Key Highlights:

- Assess energy needs by listing all electrical devices and calculating total power requirements using the formula: Total Power Requirement (kW) = (Total Wattage x Usage Hours) / Efficiency Factor.

- Consider peak load demands and consult equipment manufacturers or power calculators for accurate power needs.

- Implement a maintenance schedule including weekly and monthly inspections of oil levels, coolant, battery, and filters to ensure generator performance.

- Establish a fuel management strategy involving proper storage, contamination testing, and monitoring fuel levels to prevent operational disruptions.

- Select an optimal generator location to minimise noise and exhaust exposure, ensuring easy access for refuelling and maintenance.

- Train personnel on equipment operation and emergency procedures to enhance safety and efficiency on-site.

- Establish safety protocols, including maintaining distance from flammable materials, ensuring proper ventilation, and grounding equipment to prevent hazards.

- Regularly inspect electrical connexions and maintain a first aid kit and emergency contacts on-site for safety readiness.

Introduction

A 300kVA diesel generator stands as a formidable asset on construction sites, delivering the essential energy needed to keep projects on schedule. Understanding the best practices for its use is crucial - this includes assessing power requirements and implementing robust maintenance and safety protocols. As construction demands evolve, project managers must ensure that their generators are not only dependable but also seamlessly integrated into workflows. This article explores critical strategies that enhance generator efficiency, protect investments, and foster a safer work environment.

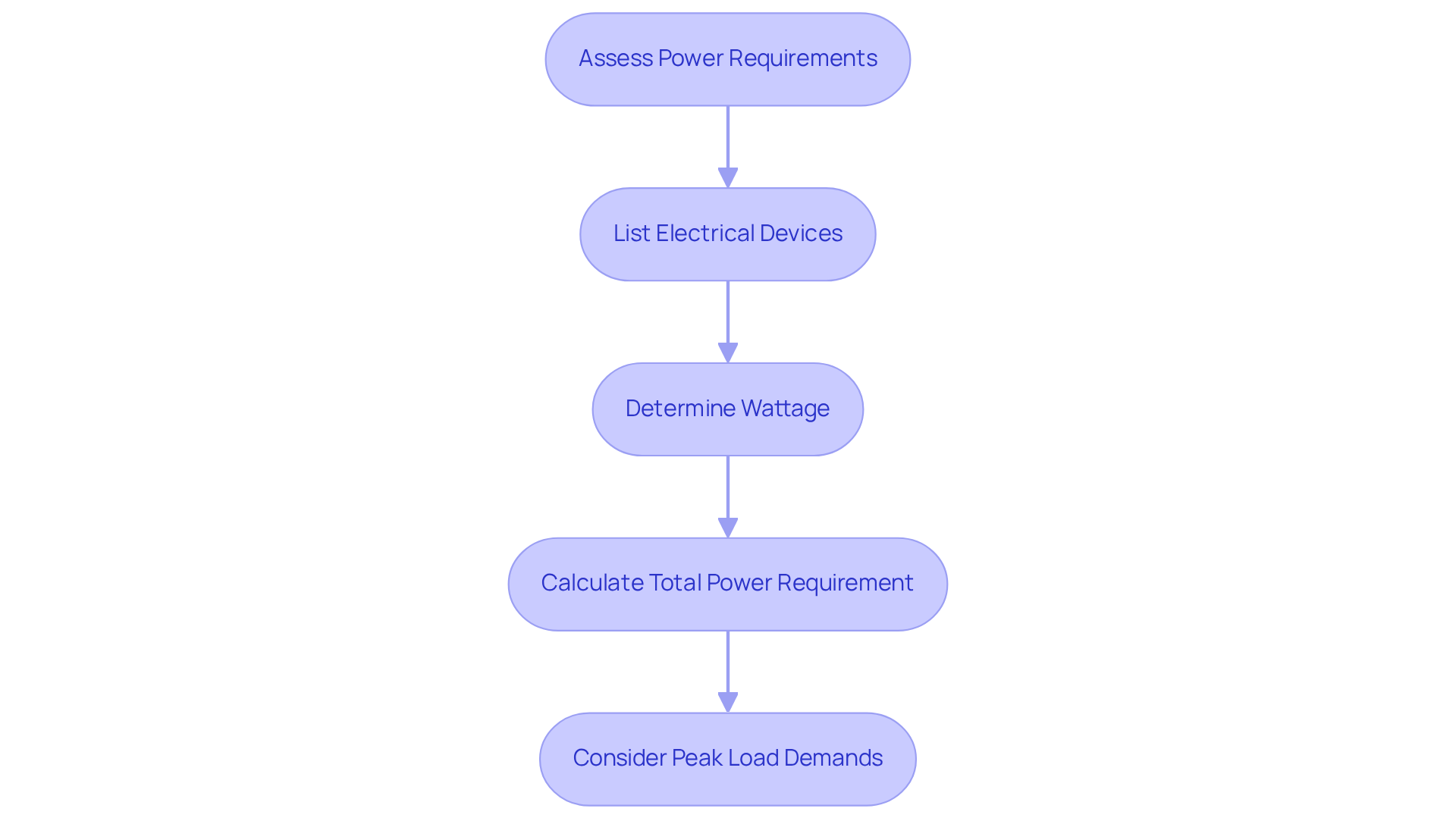

Assess Power Requirements for Construction Needs

To effectively utilize a 300kVA diesel generator on a construction site, it’s crucial to evaluate the energy needs of all equipment and tools involved. Start by listing every electrical device, from lighting to machinery and tools, and determine their wattage. Use the formula:

Total Power Requirement (kW) = (Total Wattage x Usage Hours) / Efficiency Factor

This calculation reveals the total load the generator must support, ensuring it operates efficiently.

Moreover, consider peak load demands, as certain equipment may require more electricity during startup. Consulting with equipment manufacturers or leveraging power calculators can provide valuable insights into specific power needs. This thorough evaluation guarantees that the generator functions within its optimal range, preventing overloads and ensuring efficiency throughout the project. By taking these steps, you not only enhance the reliability of your operations but also safeguard your investment in quality equipment.

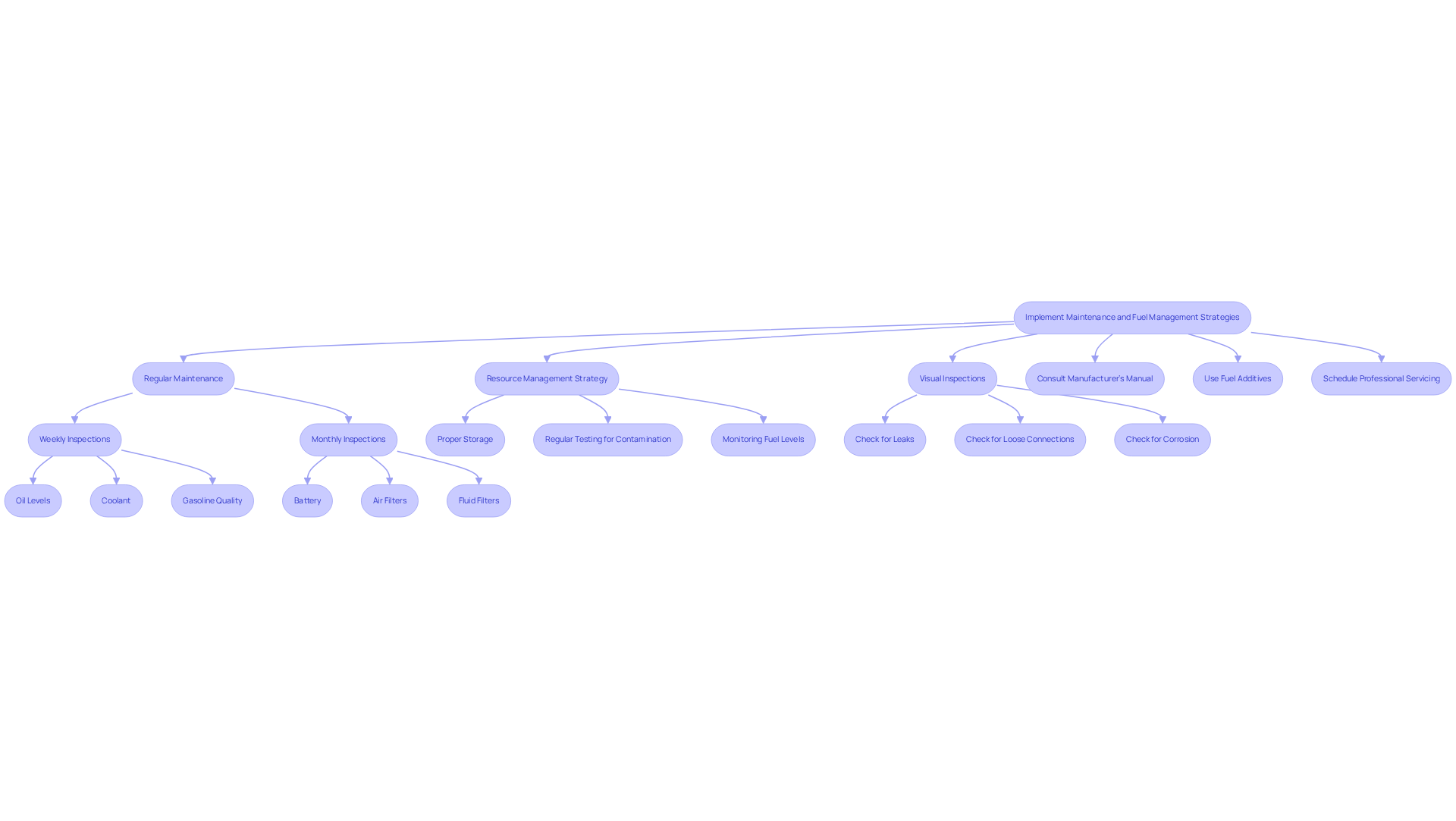

Implement Maintenance and Fuel Management Strategies

Regular maintenance and efficient energy management are essential for the optimal performance of a 300kva diesel generator. Establish a comprehensive maintenance timetable that includes:

-

Weekly inspections for:

- Oil levels

- Coolant

- Gasoline quality

-

Monthly inspections focusing on:

- Battery

- Air filters

- Fluid filters

Ensure that battery terminals remain clean and free from build-up to prevent operational issues.

In addition, implement a robust resource management strategy. This should encompass:

- Proper storage

- Regular testing for contamination

- Diligent monitoring of fuel levels to avoid running out during critical operations

Always consult the manufacturer's manual for tailored maintenance schedules and specific procedures. Utilizing fuel additives can significantly enhance fuel stability and performance.

Furthermore, conduct regular visual inspections to check for:

- Leaks

- Loose connections

- Corrosion

Scheduling professional servicing at specific intervals ensures thorough inspections by qualified technicians. By adhering to these practices, you can minimize the likelihood of equipment failure and guarantee that the machinery operates efficiently, ultimately saving time and costs on the building site.

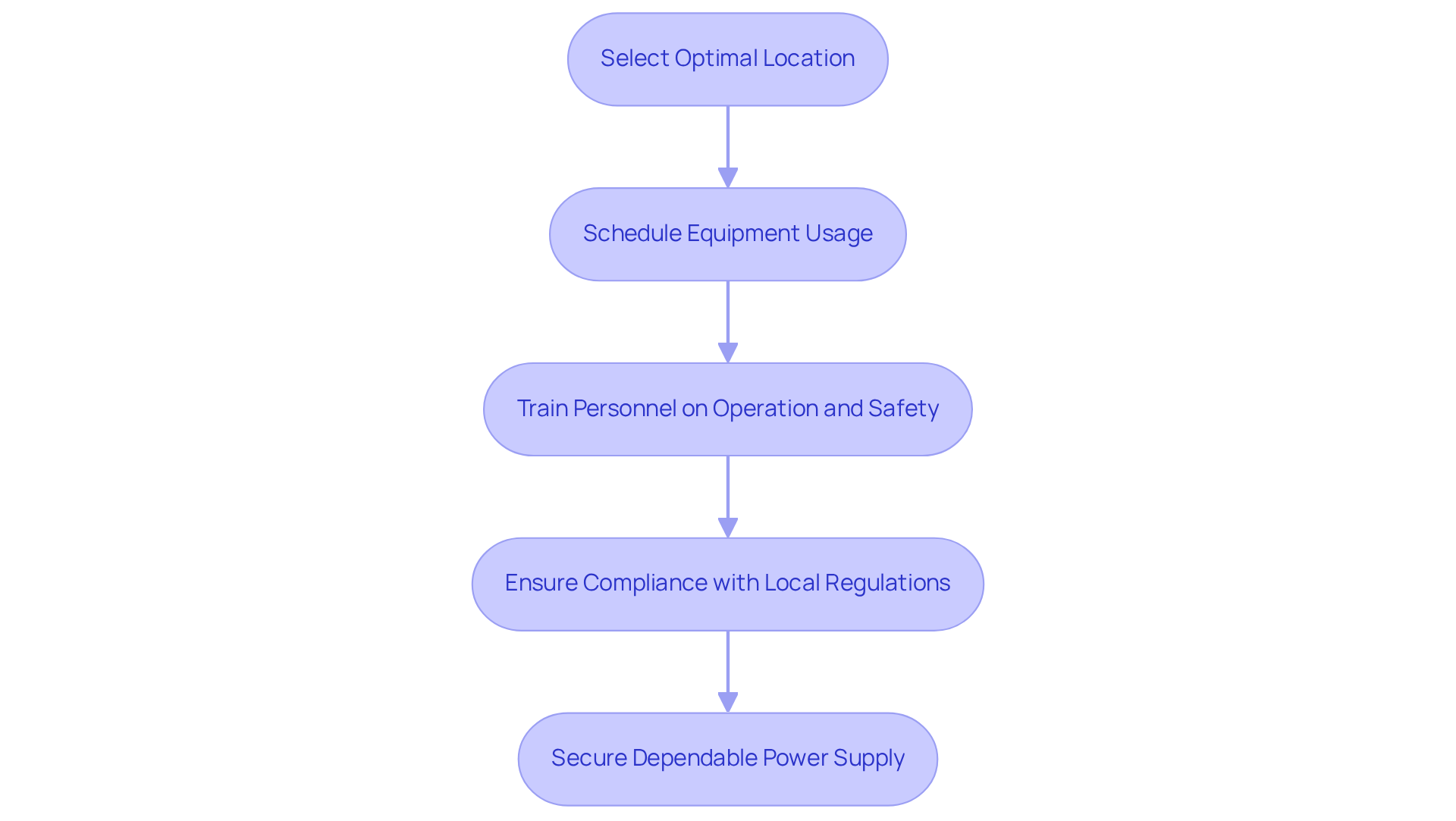

Integrate Generators into Project Workflows Effectively

Maximizing the efficiency of the 300kva diesel generator on a construction site is essential for seamless project workflow integration. Start by selecting an optimal location that allows easy access for refueling and maintenance, while also minimizing noise and exhaust exposure to workers. Position the power source away from busy areas and delicate operations to reduce interruptions.

For instance, with a fuel consumption rate of 142 gallons per hour and an operational duration of 19.72 hours on a full tank, scheduling equipment usage to align with peak operational hours guarantees that electricity is available when it’s most needed. Training personnel on proper equipment operation and emergency procedures is vital for enhancing both safety and efficiency. Furthermore, compliance with local regulations regarding noise levels is crucial to ensure adherence to best practices.

By strategically planning the device's role within the project workflow, you can secure a dependable power supply that supports uninterrupted operations. This approach ultimately contributes to the overall success of the building project, ensuring that every phase runs smoothly and efficiently.

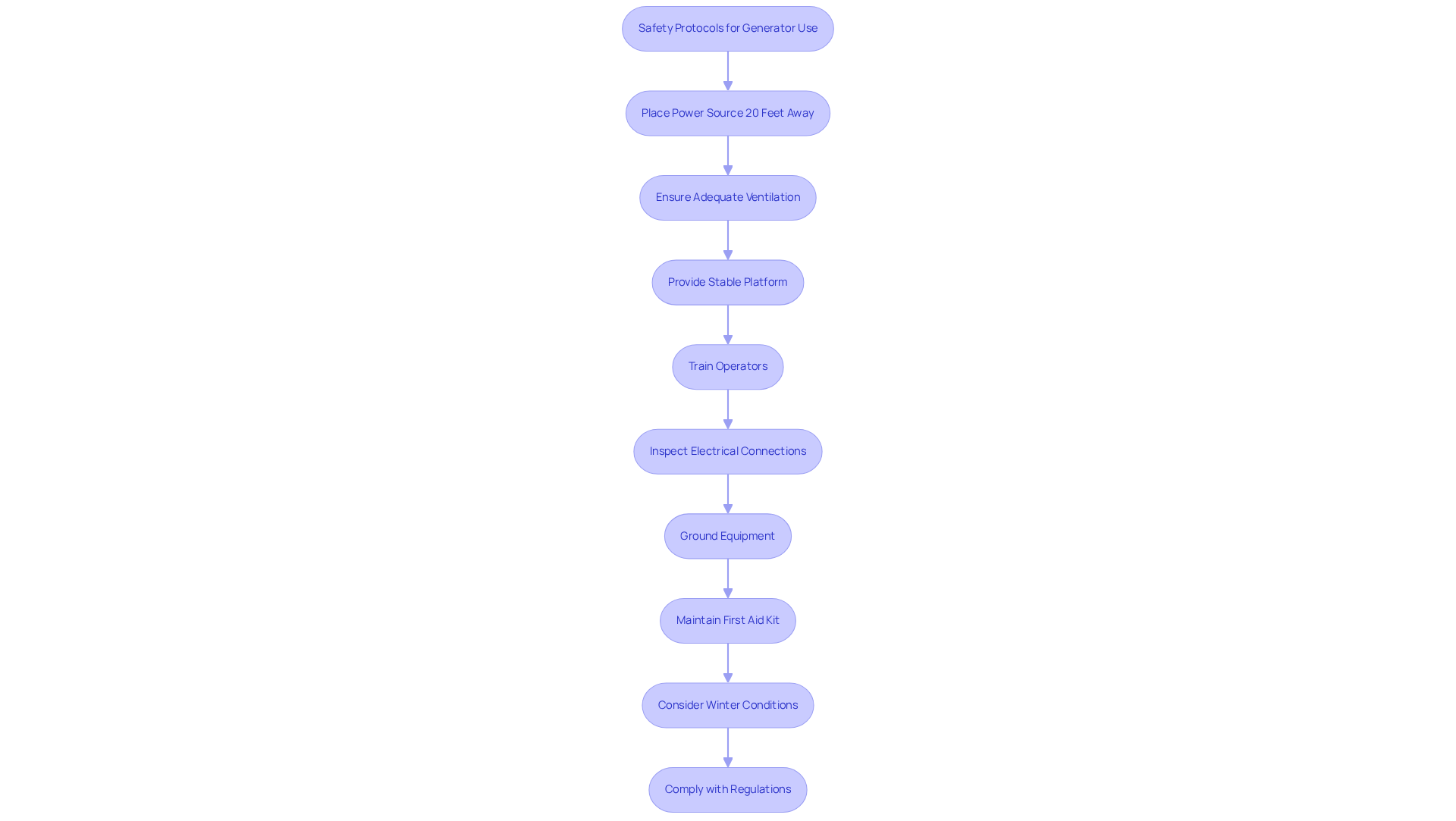

Establish Safety Protocols for Generator Use

Safety First: Operating a 300kVA Diesel Power Unit

Safety is paramount when operating a 300kVA diesel power unit on a construction site. Establishing clear safety protocols is essential. Ensure the power source is placed at least 20 feet away from structures and flammable materials, and provide adequate ventilation to prevent carbon monoxide accumulation. A stable platform is crucial to minimize vibration and wear, ensuring safe operation.

All operators must be thoroughly trained on the machine's operation, including emergency shutdown procedures. Regular inspections of electrical connections are vital, and all equipment should be grounded to prevent electrical hazards. Furthermore, maintain a first aid kit and emergency contact information readily available on-site.

Particular attention should be directed toward winter conditions, as low temperatures and high humidity can present additional hazards for power units. Compliance with local building codes and environmental regulations is also essential for safety on construction sites. By implementing these comprehensive safety protocols, you can create a safer work environment and significantly reduce the risk of accidents related to the operation of a 300kVA diesel generator.

Conclusion

Effectively utilizing a 300kVA diesel generator in construction is essential for maximizing project success. By prioritizing power assessment, maintenance, workflow integration, and safety protocols, construction teams can ensure that their operations run smoothly and efficiently. Understanding the specific energy demands of each project allows teams to operate the generator within its optimal range, significantly enhancing reliability and efficiency.

Key practices include:

- Conducting thorough evaluations of power requirements

- Implementing a rigorous maintenance schedule

- Integrating generators seamlessly into project workflows

- Establishing comprehensive safety measures

These elements work together to minimize downtime, reduce costs, and ensure the safety of personnel on site, creating a more productive work environment.

Ultimately, adopting these best practices not only optimizes the performance of the diesel generator but also contributes to the overall success of construction projects. By prioritizing these strategies, teams can achieve more efficient operations, safeguard their investments, and foster a safer work environment. Don't wait - implement these practices today to elevate your construction projects to new heights.

Frequently Asked Questions

Why is it important to assess power requirements for a construction site?

Assessing power requirements is crucial to ensure that the generator operates efficiently and can support the total load of all equipment and tools used on the site.

How do I evaluate the energy needs of equipment on a construction site?

Start by listing every electrical device, including lighting and machinery, and determine their wattage.

What formula can I use to calculate the total power requirement?

The formula is: Total Power Requirement (kW) = (Total Wattage x Usage Hours) / Efficiency Factor.

What should I consider regarding peak load demands?

Certain equipment may require more electricity during startup, so it's important to account for these peak load demands in your calculations.

Where can I find information on specific power needs for equipment?

Consulting with equipment manufacturers or using power calculators can provide valuable insights into the specific power needs of your tools and machinery.

What are the benefits of properly evaluating power requirements?

A thorough evaluation ensures that the generator functions within its optimal range, preventing overloads and enhancing the reliability of operations while safeguarding your investment in quality equipment.