Key Highlights:

- A telescoping forklift, or telehandler, is designed for lifting and placing heavy materials at various heights, making it ideal for construction sites.

- Telehandlers can be equipped with various attachments, including forks, buckets, and grapples, enhancing their versatility for different applications.

- Safe operating procedures include pre-operation inspections, capacity awareness, stability checks, proper use of components, wearing personal protective equipment (PPE), and effective communication.

- Operators must be aware that exceeding load capacities can lead to accidents, with turn-overs accounting for 42% of lift truck injuries.

- Selecting appropriate attachments is crucial for efficiency and safety; common attachments include forks for pallets, buckets for loose materials, and grapples for bulky items.

- Comprehensive training and certification for operators are essential for compliance with OSHA regulations, which require proper training to prevent accidents and legal repercussions.

- Regular refresher courses and certification renewal every three years are necessary to ensure ongoing adherence to safety standards.

Introduction

Understanding the complexities of operating a telescoping forklift is essential for ensuring safety and efficiency on construction sites. These versatile machines, known for their unique ability to extend and reach elevated areas, play a vital role in various tasks, including lifting heavy materials and navigating obstacles. However, improper use and insufficient training can lead to significant hazards. Operators must find ways to maximize the benefits of these powerful tools while minimizing accidents and ensuring compliance with safety regulations.

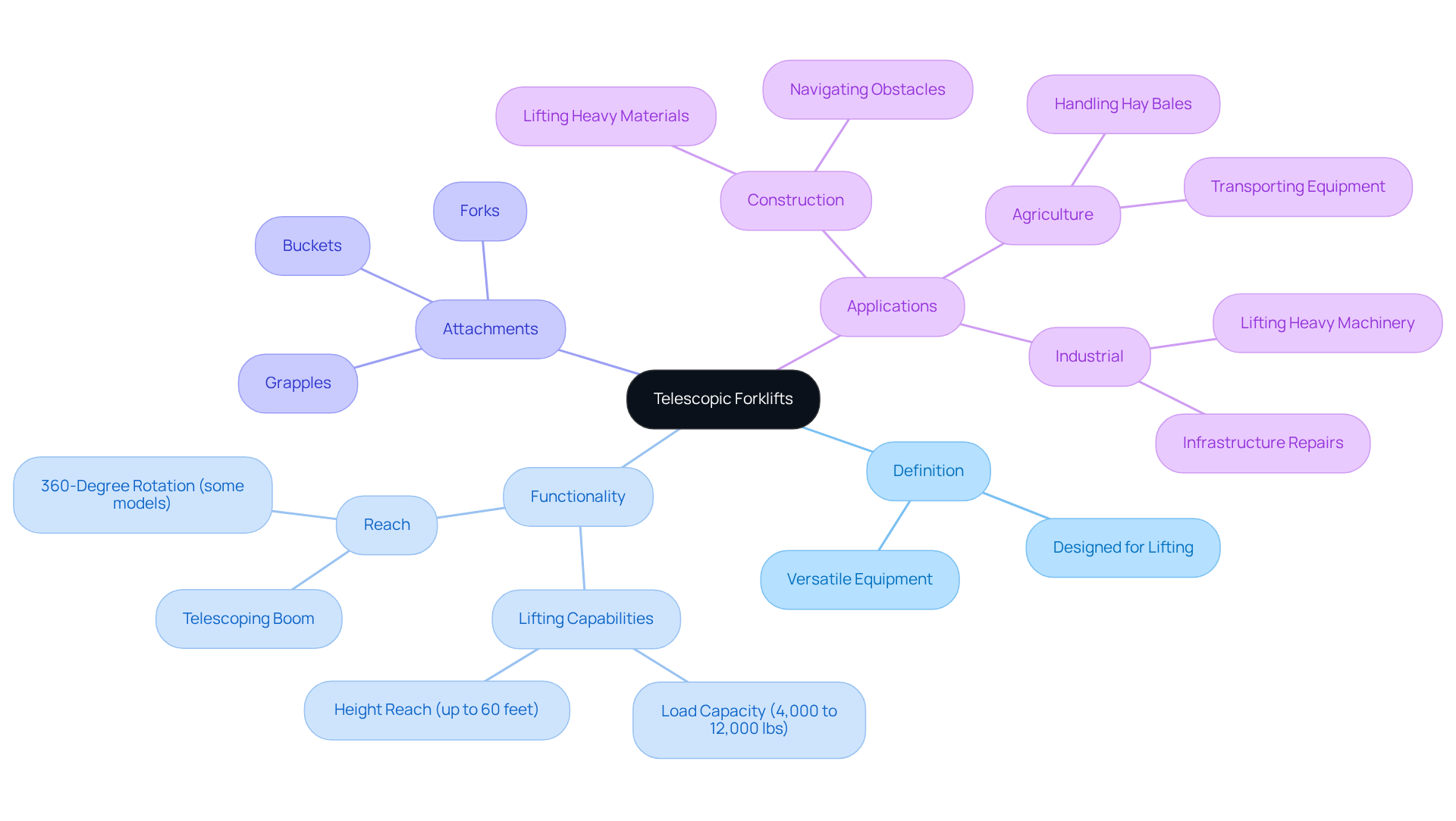

Understand Telescopic Forklifts: Definition and Functionality

A telescoping forklift, commonly referred to as a telehandler, is a highly versatile piece of equipment designed for lifting, carrying, and placing heavy materials at various heights. Its unique telescoping forklift allows for extended reach, making it ideal for construction sites where lifting capabilities exceed those of standard equipment. Boom lifts, which offer exceptional vertical and horizontal reach, enable workers to access elevated areas and navigate around obstacles with ease. This functionality is invaluable for tasks such as painting, repairs, and construction work.

Telehandlers can be outfitted with a range of attachments, including forks, buckets, and grapples, which enhance their versatility for different applications. At EZ Equipment Rental in Dallas, our diverse fleet features specialized machinery, such as electric lift trucks and rough terrain lift trucks, ensuring that you receive the right equipment tailored to your specific needs. Understanding the mechanics of these machines, including their load capacities and operational limits, is essential for maximizing efficiency and ensuring safety on the job site.

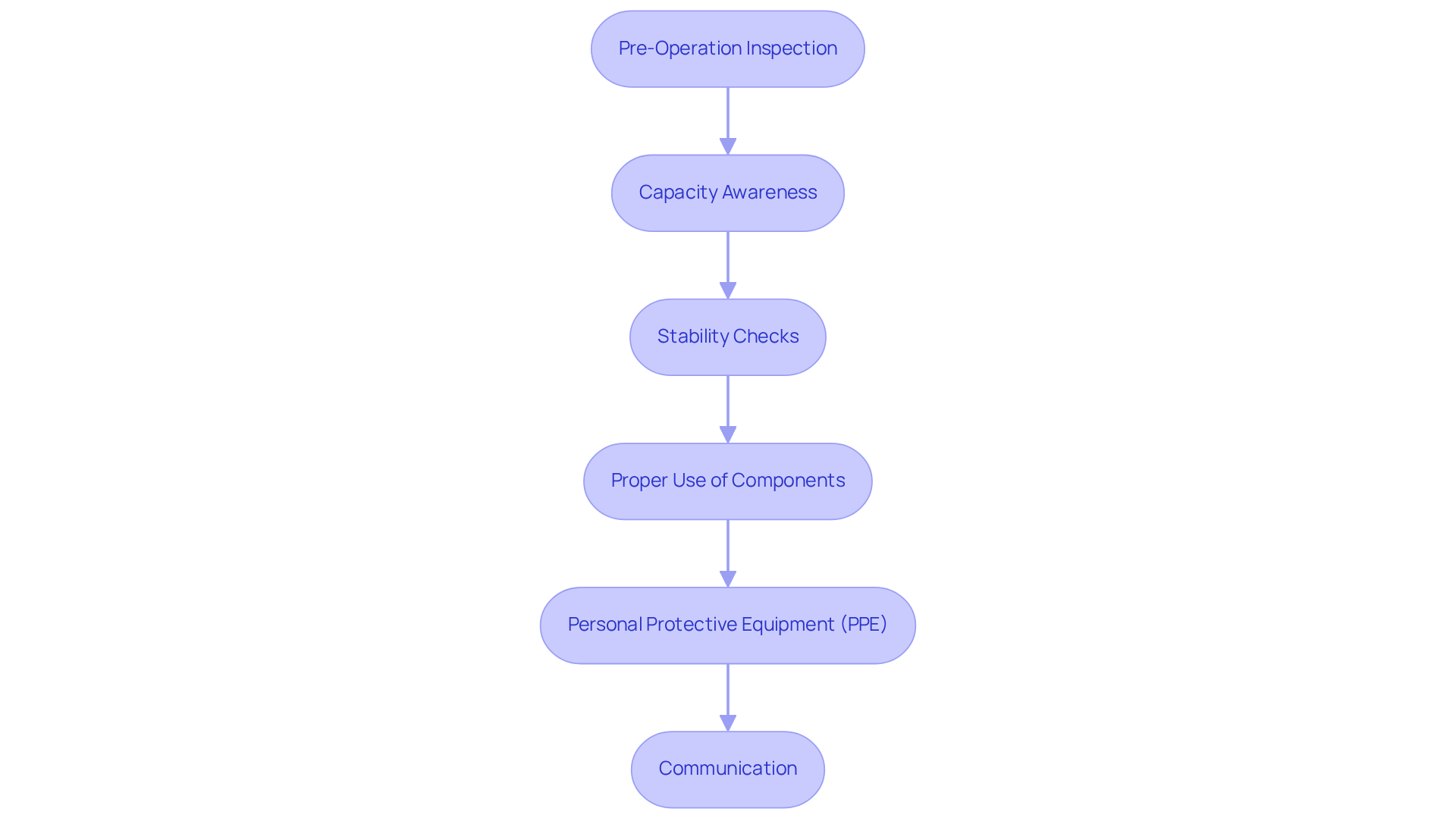

Implement Safe Operating Procedures for Telescopic Forklifts

To ensure the safe operation of telescopic forklifts, operators must adhere to essential procedures:

-

Pre-Operation Inspection: Conduct a thorough inspection of the telehandler before use. This includes checking for mechanical issues, fluid leaks, and verifying that all safety features are operational. Regular inspections are crucial, as they can prevent accidents caused by overlooked mechanical failures. According to OSHA, inspections should confirm the functioning of horns, check for leaks, assess tire pressure, and evaluate brakes and steering responsiveness.

-

Capacity Awareness: Operators must be fully aware of the telehandler's capacity and strictly adhere to it. Exceeding this limit can lead to hazardous accidents, as improper handling of cargo is a primary factor in incidents involving telescoping forklifts. Always refer to the manufacturer's weight chart for guidance. Notably, turn-overs or rollovers account for 42% of all documented lift truck injuries, underscoring the importance of load capacity awareness.

-

Stability Checks: Before lifting, ensure that the ground is stable and level. Utilizing outriggers, when available, can significantly enhance stability and reduce the risk of tip-overs, which represent a substantial percentage of forklift-related injuries. A single forklift has a 90% chance of being involved in a serious accident during its service life, highlighting the need for vigilance in stability checks.

-

Proper Use of Components: Confirm that the appropriate component is securely fitted for the specific task. Using the incorrect attachment can jeopardize security and efficiency, leading to potential accidents.

-

Personal Protective Equipment (PPE): Operators must wear suitable PPE, including hard hats, gloves, and protective boots, to minimize the risk of injury. This is particularly important in construction environments where hazards are prevalent.

-

Communication: Effective communication is vital, especially in crowded areas. Utilize hand signals or radios to communicate with ground personnel during lifting operations, ensuring that everyone is informed of the activity to avoid accidents.

By following these protocols, operators can significantly reduce the risk of accidents and enhance safety in construction settings where a telescoping forklift is employed. Additionally, understanding common mistakes, such as the dangers of improper load management or neglecting daily checks, can further improve operational effectiveness.

Select Appropriate Attachments for Enhanced Efficiency

Choosing suitable accessories for a telescoping forklift is essential for enhancing efficiency and ensuring safety on the job site. Below are some of the most commonly used attachments along with their specific applications:

-

Forks: Essential for lifting pallets and heavy materials, forks must be selected based on appropriate length and weight rating to prevent accidents. Fork carriage additions enhance safety and efficiency in managing various materials, making them crucial for numerous tasks.

-

Buckets: Ideal for moving loose materials such as gravel or sand, buckets should be chosen according to the telehandler's capacity to ensure optimal performance.

-

Grapples: Designed for handling bulky items like logs or bales, grapples provide a secure grip and can be adjusted to accommodate various load sizes, enhancing operational flexibility.

-

Truss Booms: These additions extend the reach of the telehandler, enabling the lifting of materials to greater heights, particularly beneficial in construction projects requiring elevation.

-

Augers: Perfect for drilling holes in the ground, augers are especially useful in landscaping and construction tasks, allowing for precise placement of materials.

-

Jibs and Winches: These devices improve telehandler functions and site security by minimizing the need for cranes, enabling more effective material handling and positioning.

Selecting the appropriate accessory for the telescoping forklift not only boosts efficiency but also enhances safety by ensuring that the equipment is well-suited to the specific task at hand. This careful selection process can lead to significant improvements in productivity and operational effectiveness. Additionally, avoiding common pitfalls, such as mismatching attachments to tasks, is essential for maximizing the benefits of telehandlers.

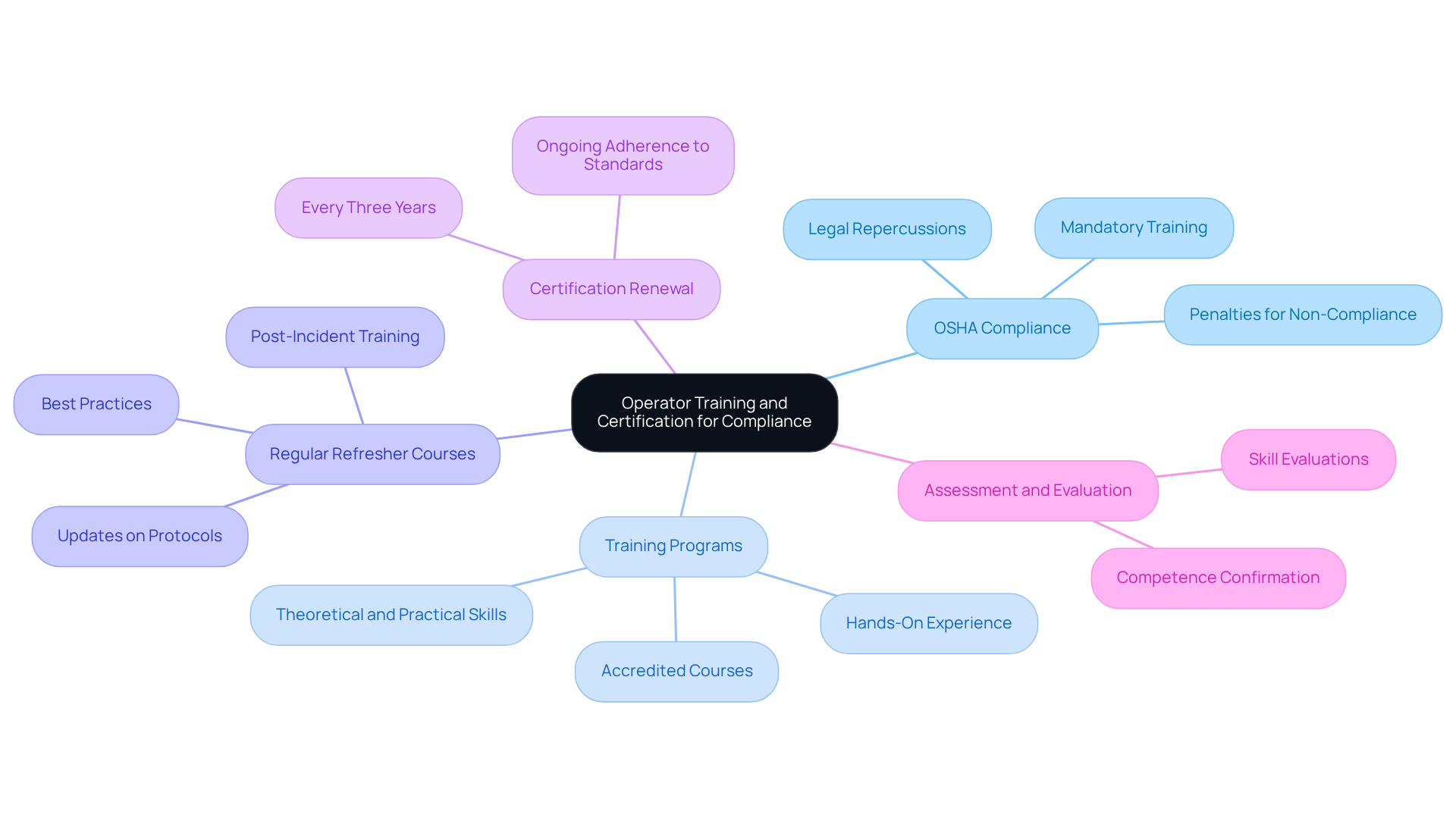

Prioritize Operator Training and Certification for Compliance

To ensure the safe and efficient operation of a telescoping forklift, comprehensive training and certification for operators are essential. Key considerations include:

-

OSHA Compliance: Adherence to OSHA regulations is mandatory, requiring all powered industrial truck operators to undergo proper training and certification. Non-compliance can lead to severe penalties and legal repercussions, including lawsuits from injured workers.

-

Training Programs: Operators should enroll in accredited training programs that encompass both theoretical knowledge and practical skills, including hands-on experience with the equipment.

-

Regular Refresher Courses: Implementing regular refresher courses is essential for keeping operators informed about updated protocols and operational best practices.

-

Certification Renewal: Certifications must be renewed every three years to ensure ongoing adherence to standards.

-

Assessment and Evaluation: Conducting assessments to evaluate operator skills and knowledge is vital to confirm their competence in safely operating the equipment.

Statistics indicate that from 2011 to 2017, forklift-related incidents claimed the lives of more than 600 workers and caused over 7,000 nonfatal injuries annually. This underscores the necessity of a robust training program. Investing in operator training not only improves security but also increases overall productivity on the job site. Furthermore, OSHA emphasizes that non-compliance can lead to severe penalties and legal repercussions, making it imperative for employers to prioritize safety training.

Conclusion

Understanding and implementing best practices for telescoping forklifts is essential for ensuring safety and efficiency on construction sites. This versatile equipment can lift and place heavy materials at various heights, necessitating careful handling and adherence to established protocols to prevent accidents and enhance productivity.

Key insights emphasize the importance of:

- Thorough pre-operation inspections

- Awareness of load capacities

- Necessity of using appropriate attachments

Operators must prioritize:

- Personal protective equipment

- Effective communication

To mitigate risks associated with operating these powerful machines. Additionally, investing in comprehensive training and certification for operators not only complies with OSHA regulations but also significantly reduces the likelihood of accidents and injuries.

Ultimately, prioritizing safety and efficiency in telescoping forklift operations transcends mere compliance; it reflects a commitment to creating a safer work environment. By adhering to these best practices, operators can maximize the capabilities of their equipment while minimizing risks, leading to a more productive and secure job site. Emphasizing ongoing training and proper equipment usage fosters a culture of safety that benefits everyone involved in the operation.

Frequently Asked Questions

What is a telescopic forklift?

A telescopic forklift, also known as a telehandler, is a versatile piece of equipment designed for lifting, carrying, and placing heavy materials at various heights.

What are the main features of a telescopic forklift?

The main feature of a telescopic forklift is its unique telescoping boom, which allows for extended reach, making it suitable for construction sites where lifting capabilities exceed those of standard equipment.

What tasks are telehandlers commonly used for?

Telehandlers are commonly used for tasks such as painting, repairs, and construction work, as they provide exceptional vertical and horizontal reach to access elevated areas and navigate around obstacles.

What types of attachments can be used with telehandlers?

Telehandlers can be outfitted with a variety of attachments, including forks, buckets, and grapples, which enhance their versatility for different applications.

What should be considered when using a telescopic forklift?

It is essential to understand the mechanics of telescopic forklifts, including their load capacities and operational limits, to maximize efficiency and ensure safety on the job site.

List of Sources

- Understand Telescopic Forklifts: Definition and Functionality

- Exploring the Versatility of Telescopic Forklifts in Modern Construction (https://highrichtrade.com/blog/versatility-of-telescopic-forklifts-in-construction)

- Telehandler Market to Reach a value of USD 12.2 bn by 2034 (https://dimensionmarketresearch.com/report/telehandler-market)

- Telescopic Forklift Global Market Insights 2025, Analysis and Forecast to 2030, by Manufacturers, Regions, Technology, Application (https://researchandmarkets.com/reports/6036623/telescopic-forklift-global-market-insights?srsltid=AfmBOooDgQd4GV5XIqknswsx0mzPI30Y0z8r2aygd3BV2dXYBHHiSYOf)

- Telescopic Forklift: 13 Ways to Use It and 5 Mistakes to Avoid - Bobcat of North Texas (https://bobcatofnorthtexas.com/knowledge-center/telescopic-forklift-13-ways-to-use-it-and-5-mistakes-to-avoid)

- Telehandlers Offer 3-in-1 Capabilities for Construction Sites that Need Multitasking Heroes (https://forconstructionpros.com/equipment/article/22591857/telehandlers-offer-3in1-capabilities-for-construction-sites-that-need-multitasking-heroes)

- Implement Safe Operating Procedures for Telescopic Forklifts

- Top 10 Most Common Forklift Accidents [With Statistics] | Conger (https://conger.com/forklift-accidents)

- Forklift Injury Statistics 2025 | How to Reduce Forklift Accident Risks (https://certifyme.net/osha-blog/forklift-injuries-key-statistics)

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- National Forklift Safety Day Statistics │ MHEDA (https://mheda.org/journal/national-forklift-safety-day-statistics)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Select Appropriate Attachments for Enhanced Efficiency

- Top 9 Forklift Attachments for Increased Productivity (https://almarwan.com/news/4603/top-nine-forklift-attachments)

- Our Best Telehandler Attachments: Improve Your Telehandler (https://mctequip.com.au/the-7-best-attachments-to-improve-your-telehandler)

- Prioritize Operator Training and Certification for Compliance

- Top Forklift Accident Statistics & Prevention Tips for 2025 | CertifyMe (https://certifyme.net/osha-blog/forklift-accidents)

- OSHA Top 10 Citations for 2024 (https://forklifttraining.com/osha-top-10-citations-2024)

- National Forklift Safety Day Statistics │ MHEDA (https://mheda.org/journal/national-forklift-safety-day-statistics)

- Why Forklift Operator Training Matters (From an… | Forklifts Group (https://dmhs-socal.com/news/why-forklift-operator-training-matters-from-an-expert-trainer)

- Training day: OSHA advocates formalized telescopic forklift training (https://accessbriefing.com/news/training-day-osha-advocates-formalized-telescopic-forklift-training/1004979.article)