Key Highlights:

- Choosing the right skid steer concrete bucket enhances project efficiency; consider container size, type, material compatibility, and attachment compatibility.

- Container sizes typically range from 0.5 to 1 cubic yard; larger projects may require larger containers to avoid increased trips.

- Hydraulic gates are recommended for precise pouring in larger projects, while manual options may suffice for simpler tasks.

- Ensure the container matches the specific concrete mix for optimal pouring efficiency.

- Avoid selecting containers based solely on price; quality and suitability for project needs are crucial.

- Pre-operation checks are essential for safety; inspect for damage and ensure all safety features are functional.

- Proper positioning of the skid steer minimises spillage and enhances control during concrete pouring.

- Maintain load management by adhering to the manufacturer's weight limits to prevent tipping.

- Utilise hydraulic gates for controlled pouring and ensure visibility during operation to avoid accidents.

- Regular cleaning, inspection for damage, lubrication, and checking hydraulic systems are vital for maintenance.

- Operators should receive comprehensive training covering equipment operation, safety protocols, and maintenance practises.

- Hands-on training in a controlled environment builds operator confidence and competence.

- Regular refresher courses and feedback mechanisms are important for ongoing training and improvement.

Introduction

Choosing the right tools for construction is critical to a project's success, and the skid steer concrete bucket exemplifies this principle. This versatile attachment not only boosts efficiency but also plays a vital role in ensuring quality pours and safety on the job site. Despite its advantages, many operators find it challenging to maximize the potential of their equipment, often overlooking best practices that could lead to smoother operations and reduced risks. Understanding the key strategies that can elevate the use of a skid steer concrete bucket from ordinary to extraordinary is essential for achieving optimal results.

Choose the Right Skid Steer Concrete Bucket for Your Project

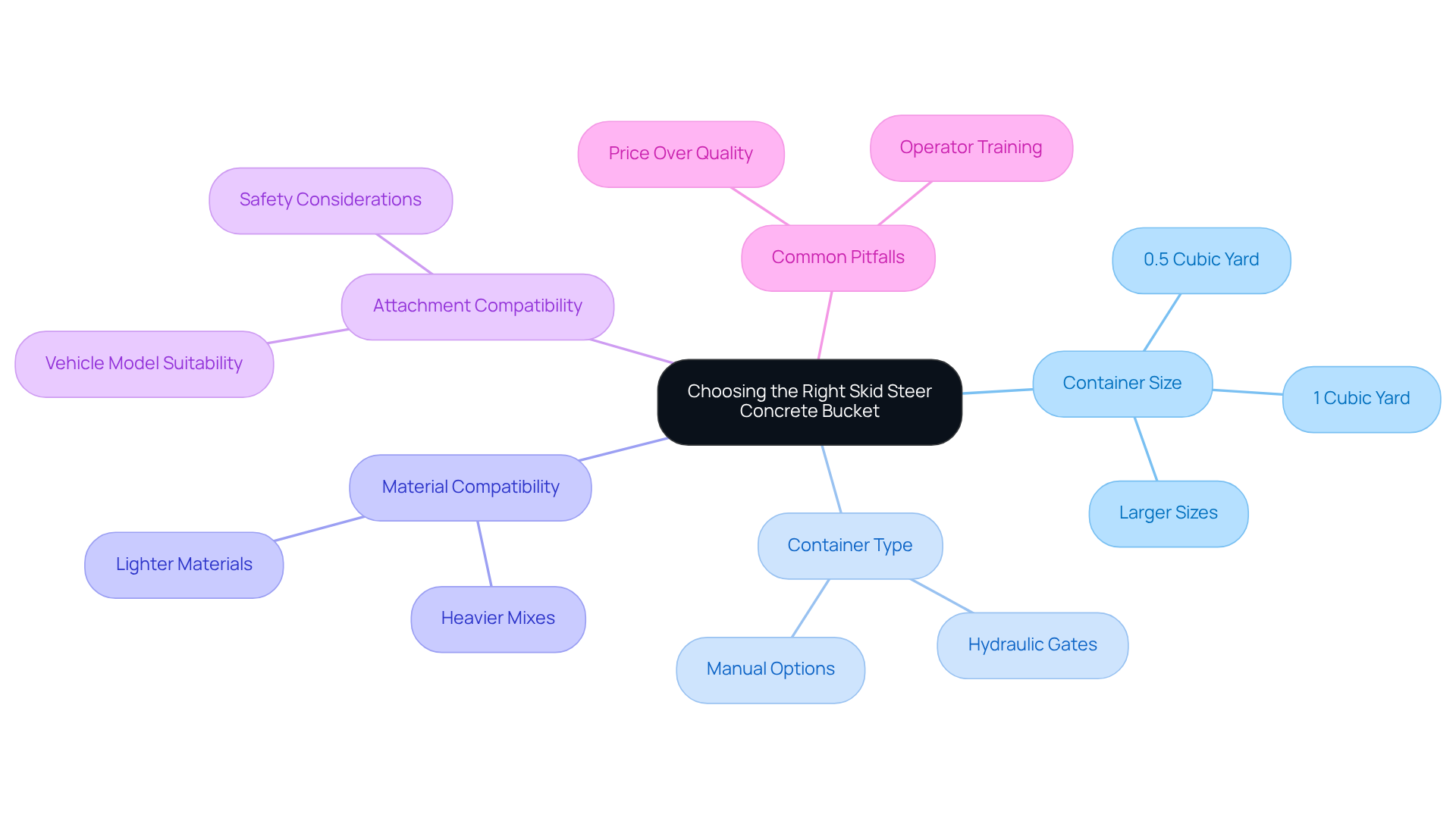

Choosing the proper skid steer concrete bucket is essential for enhancing project efficiency. Here are key factors to consider:

-

Container Size: The average container size for concrete pouring projects in 2026 typically ranges from 0.5 to 1 cubic yard, with capacities extending from 0.5 to several cubic yards. For smaller tasks, a 0.5-yard container may suffice, while larger projects often require a 1-yard container. Opting for a container that is too small can lead to increased trips, ultimately reducing overall efficiency.

-

Container Type: There are various container styles available, including those with hydraulic gates for precise pouring and manual options for simpler tasks. Experts recommend hydraulic containers for larger, more complex pours to enhance control and accuracy. As industry professionals note, "Selecting the appropriate container type can significantly influence the quality of your pour and overall project success."

-

Material Compatibility: It is essential to ensure that the container is compatible with the specific concrete mix you plan to use. Some containers are designed for heavier mixes, while others are optimized for lighter materials, which can affect pouring efficiency and quality.

-

Attachment Compatibility: Confirm that the container is suitable for your vehicle model. This is vital for safe operation and optimal performance, as mismatched attachments can create operational hazards. Standard containers accounted for approximately 45% of the global market for skid steer concrete buckets in 2024, underscoring their popularity and utility.

-

Common Pitfalls: Avoid selecting a container solely based on price; consider the long-term benefits of investing in a quality item that meets your project needs. Additionally, ensure that operators receive proper training to maximize the effectiveness of the chosen container.

By carefully selecting the appropriate container based on these criteria, you can significantly enhance productivity and minimize downtime on your construction site.

Implement Safe and Efficient Operating Techniques

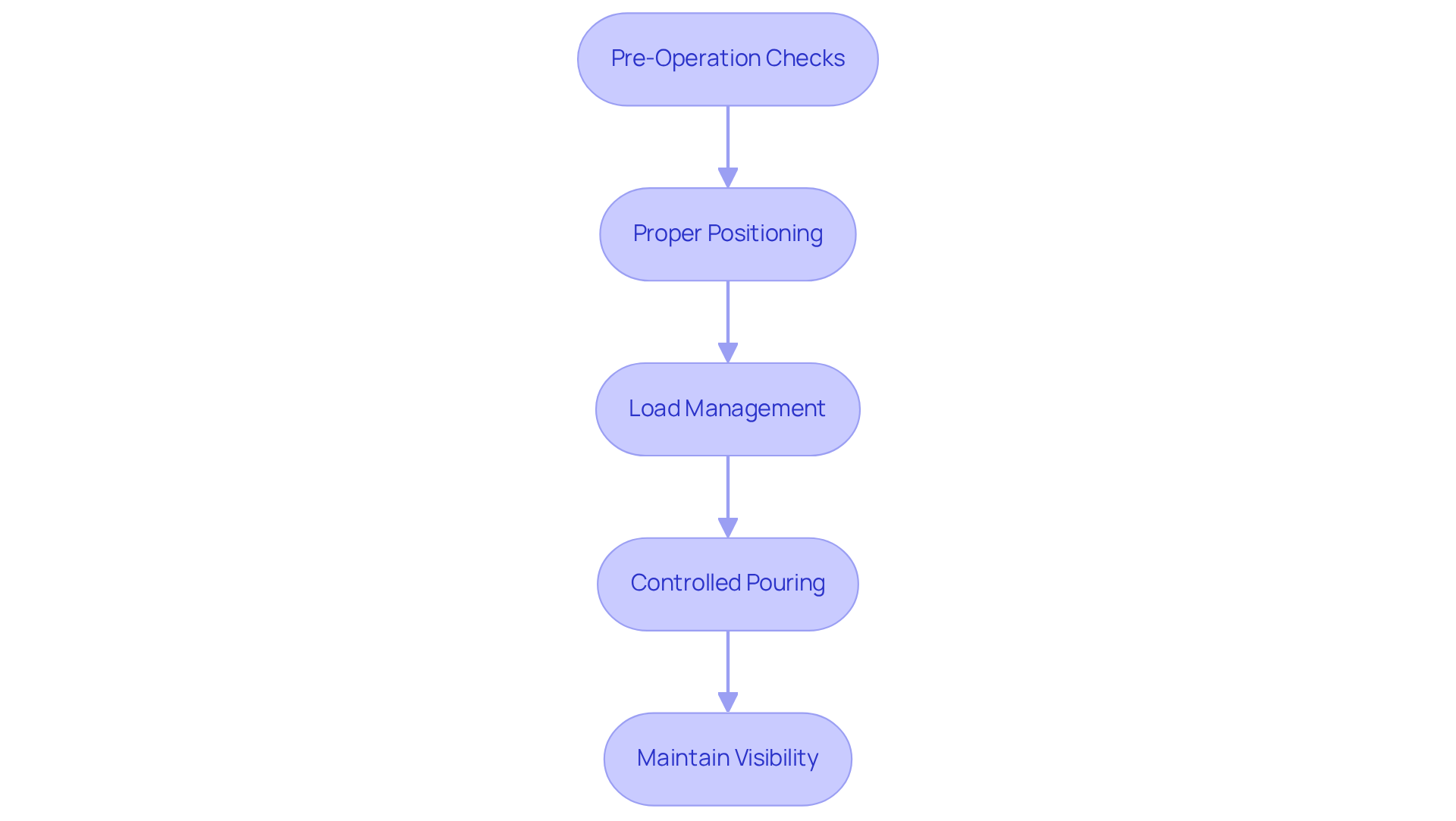

To operate a skid steer concrete bucket safely and efficiently, it is essential to adhere to several best practices:

-

Pre-Operation Checks: Conduct a thorough examination of the loader and bucket before use. Look for visible damage, check fluid levels, and confirm that all safety features are operational. Reports indicate that from 2015 to 2020, there were 68 reported agricultural vehicle injuries, including 48 fatal and 20 nonfatal incidents. This statistic underscores the importance of thorough pre-operation checks.

-

Proper Positioning: Position the skid steer at an optimal angle relative to the pour site. This approach minimizes the risk of spillage and enhances control during the pour. Operators should remain vigilant about their surroundings, as emphasized by safety expert Serap Gorucu, to avoid accidents.

-

Load Management: Avoid exceeding the container's weight limits as specified by the manufacturer. Proper load management is crucial for maintaining stability and preventing tipping. It is advisable to maintain the torque setting below 25 percent of the maximum torque rating to avoid dangerous operating conditions.

-

Controlled Pouring: Utilize the hydraulic gate, if available, to regulate the flow of concrete. This level of control facilitates a clean pour and minimizes waste.

-

Maintain Visibility: Ensure an unobstructed view while operating. Keep the container low to the ground during movement to lower the center of gravity and enhance stability. Be aware of common hazards, such as working with a blocked view or overloading the container, which can lead to accidents.

By following these techniques, operators can significantly improve safety and efficiency on the job site.

Maintain Your Skid Steer Concrete Bucket for Optimal Performance

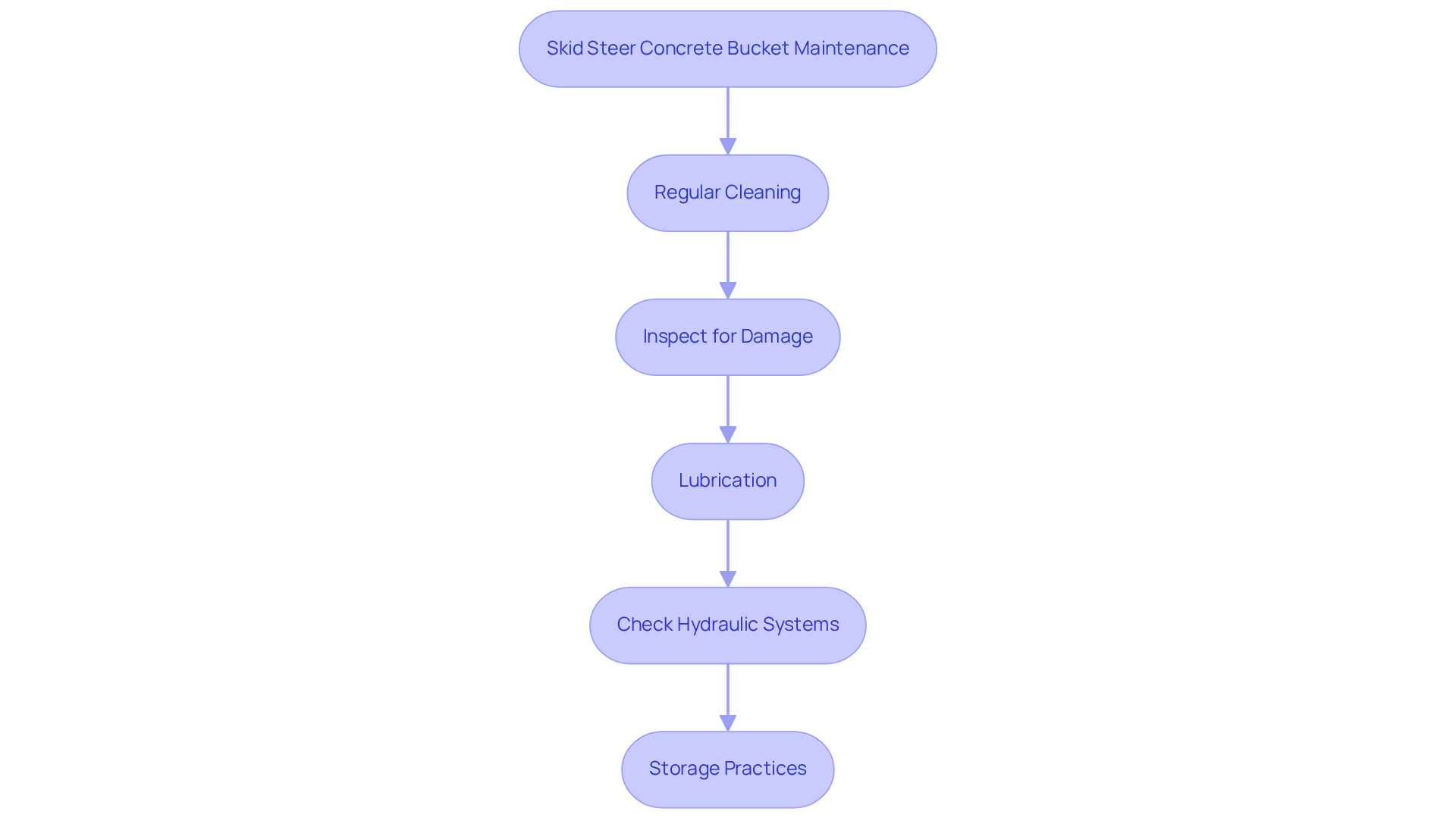

To keep your skid steer concrete bucket in top shape, follow these essential maintenance practices:

-

Regular Cleaning: After each use, clean the container thoroughly to remove concrete residue. This prevents buildup that can impair performance and lead to corrosion, ultimately extending the container's lifespan. Regular cleaning also helps avoid clogs that can decrease efficiency and cause overheating.

-

Inspect for Damage: Regularly check for cracks, dents, or signs of wear. Addressing minor issues promptly can prevent more significant problems, ensuring the container remains reliable during operations. Neglecting maintenance can result in costly repairs and decreased productivity.

-

Lubrication: Ensure all moving parts are adequately lubricated. Proper lubrication reduces friction and wear, enhancing the equipment's operational efficiency and longevity. Some components require greasing every 5 hours, while others need it every 10.

-

Check Hydraulic Systems: Regularly inspect hydraulic hoses and connections for leaks or wear. A well-maintained hydraulic system is crucial for the effective functioning of the loader's controls, preventing downtime and costly repairs. It's also recommended to regularly check fluid levels, including hydraulic fluid, to ensure they are within acceptable limits.

-

Storage Practices: Store the container in a clean, dry environment to prevent rust and damage. When not in use, cover it to protect it from the elements, further safeguarding its integrity. Proper storage can significantly extend the lifespan of your attachments.

By implementing these maintenance techniques, you can ensure that your concrete bucket operates effectively and enjoys an extended service life, ultimately contributing to the success of your construction projects. Remember, proper upkeep of your equipment attachments is an investment in both productivity and cost savings.

Train Operators for Safe and Effective Use

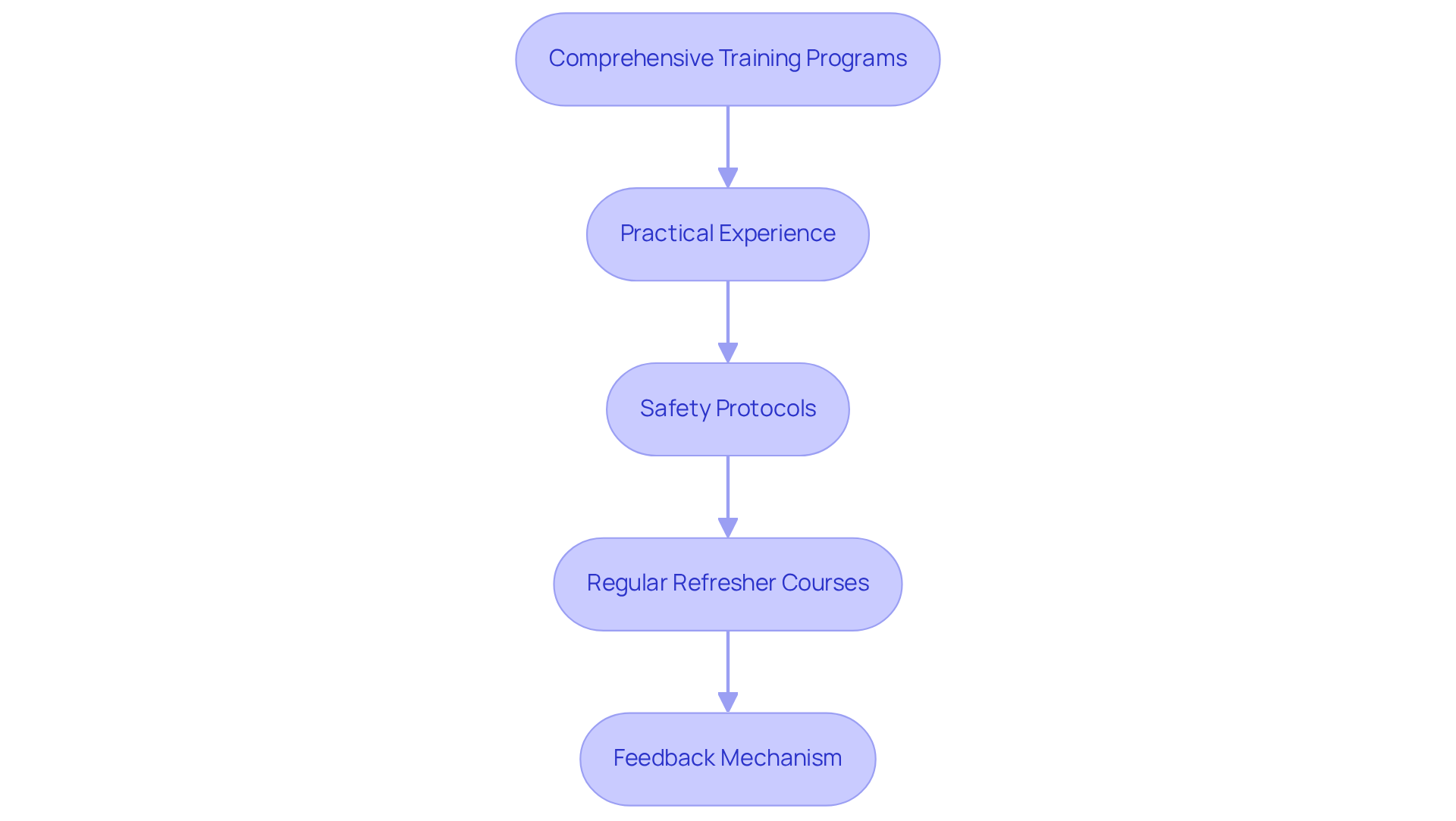

Effective training for compact vehicle operators is crucial for ensuring safety and efficiency in operations. To achieve this, organizations should consider the following steps:

-

Comprehensive Training Programs: It is essential to develop training programs that encompass both theoretical knowledge and practical skills. These programs should cover critical topics such as equipment operation, safety protocols, and maintenance practices.

-

Practical experience: Providing opportunities for operators to train with machinery and a skid steer concrete bucket in a controlled environment is vital. This hands-on experience prepares them for real job sites, enhancing their confidence and competence.

-

Safety Protocols: Emphasizing the importance of safety measures is non-negotiable. Operators must be trained in the use of personal protective equipment (PPE) and adhere strictly to safety guidelines during operation to minimize risks.

-

Regular refresher courses are necessary to implement ongoing training sessions that keep operators informed about best practices and new technologies related to the use of skid steer concrete bucket. This continuous education fosters a culture of safety and efficiency.

-

Feedback Mechanism: Establishing a system for operators to provide feedback on their training and operational experiences is beneficial. This feedback can help identify areas for improvement in training programs, ensuring they remain relevant and effective.

By investing in comprehensive operator training, organizations can significantly enhance safety, boost efficiency, and contribute to overall project success.

Conclusion

Choosing the right skid steer concrete bucket and utilizing it effectively can significantly enhance productivity on construction sites. By focusing on key factors such as container size, type, material compatibility, and proper training, operators can ensure that their projects run smoothly and efficiently.

This article outlines essential best practices, including safe operating techniques and regular maintenance. Pre-operation checks, proper load management, and controlled pouring are crucial to preventing accidents and ensuring the longevity of the equipment. Additionally, maintaining the bucket through regular cleaning and inspections is vital for optimal performance. Comprehensive training programs empower operators to handle the equipment safely and effectively.

Ultimately, investing time and resources into selecting the appropriate concrete bucket, following operational best practices, and training personnel not only boosts efficiency but also contributes to the overall success of construction projects. Embracing these strategies reinforces the importance of preparation and safety in achieving outstanding results in the field.

Frequently Asked Questions

What is the average container size for skid steer concrete buckets in 2026?

The average container size typically ranges from 0.5 to 1 cubic yard, with capacities extending from 0.5 to several cubic yards.

How do I determine the right container size for my project?

For smaller tasks, a 0.5-yard container may suffice, while larger projects often require a 1-yard container. Choosing a container that is too small can lead to increased trips and reduced efficiency.

What types of containers are available for skid steer concrete buckets?

There are various container styles, including those with hydraulic gates for precise pouring and manual options for simpler tasks. Hydraulic containers are recommended for larger, more complex pours.

Why is the type of container important for my project?

Selecting the appropriate container type can significantly influence the quality of your pour and overall project success, especially for larger and more complex tasks.

How does material compatibility affect my choice of container?

It's essential to ensure that the container is compatible with the specific concrete mix you plan to use, as some containers are designed for heavier mixes while others are optimized for lighter materials.

What should I consider regarding attachment compatibility?

Confirm that the container is suitable for your vehicle model to ensure safe operation and optimal performance, as mismatched attachments can create operational hazards.

What are common pitfalls to avoid when selecting a skid steer concrete bucket?

Avoid choosing a container solely based on price; consider the long-term benefits of investing in a quality item. Additionally, ensure that operators receive proper training to maximize effectiveness.

How can I enhance productivity on my construction site with the right container?

By carefully selecting the appropriate container based on size, type, material compatibility, and attachment compatibility, you can significantly enhance productivity and minimize downtime.

List of Sources

- Choose the Right Skid Steer Concrete Bucket for Your Project

- North America Aluminum and Steel Concrete Bucket Market, 2031 (https://persistencemarketresearch.com/market-research/north-america-aluminum-and-steel-concrete-bucket-market.asp)

- Skid Steer Loader Market Share and Statistics 2025-2035 (https://factmr.com/report/389/skid-steer-loader-market)

- Skid Steer Loaders Market Size, Share, Growth Report, 2030 (https://grandviewresearch.com/industry-analysis/skid-steer-loaders-market)

- Skid Steer Bucket Attachments Market Size, Share & Growth Report [2024-2034] (https://emergenresearch.com/industry-report/skid-steer-bucket-attachments-market?srsltid=AfmBOor4WXe9nuFPcN98hmR2hZyAq8WZGp4nBvjtmYkrhf_QSF8QCFjo)

- Aluminum and Steel Concrete Bucket Market Size, Share, Trends & Forecast Report 2035 (https://marketresearchfuture.com/reports/aluminum-steel-concrete-bucket-market-34995)

- Implement Safe and Efficient Operating Techniques

- 8 Pro Tips for Operating Your Skid Steer Efficiently (https://typhonmachinery.com/tips-for-operating-your-skid-steer-efficiently?srsltid=AfmBOooweuQh0WQviEq8bEikz-5py_pB8rIVmyaNFwj8Rp-Uul7BulAk)

- Injuries and Fatalities Related to Skid Steers: 2015–2020 | MDPI (https://mdpi.com/2313-576X/8/3/56)

- Essential Safety Tips for Skid Steer Beginners (https://stoutbuckets.com/blogs/news/essential-safety-tips-for-skid-steer-beginners?srsltid=AfmBOopJR4r_EoX7HHCZBRLTmWtrwSFPER1FpHoOTDOLM0EF6Q9ZH-pS)

- Injuries and Fatalities Related to Skid Steers: 2015–2020 (https://stacks.cdc.gov/view/cdc/230081)

- Skid Steer Safety Stats & Fact (https://ilt.safetynow.com/skid-steer-safety-stats-fact?print=pdf)

- Maintain Your Skid Steer Concrete Bucket for Optimal Performance

- 6 Essential Maintenance Tips for Your Skid Steer Attachments (https://typhonmachinery.com/maintenance-tips-skid-steer-attachments?srsltid=AfmBOop5RosYQCJnobvMwzTK49bpz_B_cvbG-gD5KR0rmtSZ95HVwaE1)

- Understanding Skid Steer Lifespan: How Long Do They Last? (https://typhonmachinery.com/understanding-skid-steer-lifespan?srsltid=AfmBOordcscifQ-50vyf5wuAC2mYpjZw_JDb4zt5sDfRZiK96L4XziU_)

- How to Properly Maintain Your Skid Steer for Optimal Performance - Groff Tractor & Equipment (https://grofftractor.com/about-us/blog/how-to-properly-maintain-your-skid-steer-for-optimal-performance)

- "How Many Hours Should A Skid Steer Last?" Maintenance Tips That Make or Break Heavy Equipment Life - Sur-Flow Hydraulics and Equipment Repair (https://surflowrepair.com/blog/how-many-hours-should-a-skid-steer-last-maintenance-heavy-equipment)

- Proven Skid Steer Attachment Maintenance to Extended Lifespan (https://omniattachments.com/blog/skid-steer-attachment-maintenance-tips)

- Train Operators for Safe and Effective Use

- Safety Quotes: Motivation to Improve Work Safety Culture (https://osha.com/blog/work-safety-quotes)

- John Deere (https://deere.com/en/parts-and-service/manuals-and-training/construction-operator-training/top-reasons-operator-training)

- Why Operator Training Is Just as Important as the Right Equipment (https://genequipgy.com/post/why-operator-training-is-just-as-important-as-the-right-equipment)

- Safety Training for Machinery Operators: Boost Efficiency (https://visionarylawgroup.com/importance-of-safety-training-benefits-for-machinery-operators)

- Boost Job Performance with Skid Steer Certification (https://lifttraining.com/skid-steer-certification-improves-job-performance)