Key Highlights:

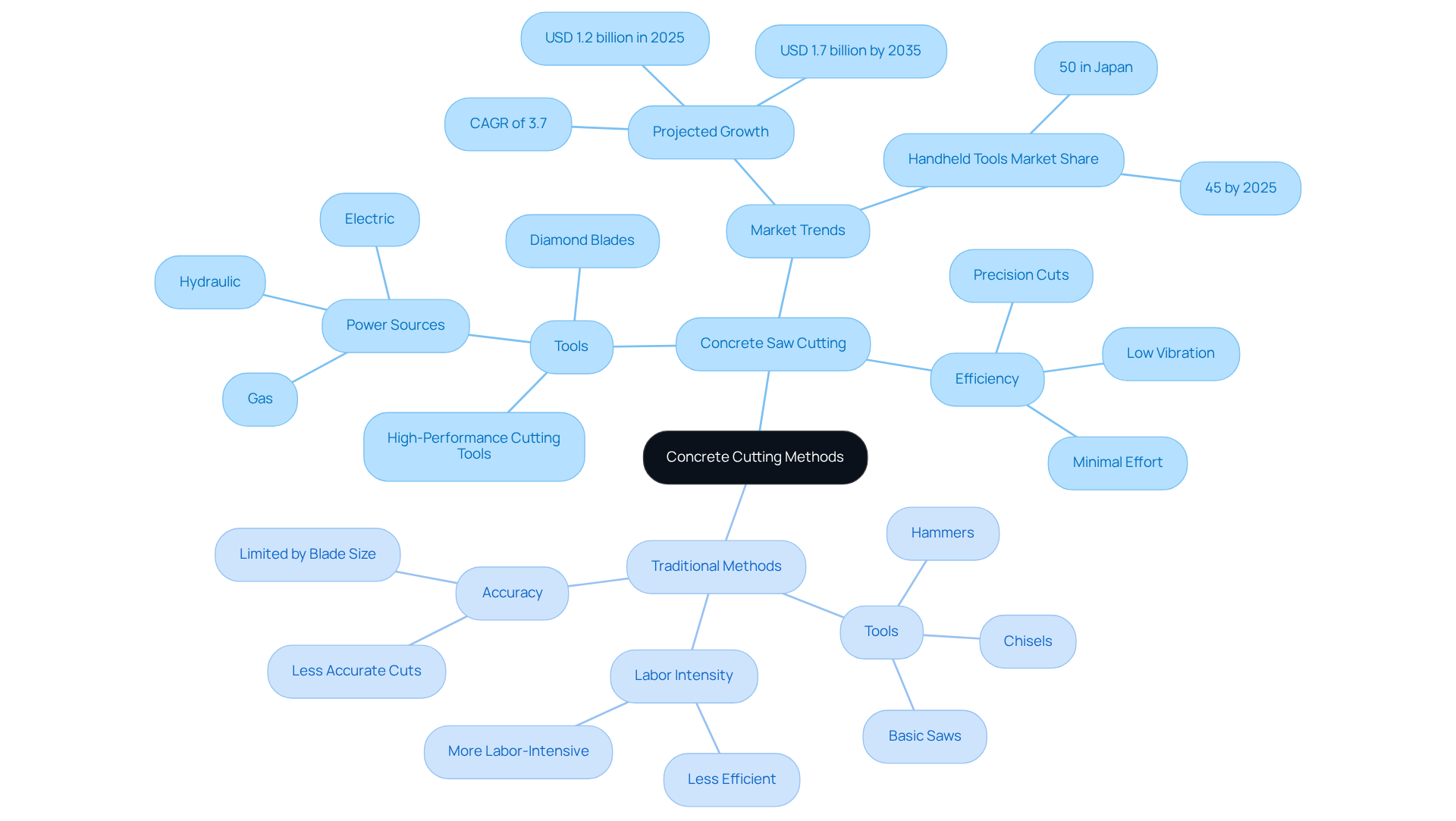

- Concrete saw cutting uses specialised tools with diamond blades for precise and efficient cuts, powered by electricity, gas, or hydraulics.

- The concrete saw rental market is projected to grow from USD 1.2 billion in 2025 to USD 1.7 billion by 2035, with handheld tools dominating the market.

- Traditional methods involve manual tools like chisels and hammers, which are labour-intensive and less accurate compared to concrete saw cutting.

- Advantages of concrete saw cutting include precision, efficiency, and versatility, making it suitable for large-scale and complex projects.

- Drawbacks of concrete saw cutting include high initial costs, noise, and dust generation.

- Traditional cutting methods have lower initial costs and are simpler to use but are labour-intensive and less precise.

- Concrete saw cutting is ideal for large-scale projects and intricate cuts, while traditional methods are better for small repairs and DIY projects.

- Cost implications for concrete saw cutting include equipment, operational, and labour costs, while traditional methods have lower equipment costs but higher labour costs due to time consumption.

Introduction

Concrete cutting plays a crucial role in construction, significantly affecting project efficiency and precision. As the industry progresses, the discussion surrounding concrete saw cutting versus traditional methods becomes increasingly relevant, presenting a vital decision for builders and contractors. This article examines the advantages and disadvantages of both techniques, assessing their appropriateness for different projects while considering the financial implications that can greatly influence decision-making.

Which method will prove most effective for specific construction needs? How can stakeholders effectively navigate the complexities of cost, efficiency, and precision?

Define Concrete Saw Cutting and Traditional Methods

Concrete saw cutting involves specialized tools that are designed to cut through concrete, masonry, and other hard materials. This method typically utilizes diamond blades or high-performance cutting tools for concrete saw cutting, enabling precise and efficient cuts. Concrete saw cutting tools can be powered by electricity, gas, or hydraulics, allowing for deep cuts with minimal effort. The concrete saw rental market is projected to grow from USD 1.2 billion in 2025 to USD 1.7 billion by 2035, reflecting a compound annual growth rate (CAGR) of 3.7% during this period. Handheld cutting tools are expected to dominate, capturing a 45% market share by 2025, and they currently represent 50.0% of the Japanese market, underscoring their significance in the global landscape.

In contrast, conventional techniques for shaping concrete often rely on hand tools such as chisels, hammers, or basic saws. These methods tend to be more labor-intensive and may result in less accurate cuts. Traditional slicing techniques might involve scoring the surface with a chisel or using a hand saw, which can be effective for smaller tasks but generally lack the efficiency and precision of concrete saw cutting.

Understanding these definitions is crucial for evaluating the effectiveness and applicability of each approach in various construction scenarios. As noted by Fine Cut Concrete Drilling & Sawing:

- "At Fine Cut Concrete Drilling & Sawing, we use both approaches depending on the material, location, and scope of work."

This perspective emphasizes the importance of selecting the appropriate slicing technique based on specific project requirements.

Compare Advantages and Disadvantages of Each Method

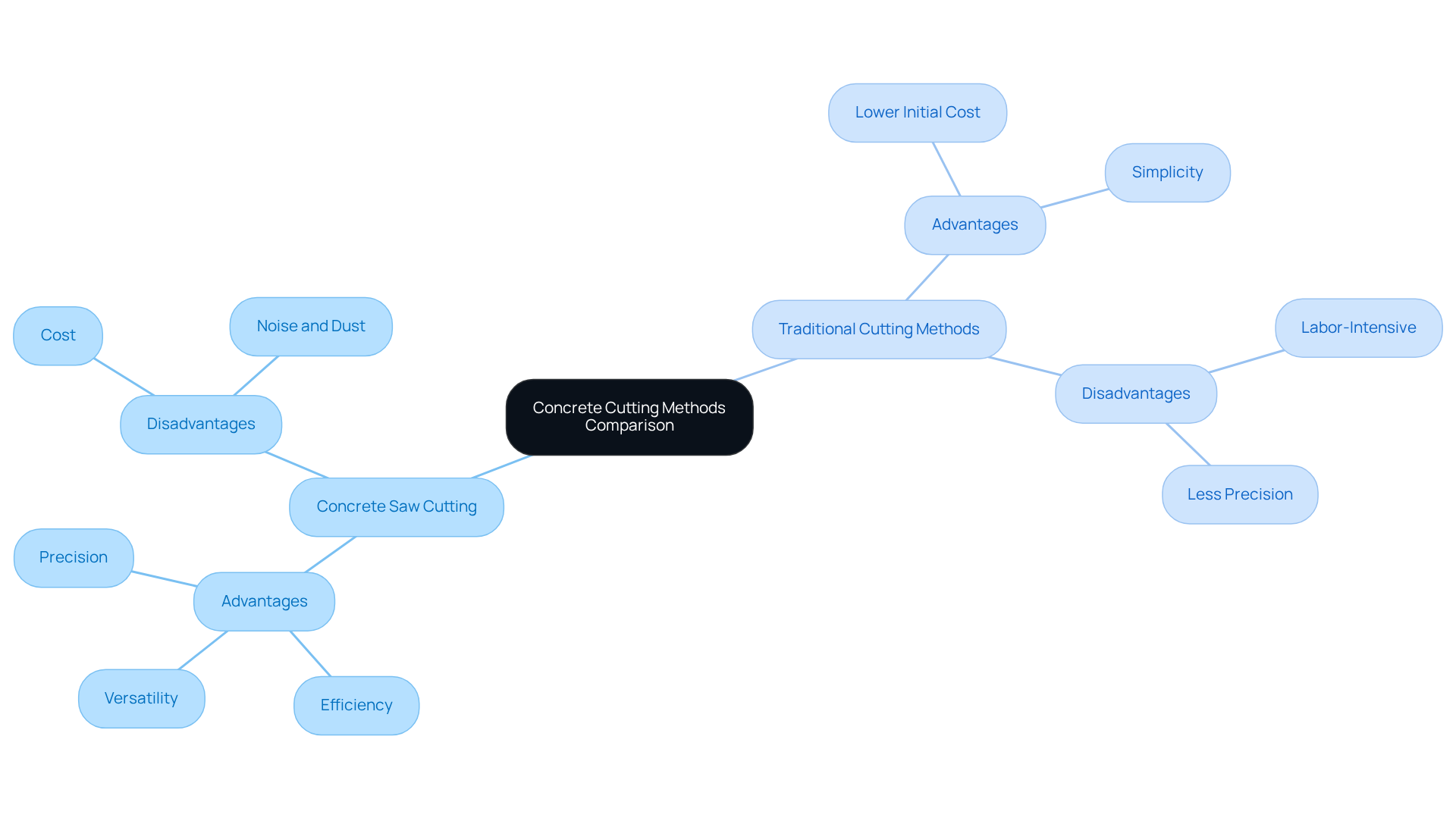

Concrete saw cutting offers several advantages that make it a preferred choice for many construction projects:

- Precision: By utilizing diamond blades, concrete saws provide clean and accurate cuts, which are crucial for projects that demand tight tolerances. This precision minimizes the risk of structural issues, particularly when sawing near reinforcement bars or load-bearing elements. The importance of accuracy in these techniques is underscored when interacting with structural components.

- Efficiency: Capable of swiftly cutting through thick materials, concrete cutting tools significantly reduce labor time, thereby enhancing on-site productivity. Early saw cuts in new slabs help control cracking and maintain structural integrity, showcasing the preventative benefits of this method.

- Versatility: These saws are adaptable for various applications, including wall sawing, slab sawing, and intricate cuts, making them suitable for both renovation and new construction tasks.

Despite these benefits, concrete saw cutting does have its drawbacks:

- Cost: The initial investment in high-quality equipment can be substantial, and ongoing maintenance costs may accumulate, impacting overall project budgets.

- Noise and Dust: This method generates considerable noise and dust, which can be disruptive in residential areas or sensitive environments, necessitating additional measures for dust control and noise reduction. The environmental impact of dust produced during concrete processing is a significant concern that should be addressed.

In contrast, traditional cutting methods present their own advantages:

- Lower Initial Cost: Manual tools typically require a smaller upfront investment, making them accessible for smaller projects or budgets.

- Simplicity: These techniques are often easier to learn and apply, particularly for small-scale tasks where precision is less critical.

However, traditional methods also come with notable disadvantages:

- Labor-Intensive: They demand more physical effort and time, potentially leading to higher labor costs and extended project timelines.

- Less Precision: Manual trimming can result in uneven edges and inaccuracies, especially in larger projects, which may necessitate additional finishing work.

Furthermore, consulting engineers when there is any uncertainty regarding load or prestressing is vital, especially when working near load-bearing elements. This consideration enriches the discussion about the risks associated with both approaches.

This comparison emphasizes the importance of selecting the appropriate cutting technique based on specific requirements, balancing cost, efficiency, and precision.

Evaluate Suitability for Various Construction Projects

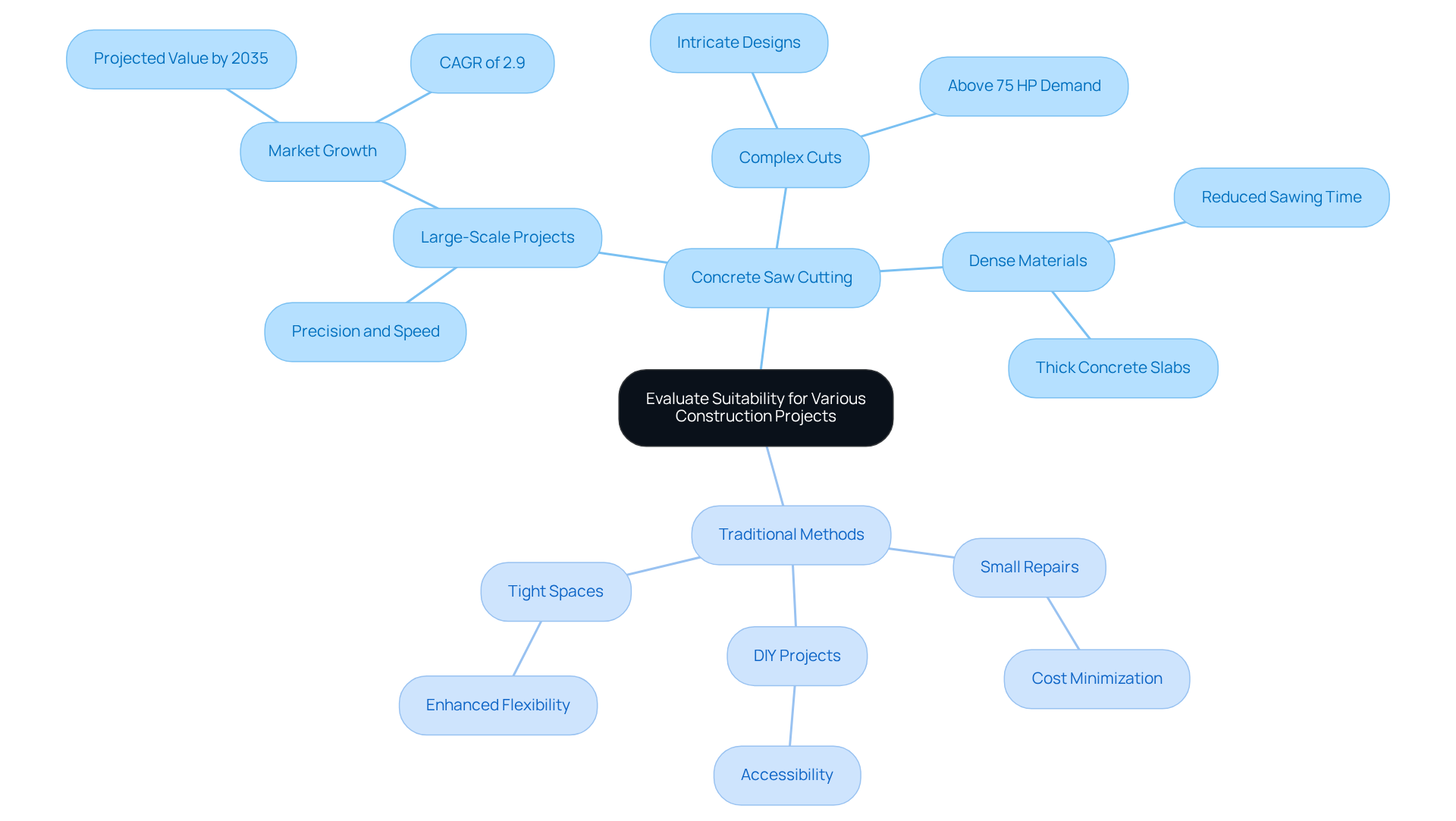

Concrete saw cutting excels in several key areas that are essential for construction projects.

Large-Scale Projects: This method is particularly well-suited for commercial buildings and infrastructure work, where precision and speed are essential. The concrete saw market is projected to grow significantly, reaching USD 725.3 million by 2035, with a compound annual growth rate (CAGR) of 2.9%. This growth is driven by increased investments in infrastructure, which highlights the importance of reliable tools for concrete saw cutting in large-scale applications.

Complex Cuts: For tasks that require intricate designs or specific angles, concrete cutting tools deliver the precision necessary to achieve high-quality results. Insights from a case study on the rise of above 75 HP concrete saw cutting indicate a growing demand for powerful saws in large-scale infrastructure projects, further emphasizing their effectiveness in complex cutting scenarios.

When dealing with dense materials such as thick concrete slabs or walls, concrete saw cutting often proves to be the most effective approach. This method significantly reduces sawing time compared to conventional techniques, making it a preferred choice for heavy-duty applications.

Conversely, traditional methods may be more suitable for certain situations:

-

Small Repairs: For minor renovations or repairs where precision is less critical, traditional methods can effectively minimize costs. These techniques are often sufficient for straightforward tasks that do not require advanced equipment.

-

DIY Projects: Homeowners or small contractors frequently opt for manual tools for simple tasks due to their lower cost and ease of use. Statistics indicate that a considerable share of DIY endeavors employs conventional techniques, underscoring their accessibility and practicality.

-

Tight Spaces: In scenarios where maneuverability is limited, conventional techniques offer enhanced flexibility, allowing for efficient slicing in restricted areas.

By thoroughly assessing the appropriateness of each slicing method, construction experts can align their techniques with the specific requirements of their projects, ensuring optimal results.

Analyze Cost Implications of Each Cutting Method

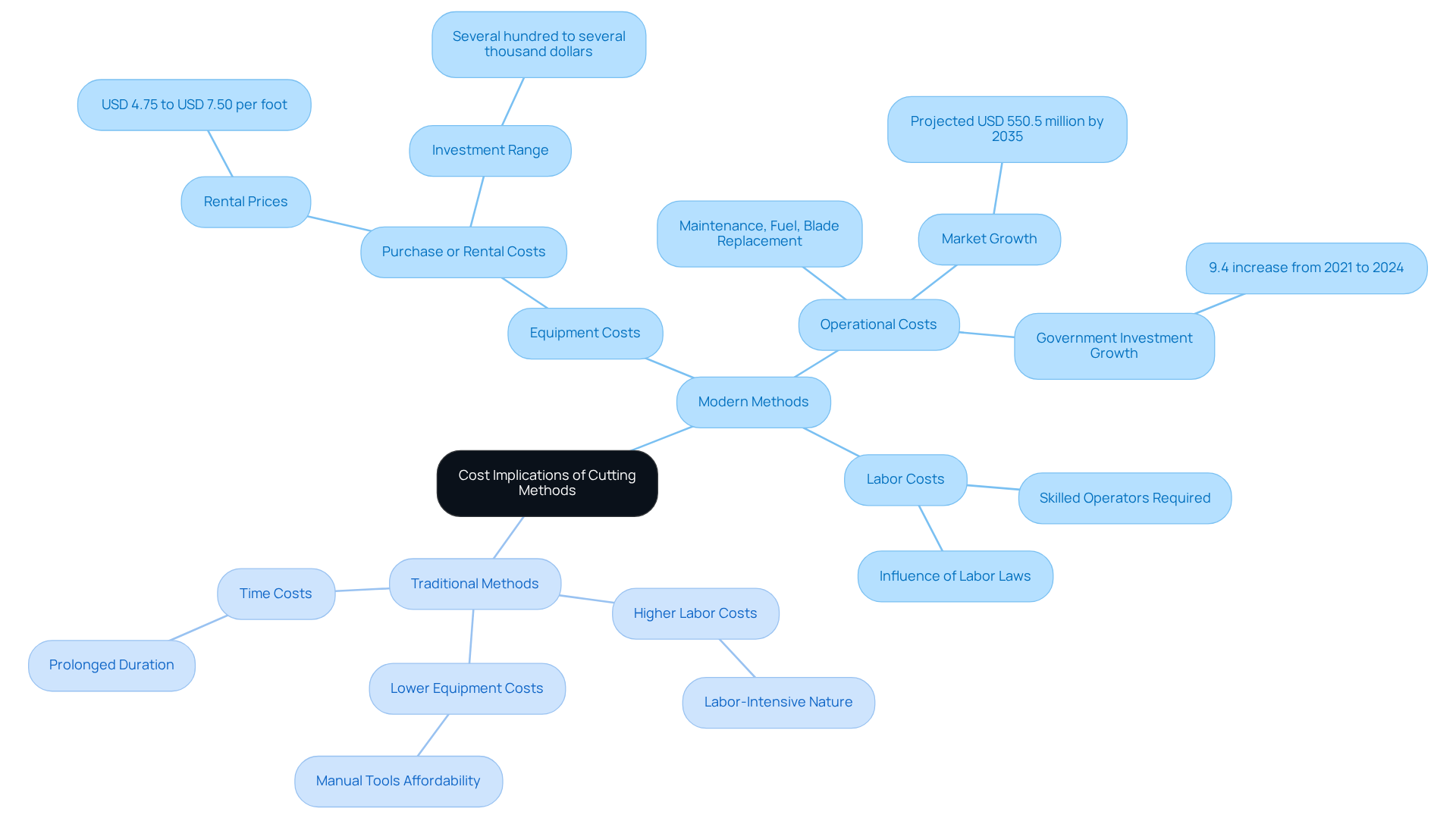

When evaluating the cost implications of concrete saw cutting, several critical factors must be considered:

-

Equipment Costs: The investment in concrete saws, whether through purchase or rental, can vary significantly. Prices typically range from several hundred to several thousand dollars, depending on the saw's type and capabilities. For instance, rental expenses for concrete saw cutting equipment can range from USD 4.75 to USD 7.50 per foot of cutting, making it essential to evaluate the project's scale and duration.

-

Operational Costs: Ongoing expenses such as maintenance, fuel, and blade replacement contribute to the overall cost. The concrete chain saw market is anticipated to attain USD 550.5 million by 2035, indicating the increasing demand for effective slicing solutions that balance operational costs with performance. Additionally, the U.S. government's investment in infrastructural development is projected to grow by 9.4% from 2021 to 2024, which may further influence operational costs in the sector.

-

Labor Costs: While concrete saw cutting can significantly reduce labor time, it often necessitates hiring skilled operators, which can increase initial expenses. The demand for skilled labor in this sector is influenced by the complexity of the tasks and the need for precision. Legal factors, such as changes in labor laws, can also influence labor costs and the availability of skilled workers, thereby affecting overall expenses in concrete saw cutting.

In contrast, traditional cutting methods present a different financial landscape:

-

Lower Equipment Costs: Manual tools are generally more affordable, making them accessible for smaller projects. This lower initial investment can be appealing for budget-conscious contractors.

-

Higher Labor Costs: The labor-intensive nature of traditional methods often leads to increased costs, particularly for larger jobs. The extended duration needed for manual slicing can result in increased overall expenses, as labor costs accumulate.

-

Time Costs: The prolonged duration of manual cutting not only influences labor expenses but can also postpone schedules, affecting overall efficiency and budget.

By thoroughly analyzing these cost implications, project managers can make informed decisions that align with their budgetary constraints and project objectives, ensuring optimal resource allocation and project success.

Conclusion

Concrete saw cutting and traditional methods present unique advantages and disadvantages that can significantly influence construction project outcomes. Understanding these differences enables stakeholders to make informed decisions tailored to their specific project needs. Concrete saw cutting is distinguished by its precision, efficiency, and versatility, making it particularly suitable for large-scale and complex tasks. Conversely, traditional methods, while often more accessible and cost-effective for smaller projects, may lack the accuracy and labor efficiency that concrete saw cutting provides.

This article underscores key insights, including:

- The expanding market for concrete saw cutting

- The necessity of selecting the appropriate method based on project requirements

- The financial implications associated with each approach

Concrete saw cutting is increasingly preferred for its capacity to deliver high-quality results swiftly, while traditional techniques continue to hold relevance for simpler tasks and DIY projects. Striking a balance between cost, efficiency, and precision is essential in determining the most suitable cutting method for any given scenario.

Ultimately, the decision between concrete saw cutting and traditional methods should be guided by the specific demands of the project at hand. As construction practices evolve, adopting the right technology and techniques will not only enhance productivity but also contribute to successful project completion. Stakeholders are encouraged to carefully assess their project requirements and consider the implications of their chosen cutting method, paving the way for smarter, more efficient construction practices.

Frequently Asked Questions

What is concrete saw cutting?

Concrete saw cutting is a method that involves specialized tools designed to cut through concrete, masonry, and other hard materials, utilizing diamond blades or high-performance cutting tools for precise and efficient cuts.

What types of power sources are used for concrete saw cutting tools?

Concrete saw cutting tools can be powered by electricity, gas, or hydraulics, allowing for deep cuts with minimal effort.

What is the projected growth of the concrete saw rental market?

The concrete saw rental market is projected to grow from USD 1.2 billion in 2025 to USD 1.7 billion by 2035, reflecting a compound annual growth rate (CAGR) of 3.7% during this period.

What is the market share of handheld cutting tools in concrete saw cutting?

Handheld cutting tools are expected to dominate the market, capturing a 45% market share by 2025, and currently represent 50.0% of the Japanese market.

How do traditional concrete cutting methods differ from concrete saw cutting?

Traditional methods for shaping concrete rely on hand tools such as chisels, hammers, or basic saws, which are more labor-intensive and may result in less accurate cuts compared to concrete saw cutting.

What are some examples of traditional slicing techniques?

Traditional slicing techniques might involve scoring the surface with a chisel or using a hand saw, which can be effective for smaller tasks but generally lack the efficiency and precision of concrete saw cutting.

Why is it important to understand the differences between concrete saw cutting and traditional methods?

Understanding these definitions is crucial for evaluating the effectiveness and applicability of each approach in various construction scenarios, allowing for better selection based on specific project requirements.

List of Sources

- Define Concrete Saw Cutting and Traditional Methods

- Concrete Saw Market Growth & Forecast 2025-2035 (https://futuremarketinsights.com/reports/concrete-saw-market)

- Concrete Saw Rental Market | Global Market Analysis Report - 2035 (https://factmr.com/report/concrete-saw-rental-market)

- Concrete Wire Sawing vs. Traditional Concrete Cutting (https://finecutusa.com/concrete-wire-sawing-vs-traditional-concrete-cutting-which-is-better-for-your-project)

- Compare Advantages and Disadvantages of Each Method

- Why Concrete Saw Cutting Matters for Structural Integrity (https://diamondcutandcore.com/how-critical-is-concrete-saw-cutting-for-structural-integrity)

- The Global Cut-off Concrete Saw Market Trends, Applications, and Forecast at a 7.4% CAGR from 2026 to 2033 (https://linkedin.com/pulse/global-cut-off-concrete-saw-market-trends-applications-z7dje)

- Concrete Cutting Pros and Cons: What You Need to Know (https://alsarhtechnicalservices.com/blog/concrete-cutting-pros-and-cons-what-you-need-to-know)

- Concrete Saw Market Growth & Forecast 2025-2035 (https://futuremarketinsights.com/reports/concrete-saw-market)

- 10 Reasons to Leave Concrete Slab Cutting and Core Drilling to the Professionals - National Concrete Cutting Inc. (https://nationalconcrete.ca/choose-a-professional-concrete-cutter)

- Evaluate Suitability for Various Construction Projects

- Demolition Projects Involving Concrete Cutting Specialists (https://interstatesawing.com/3-demolition-projects-that-may-involve-concrete-cutting-specialists)

- Concrete Saw Market Growth & Forecast 2025-2035 (https://futuremarketinsights.com/reports/concrete-saw-market)

- Pile-Cut | Case Studies | Wheatway Solutions (https://wheatway.com/case-studies/pile-cut)

- Selective Demolition Case Studies | Cutting Technologies (https://cuttingtechnologies.com/case-studies)

- Analyze Cost Implications of Each Cutting Method

- Concrete Cutting Service Market Report | Global Forecast From 2025 To 2033 (https://dataintelo.com/report/concrete-cutting-service-market)

- Concrete Cutting Market Size, Share, Forecast | Growth [2034] (https://fortunebusinessinsights.com/concrete-cutting-market-104740)

- Cut off Concrete Saw Market Analysis 2026, Market Size, Share, Growth, CAGR, Forecast, Trends, Revenue, Industry Experts, Consultation, Online/Offline Surveys, Syndicate Reports (https://cognitivemarketresearch.com/cut-off-concrete-saw-market-report)

- Concrete Chain Saw Market | Global Market Analysis Report - 2035 (https://futuremarketinsights.com/reports/concrete-chain-saw-market)

- Concrete Cutting Saw Consumer Trends: Insights and Forecasts 2026-2034 (https://datainsightsmarket.com/reports/concrete-cutting-saw-23432)