Key Highlights:

- Forklifts vary in weight, with standard models typically weighing between 8,000 and 9,000 pounds.

- Light-duty forklifts weigh between 3,000 and 5,000 pounds, suitable for small warehouses.

- Standard forklifts average 7,000 to 10,000 pounds, commonly used in various industrial applications.

- Heavy-duty forklifts can exceed 20,000 pounds, designed for heavy lifting and outdoor use.

- Methods to determine forklift weight include checking manufacturer specifications, service manuals, using weighing scales, and consulting online resources.

- Forklift weight impacts load capacity, manoeuvrability, floor load limits, and fuel efficiency.

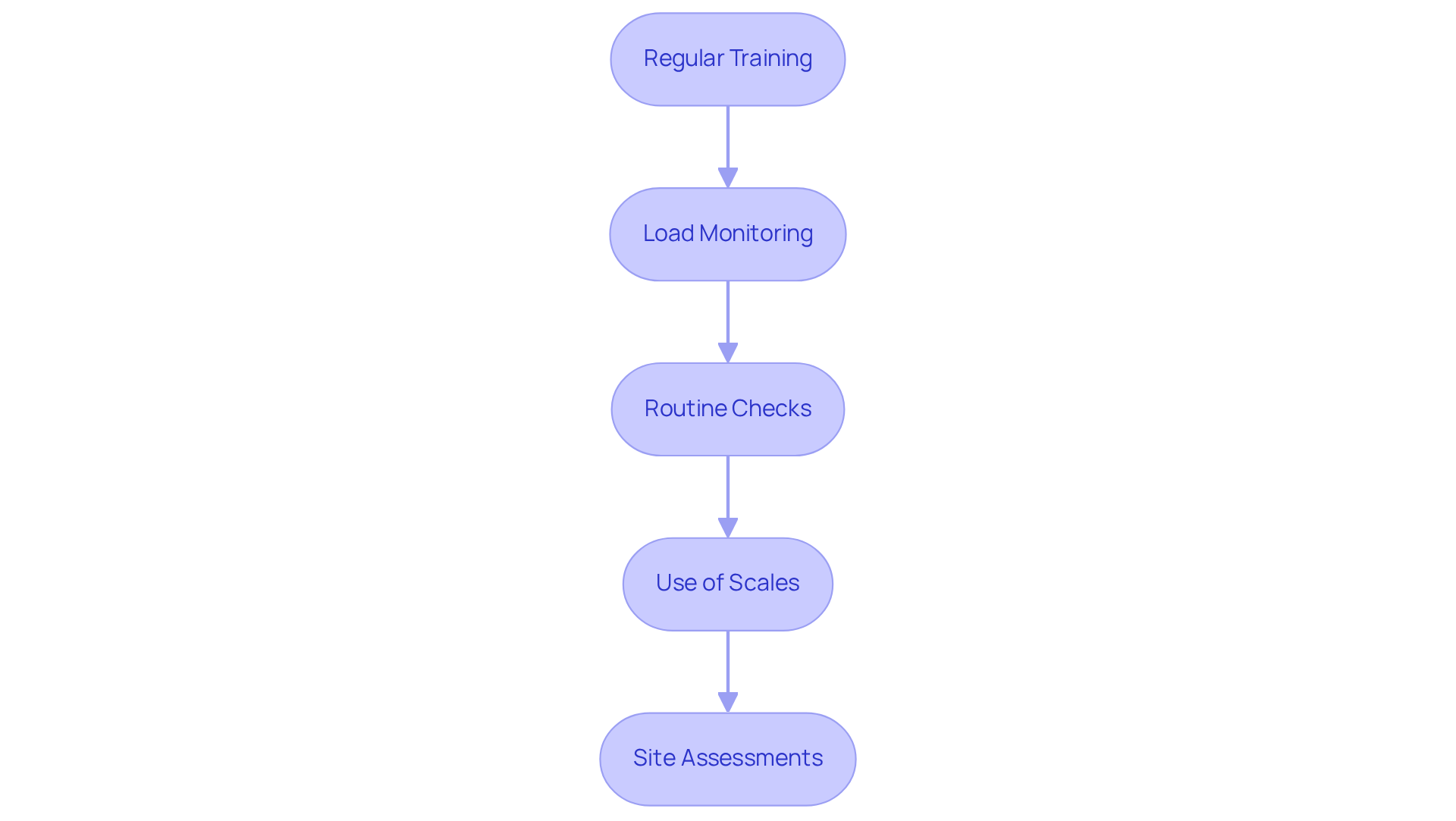

- Best practises for managing forklift weight include regular operator training, load monitoring, routine checks, using scales for load weighing, and site assessments.

Introduction

Understanding the weight of a forklift is essential for project managers navigating the complexities of material handling. Forklifts vary significantly in size and weight - from light-duty models at 3,000 pounds to heavy-duty machines exceeding 20,000 pounds. Determining the right equipment can directly impact operational efficiency and safety.

How can managers ensure they select the appropriate forklift for their specific needs while adhering to safety regulations? This article explores the essential insights surrounding forklift weights, providing practical guidance for making informed decisions in the field.

Understand Forklift Weight Basics

Forklifts come in various types and sizes, each designed with specific load characteristics. When considering standard lift trucks, it's important to note that they typically weigh between 8,000 and 9,000 pounds, raising the question of how heavy is a forklift compared to an average passenger vehicle, as this weight is about three times greater. However, the weight can vary significantly depending on the forklift type:

- Light-Duty Forklifts: Weighing between 3,000 and 5,000 pounds, these are ideal for small warehouses.

- Standard Forklifts: Averaging around 7,000 to 10,000 pounds, this raises the question of how heavy is a forklift commonly used across various industrial applications.

- Heavy-Duty Forklifts: These can exceed 20,000 pounds, prompting the inquiry of how heavy is a forklift, as they are specifically designed for heavy lifting and outdoor use.

At EZ Equipment Rental, we offer a diverse selection of well-maintained lifting machines, ensuring that clients find the perfect match for their specific needs. Understanding these load classifications is essential for supervisors to select the appropriate lift for their tasks and site conditions. With expert support from EZ Equipment Rental, you can navigate your equipment rental experience with ease.

Determine Forklift Weight Using Key Methods

To determine the weight of a forklift, project managers can employ several reliable methods:

- Manufacturer Specifications: The most dependable reference for lift truck mass, specifically regarding how heavy is a forklift, is the producer's data plate, which details the mass alongside other specifications.

- The forklift service manual frequently includes comprehensive details about how heavy is a forklift and its load capacities.

- Weighing Scales: For more precise measurements, utilizing a lifting truck scale can provide exact readings. These scales can be integrated into the forklift or used separately.

- Online Resources: Many manufacturers and equipment rental companies offer load information on their websites, serving as a quick reference.

By employing these techniques, managers can ensure they possess accurate mass information, such as how heavy is a forklift, which is essential for safe operation and compliance with safety regulations.

Evaluate the Impact of Forklift Weight on Operations

The weight of a forklift significantly influences several operational factors:

- Load Capacity: Heavier forklifts typically offer higher load capacities, which is essential for projects that involve moving heavy materials.

- Maneuverability: Lighter lifting machines can navigate tighter spaces more effectively, making them ideal for indoor or congested job sites.

- Floor Load Limits: The mass of the lifting device affects the floor load limits of the worksite. Project managers must verify how heavy a forklift is to ensure that the flooring can support the weight of the lifting device and avoid structural damage.

- Fuel Efficiency: Understanding how heavy a forklift is can help determine its fuel consumption, as heavier forklifts may consume more fuel, impacting operational costs. Understanding the load requirements can help in selecting the most economical equipment for the task.

By evaluating these factors, leaders can make informed decisions about their equipment selections, ultimately enhancing overall efficiency.

Implement Best Practices for Forklift Weight Management

To effectively manage forklift weight, project managers should consider the following best practices:

- Regular Training: It is essential that all operators understand the importance of comprehending lifting equipment loads and their impact on safety and efficiency.

- Load monitoring involves implementing systems to track load measures, ensuring they do not exceed how heavy is a forklift's rated capacity.

- Routine Checks: Conduct regular assessments of lifting vehicles to confirm they are in proper working order and that load distribution is balanced.

- Use of Scales: Employ lifting equipment scales to weigh loads prior to lifting, ensuring operators are aware of the weight they are handling.

- Site Assessments: Regularly evaluate job sites for floor load limits and confirm that the selected forklifts are suitable for the conditions.

By adhering to these best practices, project managers can enhance safety, improve operational efficiency, and ensure compliance with industry standards.

Conclusion

Understanding the weight of forklifts is essential for project managers responsible for selecting the appropriate equipment for various operational needs. This article outlines the diverse weight ranges of forklifts, from light-duty models weighing approximately 3,000 pounds to heavy-duty versions exceeding 20,000 pounds. Such knowledge is vital for ensuring safety, compliance, and efficiency in material handling tasks.

Key insights include methods for determining forklift weight, such as:

- Consulting manufacturer specifications

- Utilizing weighing scales

- Accessing online resources

The impact of forklift weight on load capacity, maneuverability, floor load limits, and fuel efficiency is also examined. By considering these factors, project managers can make informed decisions that enhance productivity while maintaining safety standards.

Effectively managing forklift weight extends beyond merely selecting the right machine; it encompasses implementing best practices like:

- Regular training

- Load monitoring

- Site assessments

By prioritizing these strategies, project managers can optimize operations, mitigate risks, and ensure compliance with industry regulations. Emphasizing the significance of understanding forklift weight can lead to improved project outcomes and a safer work environment.

Frequently Asked Questions

What is the typical weight range of standard forklifts?

Standard forklifts typically weigh between 8,000 and 9,000 pounds.

How does the weight of a forklift compare to an average passenger vehicle?

The weight of a standard forklift is about three times greater than that of an average passenger vehicle.

What are the weight classifications for different types of forklifts?

Light-Duty Forklifts weigh between 3,000 and 5,000 pounds, suitable for small warehouses. Standard Forklifts average around 7,000 to 10,000 pounds, commonly used in various industrial applications. Heavy-Duty Forklifts can exceed 20,000 pounds, designed for heavy lifting and outdoor use.

Why is it important for supervisors to understand forklift load classifications?

Understanding load classifications is essential for supervisors to select the appropriate lift for their tasks and site conditions.

What services does EZ Equipment Rental provide related to forklifts?

EZ Equipment Rental offers a diverse selection of well-maintained lifting machines, ensuring clients find the perfect match for their specific needs, along with expert support for navigating the equipment rental experience.