Overview

This article highlights essential best practices for engine cherry picker rental, underscoring the critical importance of safety and efficiency in their operation. It presents vital guidelines, including operator training, regular inspections, and pre-operation checks. These measures are crucial for preventing accidents and ensuring reliable performance in construction and maintenance tasks.

Operator training is paramount; it ensures that individuals are well-equipped to handle the equipment safely. Regular inspections further enhance safety by identifying potential issues before they escalate. Pre-operation checks serve as a final safeguard, confirming that all systems are functioning correctly before use. By adhering to these practices, operators can foster a safer working environment.

In addition, implementing these best practices not only mitigates risks but also enhances productivity. Reliable equipment performance translates to fewer delays and increased efficiency on the job site. Therefore, it is imperative for rental companies and operators alike to prioritize these safety measures.

Furthermore, testimonials from satisfied customers underscore the effectiveness of these practices. Many have reported improved safety records and enhanced operational efficiency as a direct result of following these guidelines. Such feedback reinforces the necessity of a proactive approach to equipment rental and operation.

In conclusion, adhering to these essential best practices is not just a recommendation; it is a vital component of successful engine cherry picker rental. By committing to safety and efficiency, operators can ensure optimal performance and reliability in their construction and maintenance endeavors.

Key Highlights:

- Engine cherry pickers, also known as aerial or boom lifts, are essential for safely elevating workers in construction and maintenance tasks.

- The aerial lift forklift market is projected to grow at a CAGR of over 8.2% from 2025 to 2037 due to increased infrastructure maintenance needs.

- Three main types of cherry pickers include articulating boom lifts (for maneuverability), telescopic boom lifts (for height), and straight boom lifts (for reliability).

- Safety is paramount, with guidelines emphasizing operator training and adherence to protocols to prevent accidents.

- Regular inspections of key components like outriggers and safety features are crucial for ensuring equipment reliability and operator safety.

- Pre-operation safety checks must include examining for visible damage and confirming the functionality of protective features.

- Operators should maintain three points of contact when entering or exiting the lift to prevent falls.

- Effective maneuvering techniques involve slow speeds, awareness of surroundings, and proper use of outriggers for stability.

- The cherry picker rental market, particularly in the DFW area, is expected to grow, highlighting the importance of reliable local rental firms like EZ Equipment Rental.

- Customer satisfaction ratings are vital for assessing rental companies, with feedback emphasizing the importance of equipment reliability and service quality.

Introduction

In the construction and maintenance sector, cherry pickers are indispensable tools that elevate both workers and productivity to new heights. These versatile machines, also referred to as aerial lifts or boom lifts, are engineered to tackle a myriad of tasks, from electrical installations to tree trimming, all while ensuring safety and efficiency.

With the demand for these innovative devices projected to grow remarkably in the coming years, it is imperative for industry professionals to understand their applications, types, and operational best practices. This article explores the various aspects of cherry pickers, providing insights into their functionality, safety protocols, and the key components that ensure optimal performance on the job site.

Whether renting equipment or managing a project, grasping the nuances of cherry pickers can lead to enhanced operational success and safety.

Understanding Cherry Pickers: Definition and Applications

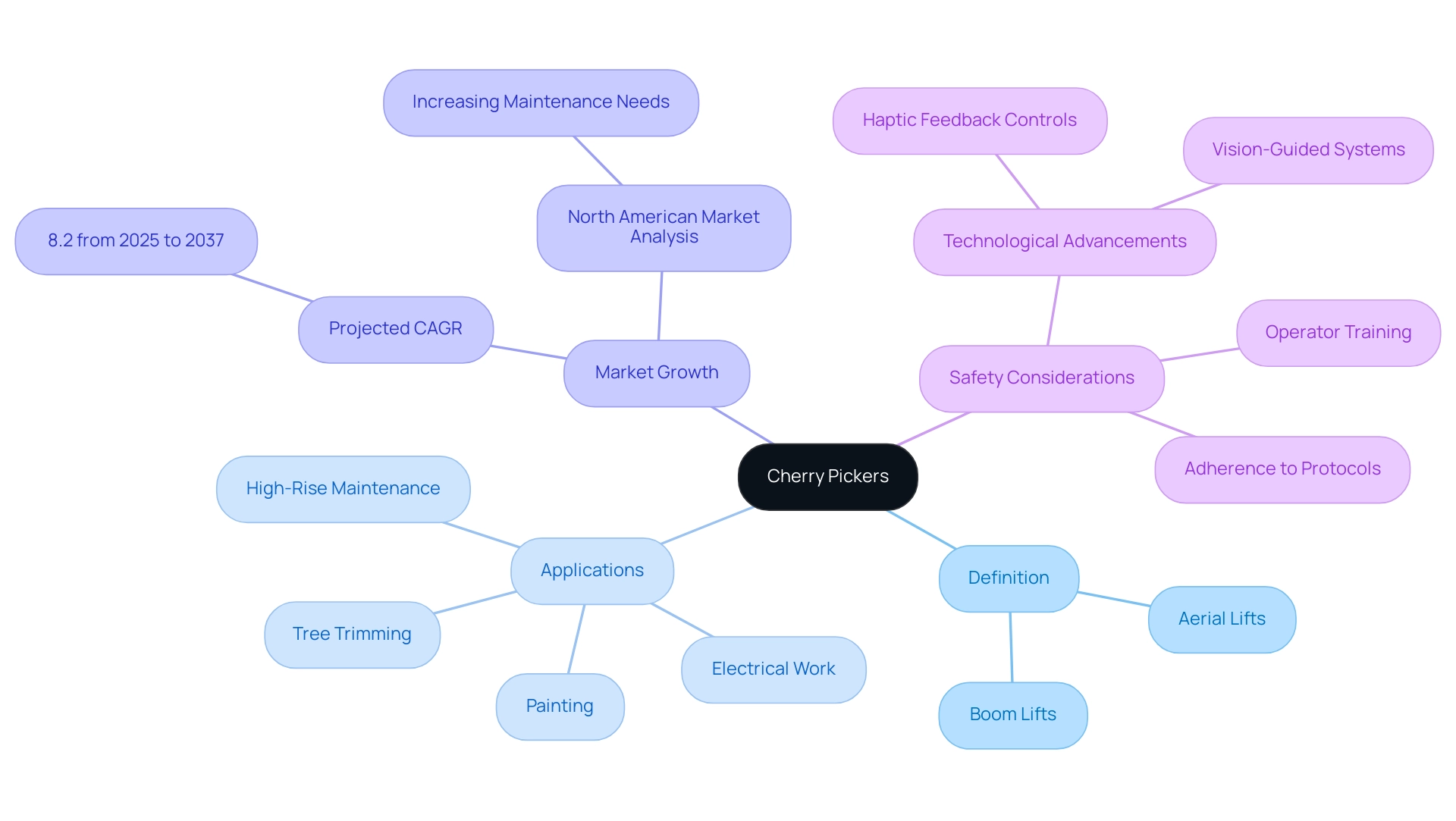

Engine cherry picker rental provides essential tools, commonly known as aerial lifts or boom lifts, specifically designed to safely elevate workers to significant heights in the construction and maintenance sectors. Their versatility allows for a wide range of applications, such as electrical work, painting, and tree trimming, making them invaluable for tasks that necessitate access to elevated areas. With the aerial lift forklift market projected to grow at a compound annual growth rate (CAGR) of over 8.2% from 2025 to 2037, the demand for these machines is on the rise, driven by increasing infrastructure maintenance and renovation needs.

In 2025, fruit harvesters will play a crucial role in various industrial applications, particularly in construction endeavors where safety and productivity are critical. Experts emphasize that modern fruit harvesters are not merely lifts; they are integral to operational efficiency. As the Technology Director at Redway Logistics notes, "Modern order selectors aren’t just lifts—they’re data hubs."

Our clients at Redway experience 34% accuracy improvements with vision-guided systems that automatically identify SKUs. Safety remains paramount; we are currently testing haptic feedback controls to mitigate overreach incidents. This underscores the technological advancements that enhance accuracy in material handling.

Practical examples demonstrate the efficiency of aerial lifts in maintenance projects. For instance, during a recent infrastructure enhancement, a construction crew utilized aerial lifts to replace high-rise building facades, significantly reducing the time and risks associated with traditional scaffolding techniques. This case aligns with the North American aerial lift forklift market analysis, which indicates substantial growth due to the rising number of buildings requiring maintenance and remodeling.

Safety is a critical consideration when utilizing engine cherry picker rental. Aerial lift guidelines for 2025 stress the importance of operator training and adherence to protocols to prevent accidents. As the industry evolves, ongoing research into operator behavior and technological advancements in mobile elevating work platforms (MEWPs) will further enhance safety measures and operational efficiency.

In conclusion, grasping the definition and applications of engine cherry picker rental is vital for construction project managers. By selecting the appropriate equipment and following safety guidelines, teams can ensure successful project outcomes while maximizing productivity.

Exploring Different Types of Cherry Pickers for Rental

Cherry lifters are available in various configurations, each specifically designed to meet distinct operational needs. The three primary types include articulating boom lifts, telescopic boom lifts, and straight boom lifts.

Articulating boom lifts stand out for their ability to navigate around obstacles effectively, thanks to their jointed arms. This flexibility makes them ideal for intricate job sites where maneuverability is crucial, ultimately enhancing overall construction productivity. In contrast, telescopic boom lifts provide a straight reach, making them the preferred choice for tasks that demand maximum height and straightforward access.

Their design facilitates efficient vertical lifting, essential for construction and maintenance projects, streamlining tasks and contributing to timely project completion. Straight boom lifts, characterized by their simple design, offer reliable vertical access for tasks that do not require the intricate maneuverability of articulating models. Each variety serves a distinct function, and understanding these distinctions is vital for selecting the appropriate lift to ensure both safety and efficiency on the job site.

As the aerial lift market continues to evolve, technological advancements such as automation and telematics are enhancing machine functionality, making these lifts even more effective. According to Vinayak Bali, the worldwide crane market for fruit harvesting is projected to expand from $4,350.2 million in 2025 to $7,092.11 million by 2033, indicating a substantial rise in demand.

The North American aerial lift forklift market is expected to grow considerably, driven by the increasing demand for upkeep and renovation of structures, as highlighted in the case study titled 'North American Aerial Lift Forklift Market Analysis.' This underscores the ongoing need for high-access equipment, which is essential for both construction and maintenance projects.

In 2025, the market share for articulating boom lifts is anticipated to reflect their versatility, while telescopic boom lifts will continue to be favored for high-reach applications. This growth trajectory emphasizes the importance of selecting the appropriate type of aerial lift based on the specific needs of each project, ensuring optimal performance and enhanced security. For dependable aerial lift rentals, consider EZ Equipment Rental in Dallas, TX, particularly for your engine cherry picker rental to meet your project requirements efficiently.

Key Components of Cherry Pickers: What to Look For

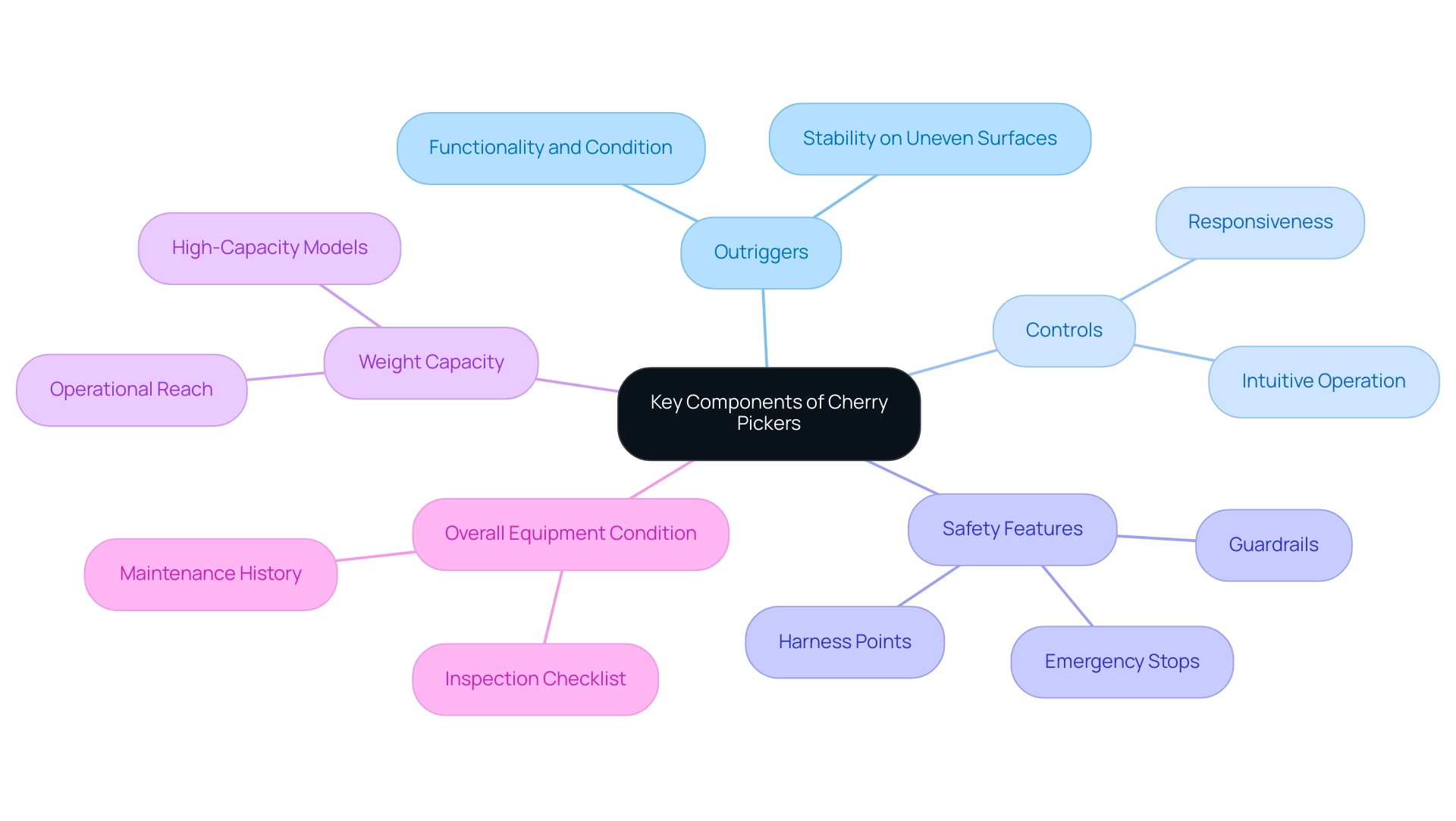

When leasing a lifting platform, conducting a thorough inspection of its crucial parts is essential for ensuring security and effectiveness. Start by assessing the outriggers, which are vital for providing stability on uneven surfaces. Sturdy outriggers significantly reduce the likelihood of tipping—a common failure point in aerial work platforms.

Furthermore, intuitive controls are necessary for smooth operation, enabling operators to maneuver the equipment with precision. Safety features must not be overlooked; emergency stop buttons, guardrails, and harness attachment points are critical for protecting operators during use. In fact, statistics indicate that fruit harvesters equipped with advanced safety features experience a lower incident rate, underscoring the importance of these components in preventing accidents. For context, conventional single-pick rounds had an average travel distance of 251.00 feet with a standard deviation of 47.75 feet, highlighting the productivity improvements achievable with well-maintained machinery.

Understanding the weight capacity and reach of the aerial lift is equally important. High-capacity models, such as telehandlers, can reduce turnaround times by up to 50%, making them ideal for demanding tasks. However, if the equipment does not meet the job's specific requirements, it can lead to inefficiencies and potential hazards.

A thorough inspection checklist for aerial lifts in 2025 should include:

- Outrigger functionality and condition

- Control system responsiveness

- Safety feature integrity (emergency stops, guardrails, harness points)

- Weight capacity and operational reach

- Overall equipment condition and maintenance history

Real-world examples underscore the necessity of these inspections. In shipping yards, for example, upgrading to contemporary aerial lifts with GPS tracking and real-time load monitoring has proven crucial for enhancing operational productivity and maintaining competitiveness. The case study on performance enhancement in shipping yards illustrates that such upgrades not only improve security but also contribute to overall productivity.

Experts emphasize that regular evaluations of lift components are a best practice for any construction project manager, aligning with EZ Equipment Rental's commitment to customer satisfaction and quality service.

Pre-Operation Safety Checks: Ensuring Equipment Readiness

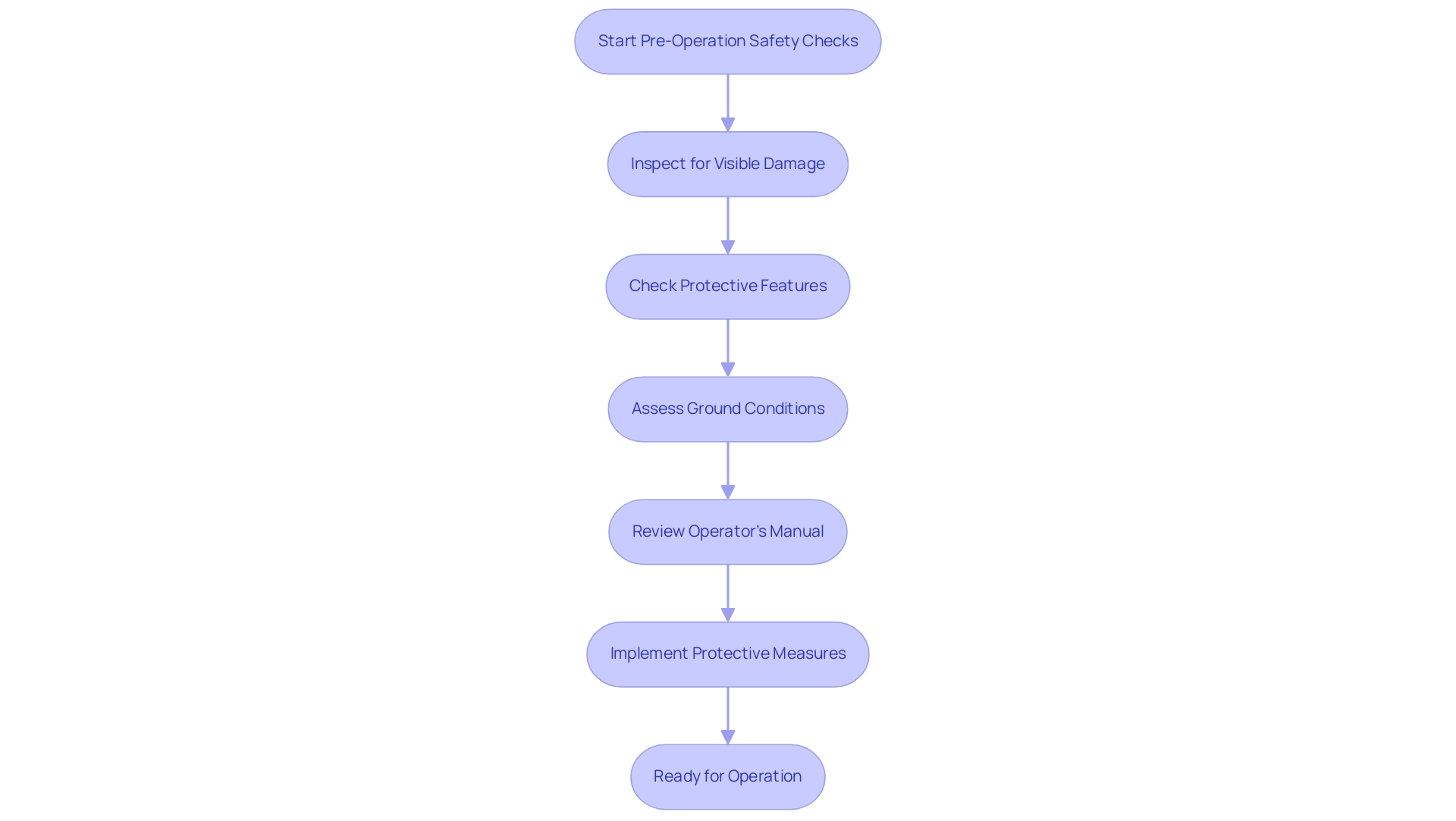

Before utilizing an aerial lift, conducting comprehensive pre-operation inspections is essential for ensuring both safety and effectiveness. Start by examining the machine for any visible damage, such as leaks or worn-out components. It is crucial to confirm that all protective features are functioning properly, including harness attachment points and emergency stop buttons.

Additionally, assess ground conditions to ensure stability, verifying that the engine cherry picker rental is placed on a level surface to prevent tipovers—an occurrence that statistics indicate is common when the equipment is extended beyond 15 feet.

Reviewing the operator's manual for specific pre-operation guidelines further enhances security and preparedness for use. According to the CPWR – Center for Construction Research and Training, implementing essential protective measures, such as maintaining a safe distance from live power lines and using insulated tools, significantly mitigates the risk of accidents and fatalities associated with aerial lift operations. The case study titled "Safety Recommendations for Aerial Lift Operations" underscores that these measures are vital for preventing electrocutions and accidents, thereby enhancing worker protection in the construction industry.

Common issues identified during engine cherry picker rental inspections in 2025 include hydraulic leaks, malfunctioning protective features, and improper setup on uneven terrain. Experts emphasize that thorough pre-operation inspections are imperative to minimize these risks. As Mike James, an independent content writer, notes, "Health and risk training, including specific working at height training, is clearly essential."

This observation highlights the necessity of preparing operators not only for static equipment but also for the unique challenges posed by moveable elevated platforms like cherry pickers. The connection between comprehensive training and effective checks cannot be overstated, as it is vital for secure operation and adherence to safety precautions.

Integrating these practices not only ensures compliance with regulations but also fosters a culture of safety within the workplace, ultimately enhancing worker protection and operational effectiveness.

Operating a Cherry Picker: Step-by-Step Guide

Utilizing an engine cherry picker rental requires adherence to a series of essential steps to guarantee both security and efficiency. Begin by donning all necessary protective gear, including a harness that is securely attached to the designated anchor points on the machine. This precaution is vital for preventing falls and ensuring worker safety.

Next, engage the parking brake and start the machine, strictly following the manufacturer's operational guidelines. Familiarize yourself with the controls before proceeding. When raising the platform, do so slowly and with caution, maintaining constant awareness of your surroundings and any potential hazards, such as overhead power lines, which pose significant risks of electrocution and serious injury. Recognizing these hazards is crucial, as they are a leading cause of accidents in aerial lift operations.

Moreover, it is imperative to maintain three points of contact when entering or exiting the basket. This practice significantly mitigates the risk of falls. Once your work is complete, lower the platform fully before shutting down the machine to ensure stability and security.

In 2025, accident rates during lift operations underscore the importance of these protective measures, emphasizing operational guidelines that encompass the manufacturer's manual and organizational risk management recommendations. A case study titled "Ignoring Operational Guidelines" illustrates that providing comprehensive hands-on training and certification for employees can enhance adherence to these guidelines, thereby reducing the likelihood of accidents. This reinforces the necessity of understanding and following operational protocols.

Furthermore, as noted by the Editorial Team, before using third-party rigging equipment, a thorough examination by a competent person is essential. This highlights the significance of guidelines in ensuring a secure working environment.

By adhering to these procedures and emphasizing the need for protective equipment, operators can guarantee a secure and efficient lift operation when using an engine cherry picker rental, contributing to a safer work atmosphere overall. Additionally, with the Cherry Picker Crane market projected to reach $594.585 Million in 2025, the importance of following best practices in this growing industry cannot be overstated.

Maneuvering Techniques: Navigating Your Cherry Picker Safely

Navigating a lift requires a cautious approach to ensure both safety and efficiency, particularly in busy or irregular settings. Operators must maintain a slow and controlled speed, which allows for improved reaction times to any potential hazards. Awareness of the surroundings is crucial; this includes monitoring overhead obstacles and the proximity of personnel.

Smooth operation of the machine's controls is essential to prevent abrupt movements that could destabilize the platform. When navigating slopes or uneven terrain, it is vital to deploy the outriggers correctly, as they provide crucial stability. Training programs emphasize that operators should be well-versed in identifying hazards and unsafe practices, empowering them to halt any unsafe activities immediately. As noted by aviation experts, while recent accidents are tragic, they may not indicate a broader safety problem but rather an unfortunate coincidence, underscoring the necessity for ongoing training and vigilance in operations.

Real-world examples illustrate the effectiveness of these techniques. For example, a case study titled "Using an Operated Lift Rental" demonstrated that certified operators, trained in safe navigation, significantly reduced the risks associated with operating lifts in busy work sites. Their focus on rapid service and 24-hour response times ensured that operations remained smooth and efficient. This case study reinforces the importance of having trained personnel who can navigate safely in crowded areas.

Statistics indicate that maneuvering accidents with aerial lifts are a concern, with a significant percentage occurring in crowded areas. The South Africa Cherry Picker Crane Market Sales Revenue is projected to reach $82.474 Million by 2025, highlighting the growing demand for safe and efficient operations in this sector. By adhering to best practices for engine cherry picker rental navigation, operators can effectively mitigate these risks.

Expert insights from trainers emphasize the importance of these techniques, especially in environments where space is limited. Applying these approaches not only enhances safety but also contributes to the overall effectiveness of operations across various sectors.

Utilizing the Lifting Mechanism: Maximizing Efficiency

Enhancing productivity with a lifting device hinges on a thorough understanding of its raising mechanism. Operators must familiarize themselves with the controls that govern the boom and platform; this knowledge is essential for executing smooth and precise movements. Adhering to the manufacturer's specified weight limits is non-negotiable; overloading the platform can result in serious safety violations and operational hazards.

To boost productivity, position the lift as close to the work zone as possible, thereby minimizing the distance the platform must cover. This strategic placement not only streamlines operations but also reduces the risk of accidents.

In 2025, the cherry picker forklift market is projected to reach a valuation of USD 42 billion, with expectations to double by 2035, reflecting a compound annual growth rate (CAGR) of 7.1%. This growth is primarily driven by increased adoption in sectors such as logistics and construction, where effective material handling solutions are crucial. The significance of forklifts and boom lifts in these sectors cannot be overstated, as they significantly enhance operational effectiveness and safety.

Furthermore, the lifting equipment market size is anticipated to reach $112.8 billion in 2029, with a CAGR of 5.9% during the forecast period. As the industry evolves, advancements in safety technologies will further enhance operational efficiency. Key participants in the aerial lift forklift market, including JLG Industries, Terex Corporation, and Haulotte Group, are at the forefront of these advancements, contributing to a more connected and safety-aware future.

Real-world examples underscore the effectiveness of these practices. For instance, construction crews that prioritize understanding lift controls report significantly improved task completion times and fewer instances of weight limit violations. As Brent Miller, Vice President of Sales Administration, Marketing & Latin America, states, "By embracing these trends, the access industry is poised for a more connected, productive, and safety-conscious future."

By implementing these best practices, operators can not only enhance productivity but also foster a safer work environment, aligning with the industry's shift towards more connected and safety-conscious operations. At EZ Equipment Rental, we offer a variety of aerial lift rental options, including towable models and engine cherry picker rentals, to improve the efficiency and safety of your construction projects.

Where to Rent a Cherry Picker: Local Options and Considerations

When evaluating engine cherry picker rental options, it is essential to focus on local equipment rental firms that specialize in these machines. A comprehensive examination of their inventory is vital to ensure they provide a diverse selection of lift types tailored to your specific project needs. Customer satisfaction ratings serve as a crucial indicator of reliability; thus, reviewing feedback and ratings can effectively assess the quality of both equipment and service.

In 2025, the aerial lift rental market in the DFW area is expected to undergo significant growth, reflecting a broader trend within the equipment rental sector. Notably, the South Africa Cherry Picker Crane Market Sales Revenue is projected to reach $82.474 Million by 2025, signaling a global trend that could influence local markets. According to industry insights from IBISWorld, local companies are increasingly prioritizing customer satisfaction, with many achieving high ratings for their service and equipment reliability.

When assessing potential rental companies, it is advisable to inquire about rental terms, including:

- Delivery options

- Maintenance support

- Safety training

Businesses such as EZ Equipment Rental in Irving, TX, stand out by offering a wide selection of machinery, including various types of aerial lifts, along with expert support. Their commitment to exceptional client service and assistance is evident, as they prioritize customer satisfaction through prompt delivery and maintenance, making them a leading choice for engine cherry picker rental in the DFW region.

Customer testimonials further reinforce the reliability of EZ Equipment Rental. For instance, one customer remarked, "The cherry picker we rented was in excellent condition, and the delivery was prompt. The team was very helpful in explaining how to operate the equipment safely."

Such feedback highlights the effectiveness and safety of the equipment, underscoring the importance of selecting a trustworthy rental company like EZ Equipment Rental. As you explore your options, consider expert recommendations for evaluating equipment rental services, particularly engine cherry picker rentals, to make informed decisions that enhance both safety and efficiency in your projects. For inquiries and reservations, customers can reach out to EZ Equipment Rental at (214) 951-7800, ensuring they have a reliable partner for their cherry picker rental needs.

Conclusion

Cherry pickers stand as critical assets in the construction and maintenance sectors, seamlessly combining safety, efficiency, and versatility to address a diverse array of tasks. Their applications—from electrical work to tree trimming—underscore their significance in modern project management. As the cherry picker market is projected to grow, industry professionals must remain informed about the various types available, including:

- Articulating lifts

- Telescopic lifts

- Straight boom lifts

Each type is tailored to meet distinct operational needs.

Equally crucial is the emphasis on safety and operational best practices. Conducting thorough pre-operation checks, comprehending the lifting mechanism, and adhering to established safety protocols are essential steps that safeguard both operator safety and equipment reliability. The insights presented here highlight the necessity of comprehensive training and awareness of hazards, which are paramount in navigating the complexities of aerial lift operations.

As the cherry picker market continues to expand, the demand for reliable rental options that prioritize customer satisfaction and safety also increases. Companies like EZ Equipment Rental exemplify the value of selecting reputable services that provide well-maintained equipment and knowledgeable support. By making informed choices, project managers can enhance operational efficiency while fostering a safer work environment.

Ultimately, the effective utilization of cherry pickers not only boosts productivity but also cultivates a culture of safety within the industry. As demand escalates, embracing best practices in equipment selection, operation, and maintenance will be vital for achieving successful project outcomes in the years ahead.

Frequently Asked Questions

What is an engine cherry picker rental?

Engine cherry picker rental provides essential aerial lifts or boom lifts designed to safely elevate workers to significant heights for various applications such as electrical work, painting, and tree trimming in the construction and maintenance sectors.

What is driving the demand for aerial lifts?

The demand for aerial lifts is projected to grow at a compound annual growth rate (CAGR) of over 8.2% from 2025 to 2037, driven by increasing infrastructure maintenance and renovation needs.

What are the primary types of cherry pickers available for rental?

The three primary types of cherry pickers are articulating boom lifts, telescopic boom lifts, and straight boom lifts, each designed for distinct operational needs.

What are the benefits of articulating boom lifts?

Articulating boom lifts have jointed arms that allow them to navigate around obstacles effectively, making them ideal for intricate job sites and enhancing overall construction productivity.

When would one choose a telescopic boom lift?

Telescopic boom lifts are preferred for tasks that demand maximum height and straightforward access due to their straight reach design.

What is the significance of straight boom lifts?

Straight boom lifts offer reliable vertical access for tasks that do not require the intricate maneuverability of articulating models, providing efficient vertical lifting.

How are technological advancements impacting aerial lifts?

Technological advancements such as automation and telematics are enhancing the functionality of aerial lifts, making them more effective for construction and maintenance projects.

Why is safety important when using engine cherry pickers?

Safety is critical when utilizing engine cherry pickers, with guidelines emphasizing operator training and adherence to protocols to prevent accidents.

What improvements in accuracy have been noted with modern fruit harvesters?

Clients at Redway experience a 34% accuracy improvement with vision-guided systems that automatically identify SKUs, highlighting the advancements in material handling technology.

How can selecting the appropriate equipment affect construction project outcomes?

By selecting the appropriate equipment and following safety guidelines, construction project managers can ensure successful project outcomes while maximizing productivity.