Overview

Slab scissor lifts serve as indispensable tools in construction, ensuring safe vertical access on flat surfaces while significantly enhancing efficiency and safety on job sites. Selecting the appropriate model tailored to project needs is crucial, as it directly impacts operational effectiveness. Furthermore, adhering to established safety guidelines is paramount; this not only protects workers but also fosters a culture of safety on-site.

Implementing best practices, such as:

- Regular maintenance

- Comprehensive operator training

is essential for maximizing productivity and minimizing risks. These practices ensure that equipment remains in optimal condition, reducing the likelihood of unexpected downtime. In addition, investing in operator training equips personnel with the necessary skills to handle the equipment safely and effectively, further enhancing overall job site safety.

In conclusion, the strategic selection of slab scissor lifts, combined with adherence to safety protocols and best practices, positions your project for success. Engage with our experts today to explore the best options for your specific needs and elevate your operational efficiency.

Key Highlights:

- Slab scissor lifts are designed for flat surfaces and can extend vertically, ideal for accessing elevated areas, especially in confined spaces.

- The market for slab scissor lifts is projected to grow due to infrastructure development, e-commerce, and government funding, with CanLift reporting a 100% growth rate over two years.

- Different models, such as Genie GS-1932 and JLG 1930ES, are tailored for specific operational needs, emphasizing the importance of choosing the right lift based on project requirements.

- Safety guidelines include pre-operation inspections, operator training, and compliance with regulations to reduce accident risks and enhance project efficiency.

- The integration of electric drive systems in slab scissor lifts reduces noise and emissions, making them suitable for indoor use and aligning with sustainability goals.

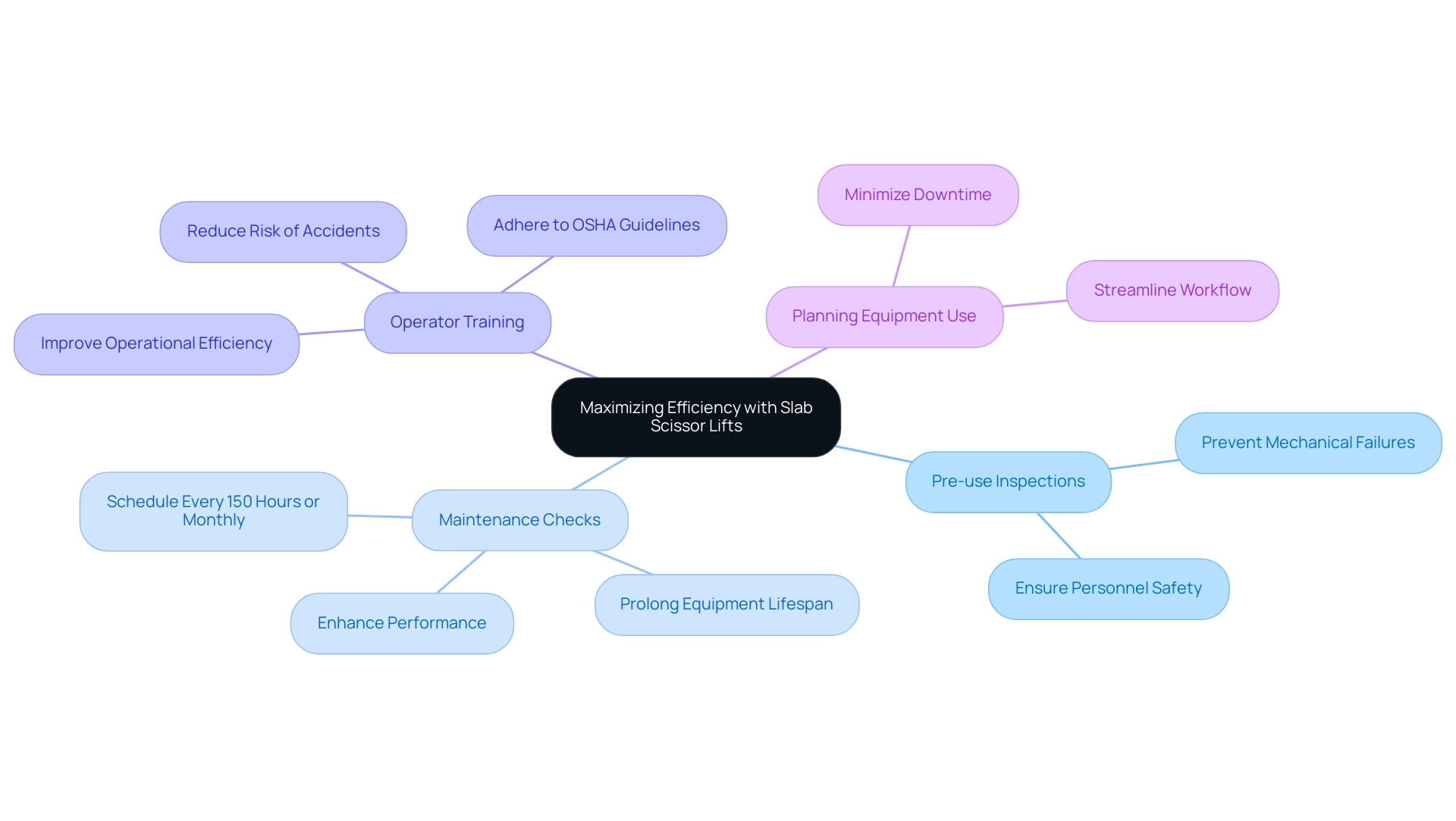

- Best practices for maximizing efficiency include regular maintenance checks, thorough training for operators, and effective planning of equipment use to minimize downtime.

Introduction

In the dynamic landscape of construction, slab scissor lifts have emerged as indispensable tools, fundamentally transforming project execution. Designed for operation on flat surfaces, these mobile elevating work platforms provide unparalleled access to elevated areas, making them particularly suitable for confined spaces and indoor environments.

As the demand for efficient construction solutions continues to grow, understanding the capabilities and applications of these lifts becomes increasingly significant. With the market projected to expand substantially in the coming years—driven by infrastructure development and technological advancements—project managers must remain informed about the latest models, safety practices, and best operational strategies.

This article delves into the essential features, real-world applications, and safety guidelines surrounding slab scissor lifts, equipping professionals with the knowledge necessary to enhance productivity and ensure safety on job sites.

Understanding Slab Scissor Lifts: An Overview

Slab scissor lifts represent a crucial advancement in mobile work platforms, expertly designed for operation on flat, stable surfaces, such as concrete. Their standout feature is the ability to extend vertically, empowering workers to safely access elevated areas. This capability proves especially beneficial in indoor environments and tight spaces, where maneuverability is paramount.

With their compact footprint, slab scissor lifts excel at navigating narrow aisles and confined job sites, rendering them indispensable for a variety of construction tasks. In fact, the market share of slab scissor lifts within the construction sector is projected to expand significantly by 2025. This growth is driven by rising infrastructure development, booming e-commerce activities, and substantial government funding for construction initiatives. Recent statistics reveal a notable surge in demand for slab scissor lifts, underscoring their vital role in enhancing productivity and safety on job sites. Notably, CanLift achieved an impressive 100% growth rate over two years, reflecting the increasing interest in mobile elevating work platforms.

Practical applications of slab scissor lifts highlight their efficiency in confined areas. For example, during a recent construction project involving the refurbishment of a historic building, slab hoists were employed to navigate narrow corridors and provide access to elevated spaces without compromising the integrity of the structure. This case study illustrates the importance of selecting the appropriate equipment for specific job site conditions.

Current trends indicate a shift towards more advanced slab scissor lift models, equipped with enhanced safety features and improved energy efficiency. As the construction sector increasingly prioritizes sustainability, these innovations are becoming essential for managers striving to meet operational and environmental standards.

Expert opinions further emphasize the effectiveness of slab scissor lifts in streamlining workflows and minimizing accident risks. , Commercial Director, remarked, "We have purchased recently a report from SkyQuest Technology, and we are happy to inform you that this report was so useful and practical for our team." By understanding the functions and applications of these devices, managers can make informed decisions that contribute to the overall success of their construction projects.

Exploring Different Models of Slab Scissor Lifts

The market offers a diverse array of slab scissor lift devices, each tailored to meet specific operational needs, playing a crucial role in enhancing construction efficiency and safety at EZ Equipment Rental. The Genie GS-1932 is notable for its compact design, enabling it to reach heights of up to 25 feet, making it an optimal choice for indoor applications where space is at a premium. Conversely, the JLG 1930ES boasts a wider platform and superior gradeability, particularly advantageous in varied construction environments, especially on uneven terrain.

When selecting a slab scissor lift, project managers must evaluate essential specifications such as lift capacity and working height. For example, the Genie GS-4047 slab elevating platform significantly boosts productivity in high-rise settings, offering a maximum working height of 44 feet 11 inches and a capacity of 550 pounds. Its dimensions—3 feet 11 inches in width and 8 feet 2 inches in length—along with a weight of 7,185 pounds, position it as a robust option for a range of construction tasks.

Additionally, the JLG 2630ES elevating platform, reaching a height of 26 feet, is engineered for maneuverability and efficiency. Its tight turning radius and electric drive components not only minimize operating costs but also extend battery life, making it a dependable choice for various applications. Notably, provides 200% more battery life compared to a competing model under similar test conditions, underscoring the efficiency of JLG's offerings.

Understanding these specifications is vital for managers to ensure they select the most suitable lift for their specific tasks. As Bob Begley, Director of Product Management, articulates, "Engineered to meet customers' needs, both on and off the slab scissor lift, JLG's ES4046 electric scissor lift will continue to evolve as operators' needs change, expand jobsite capabilities and deliver productivity and efficiency." This statement emphasizes the importance of choosing the right tools, which can significantly impact jobsite efficiency and safety, ultimately leading to successful outcomes.

Moreover, protective features such as proximity sensors and comprehensive operator training programs, as highlighted by CanLift, are critical considerations in equipment selection. These elements ensure that managers prioritize safety alongside operational efficiency, reinforcing the essential role of forklifts and hoists in facilitating task completion.

Safety First: Essential Guidelines for Using Slab Scissor Lifts

requires strict adherence to guidelines to protect operators and enhance project efficiency. A comprehensive pre-operation inspection is crucial; operators must meticulously check for mechanical issues and verify that all safety features, such as guardrails, are correctly installed. Ensuring a stable and level surface for the hoist is essential, as is avoiding operation in adverse weather conditions, which can significantly heighten the risk of accidents.

Training is of utmost importance. Operators must be well-trained in the proper use of slab elevating devices, and wearing appropriate personal protective equipment (PPE) is non-negotiable. The importance of training in risk management cannot be overstated; studies by the American Society of Safety Engineers reveal that effective plans can save companies an average of $4 to $6 for every dollar invested. This not only highlights the financial benefits of prioritizing safety but also emphasizes the responsibility project managers have in cultivating a culture of vigilance on-site.

As we approach 2025, the rising concern over accident rates involving slab scissor lifts underscores the necessity for continuous education and strict adherence to safety protocols. Compliance with guidelines is not merely a regulatory obligation; it is a fundamental component of operational success. For example, OSHA's increased fines—up to $161,323 per violation—serve as a stark reminder of the financial repercussions of non-compliance.

Real-world examples further illustrate the effectiveness of these protective measures. A recent case study on advancements in hoist design demonstrated that while new models were introduced for rugged terrain, the responsibility for ensuring safety remains with managers. This reinforces the need for a proactive approach to security, which includes regular training and adherence to established guidelines.

For managers seeking to rent equipment that meets safety standards, EZ Equipment Rental stands out as a reliable resource. Their commitment to quality and customer satisfaction positions them as a leading choice in the DFW metro region.

In conclusion, prioritizing safety in operations involving slab scissor lifts is essential for protecting workers and ensuring successful outcomes. By implementing thorough safety training, conducting meticulous inspections, and maintaining compliance with safety regulations, construction managers can significantly mitigate risks and enhance overall efficiency on the job site.

Key Features and Specifications of Slab Scissor Lifts

Slab scissor lifts are indispensable tools in the construction industry, defined by key features that markedly influence their performance and suitability for various tasks. At , these lifts boast a platform capacity typically ranging from 500 to 1,200 pounds, ensuring they can safely support both workers and materials. Furthermore, they can achieve maximum working heights of up to 45 feet, making them versatile for a wide array of applications—from indoor maintenance to outdoor construction projects.

A notable advancement in slab elevating platforms is the integration of electric drive systems, which not only reduce noise levels but also eliminate emissions, rendering them ideal for indoor use. For instance, the JLG ES1530L scissor lift exemplifies this innovation with its lightweight design and electric operation, resulting in fewer scheduled services and a quieter working environment. This model is particularly advantageous for sensitive flooring, boosting productivity while ensuring compliance with the latest ANSI A92.20 specifications.

As Hy-Brid Lifts states, "At Hy-Brid Lifts, we take pride in producing equipment that do just that," highlighting the significance of quality and innovation in design. Understanding these specifications is vital for project managers, as they directly impact the lift's effectiveness in specific environments. Selecting a lift with the appropriate load capacity and working height guarantees that it meets the task's requirements while adhering to industry regulations.

Moreover, the incorporation of advanced safety technologies and comprehensive training programs is increasingly relevant in the industry, further enhancing the operational safety of slab scissor lifts. Real-world applications, such as the Genie GS-2646 E-Drive slab scissor lift, illustrate how these features contribute to successful outcomes, particularly in confined spaces where maneuverability is crucial. Equipped with deep cycle batteries that provide approximately 10 hours and 30 minutes of operation on a full charge, these machines are designed for efficiency and reliability, making them invaluable assets on any construction site.

Forklifts, including slab elevation devices, play a critical role in enhancing construction efficiency and safety at EZ Equipment Rental, facilitating task completion and ensuring a more secure work environment.

Best Practices for Maximizing Efficiency with Slab Scissor Lifts

To maximize efficiency when using a slab scissor lift, project managers must adopt several key best practices. Conducting thorough pre-use inspections is essential; this not only prevents mechanical failures but also ensures the safety of all personnel involved. In 2025, it is recommended that maintenance checks be scheduled every 150 hours of operation or at least once a month, depending on usage. This approach prolongs the lifespan of the equipment and enhances its performance, aligning with industry standards that emphasize regular maintenance to prevent downtime and ensure operational efficiency.

Training operators on the specific features and capabilities of the equipment is crucial for improving operational efficiency. Proper training, aligned with OSHA guidelines, significantly reduces the risk of accidents and costly violations, ultimately leading to a safer work environment. Furthermore, planning the equipment's use in advance—including the layout of the job site and the specific tasks to be performed—greatly minimizes downtime and streamlines workflow.

Real-world examples underscore the effectiveness of these practices. For instance, a construction firm that implemented reported a 25% increase in productivity and a notable decrease in equipment-related incidents. Specialists advise that managers frequently assess operational protocols and promote input from operators to consistently enhance optimal methods.

As noted by Shweta Patidar, the North America area is projected to be the largest market for aerial devices, with an anticipated share of around 37% by 2037. This growth is fueled by the rise in online shopping habits and the subsequent expansion in the logistics industry. Such developments underscore the importance of maximizing efficiency using slab scissor lifts to meet the rising demand. By focusing on these strategies, construction teams can ensure that projects are completed on time and within budget while maintaining a high standard of safety with slab scissor lifts.

Conclusion

The insights provided on slab scissor lifts underscore their pivotal role in modern construction, highlighting both their operational advantages and the critical importance of safety practices. As mobile elevating work platforms, these lifts are specifically engineered to enhance access to elevated areas, particularly in confined spaces. The anticipated growth in the market reflects their increasing demand, driven by infrastructure development and the need for efficient construction solutions.

Understanding the various models and specifications available is crucial for project managers aiming to select the most suitable equipment for their specific tasks. Key features such as load capacity, working height, and safety enhancements significantly optimize job site efficiency. Furthermore, the emphasis on regular maintenance and operator training cannot be overstated, as these practices not only ensure compliance with safety regulations but also contribute to the overall success of construction projects.

Ultimately, prioritizing safety and efficiency when utilizing slab scissor lifts is essential for protecting workers and enhancing productivity. By adhering to best practices, conducting thorough inspections, and fostering a culture of safety, project managers can significantly reduce risks and ensure that projects are completed effectively. As the construction landscape continues to evolve, staying informed about the latest advancements in slab scissor lifts will equip professionals to navigate the challenges ahead and drive successful outcomes on job sites.

Frequently Asked Questions

What are slab scissor lifts designed for?

Slab scissor lifts are designed for operation on flat, stable surfaces, such as concrete, and are capable of extending vertically to allow workers to safely access elevated areas.

In what environments are slab scissor lifts especially beneficial?

They are particularly beneficial in indoor environments and tight spaces where maneuverability is crucial.

What advantages do slab scissor lifts offer in construction tasks?

Their compact footprint allows them to navigate narrow aisles and confined job sites, making them indispensable for various construction tasks.

What is the projected market trend for slab scissor lifts by 2025?

The market share of slab scissor lifts within the construction sector is expected to expand significantly, driven by rising infrastructure development, booming e-commerce activities, and substantial government funding for construction initiatives.

Can you provide an example of a practical application of slab scissor lifts?

During a refurbishment project of a historic building, slab hoists were used to navigate narrow corridors and provide access to elevated spaces without compromising the structure's integrity.

What current trends are emerging in slab scissor lift models?

There is a shift towards more advanced models that feature enhanced safety and improved energy efficiency, aligning with the construction sector's focus on sustainability.

How do slab scissor lifts contribute to safety and productivity on job sites?

They streamline workflows and minimize accident risks, making them vital for enhancing productivity and safety in construction projects.

What should project managers consider when selecting a slab scissor lift?

Project managers should evaluate essential specifications such as lift capacity and working height to ensure they choose the most suitable lift for their specific tasks.

What specific models of slab scissor lifts are mentioned, and what are their key features?

The Genie GS-1932 is compact and reaches heights up to 25 feet, while the JLG 1930ES has a wider platform and better gradeability for varied environments. The Genie GS-4047 offers a maximum working height of 44 feet 11 inches and a capacity of 550 pounds.

Why is understanding the specifications of slab scissor lifts important?

Understanding specifications is vital for managers to select the appropriate lift that ensures efficiency and safety, ultimately leading to successful project outcomes.

What safety features should be considered in equipment selection?

Protective features such as proximity sensors and comprehensive operator training programs are critical to ensuring safety alongside operational efficiency.