, and the list of benefits is continually expanding.'

Furthermore, the remote control sheepsfoot roller possesses the ability to automatically adjust when encountering obstacles, ensuring consistent compaction crucial for structural stability, especially in challenging soil types such as clay and rocky terrain. As remote operation technology continues to evolve, its impact on construction efficiency becomes increasingly evident.

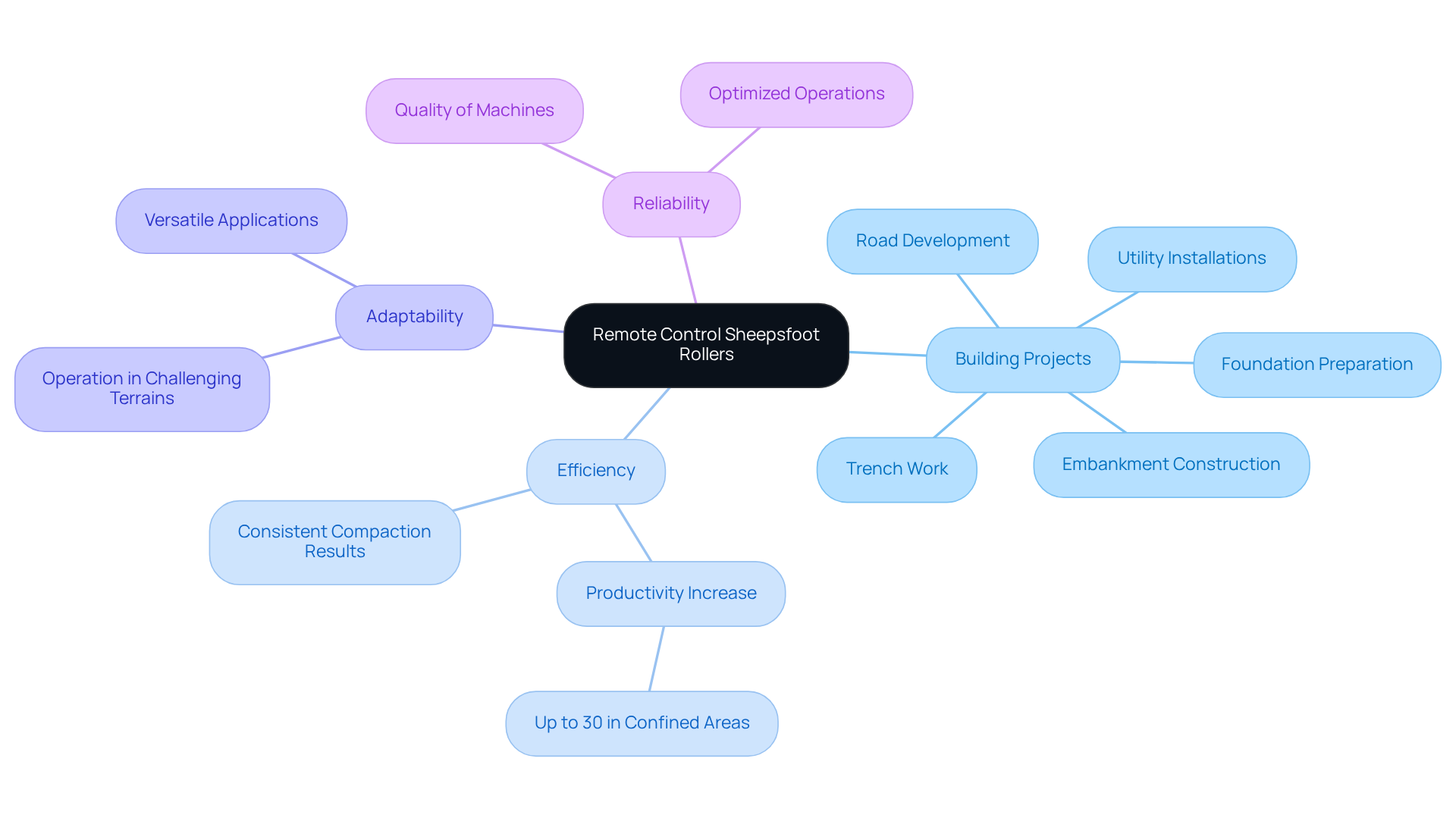

Versatile Applications: Utilize Remote Control Sheepsfoot Rollers for Diverse Projects

The versatility of remote control sheepsfoot rollers makes them suitable for a wide range of building projects. These machines excel at compacting soil for road development, preparing foundations for buildings, and executing tasks in confined areas. Their design enables effective operation in challenging terrains, making them ideal for trench work, embankment construction, and utility installations. This adaptability not only enhances efficiency in tasks but also maximizes the return on investment for contractors.

Statistics indicate that utilizing remote operation equipment can significantly boost productivity on job sites, with research demonstrating a productivity increase of up to 30% in confined areas. Contractors have recognized the effectiveness of sheepsfoot devices in these spaces, with one contractor stating, "These tools allow us to achieve consistent compaction results even in the tightest spots, which is crucial for our projects." This adaptability ensures that remote-operated sheepsfoot devices provide substantial benefits across diverse building applications.

In addition, the reliability and quality of these machines make them indispensable for contractors seeking to optimize their operations. The ability to perform in various environments not only improves project timelines but also enhances the overall quality of work. Therefore, investing in remote control sheepsfoot rollers is a strategic choice for contractors who aim to elevate their project outcomes.

Cost-Effectiveness: Save on Labor and Time with Remote Control Technology

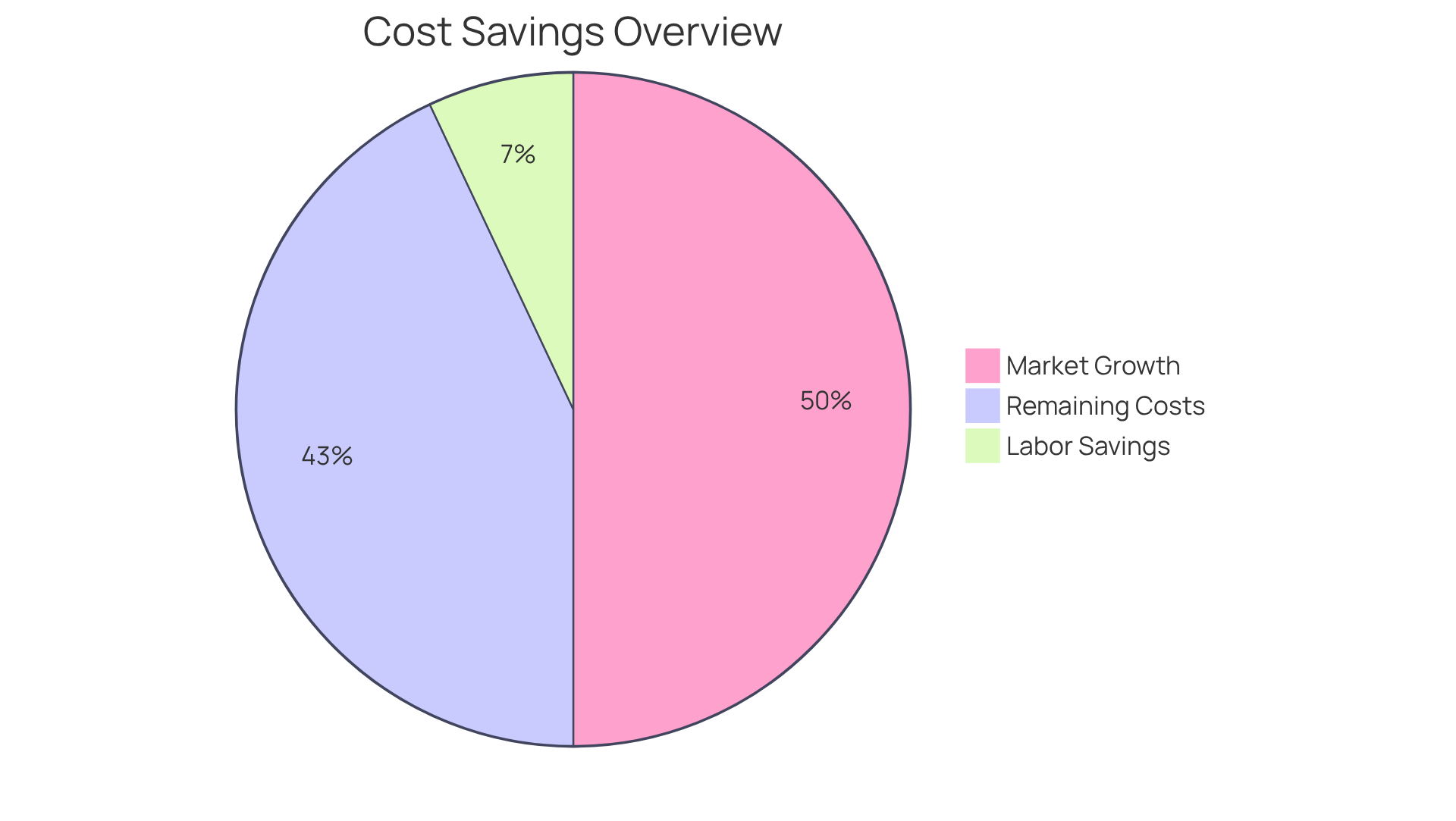

Remote control sheepsfoot rollers provide substantial savings in both labor and time, making them an invaluable investment for contractors. By minimizing the need for multiple operators and streamlining compaction tasks, the remote control sheepsfoot roller significantly reduces labor costs. For example, construction experts utilizing remote operation technology have reported average labor cost reductions of up to 14%, a testament to enhanced operational efficiency. Additionally, ALICE users enjoy an average of 14% labor cost savings, further underscoring the efficiency gains linked to the remote control sheepsfoot roller technology.

The remote control sheepsfoot roller allows for operation from a secure distance, which not only accelerates project timelines but also mitigates risks associated with hazardous environments. This efficiency leads to quicker task completions, ultimately driving down total costs.

As the market for remote control sheepsfoot rollers is projected to grow from USD 150 million in 2024 to USD 300 million by 2033, with a CAGR of 8.5% from 2026 to 2033, the demand for such cost-effective solutions is expected to surge. Moreover, remote-controlled trench compactors excel in densifying challenging soil conditions, making them an increasingly attractive option for optimizing return on investment in construction projects.

Advanced Technology: Leverage Cutting-Edge Features of Remote Control Sheepsfoot Rollers

Remote control sheepsfoot rollers are leading the way in construction technology, featuring advancements that greatly improve performance and usability. With the remote control sheepsfoot roller, operators can execute compaction tasks from a safe distance, effectively reducing exposure to noise and vibration. Automated compaction settings guarantee consistent results, while real-time monitoring capabilities deliver immediate feedback on soil compaction progress, including real-time soil strength data that can be accessed at the operator's workstation or through a dedicated app. This functionality allows for on-the-fly adjustments, ensuring uniform soil strength, which is crucial for supporting asphalt or concrete paving and assisting contractors in meeting contract requirements.

These advancements not only streamline the compaction process but also elevate user satisfaction. Studies reveal that operators value the ease of use and efficiency that these technologies contribute to their projects. For example, the integration of soil strength monitoring technology enables contractors to meet contract requirements by providing precise data on compaction levels.

Moreover, modern compaction equipment, including the Wacker Neuson RC70 and Caterpillar's latest models, incorporates enhanced safety protocols and intuitive operator interfaces, making them accessible even for less experienced users. As the construction sector continues to evolve, leveraging these innovative features will be essential for contractors aiming to improve their operations and deliver high-quality results.

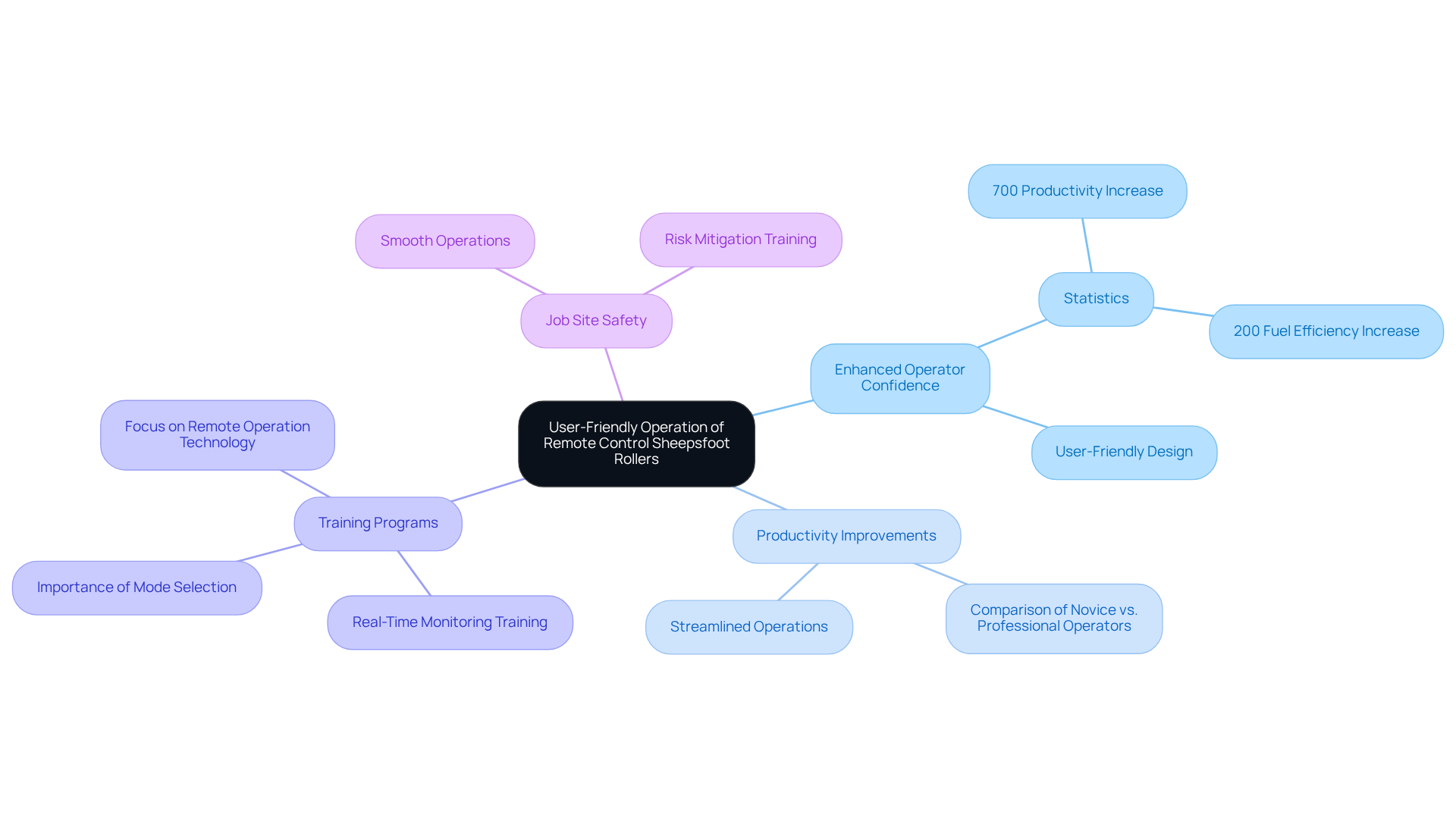

User-Friendly Operation: Simplify Compaction Tasks with Remote Control

Remote control sheepsfoot rollers are engineered for intuitive operation, allowing operators to manage machine functions with ease. This user-friendly design significantly enhances operator confidence and reduces the learning curve for newcomers. Statistics reveal that operators utilizing simplified machinery experience a remarkable increase in confidence, with productivity improvements of up to 700% noted when comparing novice and professional operators. As construction teams quickly adapt to these advanced machines, they can execute compaction tasks with heightened efficiency and effectiveness.

Training programs focused on remote operation technology underscore the importance of familiarizing oneself with the equipment, including mode selection and smooth transitions. This ensures operators can fully leverage the functionalities of these innovative tools. Furthermore, maintaining consistent speed during compaction is crucial for achieving uniform density. The ease of use associated with remote sheepsfoot devices not only streamlines operations but also enhances overall job site safety and productivity.

In summary, the remote control sheepsfoot roller represents a significant advancement in construction technology, combining user-friendly design with exceptional performance. By prioritizing operator training and understanding of equipment, teams can maximize their effectiveness and ensure safety on the job site. Embrace the future of construction with these advanced tools and experience the difference in productivity and confidence.

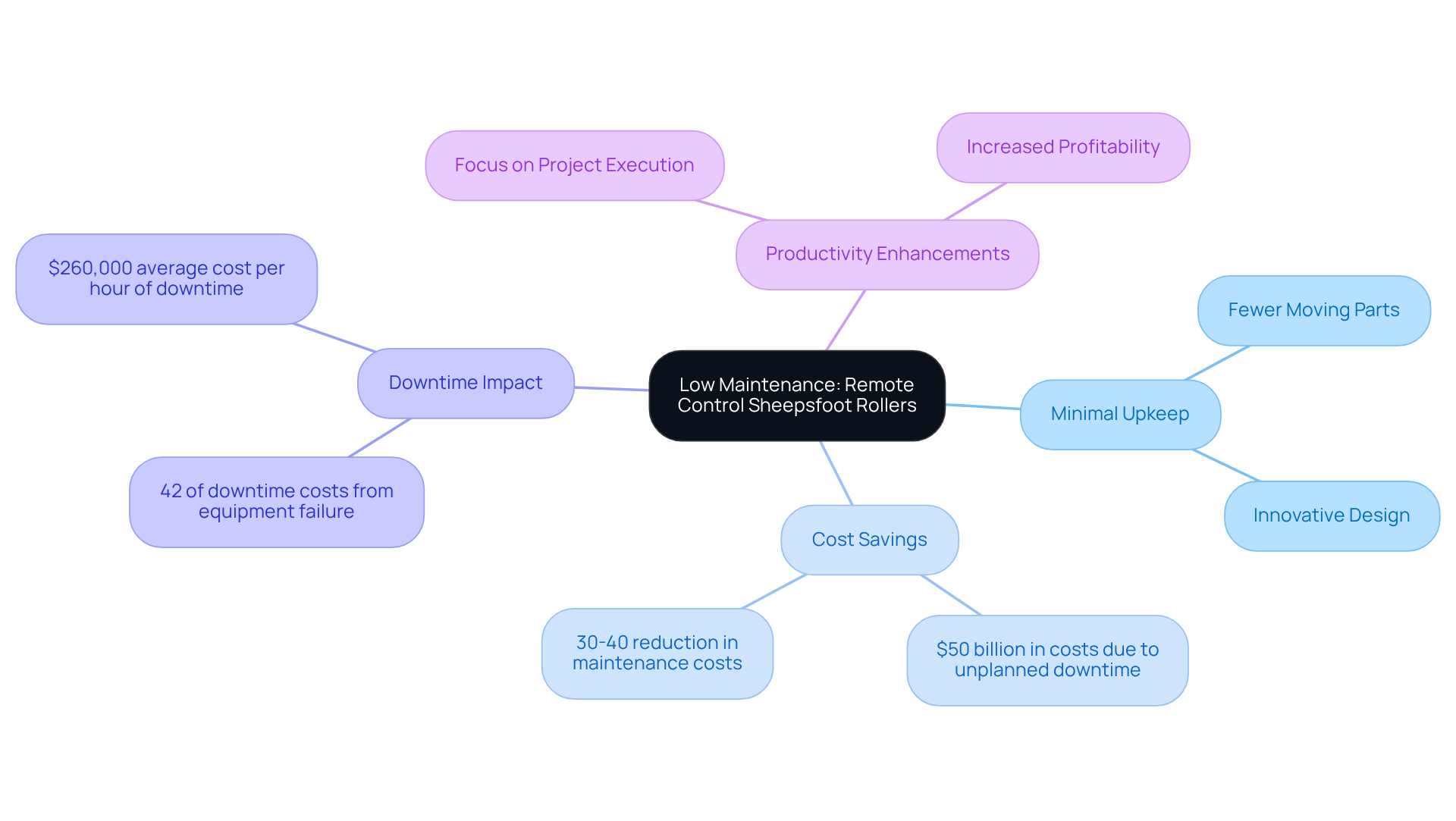

Low Maintenance: Enjoy Hassle-Free Operation with Remote Control Sheepsfoot Rollers

Remote control sheepsfoot rollers are designed for minimal upkeep, offering contractors a seamless operational experience. These machines, featuring fewer moving parts and an innovative design, necessitate less frequent servicing compared to traditional models. This reduction in maintenance not only conserves valuable time but also significantly lowers overall operational costs.

Industry insights reveal that unplanned downtime can cost manufacturers up to $50 billion annually, with equipment failure accounting for 42% of these costs. Furthermore, unexpected downtime expenses businesses an average of $260,000 each hour, underscoring the financial consequences of maintenance issues in the industry.

By investing in remote control sheepsfoot rollers, contractors can redirect their focus from equipment maintenance to project execution, thereby enhancing productivity and profitability. Maintenance professionals assert that effective maintenance strategies can yield a 30-40% reduction in costs when compared to reactive approaches.

As Dan Corbett, an equipment manager, aptly states, "It’s the collateral damage that really costs you money." This reality positions the remote control sheepsfoot roller as a preferred choice for those seeking to elevate their building processes.

Eco-Friendly Operations: Reduce Environmental Impact with Remote Control Technology

Remote control sheepsfoot rollers play a crucial role in promoting eco-friendly building practices by significantly reducing fuel usage and emissions. Their innovative design guarantees optimal compaction with decreased energy use, benefiting the environment and aiding in effective budget management. By minimizing reliance on various machines and operators, these rollers contribute to a smaller overall carbon footprint for building projects. This alignment with sustainability goals empowers contractors to achieve high-quality results while actively participating in reducing their environmental impact.

As emphasized by sustainability specialists, the integration of advanced technologies in building equipment is essential for lowering carbon emissions and fostering a greener industry. For example, studies indicate that utilizing a remote control sheepsfoot roller can lead to a reduction in emissions by up to 30%. This statistic showcases the potential of transforming construction operations into more sustainable practices, reinforcing the importance of adopting such innovative solutions in the industry.

Conclusion

The advantages of utilizing remote control sheepsfoot rollers in construction are profound, offering a blend of precision, safety, efficiency, and sustainability. These advanced machines not only enhance operational accuracy but also significantly reduce on-site risks, streamline compaction processes, and minimize labor costs. As the construction industry continues to evolve, the integration of such innovative technology is becoming essential for achieving high-quality results while promoting eco-friendly practices.

Key insights reveal that remote control sheepsfoot rollers lead to improved compaction accuracy, enhanced safety protocols, and increased overall project efficiency. By allowing operators to work from a safe distance, these machines help mitigate hazards and promote a more productive work environment. Furthermore, their versatility and low maintenance requirements make them an attractive option for contractors aiming to optimize their operations across various project types.

Embracing remote control sheepsfoot rollers is not just a step towards modernization; it is a strategic move that aligns with the industry's growing focus on safety, efficiency, and sustainability. As demand for such equipment rises, particularly in bustling markets like Dallas, contractors are encouraged to consider these advanced solutions to elevate their project outcomes and contribute to a greener future. Investing in remote control technology today will undoubtedly yield significant benefits in productivity, safety, and environmental impact for years to come.

Frequently Asked Questions

What is EZ Equipment Rental known for?

EZ Equipment Rental is recognized as the premier supplier of remote control sheepsfoot roller rentals in Dallas, TX, providing a wide selection of high-quality equipment for various building needs.

Why is the demand for remote control sheepsfoot rollers increasing?

The demand is rising due to the growth of the equipment rental market, which is projected to reach USD 200.85 billion by 2032, driven by increased construction activities and urban development, particularly in Texas.

What advantages do remote control sheepsfoot rollers offer?

They provide enhanced efficiency, ease of use, and the capability to navigate challenging terrain, which helps construction professionals improve project outcomes.

How do remote control sheepsfoot rollers improve precision in compaction?

They allow operators to control the machine from a distance, enabling precise compaction even in difficult terrains and confined spaces. This ensures that soil density meets specifications for stable and durable foundations.

What are the safety benefits of using remote control sheepsfoot rollers?

These rollers enhance safety by allowing operators to work from a safe distance, reducing exposure to hazards such as vibrations, excessive noise, and potential accidents, particularly in confined areas.

How does remote operation technology contribute to workplace safety?

It minimizes the presence of workers in dangerous zones, leading to fewer workplace injuries and fatalities. Companies using remote operation have reported a decrease in incidents, showcasing its effectiveness in enhancing site safety.

What statistics highlight the importance of safety in the construction industry?

Falls accounted for 40% of fatalities in the building industry, with 423 deaths in 2022. This underscores the critical need for improved safety measures, including the integration of remote-controlled machinery.

Why is investing in remote operation technology considered financially sound?

With the average OSHA penalty per inspection being $4,018 and the annual cost of construction-related deaths reaching $5 billion, utilizing remote operation technology not only enhances safety but also helps reduce potential financial liabilities.