Key Highlights:

- Pipe threading machines automate the threading process, increasing operational efficiency and reducing project timelines.

- Major pipeline operators report a 25% increase in installation speed using automated pipe threading machines.

- Prefabricated plumbing modules can lower labour costs by up to 30%, showcasing financial benefits of automation.

- These machines accommodate various pipe materials, simplifying inventory management and reducing equipment costs.

- Safety features in tube cutting devices, such as automatic shutoff and protective guards, enhance workplace safety.

- Precision threading reduces the likelihood of leaks, ensuring secure connexions in plumbing and gas systems.

- The global market for pipe threading machines is projected to grow significantly, indicating rising demand for efficient solutions.

- User-friendly designs lower the learning curve for operators, improving productivity and reducing errors.

- Investing in durable equipment minimises repair costs and enhances long-term reliability.

- Comprehensive support and maintenance services ensure optimal performance and longevity of pipe threading machines.

Introduction

The construction landscape is evolving rapidly, with automation playing a pivotal role in enhancing efficiency and productivity. Pipe threading machines have emerged as essential tools, revolutionizing project execution by streamlining operations and significantly reducing labor costs. However, as reliance on these machines increases, a critical question arises: how can contractors maximize the benefits of this technology while navigating potential challenges? This article explores the key advantages of using pipe threading machines, providing insights into their impact on efficiency, cost savings, safety, and overall project success.

Increase Efficiency with Pipe Threading Machines

The use of a pipe threading machine in pipe cutting devices enhances operational efficiency by automating the threading process, resulting in uniform, high-quality outcomes much faster than manual methods. This automation accelerates timelines and enables teams to allocate resources more strategically, leading to significant cost savings.

For example, tasks that typically require hours of manual labor can often be completed in mere minutes with an automated device, facilitating quicker project completion and boosting productivity on job sites. Major pipeline operators have reported a 25% increase in installation speed when employing the pipe threading machine as an automated solution, underscoring the substantial impact of these devices in the construction industry.

Furthermore, prefabricated plumbing modules can reduce labor costs by up to 30%, further emphasizing the financial advantages of automation. As the automatic tube fabrication equipment market is projected to grow from 2026 to 2033, embracing automated fabrication technology is becoming essential for maintaining a competitive edge in the industry.

As one construction manager remarked, 'The efficiency gained from automation in the process of assembling has been a game changer for our projects.

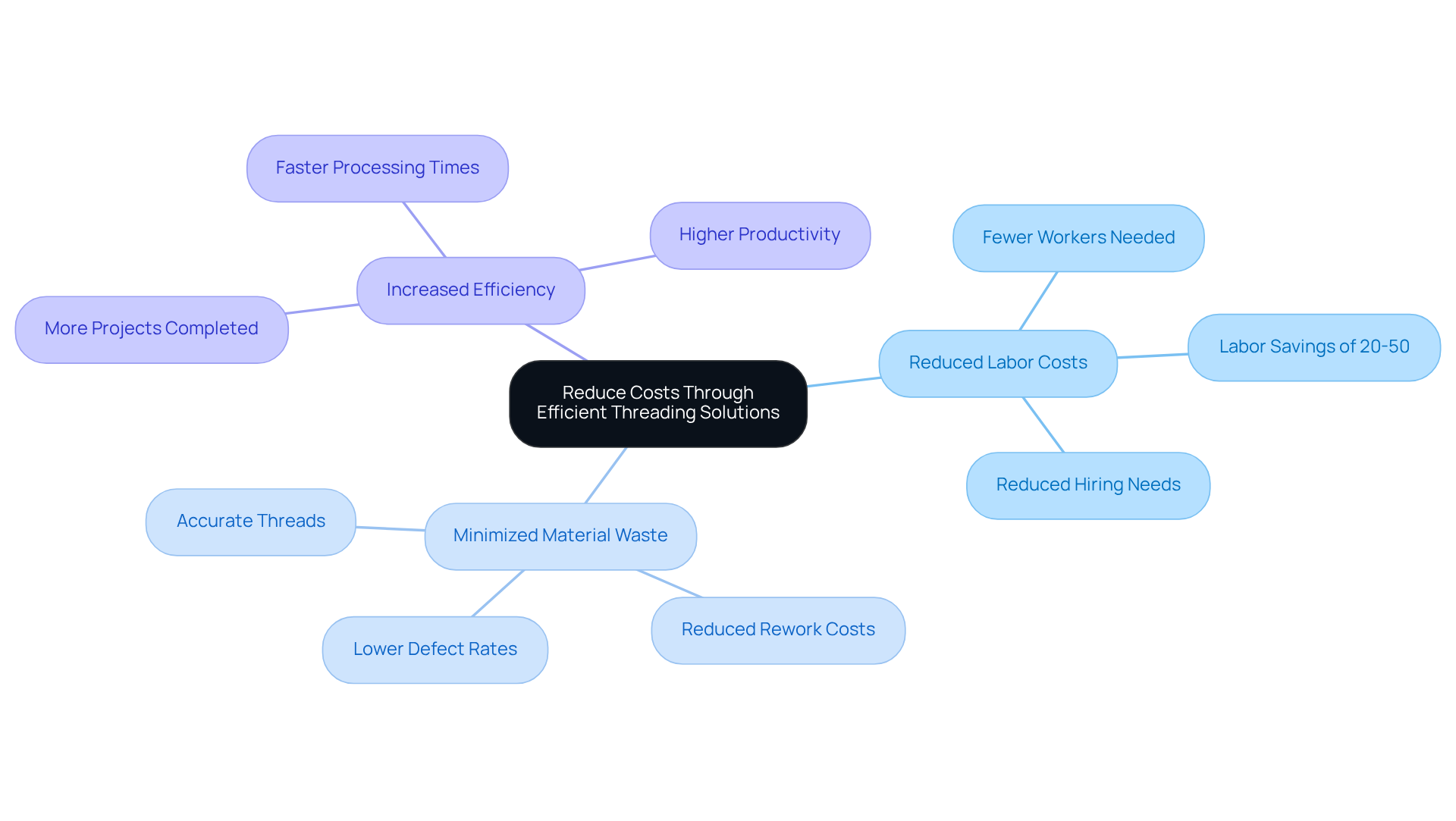

Reduce Costs Through Efficient Threading Solutions

Utilizing a pipe threading machine can lead to substantial cost savings in various ways. Firstly, automating sewing processes significantly reduces labor costs, as fewer workers are needed to achieve the same output. Moreover, the precision of these tools minimizes material waste by producing accurate threads that fit perfectly, thereby preventing costly rework. For example, a construction team using a specialized tool may find that they can complete more tasks in less time, allowing them to take on additional projects without increasing overhead costs.

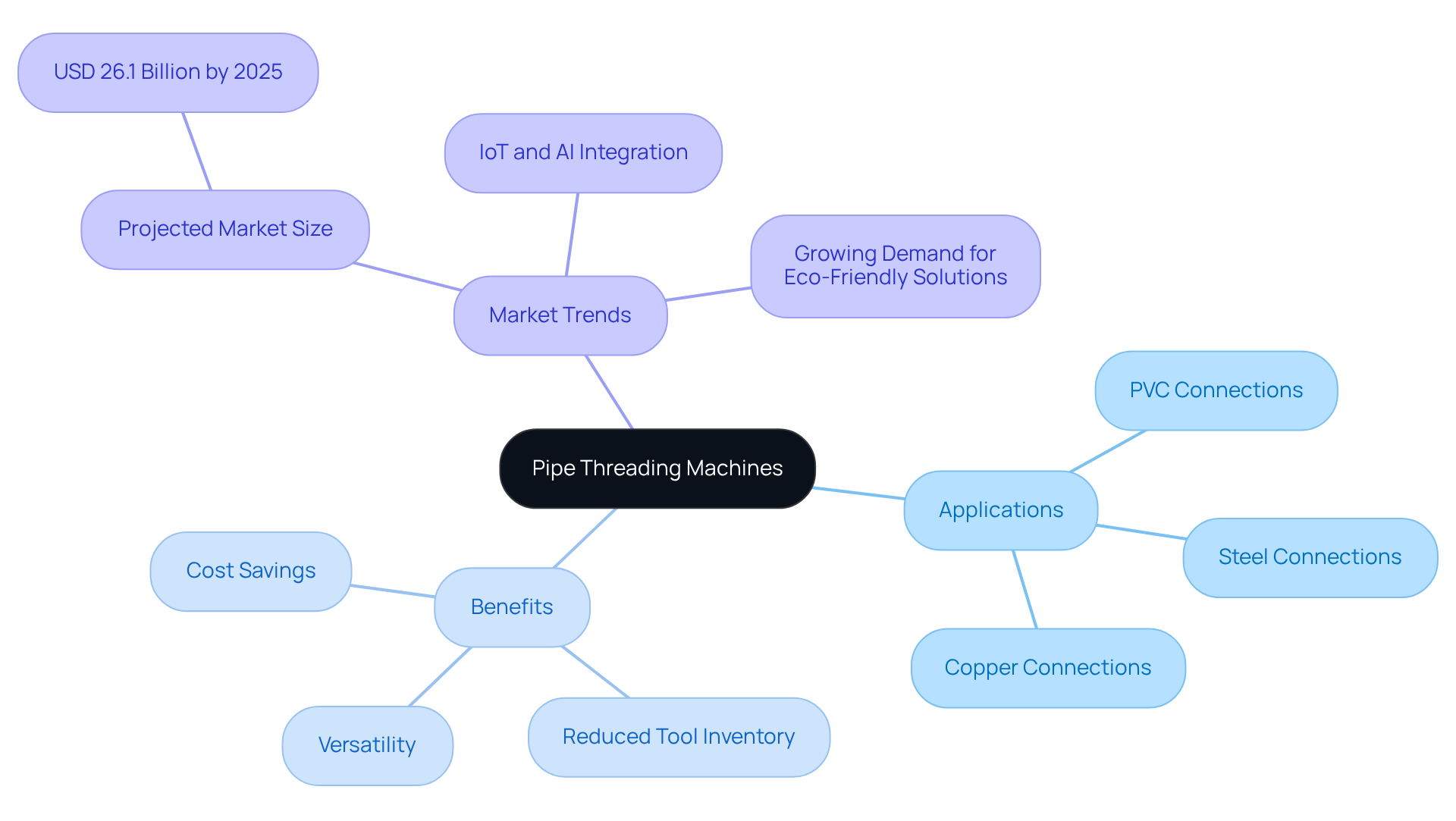

Achieve Versatility for Different Pipe Applications

Pipe threading machines are essential tools in construction, specifically designed to accommodate a wide range of tube dimensions and materials. These devices, such as a pipe threading machine, can connect PVC, steel, and copper pipes, and they can be easily modified to meet specific project requirements. This adaptability is crucial for contractors, as it minimizes the need for multiple tools and simplifies inventory management. For example, a single device can effectively support plumbing, HVAC, and gas line installations, optimizing operations and significantly reducing equipment costs.

As the construction industry increasingly embraces automation and efficiency, the demand for equipment such as the pipe threading machine continues to rise, underscoring their vital role in modern project execution. Market forecasts indicate that the tube screw equipment sector is expected to reach USD 26.1 billion by 2025, highlighting the importance of these devices in the industry. Furthermore, contractors have noted that integrating IoT and AI technologies into these devices enhances their functionality, enabling predictive maintenance and improving operational efficiency.

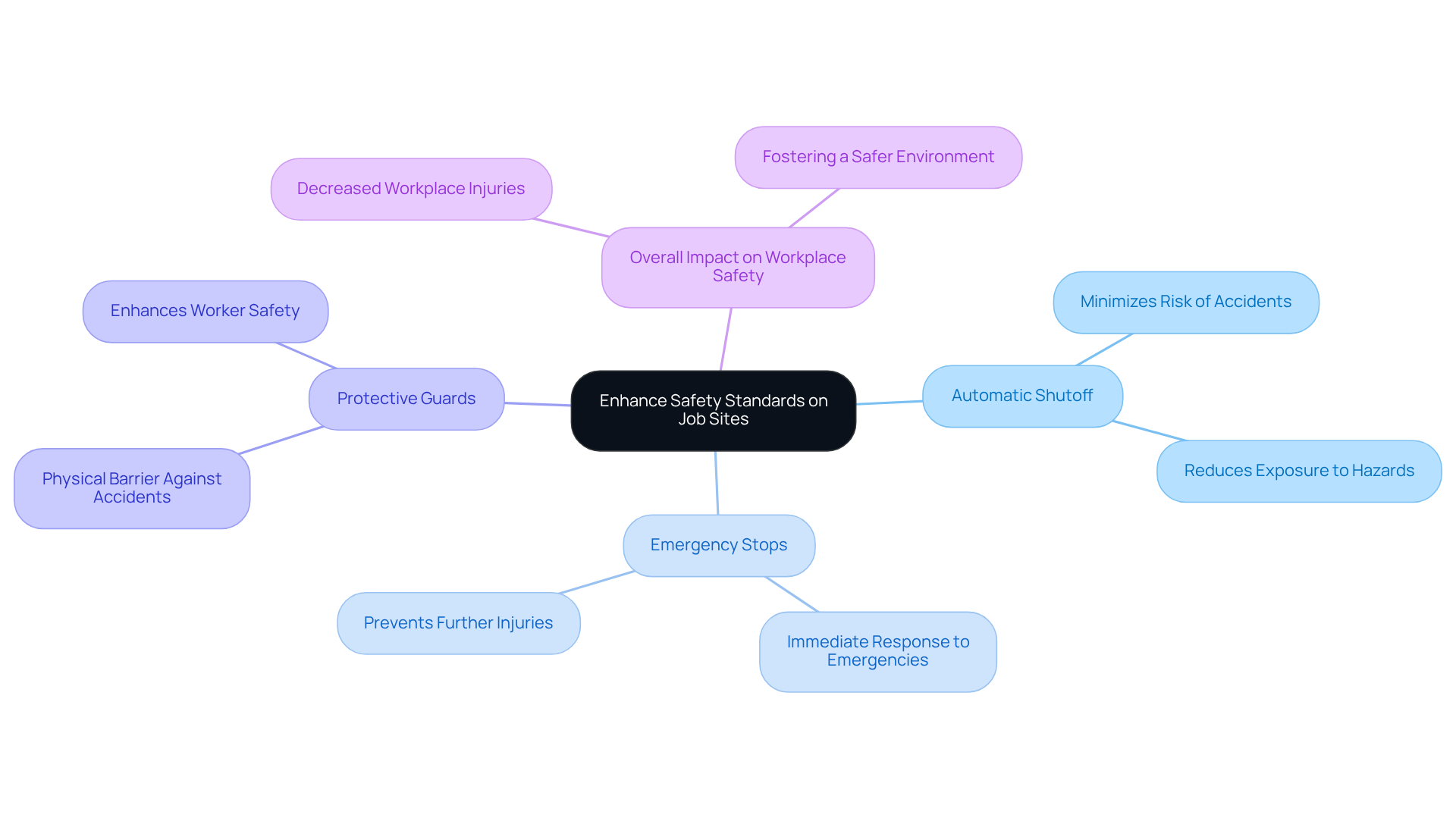

Enhance Safety Standards on Job Sites

Using tube cutting devices significantly enhances safety protocols on work sites. These devices often come equipped with essential safety features, such as:

- Automatic shutoff

- Emergency stops

- Protective guards

These features help minimize the risk of accidents. By automating the process of inserting threads, workers face reduced exposure to hazards associated with manual procedures, including:

- Repetitive strain injuries

- Accidents from handling heavy tubes

For example, a construction site that employs tube cutting devices may see a notable decrease in workplace injuries, fostering a safer and more efficient environment.

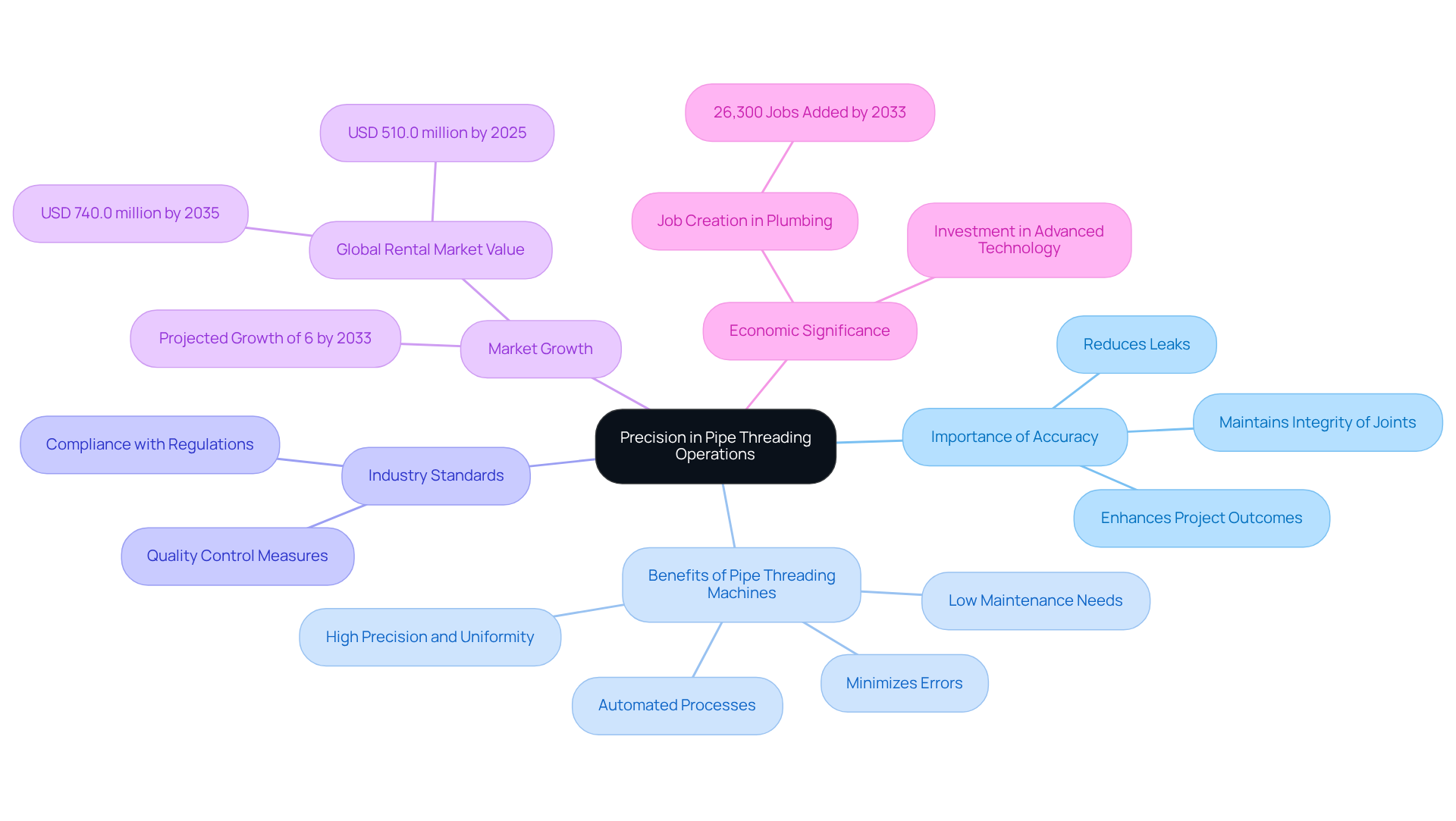

Ensure Precision in Pipe Threading Operations

Accuracy in tube screwing tasks is essential for establishing secure, leak-proof connections. A pipe threading machine is specifically engineered to create uniform and precise threads, ensuring that tubes connect effortlessly. This precision significantly reduces the likelihood of leaks and failures in plumbing and gas systems, which can lead to costly repairs and safety hazards. Projects that utilize a pipe threading machine often achieve stricter tolerances, resulting in superior quality installations that comply with industry standards.

Industry leaders emphasize that precise connections are crucial for maintaining the integrity of joints, particularly in high-pressure applications. Research indicates that automated cutting procedures can lower leak rates in plumbing systems, underscoring the importance of investing in advanced technology. Furthermore, the plumbing job market is projected to grow by 6% through 2033, reflecting the increasing demand for skilled labor in this sector. The global rental market for threaders is expected to reach USD 510.0 million by 2025, highlighting the economic significance of these tools.

By utilizing the pipe threading machine, contractors can enhance project outcomes and ensure long-lasting, reliable connections.

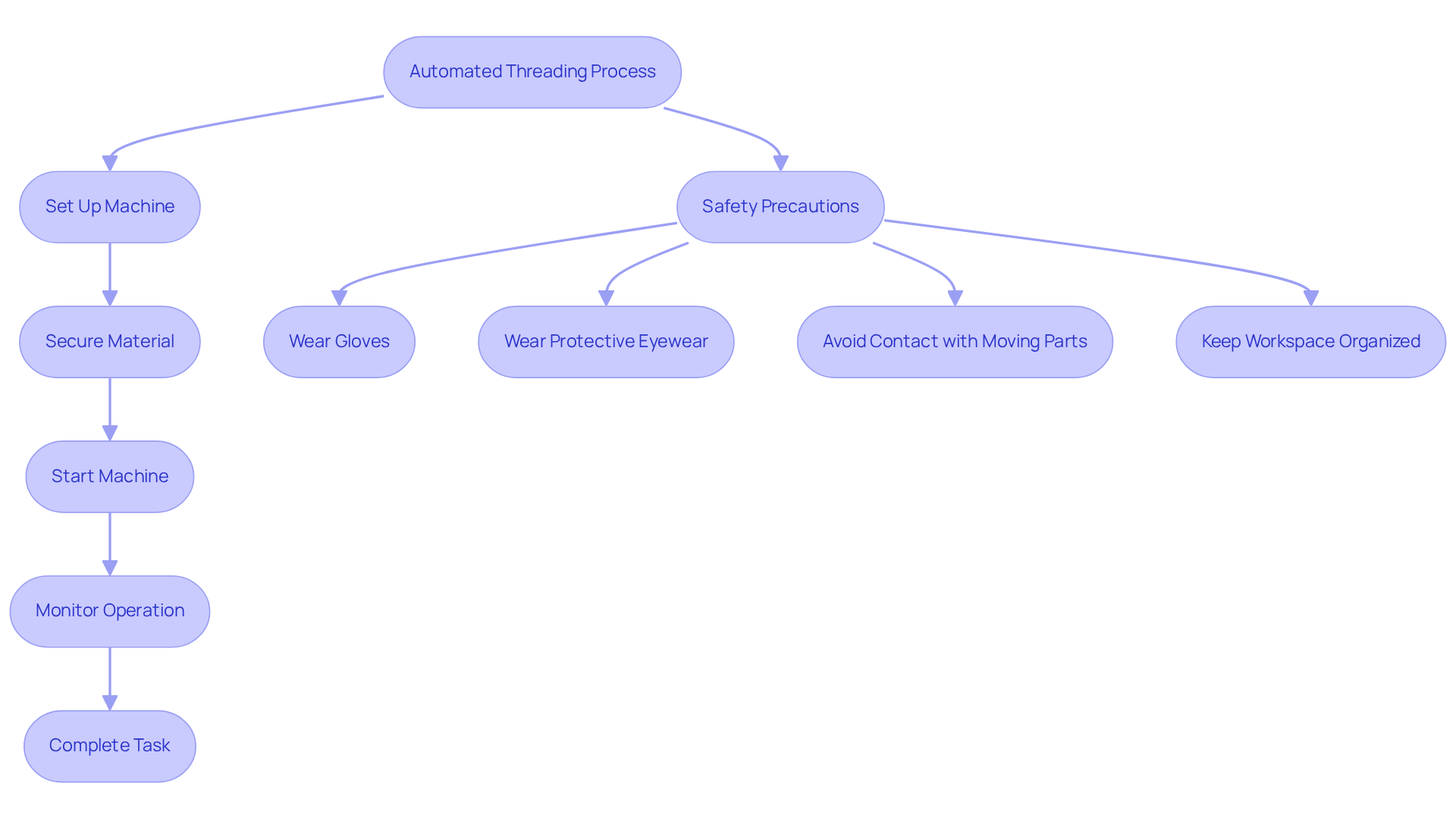

Save Time with Automated Threading Processes

Automated processes for pipe creation using a pipe threading machine significantly reduce the time required for this task compared to manual methods. Electric Pipe Cutting Machines operate swiftly, completing tasks in just a few minutes, whereas manual processes often take considerably longer, leading to inefficiencies. This time efficiency allows construction teams to focus on other essential tasks, facilitating quicker project completion and enabling them to take on additional work. Furthermore, the rapid pace of the pipe threading machine helps alleviate delays typically caused by waiting for manual labor to finish, ultimately improving overall project timelines.

To ensure safety while operating Electric Threading Machines, it is essential to adhere to specific precautions:

- Wear gloves and protective eyewear.

- Secure the material in the clamp before operation.

- Avoid contact with moving mechanical components.

- Keep the workspace organized and free of moisture.

By following these safety protocols, teams can enhance efficiency while minimizing risks associated with equipment operation.

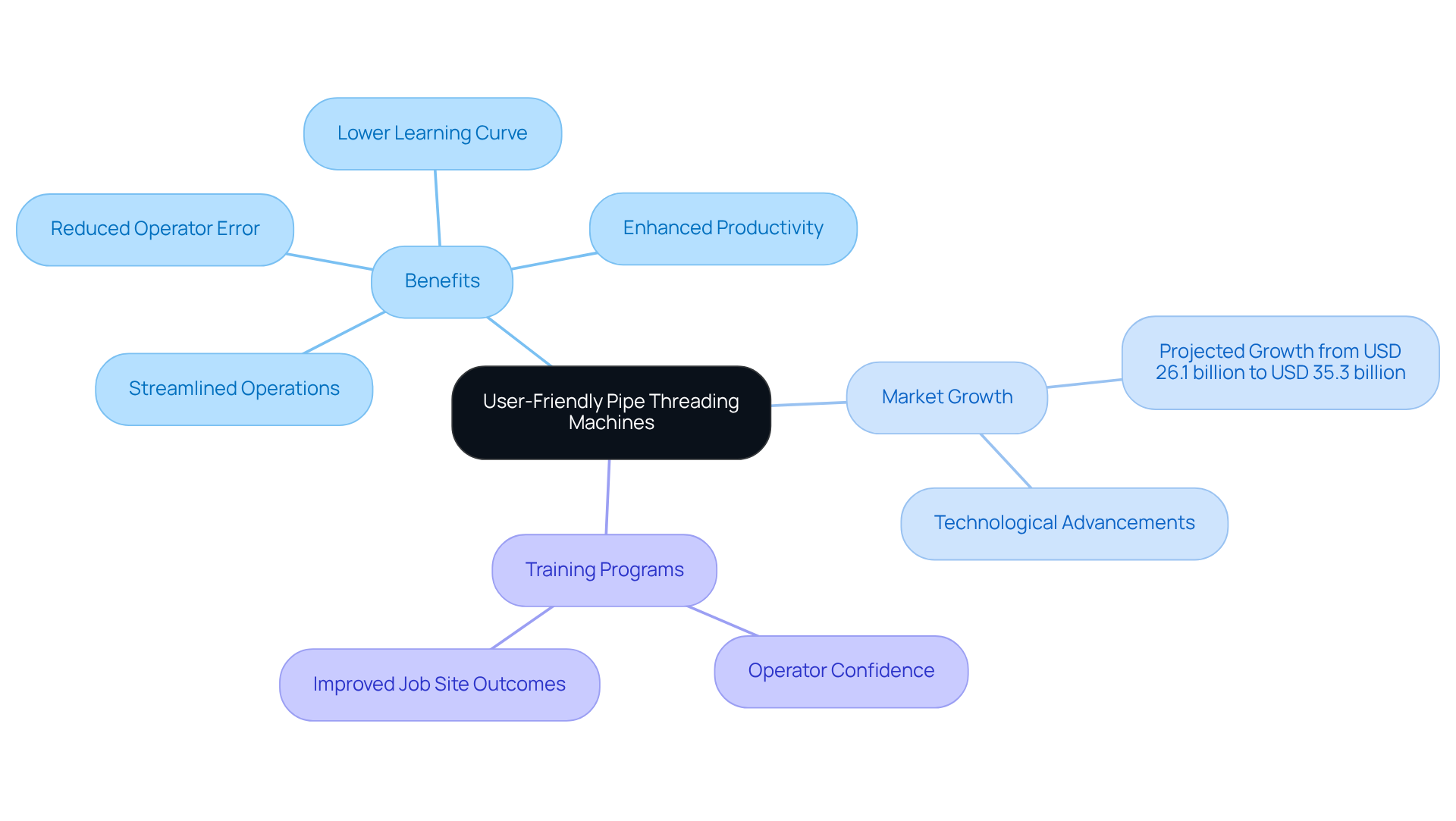

Simplify Operations with User-Friendly Machines

User-friendly pipe threading machines are engineered to streamline operations and significantly lower the learning curve for new operators. Many contemporary devices feature intuitive controls and automated settings, making them accessible to workers with diverse experience levels. This ease of use not only enhances productivity but also reduces the risk of operator error, a critical concern in the field. For example, a device with a straightforward interface enables even less experienced workers to operate it effectively, ensuring that projects progress smoothly without delays due to equipment mishandling.

Market research indicates that the global market for pipe threading machines is projected to grow from USD 26.1 billion in 2025 to USD 35.3 billion by 2032, reflecting a robust demand for efficient and user-friendly solutions. As noted by Jitendra Deviputra, a market research consultant, "Technological advancements are another key opportunity shaping the industry." Training programs focused on these user-friendly devices can further enhance operator confidence and competence, leading to improved outcomes on job sites.

As the construction sector increasingly adopts innovative fastening solutions, prioritizing user-friendly design to minimize operator mistakes becomes essential for ensuring efficiency and safety.

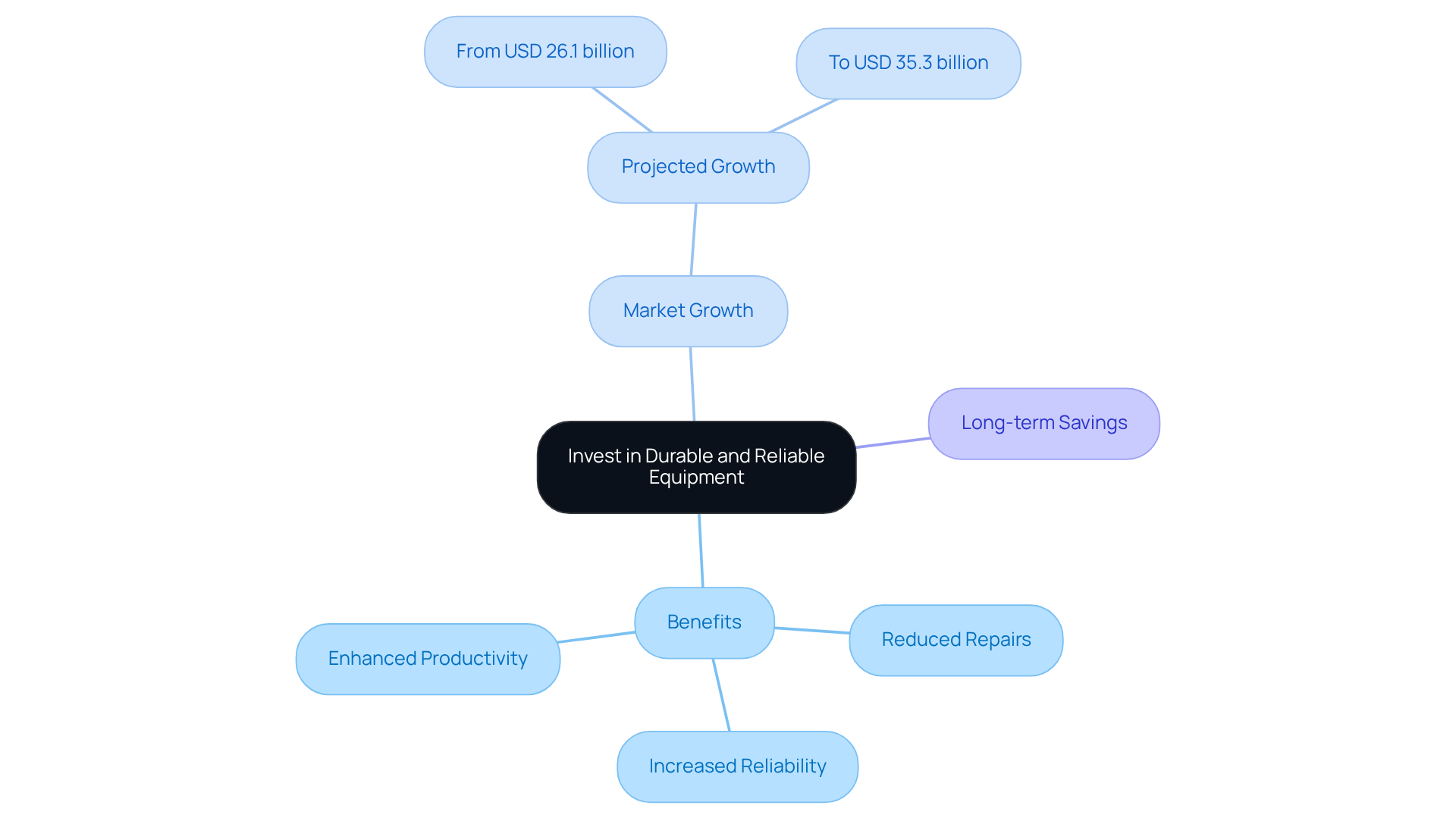

Invest in Durable and Reliable Equipment

Investing in a durable and dependable pipe threading machine is essential for achieving long-term success in construction projects. At EZ Equipment Rental, we emphasize reliability by offering high-quality equipment designed to endure the demands of daily use. This focus on durability minimizes the need for frequent repairs and replacements, ultimately leading to reduced operational expenses over time. Companies can depend on our well-maintained equipment, alleviating concerns about unexpected breakdowns. For instance, a properly cared-for device from EZ Equipment Rental can provide reliable performance for years, significantly lowering the total cost of ownership for contractors in the DFW Metroplex.

Moreover, the global tubing screw equipment market is projected to grow from USD 26.1 billion in 2025 to USD 35.3 billion by 2032, highlighting the increasing demand for reliable and efficient piping solutions. Contractors have noted that investing in a high-quality pipe threading machine not only enhances productivity but also leads to substantial long-term savings. This reinforces the critical importance of selecting dependable machinery for their projects.

Access Comprehensive Support and Maintenance Services

Access to comprehensive support and maintenance services is essential for maximizing the lifespan and performance of the pipe threading machine. Renting from a reputable company like EZ Equipment Rental guarantees well-maintained gear, as their devices undergo regular upkeep, including inspections, repairs, and troubleshooting. This significantly reduces the risk of breakdowns during critical operations.

Numerous producers offer service packages that include these vital maintenance services, ensuring that equipment operates at peak efficiency. For instance, contractors who invest in a maintenance plan can avoid costly downtime, which averages $108,000 per hour, while also extending the life of their equipment. This proactive approach not only enhances productivity but also provides peace of mind, knowing that expert assistance is readily available when needed.

Choose EZ Equipment Rental for Quality Pipe Threading Solutions

EZ Equipment Rental stands as the premier provider of quality tube screwing solutions in the Dallas-Fort Worth area. We offer a diverse range of reliable and durable tube cutting machines for rent, allowing clients to access top-tier equipment without the financial burden of ownership. This flexibility is especially beneficial in a market where the demand for construction equipment rentals is anticipated to rise significantly, with the global construction equipment rental market projected to reach USD 131.2 billion by 2024.

Customer satisfaction is central to EZ Equipment Rental's mission. Clients frequently share positive experiences, highlighting not only the quality of our equipment but also the expert support available throughout the rental process. For instance, contractors engaged in both minor residential projects and major commercial endeavors have chosen EZ Equipment Rental for their tube fitting needs, appreciating the seamless service and availability of high-quality tools.

With a steadfast commitment to excellence, EZ Equipment Rental guarantees that every customer receives the necessary support to complete their projects efficiently. This dedication to service is evident in our high customer satisfaction ratings, reinforcing our reputation as a trusted partner in the equipment rental industry. By selecting EZ Equipment Rental, customers can confidently address their pipe threading tasks with access to the best pipe threading machine tools and support available.

Conclusion

The advantages of using a pipe threading machine in construction projects are significant, transforming traditional methods into streamlined, efficient processes. These machines enhance productivity by automating threading tasks, leading to notable cost savings and improved safety standards on job sites. By adopting this technology, contractors can ensure high-quality outcomes while optimizing their operations.

Key insights from the discussion emphasize the efficiency gained through automation, with reports indicating increased installation speeds and reduced labor costs. The versatility of pipe threading machines allows them to accommodate various materials and applications, making them essential tools in the construction industry. Furthermore, the focus on safety features and precision highlights the importance of investing in reliable equipment that meets industry standards.

Given these benefits, it is evident that adopting pipe threading machines is not merely a matter of convenience but a strategic decision for contractors aiming to remain competitive. As the market for construction equipment continues to expand, prioritizing the use of advanced, user-friendly, and durable machines will be crucial for achieving long-term success. Embracing these innovations will not only improve project outcomes but also promote a safer and more efficient working environment.

Frequently Asked Questions

How do pipe threading machines enhance operational efficiency?

Pipe threading machines automate the threading process, resulting in uniform, high-quality outcomes much faster than manual methods. This automation accelerates timelines and allows teams to allocate resources more strategically, leading to significant cost savings.

What impact do pipe threading machines have on project timelines?

Tasks that typically require hours of manual labor can often be completed in mere minutes with an automated pipe threading machine, facilitating quicker project completion and boosting productivity on job sites. Major pipeline operators have reported a 25% increase in installation speed when using these machines.

How do pipe threading machines contribute to cost savings?

Pipe threading machines reduce labor costs by minimizing the number of workers needed to achieve the same output. Their precision also minimizes material waste by producing accurate threads that fit perfectly, preventing costly rework.

What types of pipes can be used with pipe threading machines?

Pipe threading machines can accommodate a wide range of pipe dimensions and materials, including PVC, steel, and copper pipes. They can also be modified to meet specific project requirements.

How do pipe threading machines improve inventory management for contractors?

The adaptability of pipe threading machines minimizes the need for multiple tools, simplifying inventory management. A single device can effectively support various applications such as plumbing, HVAC, and gas line installations.

What is the projected market growth for automated tube fabrication equipment?

The automatic tube fabrication equipment market is projected to grow significantly, with forecasts indicating the tube screw equipment sector is expected to reach USD 26.1 billion by 2025.

How can IoT and AI technologies enhance the functionality of pipe threading machines?

Integrating IoT and AI technologies into pipe threading machines can enhance their functionality by enabling predictive maintenance and improving overall operational efficiency.

List of Sources

- Increase Efficiency with Pipe Threading Machines

- Automatic Pipe Threading Machine in the Real World: 5 Uses You'll Actually See (2025) | Quick Primer | Top 5 Uses You’ll See in 2025 | Integration Not (https://linkedin.com/pulse/automatic-pipe-threading-machine-real-world-5-uses-youll-smejc)

- Pipe Threading Machine Market | Industry Report, 2031 (https://transparencymarketresearch.com/pipe-threading-machine-market.html)

- Top Benefits of Using a Threading Machine for Pipe Jobs - Hongli Pipe Machinery (https://honglitools.com/news/top-benefits-of-using-a-threading-machine-for-pipe-jobs)

- Pipe Threading Machine Market Poised to Grow at 4.4% CAGR by 2032, Insights by Persistence Market Research (https://einpresswire.com/article/856650682/pipe-threading-machine-market-poised-to-grow-at-4-4-cagr-by-2032-insights-by-persistence-market-research)

- Reduce Costs Through Efficient Threading Solutions

- 70 Business Automation Statistics Driving Growth in 2025 - Vena (https://venasolutions.com/blog/automation-statistics)

- Pipe Threader Rental Market | Global Market Analysis Report - 2035 (https://factmr.com/report/pipe-threader-rental-market)

- Pipe Threading Machine Market | Industry Report, 2031 (https://transparencymarketresearch.com/pipe-threading-machine-market.html)

- Labor Cost Savings from Automation: Stat Breakdown (https://patentpc.com/blog/labor-cost-savings-from-automation-stat-breakdown)

- 17 statistics measuring the impact of AR head-count reduction via automation (https://resolvepay.com/blog/17-statistics-measuring-the-impact-of-ar-head-count-reduction-via-automation)

- Achieve Versatility for Different Pipe Applications

- Threading Machines Industry’s Future Growth Prospects (https://datainsightsmarket.com/reports/threading-machines-1532732)

- The global Pipe threading machine Market size will be USD 27514.6 million in 2025. (https://cognitivemarketresearch.com/pipe-threading-machine-market-report)

- Pipe Threading Machine Market Research Report 2033 (https://marketintelo.com/report/pipe-threading-machine-market)

- Pipe Threading Machine Market Trends, 2032 (https://persistencemarketresearch.com/market-research/pipe-threading-machine-market.asp)

- Pipe Threading Machine Market Poised to Grow at 4.4% CAGR by 2032, Insights by Persistence Market Research (https://einpresswire.com/article/856650682/pipe-threading-machine-market-poised-to-grow-at-4-4-cagr-by-2032-insights-by-persistence-market-research)

- Enhance Safety Standards on Job Sites

- Safety Quotes: Motivation to Improve Work Safety Culture (https://osha.com/blog/work-safety-quotes)

- How Automation is Predicted to Reduce Workplace Injury - Lamber Goodnow Injury Lawyers (https://lambergoodnow.com/how-automation-is-reducing-workplace-injury)

- Automating Job Hazard Analysis May Revolutionize Roofing and Construction Safety (https://roofingcontractor.com/articles/100362-automating-job-hazard-analysis-may-revolutionize-roofing-and-construction-safety)

- 20+ Best Workplace Safety Quotes For Employees | Connecteam (https://connecteam.com/best-workplace-safety-quotes)

- Ensure Precision in Pipe Threading Operations

- Pipe Threader Rental Market | Global Market Analysis Report - 2035 (https://factmr.com/report/pipe-threader-rental-market)

- Top Benefits of Using a Threading Machine for Pipe Jobs - Hongli Pipe Machinery (https://honglitools.com/news/top-benefits-of-using-a-threading-machine-for-pipe-jobs)

- Plumbing Industry Statistics and Trends to Know for 2025 (and Beyond) (https://getjobber.com/academy/plumbing/plumbing-industry-statistics)

- Improving the reliability of threaded pipe joints (https://researchgate.net/publication/257916140_Improving_the_reliability_of_threaded_pipe_joints)

- Pipe Threading Machine Market Powering Precision and Efficiency in Industrial Piping Solutions (https://openpr.com/news/4193058/pipe-threading-machine-market-powering-precision)

- Save Time with Automated Threading Processes

- 5 Insightful Automation Quotes: What do they teach us? - ContentBot Blog (https://contentbot.ai/blog/updates/5-insightful-automation-quotes-what-do-they-teach-us)

- 7 Powerful Benefits of Electric Pipe Threading Machines for Fast & Accurate Threading (https://subhi.in/powerful-benefits-electric-pipe-threading-machines)

- Automation vs Manual Work Efficiency Stats 2020–2025 (https://technologyradius.com/statistic/work-efficiency-automation-vs-manual-2020-2025-stats)

- Advantages of Pipe Threading | Oster Pipe Threading Machines (https://ostermfg.com/resources/pipe-threading-advantages)

- Mastering Precision: The Significance and Process of Pipe Threading with Pipe Threading Machines (https://linkedin.com/pulse/mastering-precision-significance-process-pipe-machines-hussain-voy1f)

- Simplify Operations with User-Friendly Machines

- Pipe Threading Machine Market Poised to Grow at 4.4% CAGR by 2032, Insights by Persistence Market Research (https://einpresswire.com/article/856650682/pipe-threading-machine-market-poised-to-grow-at-4-4-cagr-by-2032-insights-by-persistence-market-research)

- Pipe Threading Machine Market Trends, 2032 (https://persistencemarketresearch.com/market-research/pipe-threading-machine-market.asp)

- The global Pipe threading machine Market size will be USD 27514.6 million in 2025. (https://cognitivemarketresearch.com/pipe-threading-machine-market-report)

- Pipe Threading Machine Market | Industry Report, 2031 (https://transparencymarketresearch.com/pipe-threading-machine-market.html)

- pipe threader machine market Market Business Models and Growth Enablers (https://linkedin.com/pulse/pipe-threader-machine-market-business-models-growth-enablers-qpuse)

- Invest in Durable and Reliable Equipment

- Pipe Threading Machine Market | Industry Report, 2031 (https://transparencymarketresearch.com/pipe-threading-machine-market.html)

- Pipe Threading Machine Market Trends, 2032 (https://persistencemarketresearch.com/market-research/pipe-threading-machine-market.asp)

- Pipe Threader Rental Market | Global Market Analysis Report - 2035 (https://factmr.com/report/pipe-threader-rental-market)

- Advantages Automatic Pipe Threading Machines Carry Over Manual Ratcheting Threaders and Hand-Held Power Drives | PipeMan Products, Inc. Blog (https://pipemanproducts.com/blog/advantages-automatic-pipe-threading-machines-carry-over-manual-ratcheting-threaders-and-hand-held-power-drives?srsltid=AfmBOope6WxCaeBh-bSC65KUAqvh4YGLjAij1po30ZgW_3iQi_5TQQjF)

- Access Comprehensive Support and Maintenance Services

- 25 Maintenance Stats, Trends, And Insights For 2026 (https://getmaintainx.com/blog/maintenance-stats-trends-and-insights)

- Unlock Hidden Savings: How Preventive Maintenance Boosts Your Bottom Line by 12-18% (https://oxmaint.com/blog/post/how-preventive-maintenance-boosts-your-bottom-line-)

- Maintenance statistics and trends 2025 • Infraspeak Blog (https://blog.infraspeak.com/maintenance-statistics-trends-challenges)

- 30 Key Maintenance Statistics & Facts Highlighting 2026 Trends (https://coastapp.com/blog/maintenance-metrics-statistics-facts)

- Maintenance Statistics: Predictive & Preventive, Labor & Costs (https://upkeep.com/learning/maintenance-statistics)

- Choose EZ Equipment Rental for Quality Pipe Threading Solutions

- Construction Equipment Rental Market Statistics 2025-2034 (https://statifacts.com/outlook/us-construction-equipment-rental-market)

- Tool & Equipment Rental in Texas - Market Research Report (2015-2030) | IBISWorld (https://ibisworld.com/united-states/industry/texas/tool-equipment-rental/40107)

- Construction Equipment Rental Market Statistics - 2034 (https://factmr.com/report/4643/construction-equipment-rental-market)

- Industrial Equipment Rental & Leasing in Texas - Market Research Report (2015-2030) | IBISWorld (https://ibisworld.com/united-states/industry/texas/industrial-equipment-rental-leasing/12451)

- 2025 Heavy Equipment Rental Industry Market Research Report (https://kentleyinsights.com/heavy-equipment-rental-industry-market-research-report)