Key Highlights:

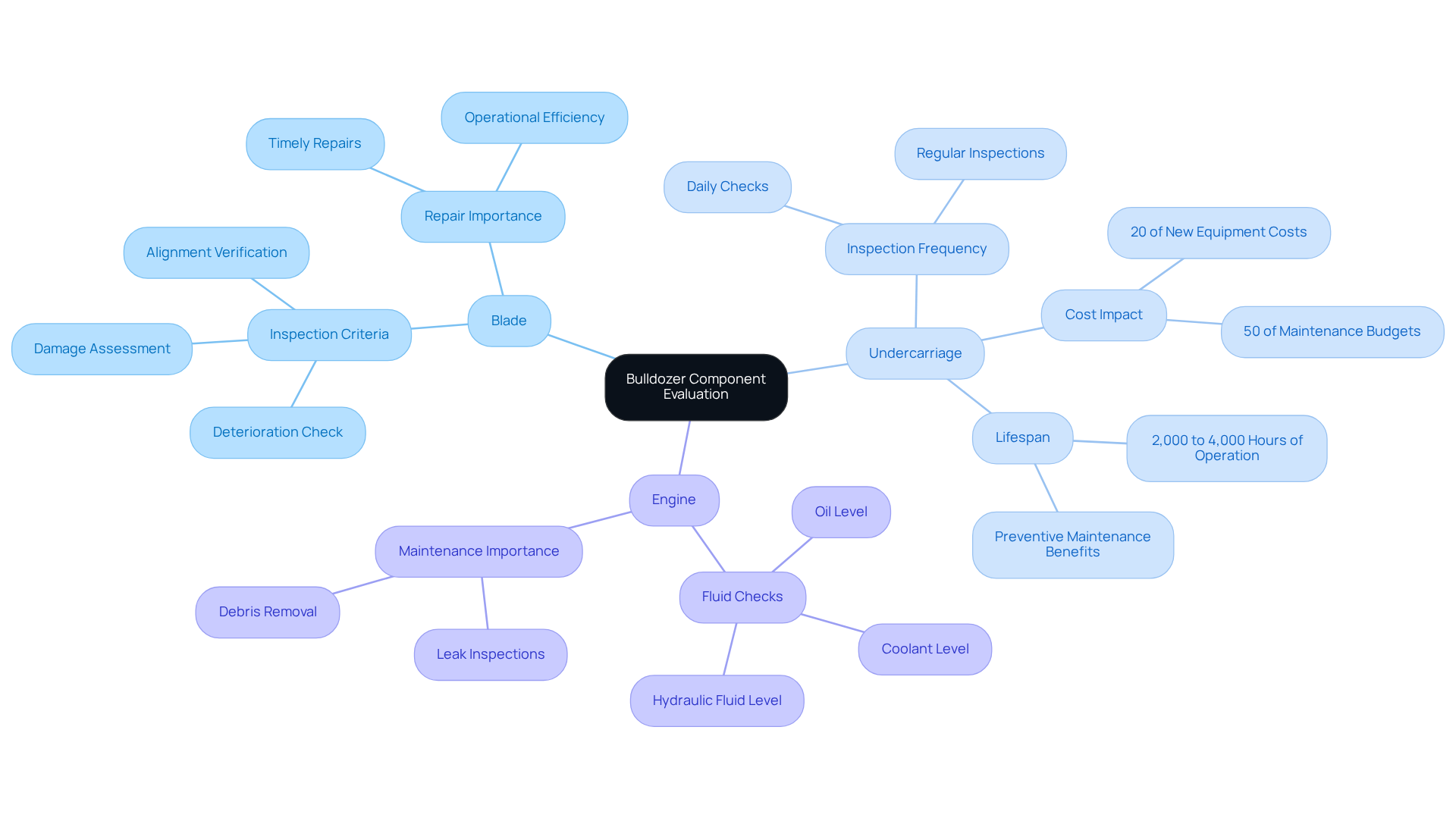

- Blade inspections are crucial for detecting deterioration and ensuring effective material pushing; timely repairs maintain operational efficiency.

- Regular undercarriage assessments help prevent costly repairs, as it represents 20% of new equipment costs and 50% of maintenance budgets.

- Engine condition checks, including fluid levels and leak inspections, are vital for reliability and overall performance.

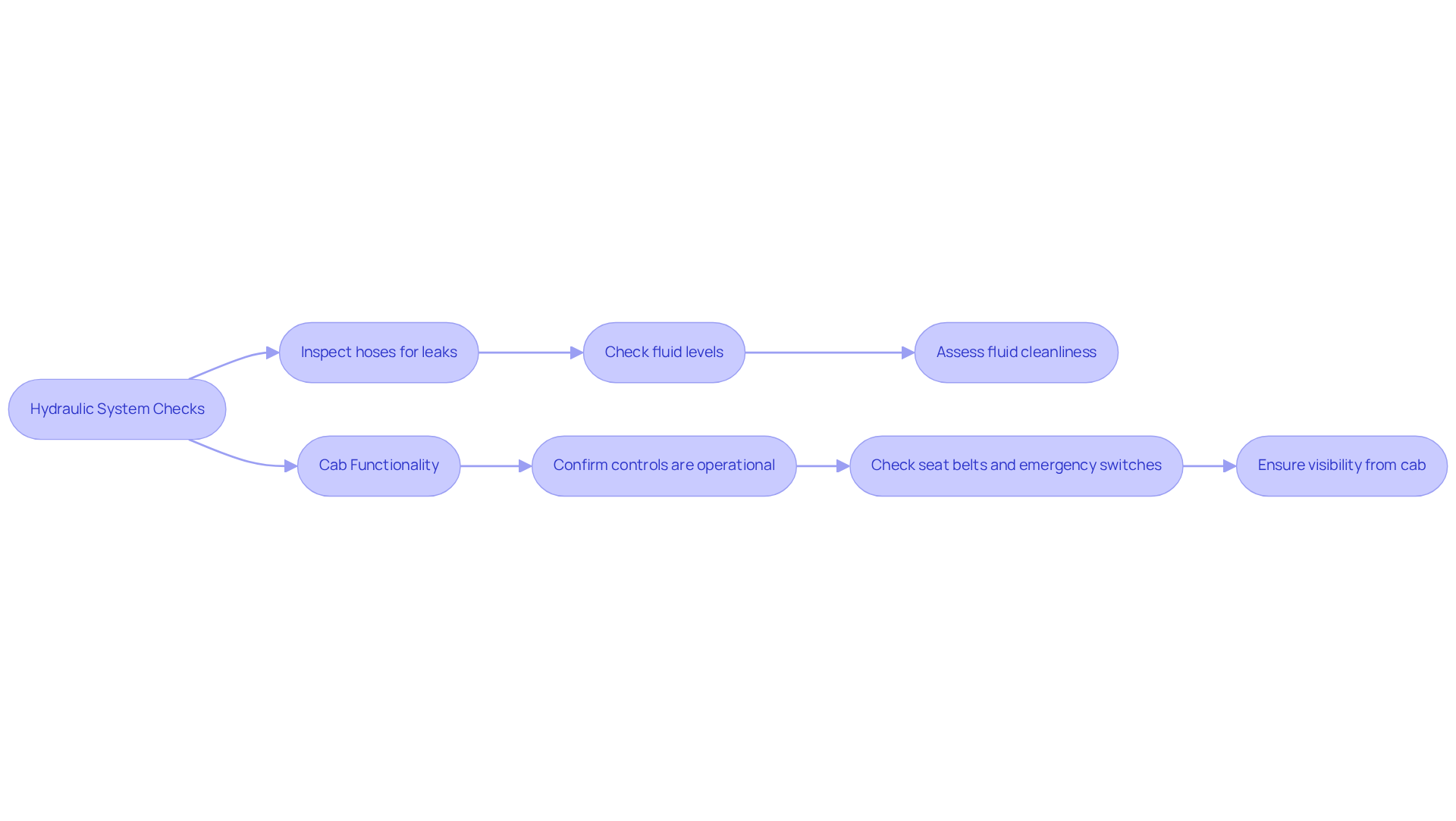

- Daily hydraulic system checks prevent shutdowns caused by contamination, which accounts for 80-90% of failures.

- Cab functionality evaluations enhance operator safety and productivity, with significant impacts on efficiency and compliance with safety regulations.

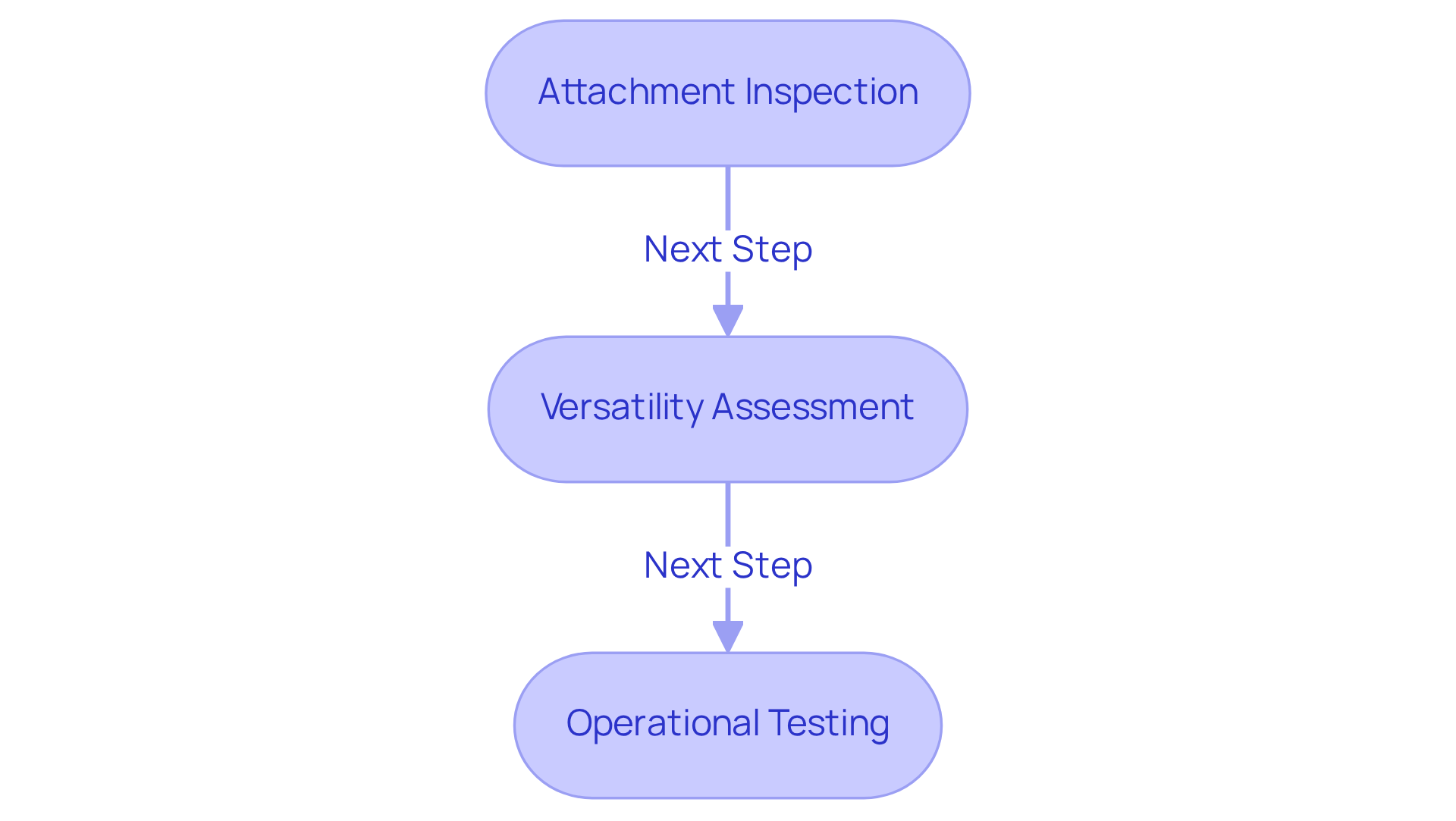

- Regular assessments of rear attachments ensure their condition and suitability for tasks, enhancing the bulldozer's versatility and operational efficiency.

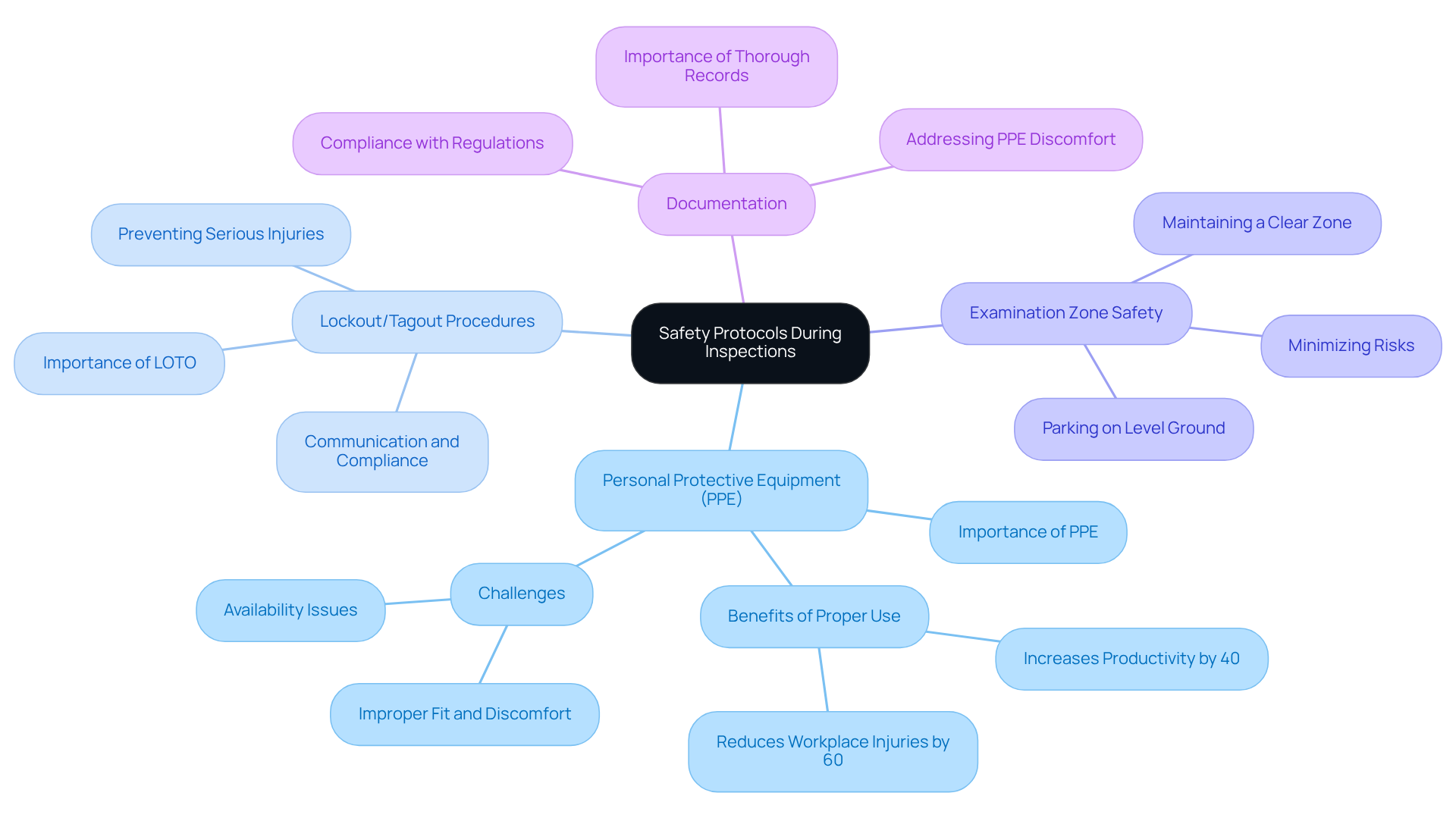

- Implementing safety protocols, including PPE use and lockout/tagout procedures, is essential to prevent accidents during inspections.

- Thorough documentation of evaluations and corrective actions is necessary for compliance and optimal equipment maintenance.

Introduction

Thorough inspections of dozer heavy equipment are not just routine; they are essential practices that protect operational efficiency and worker safety. By concentrating on critical components such as the blade, undercarriage, and engine, managers can significantly improve the machinery's performance and longevity. However, the challenge is ensuring these inspections are comprehensive and comply with safety protocols. Neglecting this can result in costly downtime and safety violations.

How can managers implement effective inspection strategies that not only meet regulatory standards but also optimize the functionality of their dozers?

Evaluate Key Components: Blade, Undercarriage, and Engine

To ensure optimal performance and safety, managers must conduct thorough evaluations of the bulldozer's blade, undercarriage, and engine.

-

Blade Inspection: It is crucial to evaluate the blade for deterioration, damage, and correct alignment. Excessive damage on the cutting edge and corners can significantly hinder the dozer's ability to push materials effectively. Timely repairs are necessary to maintain operational efficiency and prevent further issues.

-

Undercarriage Assessment: Regular inspections of tracks, rollers, and sprockets for wear and proper tension are essential. Daily checks help prevent costly repairs and ensure smooth operation. Look for signs of misalignment or damage, as these can lead to further complications. The undercarriage is a critical component, accounting for approximately 20% of new equipment costs and around 50% of maintenance budgets. Proper maintenance can significantly extend the lifespan of undercarriage components, which typically range from 2,000 to 4,000 hours of operation before requiring replacement. As highlighted by industry specialists, routine evaluations can assist in recognizing potential problems before they develop into expensive repairs or unexpected downtime.

-

Engine Condition: Regularly check fluid levels, including oil, coolant, and hydraulic fluid, and inspect for leaks. Ensure that filters are clean and that the engine is free from debris. A well-maintained engine is essential for the bulldozer's reliability and efficiency, directly affecting overall performance and productivity.

Applying these evaluation practices not only improves equipment longevity but also reduces downtime and repair expenses. This emphasizes the significance of proactive maintenance in heavy equipment management.

Inspect Hydraulic Systems and Cab Functionality

Routine evaluations of hydraulic systems and cab functionality are essential for the safe and efficient operation of dozer heavy equipment.

-

Hydraulic System Checks: Daily inspections of hydraulic hoses are necessary to identify leaks, cracks, or signs of deterioration. It's crucial to ensure that fluid levels are adequate and that the hydraulic fluid remains clean. Contamination, primarily from air and water, can lead to significant system failures, accounting for 80% to 90% of hydraulic system shutdowns. A milky appearance in hydraulic fluid often indicates water damage, which can severely impact performance. Regular checks help prevent hydraulic system shutdowns, a leading cause of equipment downtime.

-

Cab Functionality: Confirming that all controls are operational and that essential protective features, such as seat belts and emergency shut-off switches, are functional is vital. Operators must wear seat belts when ROPS is provided on equipment. Visibility from the cab is crucial; ensure mirrors and windows are clean and undamaged to enhance situational awareness. A well-maintained cab not only enhances operator security but also contributes to overall productivity. For instance, the Argos Roberta case study indicated a productivity increase of over 10 percent and saved 359 man hours in six months. Routine evaluations of cab functionality can prevent minor issues from escalating into significant safety risks. Additionally, neglecting inspections can lead to substantial penalties, with maximum fines of $16,550 per serious OSHA violation and up to $165,514 for willful or repeated violations as of 2025.

Assess Rear Attachments for Enhanced Versatility

To maximize the utility of dozer heavy equipment, managers should regularly assess the condition and functionality of its rear attachments.

-

Attachment Inspection: Regularly check for deterioration and damage on attachments such as rippers, winches, and blades. Ensure that all connections are secure and that hydraulic lines are intact to prevent operational failures. This is crucial, as deterioration can significantly impact the performance and safety of the dozer heavy equipment.

-

Versatility Assessment: Consider the types of tasks the bulldozer will be utilized for and ensure that the suitable attachments are available and in good condition. This includes assessing the suitability of attachments for specific materials or job site conditions, which can significantly impact productivity. For instance, the "Blade Inspection Techniques" case study emphasizes the importance of checking the blade face and corner bits for wear and damage to maintain optimal performance.

-

Operational Testing: Conduct thorough tests to ensure that attachments function correctly under load. This proactive approach helps identify potential issues before they disrupt productivity on the job site. For example, the integration of rear attachments has been shown to enhance the performance of dozer heavy equipment, with statistics indicating that their effective use can lead to a 20% increase in operational efficiency, as noted in industry reports.

By emphasizing these evaluation methods, managers can ensure that their machinery is prepared for adaptability and dependability, ultimately aiding the success of construction projects.

Follow Safety Protocols During Inspections

Safety is paramount during evaluations of dozer heavy equipment to prevent accidents and ensure compliance with regulations.

-

Personal Protective Equipment (PPE): All personnel involved in the assessment must wear appropriate PPE, including hard hats, gloves, and protective eyewear. The proper use of PPE can reduce workplace injuries by up to 60%, significantly lowering incidents of eye injuries, respiratory conditions, and hand injuries. This equipment is essential for protection against potential hazards encountered during evaluations. Moreover, workplaces that provide comprehensive PPE training experience a 40% increase in productivity, highlighting the dual benefits of safety and efficiency.

-

Lockout/Tagout Procedures: Implementing lockout/tagout (LOTO) procedures is critical to ensure that the dozer heavy equipment cannot be inadvertently started during evaluations. OSHA emphasizes that effective LOTO practices can prevent serious injuries or fatalities by controlling hazardous energy during maintenance activities. Clear communication regarding these procedures is vital, as misunderstandings can lead to non-compliance and heightened risk. The phrase, "You skip a step, we dig a hole," underscores the necessity of adhering to safety protocols.

-

Examination Zone Safety: Maintaining a clear and secure examination zone is essential. The dozer heavy equipment should be parked on level ground, free from obstacles that could pose dangers during the evaluation. An organized workspace minimizes risks and enhances safety for all personnel involved.

-

Documentation: Keeping thorough records of evaluations is crucial. Documenting any issues identified and the corrective actions taken not only helps maintain equipment in optimal condition but also ensures compliance with regulatory standards. This practice aligns with the need for comprehensive inspections, as workplaces with extensive PPE training see a 40% increase in productivity, emphasizing the importance of diligence in safety protocols. Additionally, addressing any discomfort associated with PPE is vital to promote consistent use and compliance among workers.

Conclusion

Effective management of dozer heavy equipment relies on rigorous inspection practices that ensure safety, efficiency, and longevity. By prioritizing evaluations of critical components - such as the blade, undercarriage, engine, hydraulic systems, and cab functionality - managers can significantly enhance operational performance and reduce costly downtime.

Key insights emphasize the importance of thorough inspections, which range from assessing the blade for wear and damage to ensuring that hydraulic systems are free of leaks and contamination. Regular checks not only prevent unexpected failures but also extend the lifespan of equipment, ultimately leading to increased productivity and reduced maintenance costs. Furthermore, a strong emphasis on safety protocols, including the use of personal protective equipment and lockout/tagout procedures, is essential to safeguard personnel during inspections.

In conclusion, adopting these essential dozer heavy equipment inspection practices is imperative for successful operation management. By implementing a structured approach to inspections and maintenance, managers can foster a culture of safety and efficiency, ensuring that their teams are well-prepared to tackle the challenges of heavy equipment operations. Embracing these best practices will enhance equipment reliability and contribute to a more productive and compliant work environment.

Frequently Asked Questions

What are the key components to evaluate in a bulldozer for optimal performance and safety?

The key components to evaluate in a bulldozer are the blade, undercarriage, and engine.

What should be inspected on the bulldozer's blade?

The blade should be inspected for deterioration, damage, and correct alignment. Excessive damage on the cutting edge and corners can hinder the bulldozer's ability to push materials effectively.

Why is it important to conduct regular inspections of the undercarriage?

Regular inspections of the undercarriage, including tracks, rollers, and sprockets, are essential to prevent costly repairs and ensure smooth operation. Misalignment or damage can lead to further complications.

How much of the bulldozer's maintenance budget is typically spent on the undercarriage?

The undercarriage accounts for approximately 50% of the bulldozer's maintenance budgets.

What is the expected lifespan of undercarriage components before requiring replacement?

Undercarriage components typically range from 2,000 to 4,000 hours of operation before requiring replacement.

What should be checked regarding the engine's condition?

The engine's condition should include checking fluid levels (oil, coolant, and hydraulic fluid), inspecting for leaks, ensuring filters are clean, and keeping the engine free from debris.

How does proper maintenance affect the bulldozer's performance and productivity?

Proper maintenance improves equipment longevity, reduces downtime and repair expenses, and directly affects the bulldozer's reliability and efficiency, enhancing overall performance and productivity.

List of Sources

- Evaluate Key Components: Blade, Undercarriage, and Engine

- Assessing Undercarriage: Tips for Tracked Equipment Inspection (https://boomandbucket.com/blog/assessing-undercarriage-tips-for-tracked-equipment-inspection?srsltid=AfmBOorpHU8Mqw4XOg7i81u21RCv7wfxjHm7WZleBjUmKjvY56gKKzTF)

- Undercarriage Maintenance Tips & Care | MacAllister Machinery (https://macallister.com/taking-care-undercarriage)

- Equipment inspection tips: dozers - Ritchie Bros. Blog (https://blog.rbauction.com/equipment-inspection-tips-dozers)

- Extend Your Dozer’s Undercarriage Life: Expert Maintenance Insights | Portland Tractor Inc. (PTI) (https://portlandtractor.com/extend-your-dozers-undercarriage-life-expert-maintenance-insights)

- Inspect Hydraulic Systems and Cab Functionality

- Equipment inspection tips: dozers - Ritchie Bros. Blog (https://blog.rbauction.com/equipment-inspection-tips-dozers)

- Construction Equipment Inspection Requirements & OSHA Standards (2026) (https://heavyvehicleinspection.com/blog/post/construction-equipment-inspections)

- Case Studies | Cat | Caterpillar (https://cat.com/en_US/support/operations/jobsite-solutions/case-studies.html)

- Why Hydraulic System Inspections Are Vital (https://servokinetics.com/why-hydraulic-system-inspections-are-vital)

- Assess Rear Attachments for Enhanced Versatility

- Equipment inspection tips: dozers - Ritchie Bros. Blog (https://blog.rbauction.com/equipment-inspection-tips-dozers)

- Dozer Attachment Market Analysis (2035) (https://wiseguyreports.com/reports/dozer-attachment-market)

- Construction Equipment Outlook 2026: Morgan Stallings, Develon (https://equipmentworld.com/market-pulse/article/15773434/construction-equipment-outlook-2026-morgan-stallings-develon)

- As Non-Road Equipment Manufacturers Face Challenges, Hope Builds for 2026 Recovery (https://aem.org/news/as-offhighway-equipment-manufacturers-face-challenges-hope-builds-for-2026-recovery)

- Follow Safety Protocols During Inspections

- Personal Protective Equipment (PPE) Statistics To Know In 2025 (https://oshagear.com/blog/ppe-statistics)

- Construction Safety Quotes That Actually Get Read (https://armedamerican.supply/blogs/news/construction-safety-quotes?srsltid=AfmBOoqV8izZad22ByXCNhlMXJJAcuYXv85WP7RA6C3rLPvTVtr7m5Zu)

- OSHA’s Top 10 List of Most Frequently Cited Standards: Control of Hazardous Energy (lockout/tagout) (https://ehs.com/blogs/oshas-top-10-list-of-most-frequently-cited-standards-control-of-hazardous-energy-lockout-tagout)

- 80+ Workplace Safety Quotes + Free Design Templates - ScreenCloud (https://screencloud.com/workplace/safety-quotes)

- Don’t Miss These OSHA Safety Deadlines in 2026 (https://conexpoconagg.com/news/don’t-miss-these-osha-safety-deadlines-in-2026)