Key Highlights:

- Walkie forklifts are compact, manoeuvrable, and ideal for indoor operations with limited space.

- Traditional forklifts are larger, offer higher load capacities, and are suitable for heavy-duty tasks outdoors.

- Walk-behind stackers excel in confined spaces, improving visibility and control for operators.

- Mobile lifting trucks typically accommodate loads of 1 to 2 tonnes, while conventional machines handle heavier weights.

- Walkie forklifts have lower initial and maintenance costs, making them cost-effective for many businesses.

- Conventional lifting machines are essential for outdoor construction, handling heavy materials and uneven terrains.

- Choosing the right forklift depends on material weight, workspace dimensions, and budget considerations.

Introduction

Selecting the appropriate forklift is crucial for enhancing operational efficiency. The choice often depends on a clear understanding of the unique advantages and limitations of walkie forklifts compared to traditional models.

- Walkie forklifts are designed for maneuverability in tight spaces, providing cost-effective solutions for indoor material handling.

- In contrast, traditional forklifts are better suited for heavy-duty tasks across diverse environments.

However, these benefits come with challenges. How can operators identify which forklift type aligns best with their specific projects? This article explores the essential features, advantages, and disadvantages of each forklift type, offering valuable insights for informed decision-making in material handling.

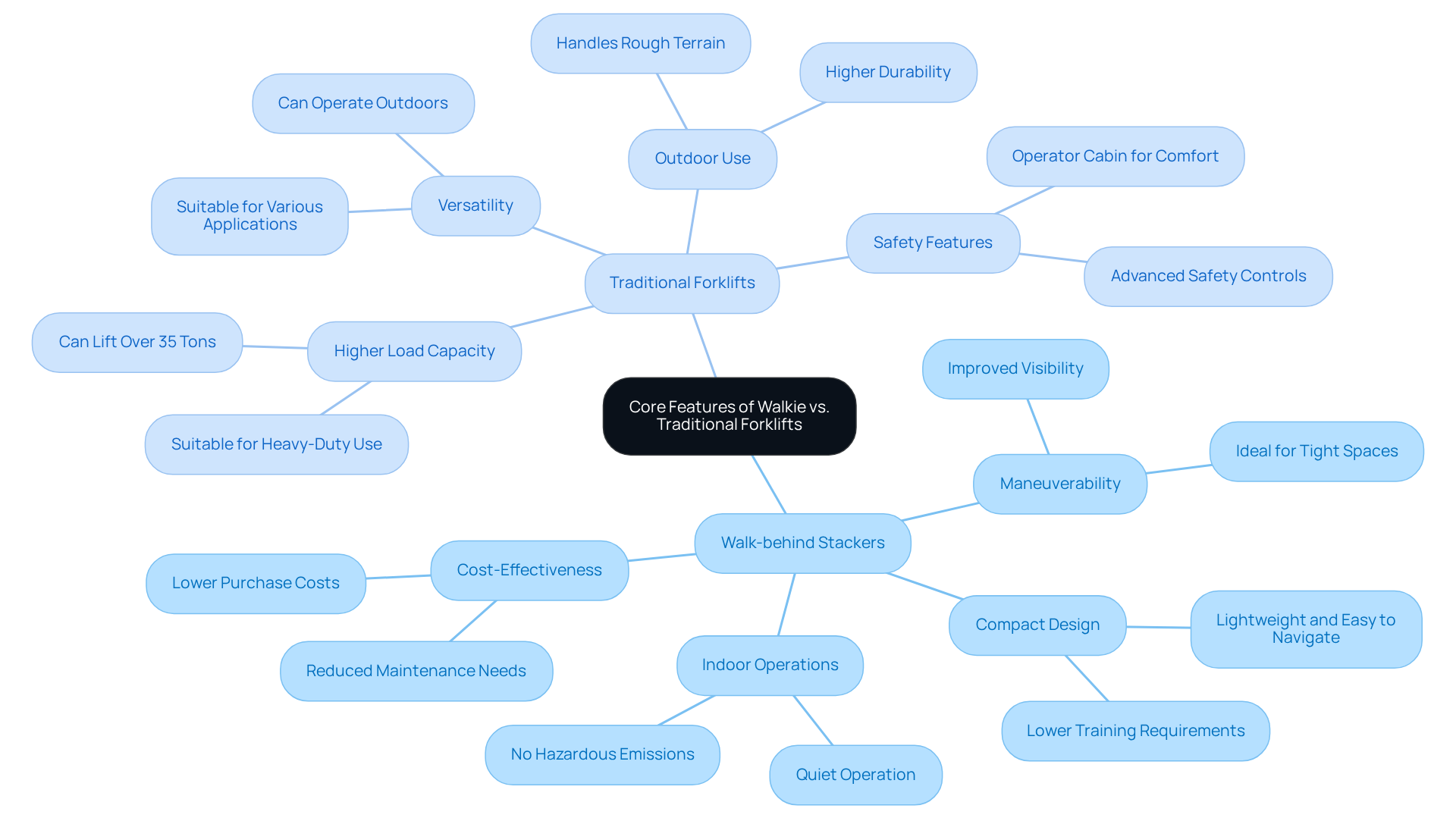

Compare Core Features of Walkie and Traditional Forklifts

Walk-behind stackers, also known as walk-behind machines, are engineered for exceptional maneuverability in tight spaces, making them an excellent choice for indoor operations. Their compact design and lightweight electric battery power allow for easy navigation through narrow aisles, significantly enhancing operational efficiency.

In warehousing and logistics, effective material handling is essential, and walkie trucks play a vital role in streamlining processes, ensuring timely movement of goods, and optimizing storage space. In contrast, conventional lifting machines, which are larger and typically powered by internal combustion engines or electric motors, are designed to handle heavier loads across a broader range of applications, including outdoor environments. These lifting machines generally offer higher lift capacities and greater versatility, making them suitable for construction sites and expansive warehouses.

Despite their limitations in load capacity, mobile lifting trucks excel in confined spaces, providing operators with improved visibility and control-critical factors in environments where safety and precision are paramount. For instance, powered pallet trucks can easily access elevated pallets and maneuver in narrow aisles, a task that standard lifting machines may struggle with.

Industry experts highlight that the design of hand-operated lifting machines enhances operator safety and efficiency, making them a valuable asset in modern warehouse operations. Furthermore, pallet stackers can elevate loads up to 4,000 lbs to heights of approximately 15 ft, and they are generally more cost-effective to acquire than traditional lift trucks. As companies increasingly prioritize space optimization and operational flexibility, the demand for walkie forklifts continues to grow, underscoring their essential role in contemporary material handling.

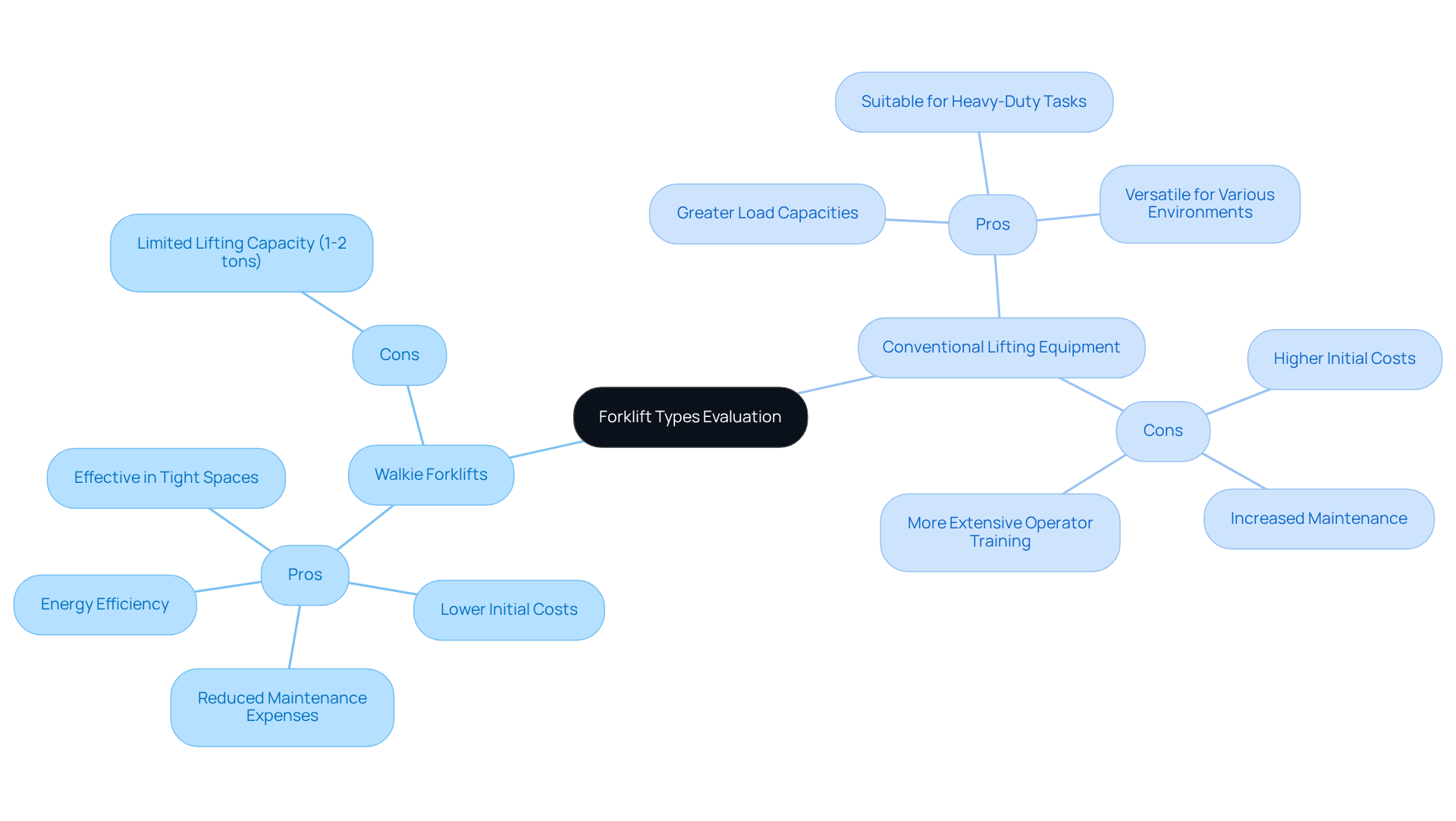

Evaluate Pros and Cons of Each Forklift Type

Walkie forklifts provide several advantages, including lower initial costs, reduced maintenance expenses, and energy efficiency. They are particularly effective in tight spaces and require less training for operators. However, their lifting capacity is limited, typically accommodating loads of 1 to 2 tons, which may not be sufficient for heavier materials.

In contrast, conventional lifting equipment provides greater load capacities, making them suitable for heavy-duty tasks. These machines are versatile and can function in various environments, including outdoor settings. Nonetheless, they come with higher initial costs, increased maintenance requirements, and necessitate more extensive operator training. Furthermore, conventional lifting trucks may lack the agility of hand-operated lifts in confined areas.

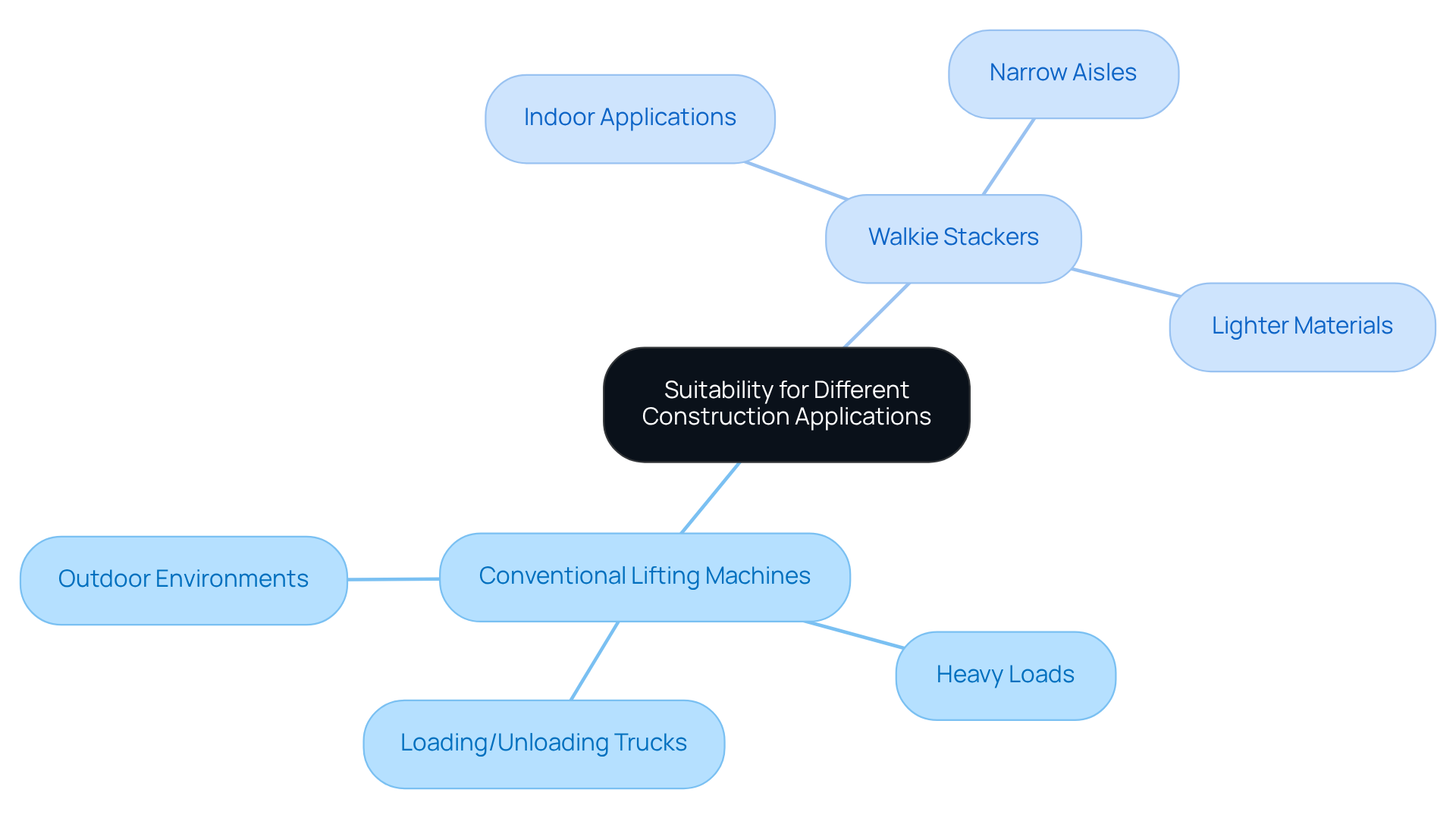

Determine Suitability for Different Construction Applications

Conventional lifting machines are particularly effective in outdoor construction environments. Their robust design allows them to handle heavier loads and navigate uneven surfaces with ease. These machines are essential for tasks that require lifting materials to significant heights or transporting bulky items across large job sites. For example, they are frequently utilized for loading and unloading trucks at construction sites, demonstrating their ability to manage substantial weight and volume.

In contrast, walkie stackers are specifically designed for indoor applications, thriving in warehouses and retail spaces. Their maneuverability is ideal for narrow aisles, making them proficient at moving lighter materials. Statistics show that conventional lifting machines dominate outdoor construction activities, highlighting the industry's reliance on equipment that can withstand the challenges of such environments.

This distinction underscores the importance of selecting the appropriate type of lifter based on the specific needs of a construction project. By understanding the strengths of each machine, operators can ensure efficiency and safety on the job site.

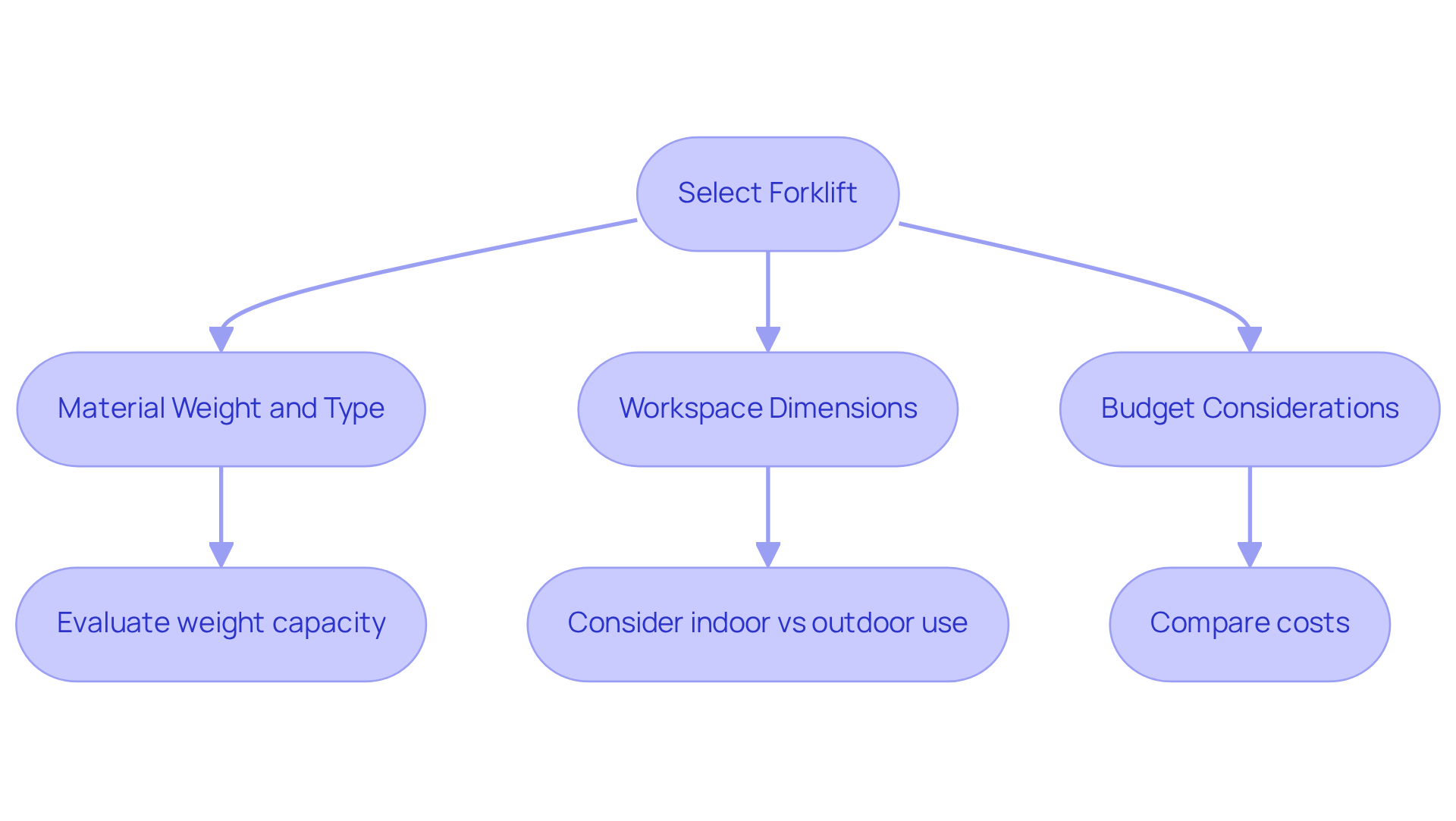

Guide to Making the Right Forklift Choice for Your Projects

Selecting the right forklift for your project requires careful consideration of several key factors:

- Material Weight and Type: It's essential to evaluate the weight and type of materials you will be handling, as this directly impacts the forklift's capacity requirements.

- Workspace Dimensions: Consider the dimensions of your workspace. Conventional lifting machines excel in outdoor environments and on uneven terrains, making them ideal for heavy loads. In contrast, walkie forklifts are designed for maneuverability in tight indoor spaces, particularly when dealing with lighter materials.

- Budget Considerations: Walkie units typically have lower acquisition and operational costs compared to traditional models, making them a cost-effective option for many businesses.

Renting from a reputable company like EZ Equipment Rental guarantees access to well-maintained forklifts. Their equipment undergoes regular maintenance, including inspections and repairs, which minimizes the risk of breakdowns during critical operations. Furthermore, their team offers comprehensive support, addressing any issues promptly to reduce downtime. Ultimately, your decision should be based on a thorough analysis of your specific project needs, operational environment, and financial constraints, ensuring you select the most efficient and effective equipment for your tasks.

Conclusion

Choosing between walkie forklifts and traditional forklifts is a crucial decision that can greatly influence operational efficiency and safety in material handling. By understanding the unique strengths and limitations of each type, businesses can align their equipment choices with specific project requirements, ultimately enhancing productivity.

Walkie forklifts excel in confined spaces, providing maneuverability and cost-effectiveness for indoor operations. They are particularly effective in handling lighter loads and navigating tight aisles, making them ideal for warehouses and retail environments. Conversely, traditional forklifts are robust machines designed for heavy-duty tasks in outdoor settings. They can lift substantial weights and traverse uneven terrains, offering versatility across various applications.

In conclusion, selecting the right forklift depends on a thorough evaluation of material weight, workspace dimensions, and budget considerations. By carefully weighing these factors, operators can ensure they choose the most suitable equipment for their projects, maximizing safety and efficiency while minimizing operational costs. An informed choice not only streamlines processes but also positions businesses to adapt to evolving material handling demands, underscoring the importance of understanding the nuances between walkie forklifts and traditional forklifts.

Frequently Asked Questions

What are walk-behind stackers?

Walk-behind stackers, also known as walk-behind machines, are designed for exceptional maneuverability in tight spaces, making them ideal for indoor operations.

What advantages do walkie trucks offer in warehousing and logistics?

Walkie trucks streamline processes, ensure timely movement of goods, and optimize storage space, playing a vital role in effective material handling.

How do traditional forklifts differ from walk-behind stackers?

Traditional forklifts are larger, typically powered by internal combustion engines or electric motors, and are designed to handle heavier loads across a broader range of applications, including outdoor environments.

What are the load capacities of mobile lifting trucks?

Mobile lifting trucks excel in confined spaces but have limitations in load capacity compared to traditional forklifts. They can elevate loads up to 4,000 lbs to heights of approximately 15 ft.

Why are walkie forklifts gaining popularity in modern warehouse operations?

Companies are increasingly prioritizing space optimization and operational flexibility, leading to a growing demand for walkie forklifts due to their ability to navigate narrow aisles and enhance safety and efficiency.

What safety and efficiency benefits do hand-operated lifting machines provide?

The design of hand-operated lifting machines enhances operator safety and efficiency, making them valuable assets in modern warehouse operations.

What environments are traditional forklifts best suited for?

Traditional forklifts are suitable for construction sites and expansive warehouses, where they can handle heavier loads and operate across a wider range of applications.

List of Sources

- Compare Core Features of Walkie and Traditional Forklifts

- Walkie Stackers vs. Forklifts: What’s the Difference? (https://sstlift.com/blog/walkie-stackers-vs.-forklifts-whats-the-difference)

- Walkie Stacker vs Forklift: Best Warehouse Choice? (https://wollongongforklift.com.au/blog/reasons-to-take-a-walkie-stacker-instead-of-a-standard-forklift)

- Walkie Forklift vs. Traditional Forklift - ARPAC (https://arpac.ca/blog/materials-handling-solutions/forklifts/walkie-forklift-vs-traditional-forklift)

- Electric Forklift Market Size, Share & Growth Report, 2030 (https://grandviewresearch.com/industry-analysis/electric-forklift-market-report)

- Warehousing Electric Forklifts vs Traditional Forklifts: Which Is Better?- Jiangsu Kinlift Equipment Co., Ltd. (https://kinlift.com/news/industry-news/warehousing-electric-forklifts-vs-traditional-forklifts-which-is-better.html)

- Evaluate Pros and Cons of Each Forklift Type

- Walkie Forklift vs. Traditional Forklift - ARPAC (https://arpac.ca/blog/materials-handling-solutions/forklifts/walkie-forklift-vs-traditional-forklift)

- Walk Behind Forklifts - The Pros and Cons (https://buyerzone.com/industrial/forklifts/ar-ac-walk-behind-forklifts)

- Walkie Stacker Forklift Types, Benefits & Safety | CertifyMe (https://certifyme.net/osha-blog/walkie-stacker-types-applications)

- Forklift or walk-behind stacker: Which solution is right for your warehouse? (https://supplychaindive.com/spons/forklift-or-walk-behind-stacker-which-solution-is-right-for-your-warehouse/735194)

- The pros and cons of different forklift types (https://nflforklifts.co.nz/the-pros-and-cons-of-different-forklift-types)

- Determine Suitability for Different Construction Applications

- Forklift Forecast Sharply Revised: What Is Driving Growth? (https://interactanalysis.com/insight/forklift-forecast-sharply-revised)

- Electric Lift Truck Market | Global Market Analysis Report - 2035 (https://futuremarketinsights.com/reports/electric-lift-truck-market)

- Forklift Statistics and Facts (2026) (https://news.market.us/forklift-statistics)

- 18 Important Forklift Statistics | BigRentz (https://bigrentz.com/blog/forklift-statistics?srsltid=AfmBOormtMjNK3U_Ra8L91gCvMLlPr_96ZVp9d8I4GeYQP3nNj03AHRC)

- Forklift Market | Global Market Analysis Report - 2035 (https://factmr.com/report/forklift-market)

- Guide to Making the Right Forklift Choice for Your Projects

- 9 Surprising Forklift Statistics - Forklift Certifcation (https://forkliftcertification.com/9-surprising-forklift-statistics?srsltid=AfmBOoqNEOALLmOFDB3Jb9k8Am7PbUSuSO4UqZTQej8joWETdn2kjWFa)

- How To Select A Forklift – Factors To Consider | Yale (https://yale.com/en-us/north-america/support-resources/white-papers/what-to-consider-when-choosing-a-lift-truck)

- 18 Important Forklift Statistics | BigRentz (https://bigrentz.com/blog/forklift-statistics?srsltid=AfmBOoo_JY6JIxu2K4uNAMTz0XdLedDO3z1ngOM_sXZ60OifnUtTniVw)

- Buying a Forklift: The Ultimate Guide to Making the Right Decision (https://conger.com/forklift-buying-guide)

- Your Equipment Finance Revolution Begins Here | Meridian (https://meridianleasing.com/resources/blog/your-forklift-buying-guide)