Key Highlights:

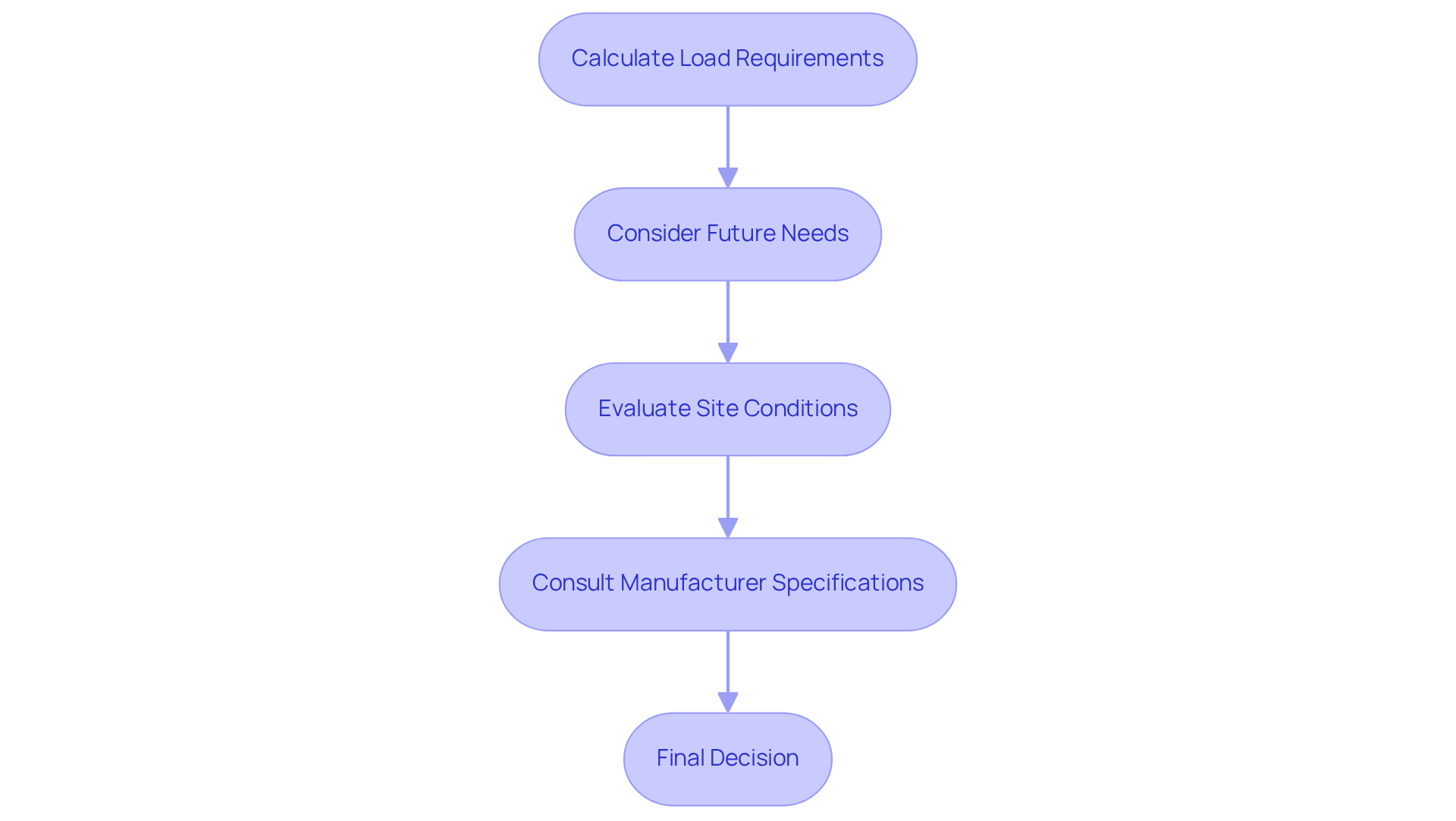

- Selecting the right 4 MW generator requires assessing both peak and steady power demands.

- Calculate load requirements by compiling a list of equipment and their wattage to determine total load.

- Anticipate future power needs by adding a 10-20% buffer to accommodate unexpected increases in demand.

- Evaluate site conditions, including accessibility and noise regulations, to influence generator selection.

- Consult manufacturer specifications to ensure the generator can handle the calculated load safely and efficiently.

- Run the generator at 70-90% capacity for optimal efficiency and reduced wear on the engine.

- Regular monitoring of fuel consumption and operational conditions helps identify inefficiencies.

- Simultaneously operating multiple generators can enhance performance and provide redundancy.

- Use high-grade fuel and maintain fuel quality to prevent engine issues and improve efficiency.

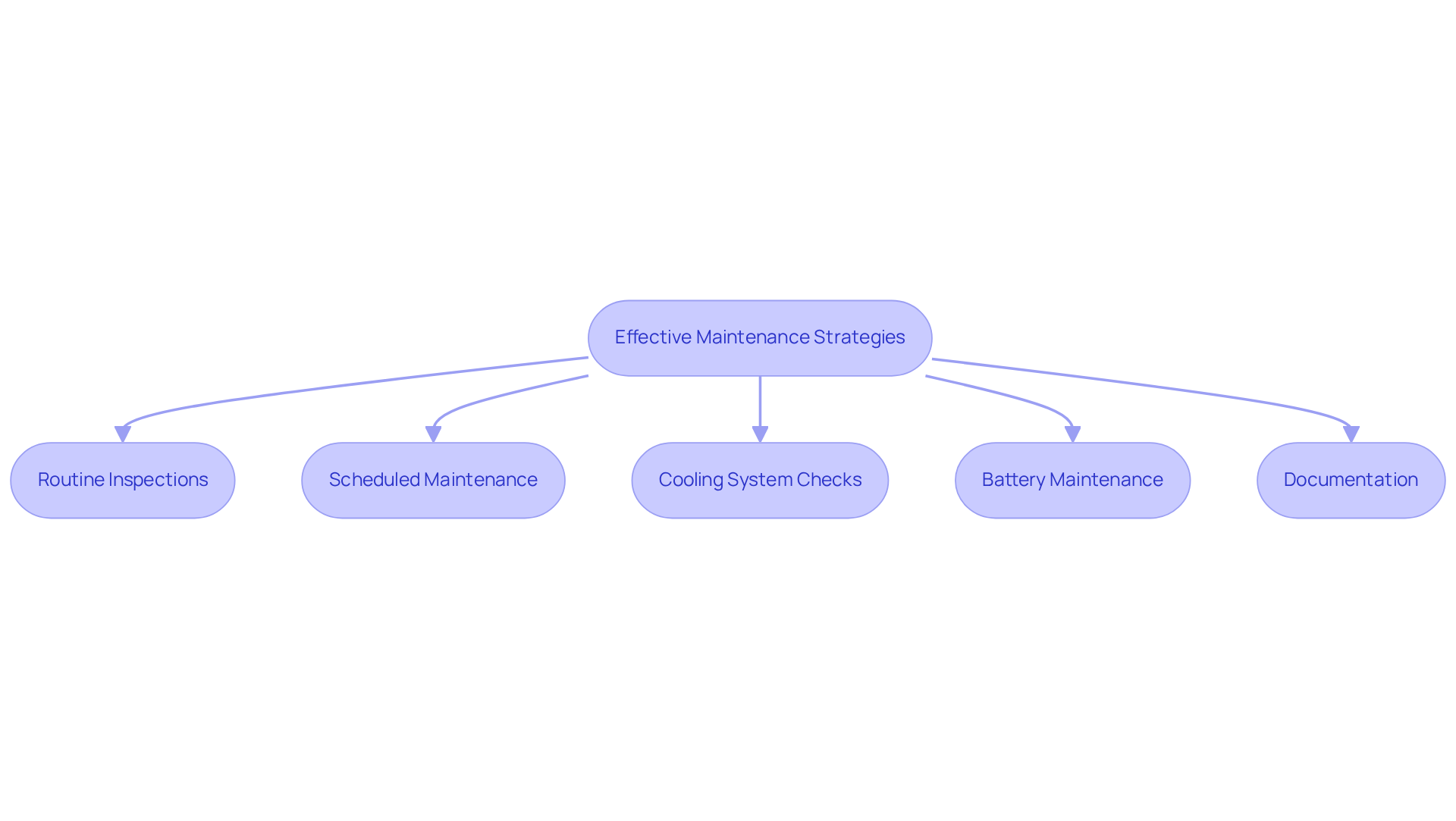

- Conduct regular inspections and adhere to a maintenance schedule to prevent major failures.

- Cheque the cooling system and battery regularly to ensure reliable operation and prevent overheating.

- Maintain documentation of all maintenance activities for troubleshooting and compliance purposes.

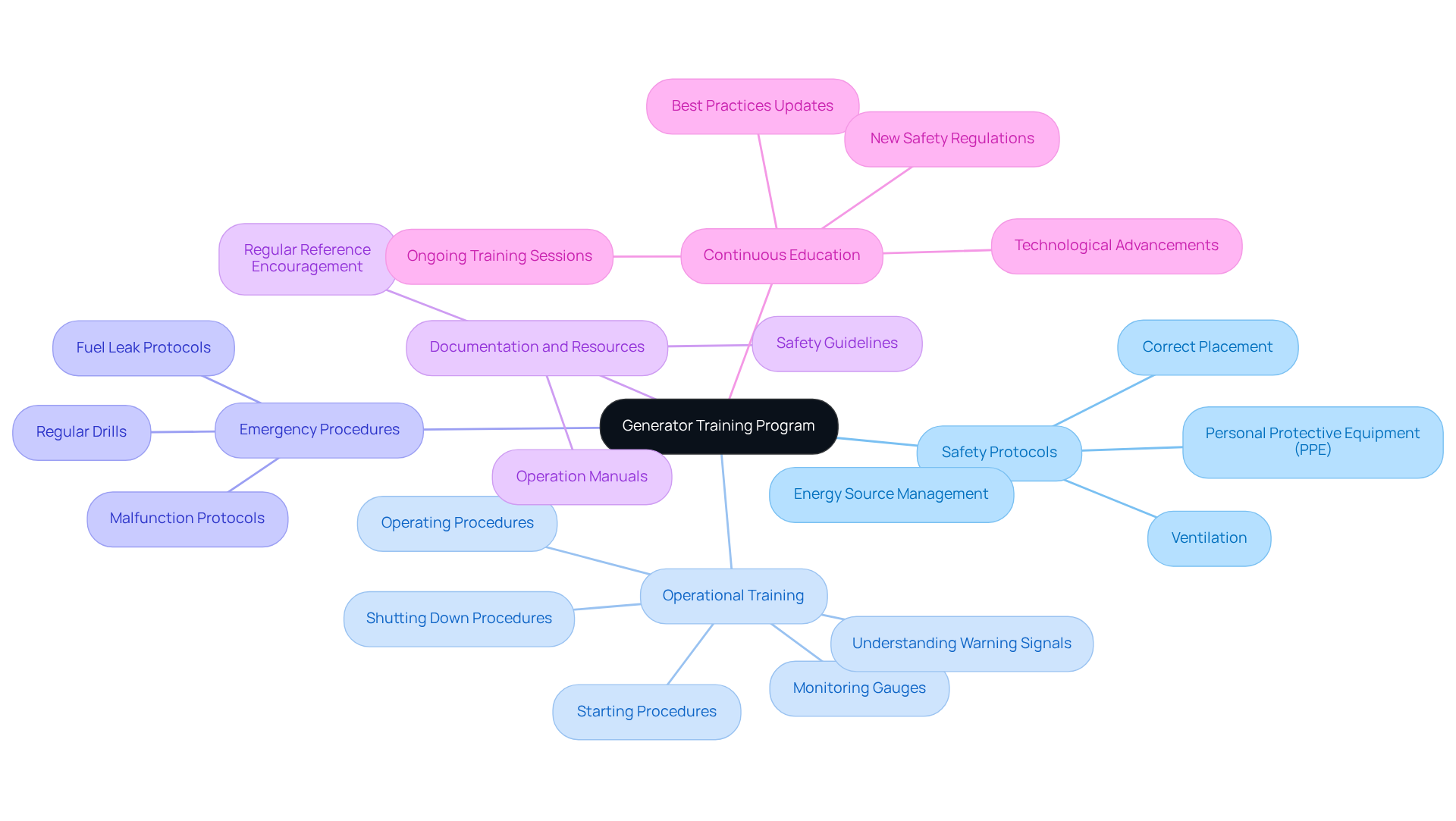

- Implement comprehensive training for personnel on safety protocols, operational procedures, and emergency responses.

Introduction

Choosing the right generator is crucial in the construction industry. Many project managers, however, often overlook the complexities involved in managing a 4 MW generator. This oversight can lead to significant challenges on the job site. By understanding best practices, construction teams can enhance operational efficiency while ensuring safety and reliability.

With high stakes and potential pitfalls lurking, how can construction teams navigate the intricacies of generator management? The answer lies in effective strategies that not only prevent costly downtime but also maximize productivity. Emphasizing reliability and quality in generator selection is essential for success.

In addition, leveraging insights from industry experts and testimonials from satisfied customers can further solidify the importance of proper generator management. By taking action now, construction teams can position themselves for success and avoid the pitfalls that come with inadequate planning.

Assess Project Requirements for Generator Selection

Choosing the right 4 MW generator for your construction project is crucial and requires a thorough assessment of your power needs. This process involves evaluating both peak and steady demands that the machine must accommodate.

Calculate Load Requirements: Begin by compiling a comprehensive list of all equipment that will be powered, including tools, lighting, and HVAC systems. Utilize the wattage ratings for each item to determine the total load. For example, if your site uses a concrete mixer, air compressor, circular saw, and lighting, the total running watts may equal 4,200W, with startup wattages adding an additional 6,600W. This foundational step ensures you understand your immediate power requirements.

Consider Future Needs: It’s essential to anticipate potential increases in power demand as your project evolves. Preparing for future needs can help you avoid the complications of requiring extra power sources later on. Industry experts recommend adding a 10-20% buffer to your total running watts to accommodate unexpected equipment additions or higher usage. This foresight can save you time and resources down the line.

Evaluate Site Conditions: Assess the construction site for accessibility, environmental factors, and noise regulations. These elements significantly influence the type and size of the power source you select. For instance, running power sources at 70-90% capacity is vital to prevent issues like wet stacking, which can lead to carbon accumulation and reduced performance. Understanding your site conditions is key to making an informed decision.

Consult Manufacturer Specifications: Always review the guidelines provided by the equipment manufacturer to ensure that the selected unit can efficiently handle the calculated load. This step is crucial for compliance with safety regulations and optimal performance. By aligning your choice with manufacturer specifications, you enhance reliability and safety on-site.

By following these steps, project managers can confidently choose a 4 MW generator as a power source that meets both current and anticipated energy requirements, thereby boosting performance and productivity. Moreover, avoiding common pitfalls like under-sizing or over-sizing the machine can prevent downtime and reduce fuel expenses. Take action now to ensure your project runs smoothly and efficiently.

Optimize Operational Efficiency of the Generator

Maximize the Operational Efficiency of Your 4 MW Generator

To ensure your 4 MW generator operates at peak efficiency, consider implementing these essential practices:

-

Load Management: Strive to run your generator at 70-90% of its rated capacity. This optimal range not only enhances energy efficiency but also minimizes wear on the engine. Operating at lower capacities can lead to increased energy consumption. As Emiliana Chiaha points out, reliable power sources significantly impact various sectors, underscoring the importance of effective energy management.

-

Regular Monitoring: Employ monitoring tools to keep an eye on fuel consumption, weight trends, and operational conditions. Analyzing this data can reveal inefficiencies and guide necessary operational adjustments. For example, the device used at GZ Industrial Supplies proved vital in maintaining operational continuity during power outages, demonstrating the advantages of consistent monitoring.

-

Simultaneous Operation: When multiple power sources are available, running them in tandem can enhance performance by distributing the load. This approach also provides redundancy, ensuring smooth operations even if one generator fails. The case study of Capino Hospital illustrates how parallel operation guarantees continuity in healthcare services, allowing critical systems to function without interruption.

-

Fuel Quality Management: Always use high-grade fuel to prevent engine issues and maintain efficiency. Regularly check filters and storage conditions to avoid contamination, which can adversely affect performance. The importance of fuel quality is evident, as diesel engines consume less fuel per kilowatt-hour compared to gasoline, leading to reduced operating costs over extended runtimes.

-

Scheduled Testing: Regular load bank testing is crucial to confirm that your equipment can handle its rated load. This proactive strategy helps identify potential issues before they escalate into critical problems. By focusing on these optimization strategies, construction managers can significantly enhance the efficiency of their 4 MW generator, resulting in lower operational costs and improved project timelines.

Implement Effective Maintenance and Support Strategies

Implementing effective maintenance strategies is crucial to ensure the reliability of your 4 MW generator. Focus on routine inspections and proactive care to safeguard your investment:

-

Routine Inspections: Conduct regular inspections to identify leaks, wear, and other potential issues. This proactive approach can prevent minor problems from escalating into major failures. For example, facilities that perform monthly visual inspections and load tests can significantly reduce unplanned downtime, which costs an average of $108,000 per hour. As GFE Power Products states, "Regular maintenance isn’t a luxury, it’s a necessity that ensures reliable operation during emergencies."

-

Scheduled Maintenance: Adhere to the manufacturer's maintenance schedule for oil changes, filter replacements, and other critical services. Regular oil changes, typically every 100 hours of operation, are essential for maintaining optimal performance and preventing costly repairs.

-

Cooling System Checks: Regularly inspect the cooling system to prevent overheating, a common cause of engine failure. Ensure that coolant levels are adequate and that there are no blockages; neglecting this can lead to severe operational disruptions.

-

Battery Maintenance: Regularly check battery connections and charge levels. A well-maintained battery is vital for reliable starting and operation. Corrosion at battery terminals can lead to poor connections, so keeping them clean is essential.

-

Documentation: Maintain detailed records of all maintenance activities, including inspections and repairs. This documentation is crucial for troubleshooting and ensuring adherence to safety regulations, particularly in settings where operational effectiveness is critical.

By following these maintenance practices, construction teams can enhance the reliability and efficiency of their power sources, reducing the risk of downtime and the associated costs of repairs. Furthermore, implementing predictive maintenance strategies can increase equipment uptime and availability by 10 to 20%, further safeguarding project timelines and budgets.

Train Personnel on Safe and Efficient Generator Use

To ensure the safe and efficient operation of your 4 mw generator, implementing a comprehensive training program for all personnel involved is crucial.

-

Safety Protocols: Educate your team on vital safety procedures, including correct placement, ventilation, and energy source management. Emphasize the importance of using personal protective equipment (PPE) to safeguard their well-being.

-

Operational Training: Provide hands-on training that covers how to start, operate, and shut down the generator. This should include instruction on monitoring gauges and understanding warning signals, ensuring that everyone is well-prepared for any situation.

-

Emergency Procedures: Familiarize all personnel with emergency protocols, detailing what to do in case of a malfunction or fuel leak. Regular drills will reinforce these procedures, keeping safety at the forefront of operations.

-

Documentation and Resources: Ensure access to operation manuals and safety guidelines. Encourage your team to refer to these resources regularly, reinforcing their training and enhancing their confidence in handling the generator.

-

Continuous Education: Offer ongoing training sessions to keep staff informed about best practices and any new safety regulations or technologies related to power generation. This commitment to education not only enhances safety but also boosts efficiency on the job site.

By investing in comprehensive training, construction managers can significantly enhance safety and efficiency, ensuring that personnel are well-prepared to operate the 4 mw generator effectively.

Conclusion

Choosing the right 4 MW generator and managing it effectively is crucial in the construction industry. Proper selection, operational efficiency, maintenance, and personnel training are not just important; they are essential for ensuring the generator's performance and reliability. By adhering to best practices, construction managers can guarantee that their power sources meet current demands while being adaptable for future needs.

Key strategies include:

- Assessing project requirements to select the appropriate generator

- Optimizing operational efficiency through effective load management and regular monitoring

- Implementing rigorous maintenance routines to prevent unexpected downtimes

- Training personnel on safe and efficient generator use to foster a culture of safety and preparedness, which is vital for smooth operations on site

Ultimately, managing a 4 MW generator requires a holistic approach that integrates careful planning, ongoing maintenance, and staff education. By prioritizing these aspects, construction teams can enhance productivity, reduce costs, and ensure that projects progress without unnecessary interruptions. Embracing these practices not only safeguards investments but also promotes a safer and more efficient work environment. Take action today-ensure your team is equipped with the knowledge and tools to manage your generator effectively.

Frequently Asked Questions

Why is it important to assess project requirements for generator selection?

Assessing project requirements is crucial for choosing the right 4 MW generator as it ensures that the generator can accommodate both peak and steady power demands of the construction project.

How do I calculate the load requirements for a generator?

To calculate load requirements, compile a comprehensive list of all equipment that will be powered, including tools, lighting, and HVAC systems. Use the wattage ratings for each item to determine the total load. For example, if equipment like a concrete mixer and air compressor is used, add their running watts plus any additional startup wattages.

Should I consider future power needs when selecting a generator?

Yes, it is essential to anticipate potential increases in power demand. Adding a 10-20% buffer to your total running watts can help accommodate unexpected equipment additions or higher usage, avoiding complications later on.

What site conditions should I evaluate when selecting a generator?

Evaluate accessibility, environmental factors, and noise regulations at the construction site. These elements significantly influence the type and size of the generator you select, as running power sources at 70-90% capacity is vital to prevent performance issues.

Why is it important to consult manufacturer specifications when choosing a generator?

Consulting manufacturer specifications ensures that the selected generator can efficiently handle the calculated load, which is crucial for compliance with safety regulations and optimal performance, enhancing reliability and safety on-site.

What are the common pitfalls to avoid when selecting a generator?

Common pitfalls include under-sizing or over-sizing the generator, which can lead to downtime and increased fuel expenses. Proper assessment of power needs and site conditions can help prevent these issues.