Overview

Utilizing a 110 CFM air compressor is crucial for enhancing tool efficiency and minimizing downtime in construction projects. Selecting the right compressor tailored to specific project needs can lead to significant improvements in productivity. Furthermore, adhering to maintenance best practices not only extends the equipment's lifespan but also reduces operational costs. Ultimately, these factors contribute to more successful project outcomes.

Key Highlights:

- Choosing the right 110 cfm air compressor enhances tool efficiency and reduces project downtime.

- Insufficient CFM can hinder performance, while excessive CFM leads to unnecessary costs.

- Understanding project requirements and tool CFM needs is crucial for informed compressor selection.

- 110 cfm air compressors deliver high air delivery, versatility, portability, and durability.

- Proper maintenance can extend compressor lifespan to 10-20 years, maximizing long-term value.

- Types of compressors include rotary screw (efficient for constant demand), reciprocating (versatile and budget-friendly), and towable units (mobile for job site flexibility).

- Electric compressors are quieter for indoor use, while diesel models provide more power for outdoor tasks.

- Best practices for usage include proper setup, regular inspections, using compatible accessories, monitoring air pressure, and adhering to safety protocols.

- Regular maintenance tasks include oil changes, draining tanks, cleaning filters, inspecting hoses, and following manufacturer guidelines.

Introduction

Choosing the right air compressor is crucial for the success of construction projects. With a plethora of options available, understanding the specific needs of each task is essential. From ensuring optimal power for pneumatic tools to maximizing efficiency and minimizing downtime, the selection process demands careful consideration. As industry standards evolve, so does the importance of aligning equipment choices with both performance expectations and regulatory requirements.

This article explores the significance of selecting the appropriate air compressor, particularly the versatile 110 CFM models. We will examine their features, types, best practices for usage, and essential maintenance tips to ensure longevity and reliability on the job site.

The Importance of Choosing the Right Air Compressor for Your Projects

Choosing the right 110 cfm air compressor is crucial for maximizing the efficiency and effectiveness of your tools on any construction project. At in Dallas, we understand that an air device tailored to meet the specific demands of your tasks can significantly enhance productivity while minimizing downtime. For instance, opting for instead of a device with insufficient CFM (Cubic Feet per Minute) guarantees adequate power for pneumatic tools, resulting in faster operations and fewer project delays.

Conversely, selecting a 110 cfm air compressor with an excessively high CFM rating may lead to unnecessary costs without delivering additional benefits. Understanding your project's requirements is the first step toward making an informed decision. Consider the types of tools you will be using and their respective CFM needs. For example, if your project involves operating multiple tools simultaneously, a 110 cfm air compressor becomes essential to ensure consistent air pressure and optimal performance.

A general guideline indicates that each horsepower of an air device typically produces about 4 to 5 CFM at 100 psi, underscoring the importance of matching horsepower with your specific output requirements. Furthermore, the effectiveness of your air pump directly influences project productivity. New energy conservation standards enacted by the US Department of Energy in 2023 highlight the necessity for devices that not only meet but exceed performance expectations. This shift emphasizes the significance of choosing an air device that aligns with both current regulations and your operational needs.

As Tajammul Pangarkar, CMO at Prudour Pvt Ltd, observes, "The right equipment can significantly influence productivity and efficiency in any project." EZ Equipment Rental offers a comprehensive selection of air machinery and tool rentals, ensuring you have access to the right equipment for your specific needs. By choosing to rent from us, you benefit from cost-effective and flexible air solutions that cater to your budget while guaranteeing you have the right tools for the job. Real-world examples illustrate how the proper air device selection can impact construction project timelines.

Projects utilizing a 110 cfm air compressor often experience smoother workflows and reduced delays, ultimately leading to enhanced overall performance. Additionally, with a lifespan ranging from 10 to 15 years when properly maintained, investing in a quality air device is not merely a short-term decision but a long-term strategy for success in the construction industry. This longevity further underscores the importance of selecting an efficient model that will serve your needs over time.

Consider renting from EZ Equipment Rental today to maximize your project's productivity and effectiveness.

Key Features and Benefits of 110 CFM Air Compressors

110 cfm air compressors deliver exceptional performance across a wide range of applications, making them indispensable on construction sites. High Air Delivery is a standout feature, boasting a robust delivery rate of 110 CFM. This efficiency allows these compressors to power multiple pneumatic tools simultaneously, particularly advantageous for larger job sites where efficiency is crucial. Versatility is another key attribute, as these devices excel in various tasks—from powering pneumatic tools and inflating tires to operating spray guns—showcasing their adaptability to different project requirements. As Pam Kleineke, managing editor of Compact Equipment, aptly notes, "The versatility of the 110 cfm air compressor makes it a valuable asset on any job site." Additionally, Portability is a significant benefit; many models are designed for easy transport, enabling contractors to move them effortlessly between job sites, thereby enhancing operational flexibility. Durability is also paramount, as the 110 cfm air compressor is constructed from high-quality materials to withstand the demanding conditions of construction environments, ensuring long-lasting performance.

The considerable benefits of utilizing are noteworthy. They contribute to increased operational efficiency, minimize downtime, and empower teams to tackle challenging tasks with confidence. For instance, the D110PKU model, recognized for its lightweight and portable design, functions as a 110 cfm air compressor that delivers 110 CFM at 100 PSI. This makes it ideal for powering paving breakers and blowing out sprinkler systems. Its user-friendly features, including a simple keyed ignition and compact design, not only reduce shipping costs but also enhance usability on-site. Furthermore, the D110PKU is noted for its lower operational costs compared to larger units, making it an ideal choice for contractors and rental businesses.

Moreover, optimizing air pump operation can lead to substantial annual savings. Estimates suggest reductions in electricity costs and carbon emissions, potentially saving between $40,000 to $46,000 over five years. This financial benefit, coupled with the operational advantages, underscores the value of the 110 cfm air compressor in construction projects. As the sector advances in 2025, the focus on productivity and sustainability positions the 110 cfm air compressor as a wise choice for contractors aiming to enhance output while minimizing ecological effects.

EZ Equipment Rental's commitment to quality, reliability, and customer satisfaction further ensures that contractors have access to the best equipment for their needs.

Types of 110 CFM Air Compressors: A Comprehensive Overview

When selecting a 110 CFM air compressor, understanding the various types available is essential, as each is tailored for specific applications.

- are renowned for their efficiency. Operating continuously at a 100% duty cycle, they are ideal for industrial settings with high and constant air demand. A recent survey indicated that 75% of industry professionals prefer these devices due to their reliability and performance, as highlighted in the case study 'Industry Preferences for Air Equipment Types.' This preference underscores their value in demanding environments.

- Reciprocating Units offer versatility, making them suitable for both light and heavy-duty tasks. Often more budget-friendly, they appeal to those undertaking smaller projects. While these units typically have a 50% duty cycle, their ease of service and lower upfront costs make them a popular choice among users.

- Towable Units are designed for mobility, allowing for easy transportation to various job sites. This feature makes them an excellent option for contractors who require flexibility in their operations, ensuring they can adapt to changing project needs.

When considering Electric vs. Diesel, electric units stand out for their quieter operation, making them ideal for indoor applications. Conversely, diesel models deliver greater power, making them better suited for outdoor tasks.

As Tajammul Pangarkar, CMO at Prudour Pvt Ltd, notes, understanding the specific demands of your work environment is crucial for selecting the right equipment. By considering the nature of your tasks, you can make an informed decision that boosts productivity and effectiveness.

For inquiries and reservations, contact at (214) 951-7800.

Best Practices for Utilizing 110 CFM Air Compressors on Job Sites

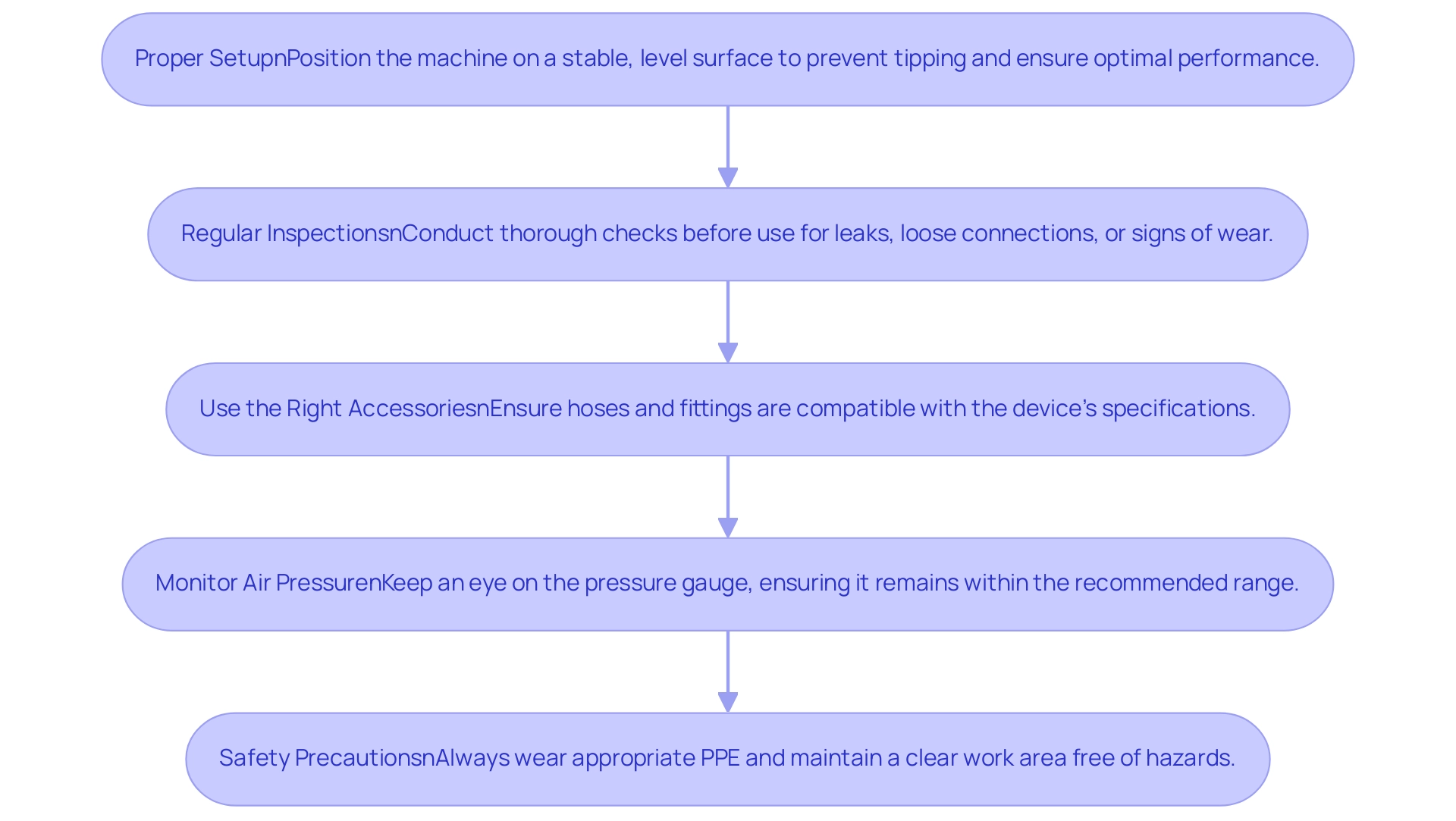

To enhance the effectiveness and safety of your 110 CFM air device on job sites, it is essential to adhere to the following best practices:

- Proper Setup: Position the machine on a stable, level surface to prevent tipping and ensure optimal performance. This foundational step is crucial for maintaining operational integrity and safety.

- Regular Inspections: Conduct thorough checks before use, looking for leaks, loose connections, or signs of wear. Regular maintenance of the 110 CFM air compressor not only prevents breakdowns but also extends the lifespan of the device, ensuring reliability throughout your project.

- Use the Right Accessories: Ensure that hoses and fittings are compatible with the device's specifications. Mismatched accessories can lead to pressure loss and safety hazards, undermining the effectiveness of your operations.

- Monitor Air Pressure: Keep a vigilant eye on the pressure gauge, ensuring it remains within the recommended range for your tools. Maintaining appropriate pressure levels is essential for optimal tool performance and safety.

- Safety Precautions: Always wear appropriate personal protective equipment (PPE) and maintain a clear work area free of hazards. Establishing safety protocols greatly lowers the chance of occurrences associated with air machinery misuse, which can result in severe injuries.

Integrating these practices not only improves the operational performance of but also promotes a safer workplace. According to Next Move Strategy Consulting, the size of the U.S. air machinery market was valued at USD 4.69 billion in 2023, highlighting the industry's significance and the importance of adhering to best practices. For example, a case study on horsepower and air efficiency indicates that each horsepower produces approximately 4 to 5 cubic feet per minute (CFM) of compressed air at 100 psi, emphasizing how understanding horsepower can influence the selection and use of devices on job sites.

Furthermore, statistics indicate that a 45-horsepower machine can accumulate around 23 gallons of water daily, underscoring the necessity of regular maintenance and monitoring to prevent operational issues. By prioritizing proper setup and safety, you can ensure that your air device operates effectively and safely throughout your project.

Maintenance Tips for Ensuring Longevity of Your Air Compressor

To ensure the longevity and reliability of your 110 cfm air compressor, implementing a comprehensive maintenance routine is essential. Adhering to key practices will not only enhance performance but also extend the life of your equipment.

- Regular Oil Changes are crucial. Following the manufacturer's recommendations for oil changes keeps the device operating smoothly and prevents wear and tear that could lead to costly repairs. Experts emphasize that neglecting this simple task can significantly shorten the lifespan of the unit. With proper maintenance, an air device can achieve a lifespan of up to 20 years, translating into substantial cost savings over time.

- Drain the Tank regularly to eliminate moisture accumulation, which can lead to rust and internal damage. This practice improves the durability and performance of the device, ensuring it operates at its best.

- Clean or Replace Filters to maintain optimal airflow and efficiency. Air filters play a critical role, and keeping them clean is essential. They should be replaced as needed to prevent airflow restrictions that can hinder performance.

- Inspect Hoses and Connections regularly to identify any signs of wear or damage. Swiftly replacing damaged components can prevent leaks and ensure the machine operates efficiently. It’s also important to confirm that are compatible with new machines, as modifications may be necessary for reticulation systems.

- Follow Manufacturer Guidelines by always referring to the user manual for specific maintenance schedules and recommendations. This ensures that all maintenance tasks are performed correctly and at the right intervals.

Incorporating these maintenance practices can significantly extend the life of your 110 cfm air compressor, allowing it to operate at peak performance. Furthermore, regular maintenance not only enhances equipment reliability but also improves productivity on job sites. As Steve Cowburn, Head of Aftermarket at Sullair, notes, "Not everyone’s running 24/7 for 365 days a year," highlighting the importance of tailored maintenance schedules.

Research shows that maintenance personnel frequently dedicate just 24.5% of their time to productive activities, underscoring the necessity for enhanced effectiveness in maintenance operations. By prioritizing maintenance, you can mitigate labor costs and maximize efficiency in your operations.

Conclusion

Selecting the right air compressor is pivotal for the success of construction projects. Understanding specific project requirements, particularly regarding the appropriate CFM ratings for pneumatic tools, is crucial. A well-matched air compressor not only enhances productivity but also minimizes downtime, leading to smoother workflows and timely project completion.

The exploration of 110 CFM air compressors highlights their versatility and efficiency across various applications, making them invaluable assets on job sites. With features such as high air delivery, portability, and durability, these compressors are engineered to meet the demands of diverse tasks, from powering tools to operating equipment. By understanding the different types of compressors available and adhering to best practices for usage and maintenance, contractors are empowered to make informed decisions that optimize their operations.

In conclusion, investing in a quality air compressor and adhering to proper maintenance routines can significantly extend the equipment's lifespan while ensuring reliable performance. By prioritizing the selection and care of air compressors, contractors can enhance operational efficiency, reduce costs, and ultimately achieve greater success in their construction endeavors. Embracing these practices not only aligns with industry standards but also positions projects for sustainable growth in an increasingly competitive marketplace.

Frequently Asked Questions

Why is choosing the right 110 cfm air compressor important for construction projects?

Choosing the right 110 cfm air compressor is crucial for maximizing the efficiency and effectiveness of tools, enhancing productivity, and minimizing downtime on construction projects.

What are the consequences of selecting an air compressor with insufficient CFM?

Opting for an air compressor with insufficient CFM can lead to inadequate power for pneumatic tools, resulting in slower operations and project delays.

What are the risks of choosing an air compressor with an excessively high CFM rating?

Selecting a 110 cfm air compressor with an excessively high CFM rating may incur unnecessary costs without providing additional benefits.

How can I determine the appropriate CFM needs for my project?

Consider the types of tools you will be using and their respective CFM requirements. If operating multiple tools simultaneously, a 110 cfm air compressor is essential for maintaining consistent air pressure and optimal performance.

What is the general guideline for horsepower and CFM production?

A general guideline indicates that each horsepower of an air device typically produces about 4 to 5 CFM at 100 psi, highlighting the importance of matching horsepower with specific output requirements.

What new regulations should be considered when selecting an air compressor?

New energy conservation standards enacted by the US Department of Energy in 2023 emphasize the necessity for devices that meet or exceed performance expectations.

How does the right equipment influence construction project productivity?

The right equipment can significantly enhance productivity and efficiency in any project, leading to smoother workflows and reduced delays.

What is the typical lifespan of a quality air compressor?

A quality air compressor, when properly maintained, can have a lifespan ranging from 10 to 15 years, making it a long-term investment for construction needs.

What advantages does a 110 cfm air compressor provide on construction sites?

The 110 cfm air compressor offers high air delivery, versatility for various tasks, portability for easy transport, and durability for demanding conditions.

Can you provide an example of a specific 110 cfm air compressor model and its benefits?

The D110PKU model is lightweight, portable, delivers 110 CFM at 100 PSI, and is ideal for powering paving breakers and blowing out sprinkler systems. It features a simple keyed ignition and compact design, reducing shipping costs and enhancing usability.

What financial benefits can be associated with optimizing air pump operation?

Optimizing air pump operation can lead to substantial annual savings, with estimates suggesting reductions in electricity costs and carbon emissions, potentially saving between $40,000 to $46,000 over five years.

How does EZ Equipment Rental support contractors in selecting air compressors?

EZ Equipment Rental offers a comprehensive selection of air machinery and tool rentals, ensuring access to quality equipment that meets specific project needs while providing cost-effective and flexible solutions.