Key Highlights:

- Understanding bulldozer components such as the blade, ripper, tracks, cab, engine, hydraulic system, and undercarriage is crucial for safe and effective operation.

- Proper entry and preparation for bulldozer operation includes wearing PPE, inspecting the cab, adjusting the seat, and conducting a pre-operational inspection.

- To drive a bulldozer confidently, start with slow movements, use joysticks for control, maintain visibility, and practise regularly.

- Effective control of the blade and ripper involves adjusting tool height and angle, monitoring load, and maintaining smooth movements.

- Safe shutdown procedures include lowering attachments, idling the engine, turning off the ignition, and conducting a final inspection.

- Regular maintenance of bulldozer tracks involves checking rail tension, inspecting for wear, cleaning tracks, lubricating parts, and scheduling regular maintenance.

- Essential safety tips for bulldozer operation include wearing appropriate PPE, conducting pre-operation checks, avoiding overloading, staying aware of surroundings, and following manufacturer guidelines.

Introduction

Mastering the art of bulldozer operation goes beyond merely sitting behind the controls; it demands a thorough understanding of the machine’s components and a steadfast commitment to safety. This guide delineates the essential steps to transform any novice into a confident bulldozer driver, encompassing everything from the machine's mechanics to the critical safety protocols that must be adhered to.

How can one navigate the complexities of operating such a powerful piece of machinery without falling prey to anxiety or mishaps? Here, you will discover key techniques and insights that empower operators to approach any job site with assurance and skill.

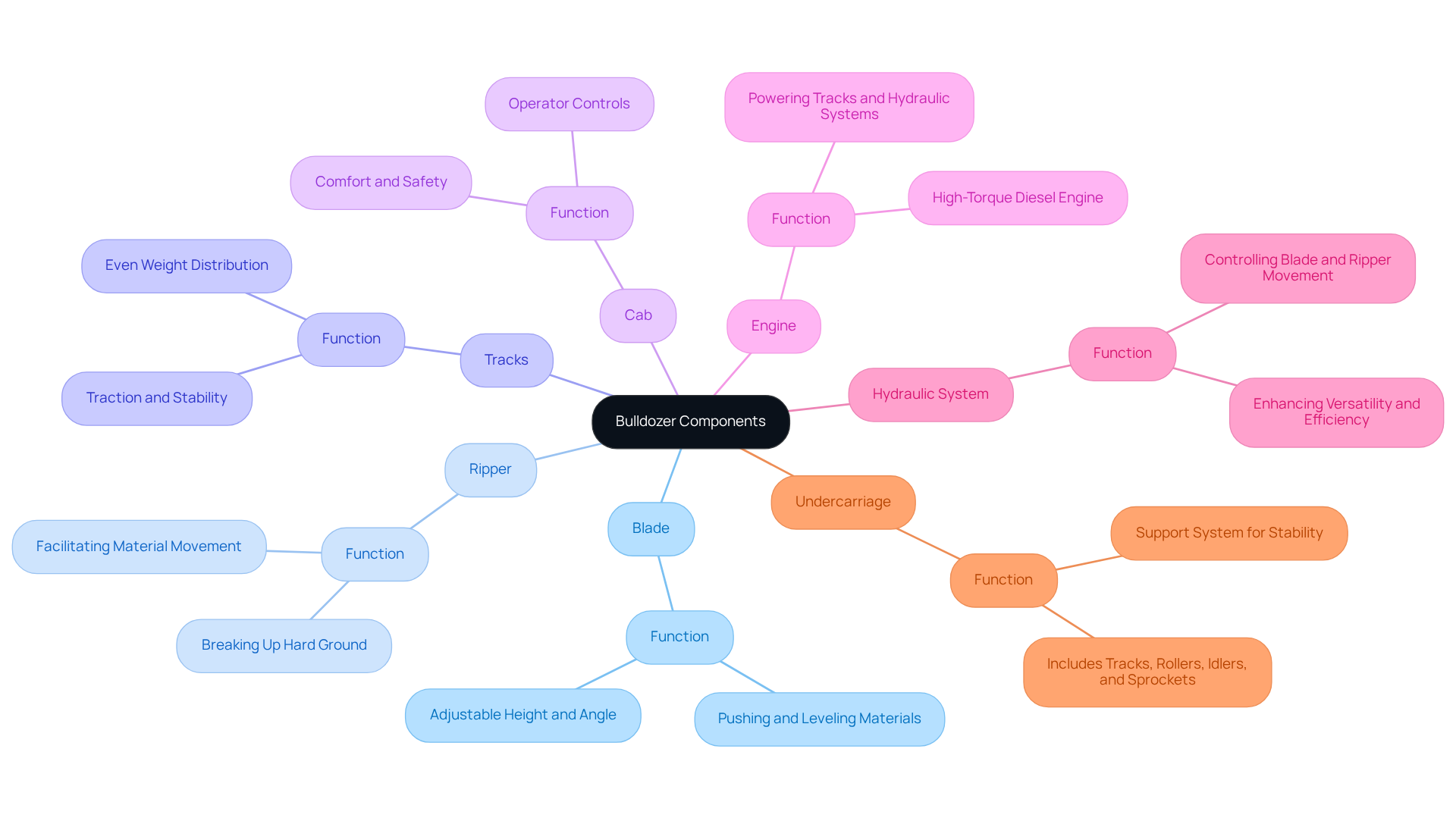

Understand Bulldozer Components and Functions

Before operating a bulldozer, it is essential to understand its key components, as each plays a vital role in ensuring safe and effective operation:

- Blade: The front-mounted blade is crucial for pushing and leveling materials. Its adjustable height and angle provide versatility for various tasks, enhancing efficiency in material handling.

- Ripper: Located at the rear, the ripper is designed to break up hard ground or compacted materials, facilitating easier movement by the blade. This attachment significantly boosts the machine's capability in challenging environments.

- Tracks: These durable steel tracks offer traction and stability, allowing the heavy machinery to navigate rough terrain without sinking. Their design ensures even weight distribution, which is critical for maintaining balance on uneven surfaces.

- Cab: The operator's compartment features controls that enable precise manipulation of the machine's functions. A well-designed cab enhances operator comfort and control, contributing to overall safety.

- Engine: Serving as the powerhouse of the vehicle, the engine drives both the tracks and the hydraulic systems. Typically, a high-torque, diesel-powered engine is used to ensure robust performance in demanding tasks.

- Hydraulic System: This system controls the movement of the blade and ripper, allowing for precise adjustments. Understanding the hydraulic system's functioning is crucial for enhancing the machine's versatility and efficiency.

- Undercarriage: The undercarriage, which includes treads, rollers, idlers, and sprockets, serves as the essential support system for the earth-moving machine. It ensures stability on various terrains and minimizes the risk of sinking on soft or uneven surfaces.

Knowledge of these components not only improves operational efficiency for a bulldozer driver but also guarantees safety during machinery operation. Each part must be adequately maintained and understood to avoid accidents and equipment breakdown. Routine evaluations, such as monitoring fluid levels and examining tracks for wear, are crucial for preserving the machine's performance and reliability.

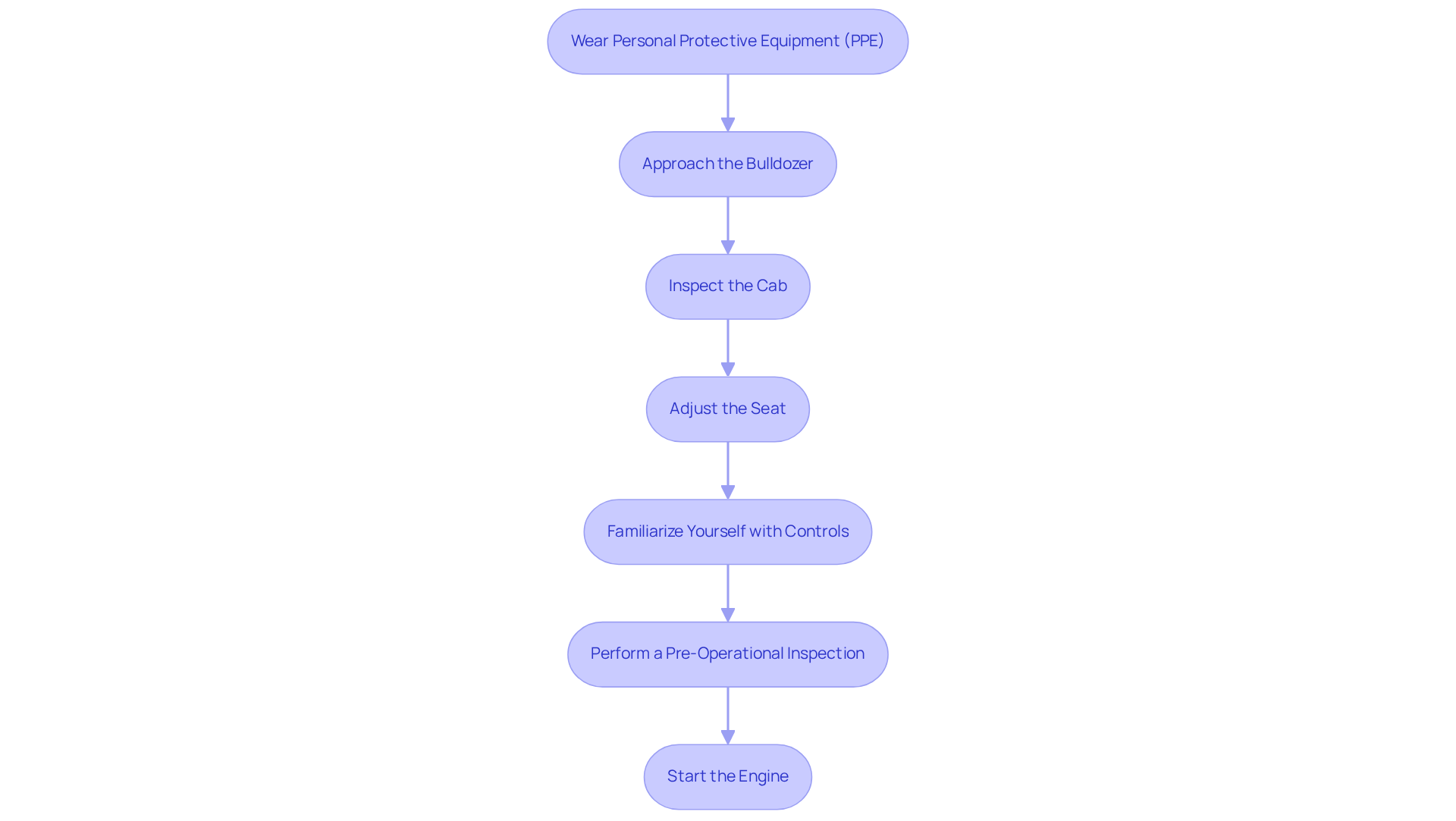

Enter and Prepare the Bulldozer for Operation

To safely enter and prepare the bulldozer for operation, follow these essential steps:

- Wear Personal Protective Equipment (PPE): Equip yourself with hard hats, gloves, steel-toed boots, high-visibility clothing, and, if necessary, respiratory protection for dust-heavy conditions. This ensures your safety during operation.

- Approach the Bulldozer: Utilize the designated steps and handholds to maintain three points of contact. This practice minimizes the risk of falls and enhances safety.

- Inspect the Cab: Before entering, check for any obstructions or hazards inside the cab. Ensuring a safe environment is crucial for effective operation.

- Adjust the Seat: Set your seat for optimal comfort and visibility. This adjustment is vital for maintaining effective control of the machine.

- Familiarize Yourself with Controls: Locate and understand the function of each control before starting the engine. This knowledge enhances operational efficiency and safety.

- Perform a Pre-Operational Inspection: Conduct a thorough check of fluid levels, brakes, safety features, and visible parts. Confirm that everything is functioning correctly to prevent mechanical failures and accidents. Additionally, check ground stability to ensure the heavy machinery is parked on stable, level ground.

- Start the Engine: Follow the manufacturer's guidelines for starting the heavy machinery. Allow it to warm up adequately before use to ensure optimal performance. When working on inclines, keep the cutting edge low to enhance stability and reduce rollover risk.

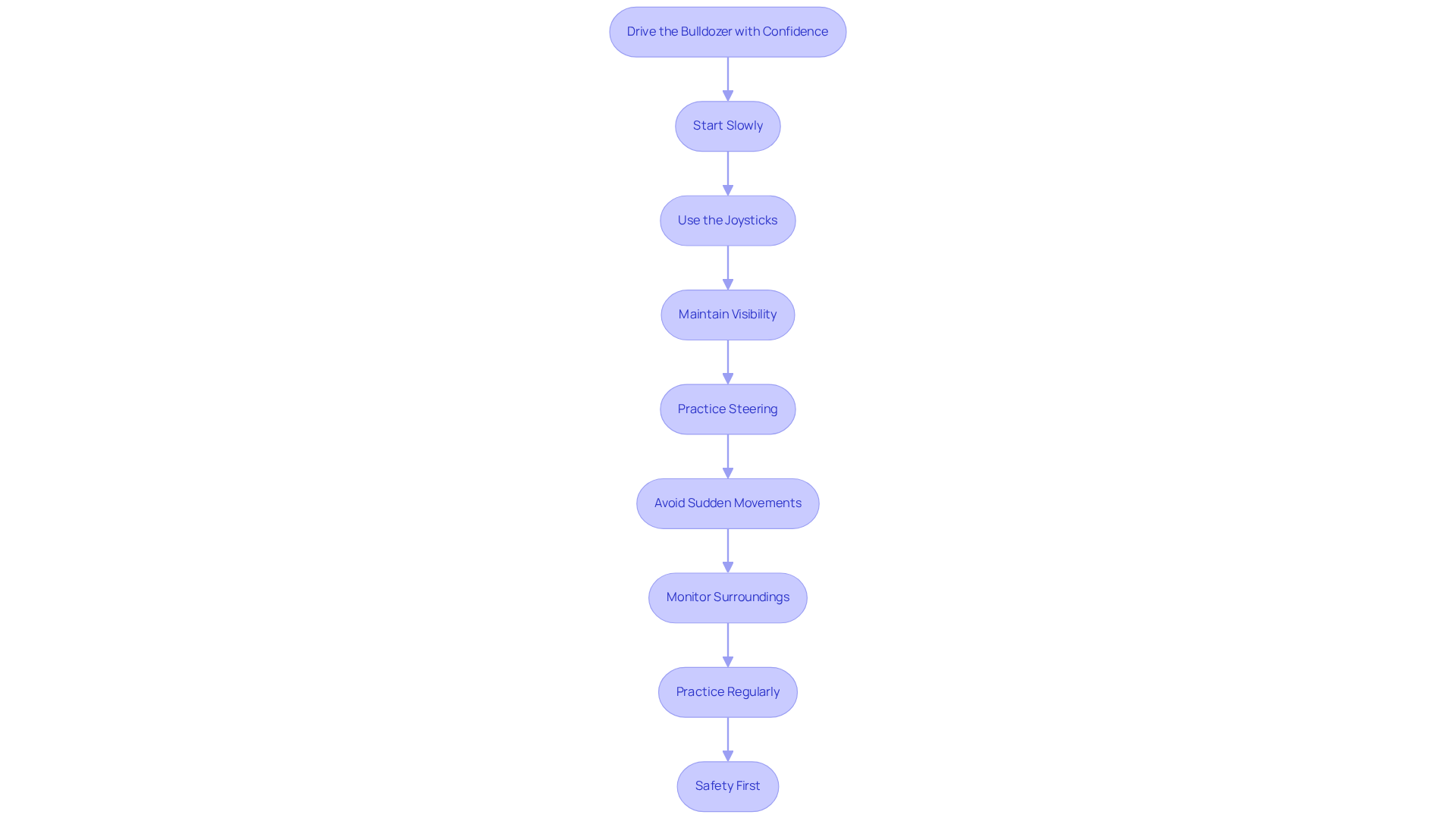

Drive the Bulldozer with Confidence

To operate the bulldozer confidently, follow these essential guidelines:

- Start Slowly: Begin with gentle movements to familiarize yourself with the controls. This approach helps you test for any sudden or jerky motions before commencing work.

- Use the Joysticks: The left joystick typically controls forward and backward motion, while the right joystick adjusts the tool's height and angle. To lower the cutter, move the right joystick forward; to raise it, pull it backward. Adjust the cutting edge's angle by moving the joystick left or right.

- Maintain Visibility: Ensure your line of sight remains unobstructed. Adjust mirrors as necessary to enhance your awareness of the surroundings.

- Practice Steering: Utilize the blade to assist in steering by angling it slightly. This technique helps guide the machine effectively.

- Avoid Sudden Movements: Make gradual adjustments to maintain control and prevent abrupt shifts in direction.

- The bulldozer driver skillfully maneuvered the machine through the construction site. As a bulldozer driver, you must monitor your surroundings and stay vigilant about your environment, including the presence of other workers and potential obstacles.

- Practice Regularly: Dedicate time to operate the bulldozer in a controlled setting. This practice enhances both your confidence and skill level.

- Safety First: Always exit the machine using three points of contact for safety. Additionally, troubleshoot any mechanical issues before operating the dozer.

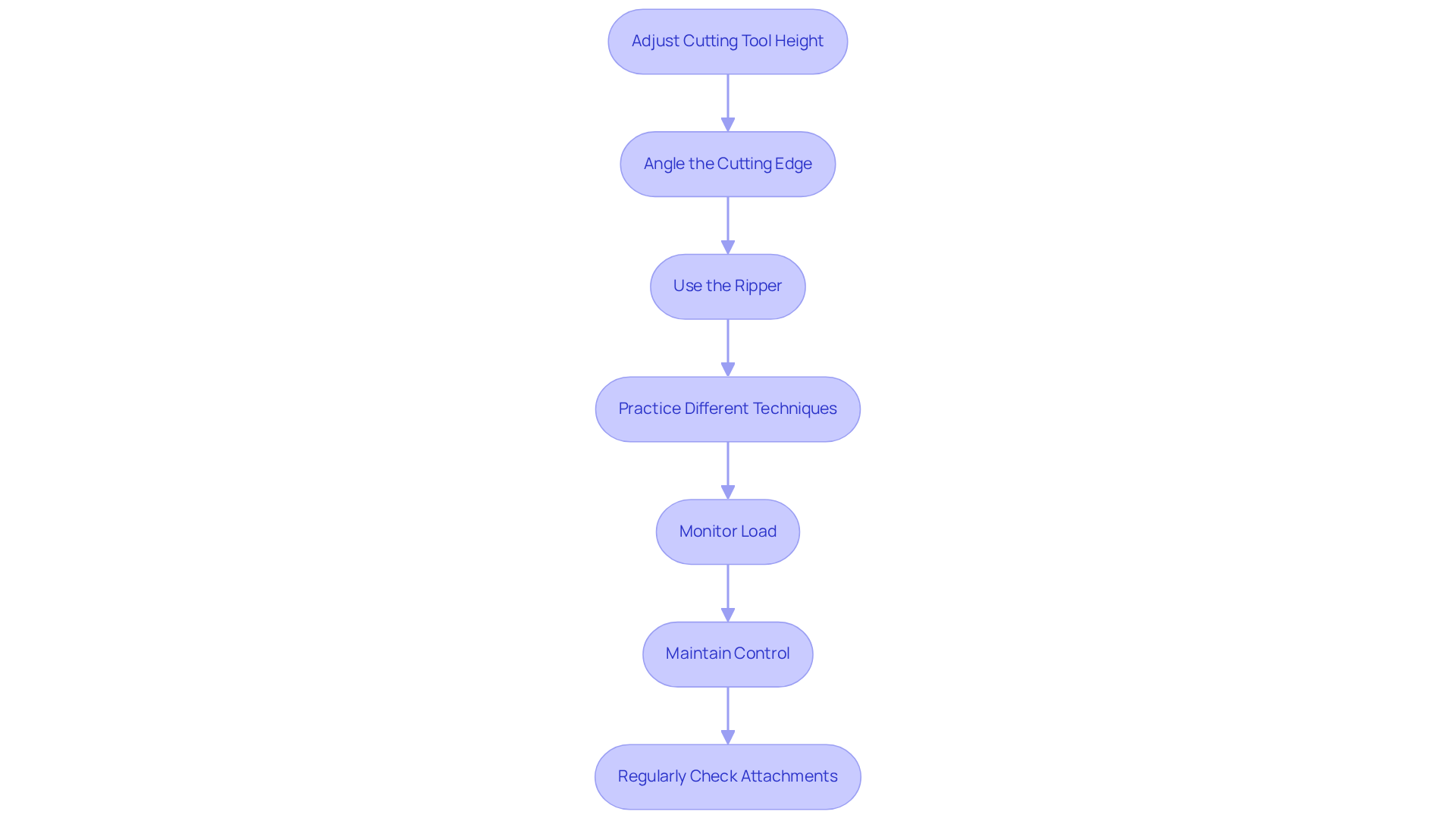

Control the Blade and Ripper for Effective Operation

To control the blade and ripper effectively, it is essential to follow these techniques:

- Adjust Cutting Tool Height: Use the right joystick to raise or lower the cutting tool based on the specific requirements of the task.

- Angle the Cutting Edge: Tilt the cutting edge left or right to direct the flow of material, optimizing efficiency. As construction expert John Ruskin noted, "Quality is never an accident. It is consistently the outcome of smart effort," emphasizing the importance of precise tool adjustments.

- Use the Ripper: Engage the ripper to break up hard ground; lower it gradually and apply pressure to avoid damaging the equipment.

- Practice Different Techniques: Experiment with various angles and heights to understand their effects on material movement, which enhances operational skills. The angle of the cutting edge significantly impacts how materials are moved, making this practice vital.

- Monitor Load: Be aware of the amount of material being pushed or ripped to prevent overloading the bulldozer, which can lead to mechanical issues. As Benjamin Franklin wisely stated, "An ounce of prevention is worth a pound of cure," highlighting the importance of load management.

- Maintain Control: Ensure all movements are smooth and controlled to avoid sudden weight shifts that could destabilize the machine.

- Regularly Check Attachments: Conduct routine inspections of the blade and ripper to confirm they are in optimal condition and functioning correctly.

These techniques not only improve operational efficiency but also enhance safety on the job site. Effective management of earthmoving machine attachments is vital for successful material handling and project execution.

Shut Down the Bulldozer Safely

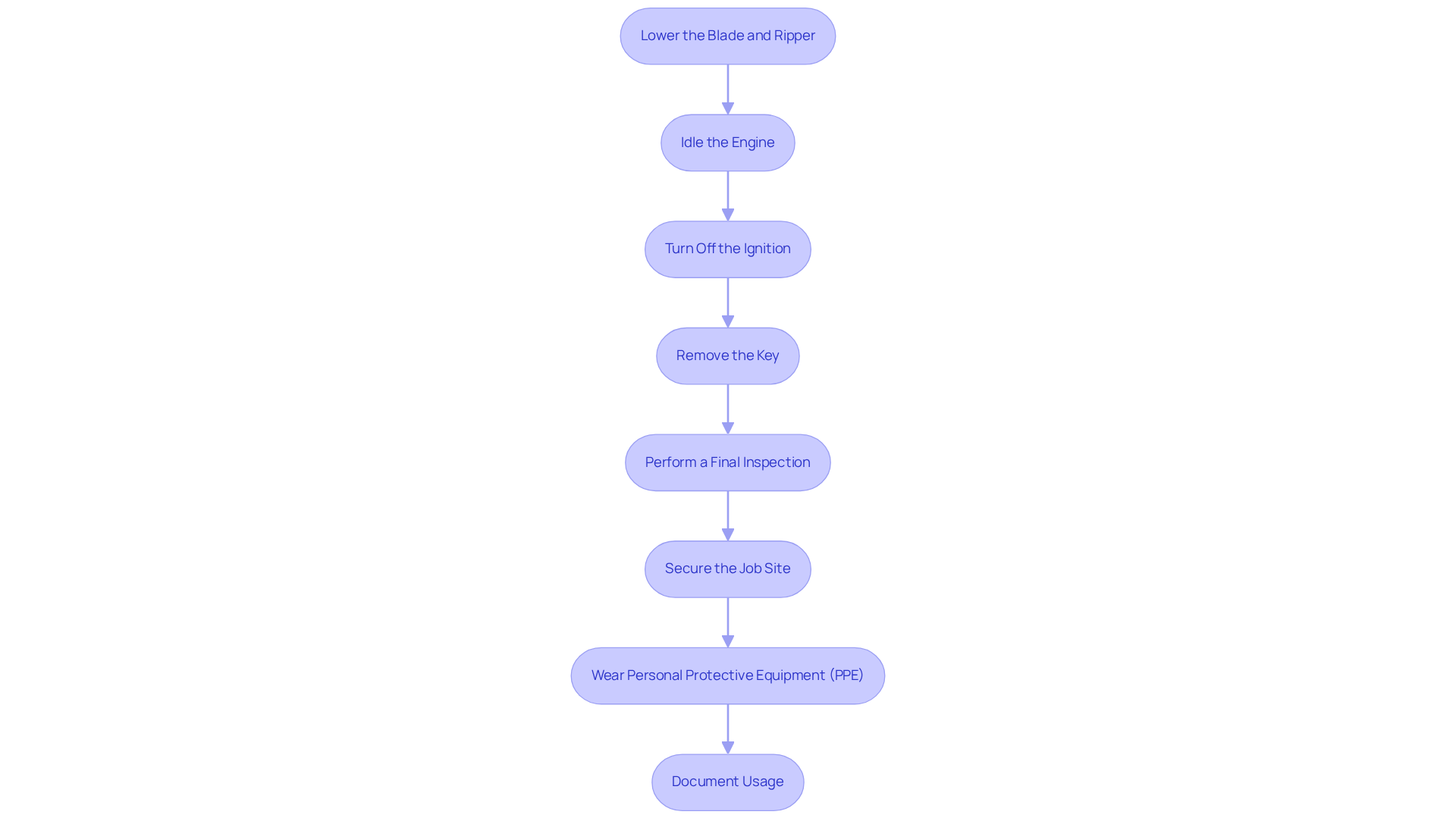

To ensure a safe shutdown of the bulldozer, follow these critical steps:

-

Lower the Blade and Ripper: Begin by bringing both attachments to the ground. This action relieves pressure on the hydraulic system, which is essential for maintaining the integrity of the equipment.

-

Idle the Engine: Allow the engine to run at low idle for a few minutes. This cooling period is vital as it helps prevent overheating and prolongs the engine's lifespan.

-

Turn Off the Ignition: Follow the manufacturer's guidelines for shutting down the engine properly. This ensures that all systems are safely disengaged.

-

Remove the Key: Always take the key with you to prevent unauthorized access, ensuring that the machinery cannot be operated by anyone else.

-

Perform a Final Inspection: Conduct a thorough check for any leaks, damage, or maintenance needs before leaving the machine. This step is crucial for identifying potential issues that could affect future operations. Record any operational issues or maintenance needs identified during this inspection to ensure equipment reliability and compliance.

-

Secure the Job Site: Confirm that the area around the bulldozer is clear of personnel and equipment. This minimizes the risk of accidents.

-

Wear Personal Protective Equipment (PPE): Ensure that you are wearing appropriate PPE throughout the shutdown process. This not only improves safety but also complies with OSHA regulations.

-

Document Usage: Record any operational issues or maintenance requirements for future reference. This practice aids in maintaining equipment reliability and safety compliance.

Adjust and Maintain Bulldozer Tracks

To effectively adjust and maintain bulldozer tracks, it is essential to follow these key steps:

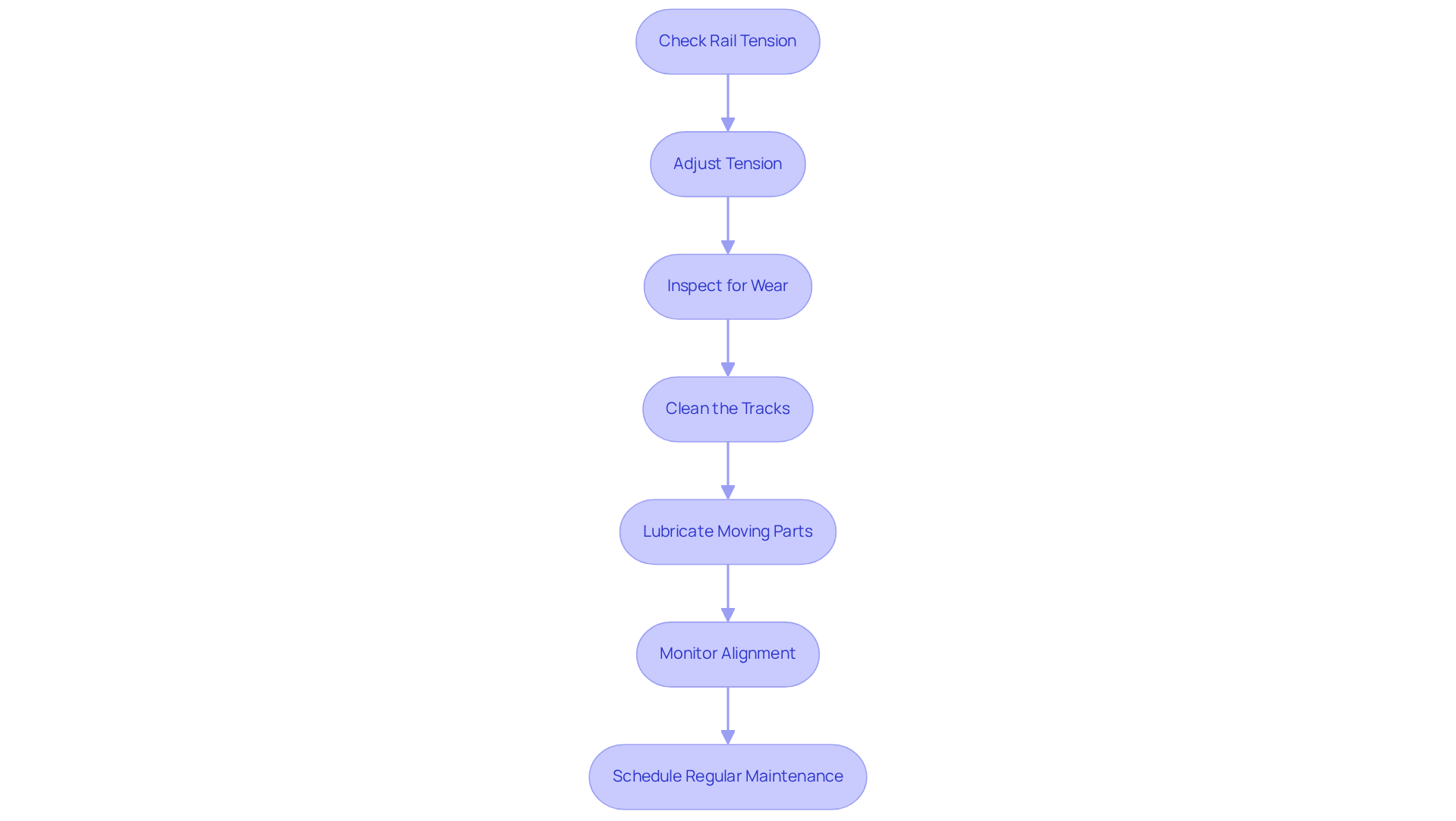

-

Check Rail Tension: Regularly inspect the tension of the rails. They should be neither too loose nor too tight, as improper tension can lead to premature wear and operational inefficiencies. Notably, the undercarriage accounts for around 50% of your maintenance budget, making proper tension management crucial.

-

Adjust Tension: Utilize the adjuster to add or release grease, achieving the correct tension as specified in your equipment manual. It is advisable to refer to your operation and maintenance manual for the proper tension test procedures specific to your machine’s undercarriage.

-

Inspect for Wear: Conduct thorough inspections for signs of wear or damage on the rails and undercarriage. Daily inspections serve as a key preventive maintenance measure, helping to prevent minor issues from escalating into costly repairs.

-

Clean the Tracks: Remove any accumulated debris or mud to prevent jamming and ensure smooth operation. Regular cleaning is vital for maintaining the integrity of the undercarriage.

-

Lubricate Moving Parts: Regularly apply lubricant to the component parts to diminish friction and wear. Proper greasing helps push dirt out and prolongs the lifespan of the undercarriage.

-

Monitor Alignment: Ensure that the rails are aligned correctly to avoid uneven wear, which can compromise performance and lead to additional maintenance costs.

-

Schedule Regular Maintenance: Adhere to a structured maintenance schedule to keep the tracks in optimal condition. Neglecting undercarriage maintenance can lead to early equipment failure, costly repairs, job site downtime, and damage to business reputation. Regular maintenance not only enhances performance but also extends the equipment's service life.

By following these steps, operators can significantly enhance the reliability and efficiency of earthmoving machines, ensuring they remain a valuable asset on any job site.

Follow Essential Bulldozer Operation Safety Tips

To ensure safe bulldozer operation, it is essential to follow these guidelines:

- Wear Appropriate PPE: Always wear hard hats, gloves, and safety boots to protect yourself from potential hazards.

- Conduct Pre-Operation Checks: The bulldozer driver must inspect the machinery before use to identify any potential issues that could compromise safety. To maintain clear visibility, the bulldozer driver must ensure that their line of sight is unobstructed, allowing for better awareness of their surroundings.

- Avoid Overloading: A bulldozer driver must not exceed the bulldozer's load capacity, as this can lead to accidents and equipment failure.

- Stay Aware of Surroundings: As a bulldozer driver, be mindful of other workers and obstacles in the area to prevent collisions and ensure a safe working environment.

- Use Caution on Slopes: Always drive straight up and down slopes as a bulldozer driver to maintain stability and reduce the risk of tipping.

- Follow Manufacturer Guidelines: As a bulldozer driver, it is essential to adhere to the operating manual for specific safety instructions, ensuring compliance with best practices.

Conclusion

Becoming a confident bulldozer driver requires a thorough understanding of the machine's components, safety protocols, and operational techniques. Mastering these elements not only boosts efficiency but also significantly lowers the risk of accidents on the job site. A solid foundation in the bulldozer's parts and their functions, along with strict adherence to safety measures, is essential for any operator aiming to excel in this demanding role.

Key steps outlined in this guide include:

- Familiarization with the bulldozer's components

- Proper entry and preparation procedures

- Driving techniques

- Effective control of the blade and ripper

The importance of regular maintenance and safety checks is emphasized, highlighting the necessity of being proactive in ensuring both personal safety and the longevity of the equipment. Each of these steps plays a vital role in building confidence and competence in operating a bulldozer.

Ultimately, the journey to becoming a skilled bulldozer driver is characterized by continuous learning and practice. By committing to safety, understanding the machinery, and refining driving techniques, operators can enhance their proficiency and contribute to a safer, more productive work environment. Embrace the challenge, invest time in training, and allow the bulldozer to become an extension of your capabilities on the job site.

Frequently Asked Questions

What are the key components of a bulldozer?

The key components of a bulldozer include the blade, ripper, tracks, cab, engine, hydraulic system, and undercarriage.

What is the function of the blade on a bulldozer?

The blade is a front-mounted component crucial for pushing and leveling materials, with adjustable height and angle for versatility in various tasks.

How does the ripper enhance a bulldozer's capabilities?

The ripper, located at the rear, is designed to break up hard ground or compacted materials, facilitating easier movement by the blade, which boosts the machine's capability in challenging environments.

Why are tracks important for a bulldozer?

Tracks provide traction and stability, allowing the bulldozer to navigate rough terrain without sinking, and ensure even weight distribution for balance on uneven surfaces.

What role does the cab play in bulldozer operation?

The cab is the operator's compartment that features controls for precise manipulation of the machine's functions, enhancing operator comfort and control for overall safety.

What type of engine is typically used in a bulldozer?

A high-torque, diesel-powered engine is typically used to drive both the tracks and hydraulic systems, ensuring robust performance in demanding tasks.

How does the hydraulic system function in a bulldozer?

The hydraulic system controls the movement of the blade and ripper, allowing for precise adjustments that enhance the machine's versatility and efficiency.

What is the purpose of the undercarriage in a bulldozer?

The undercarriage supports the bulldozer and includes treads, rollers, idlers, and sprockets, ensuring stability on various terrains and minimizing the risk of sinking on soft or uneven surfaces.

What safety measures should be taken before operating a bulldozer?

Safety measures include wearing personal protective equipment (PPE), maintaining three points of contact when entering, inspecting the cab, adjusting the seat, familiarizing yourself with controls, performing a pre-operational inspection, and following guidelines for starting the engine.

What should be included in a pre-operational inspection of a bulldozer?

A pre-operational inspection should include checking fluid levels, brakes, safety features, visible parts, and confirming that everything is functioning correctly to prevent mechanical failures and accidents.

Why is it important to warm up the bulldozer's engine before use?

Warming up the engine adequately ensures optimal performance, particularly when working on inclines where keeping the cutting edge low enhances stability and reduces rollover risk.

List of Sources

- Understand Bulldozer Components and Functions

- Productivity estimation of bulldozers using generalized linear mixed models (https://sciencedirect.com/science/article/pii/S1226798824028095)

- Essential Parts of a Bulldozer and Their Functions (https://hbxgdozer.com/news/essential-parts-of-a-bulldozer-and-their-functions.html)

- The Ultimate Guide to Bulldozer Parts: Get All the Hidden Insights (https://heavyequipmentcollege.edu/ultimate-guide-bulldozer-parts-everything-need-to-know)

- Enter and Prepare the Bulldozer for Operation

- How to Operate a Bulldozer: A Step-By-Step Guide (https://unitedrentals.com/project-uptime/equipment/how-operate-bulldozer-step-step-guide)

- Heavy Equipment (Four Other Hazards) Stats and Facts (https://icwgroup.safetynow.com/heavy-equipment-four-other-hazards-stats-and-facts?print=pdf)

- Bulldozer Safety Tips for Successful Operation at HEC (https://heavyequipmentcollege.edu/bulldozer-safety-tips-for-successful-operation)

- Bulldozer Accidents - AutoAccident.com (https://autoaccident.com/bulldozer-accidents)

- Drive the Bulldozer with Confidence

- How to Operate a Bulldozer: A Step-By-Step Guide (https://unitedrentals.com/project-uptime/equipment/how-operate-bulldozer-step-step-guide)

- Control the Blade and Ripper for Effective Operation

- How to Operate a Bulldozer: A Step-By-Step Guide (https://unitedrentals.com/project-uptime/equipment/how-operate-bulldozer-step-step-guide)

- 10 Construction Quotes to Inspire Your Project (https://horstconstruction.com/10-wise-construction-quotes-to-inspire-your-next-project-2)

- How to Operate a Bulldozer: Mastering the Basics - TelecomDrive (https://telecomdrive.com/how-to-operate-a-bulldozer-mastering-the-basics)

- 9 Inspiring Quotes About Construction (https://constructconnect.com/blog/9-inspiring-construction-quotes)

- 40 Construction Quotes to Motivate Your Team (https://projectmanager.com/blog/construction-quotes)

- Shut Down the Bulldozer Safely

- 12 Essential Safety Tips for Heavy Equipment Operations (https://safetpros.com/12-essential-safety-tips-for-heavy-equipment-operations)

- How to Operate a Bulldozer: A Step-By-Step Guide (https://unitedrentals.com/project-uptime/equipment/how-operate-bulldozer-step-step-guide)

- Staying Safe Around Heavy Equipment | Travelers Insurance (https://travelers.com/resources/business-industries/construction/staying-safe-around-heavy-equipment)

- Heavy Equipment Safety Tips | Arnold Machinery (https://arnoldmachinery.com/resources/guide-to-heavy-equipment-safety)

- Heavy Equipment Operation Stats & Facts (https://bhhcsafetycenter.com/heavy-equipment-operation-stats-facts?print=pdf)

- Adjust and Maintain Bulldozer Tracks

- Undercarriage Maintenance Tips & Care | MacAllister Machinery (https://macallister.com/taking-care-undercarriage)

- 10 Wise Quotes For Anyone Who Works In Facility Maintenance (https://linkedin.com/pulse/10-wise-quotes-anyone-who-works-commercial-building-natalia-chaaito)

- 5 "Genius" Quotes to Inspire Better Facilities Maintenance (https://brightlysoftware.com/blog/5-genius-quotes-to-inspire-better-facilities-maintenance)

- Bulldozer Maintenance Archives - Heavy Equipment Market Insights | News | Guides & Beyond (https://my-equipment.com/blog/tag/bulldozer-maintenance)

- Follow Essential Bulldozer Operation Safety Tips

- 40+ Inspiring Safety Quotes for Work to Strengthen Your Safety Culture and Motivate Your Team (https://flowdit.com/workplace-safety-quotes)

- Personal protective equipment (PPE) use and its relation to accidents among construction workers - PMC (https://pmc.ncbi.nlm.nih.gov/articles/PMC7809954)

- Top 100 Inspirational Workplace Safety Quotes (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- Inspirational Safety Quotes to Share with Your Workers (https://ehsinsight.com/blog/inspirational-safety-quotes-to-share-with-your-workers)

- 80+ Workplace Safety Quotes + Free Design Templates - ScreenCloud (https://screencloud.com/workplace/safety-quotes)