Key Highlights:

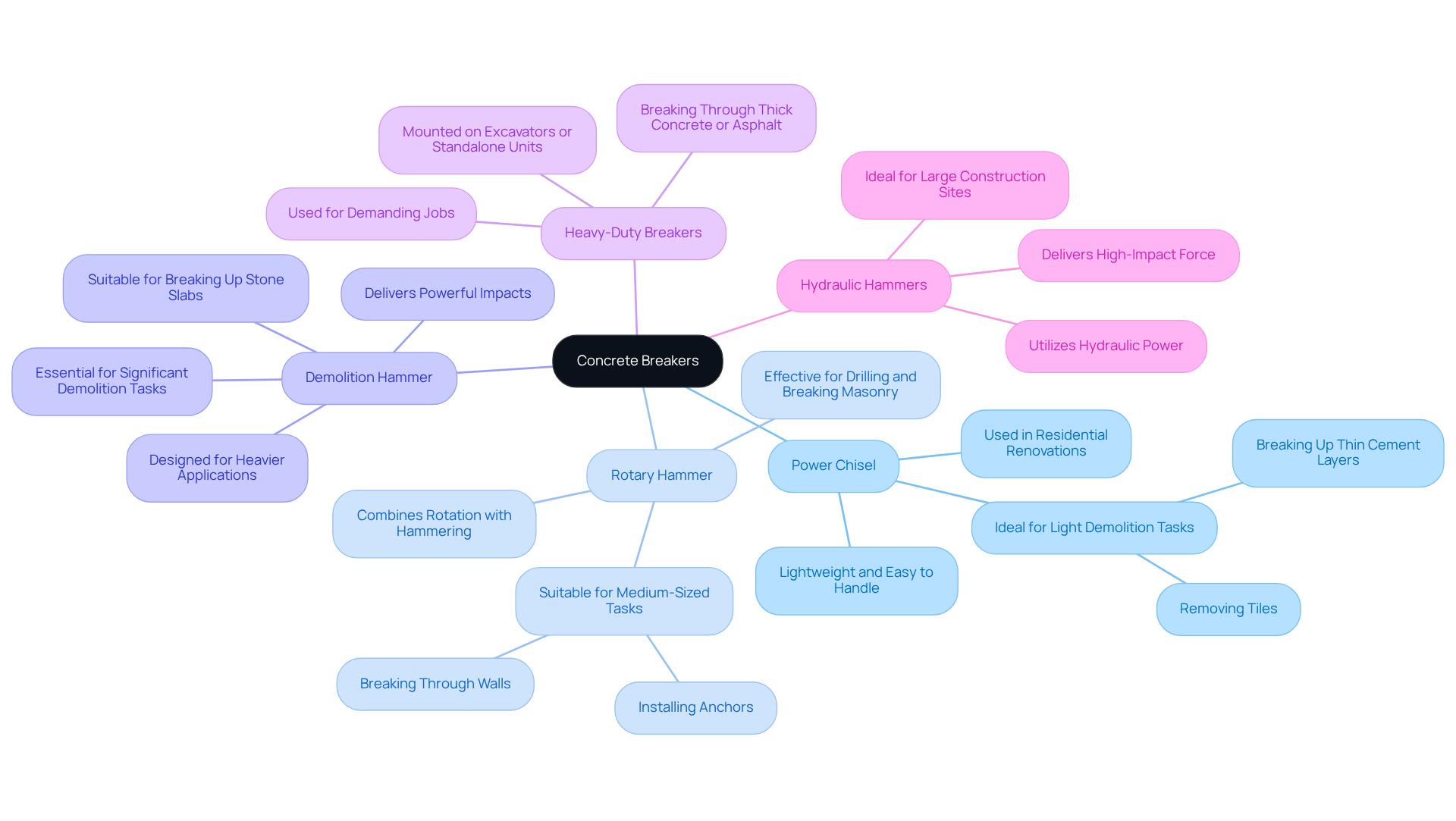

- Concrete breakers are categorised into types: Power Chisel, Rotary Hammer, Demolition Hammer, Heavy-Duty Breakers, and Hydraulic Hammers, each suited for specific tasks.

- Power Chisels are lightweight and ideal for light demolition tasks, such as tile removal.

- Rotary Hammers combine rotation and hammering, effective for medium tasks like drilling into masonry.

- Demolition Hammers are designed for heavy applications, delivering powerful impacts for breaking stone slabs.

- Heavy-Duty Breakers are used for demanding jobs, like breaking thick concrete or asphalt, often mounted on excavators.

- Hydraulic Hammers utilise hydraulic power for high-impact force, suitable for large construction sites.

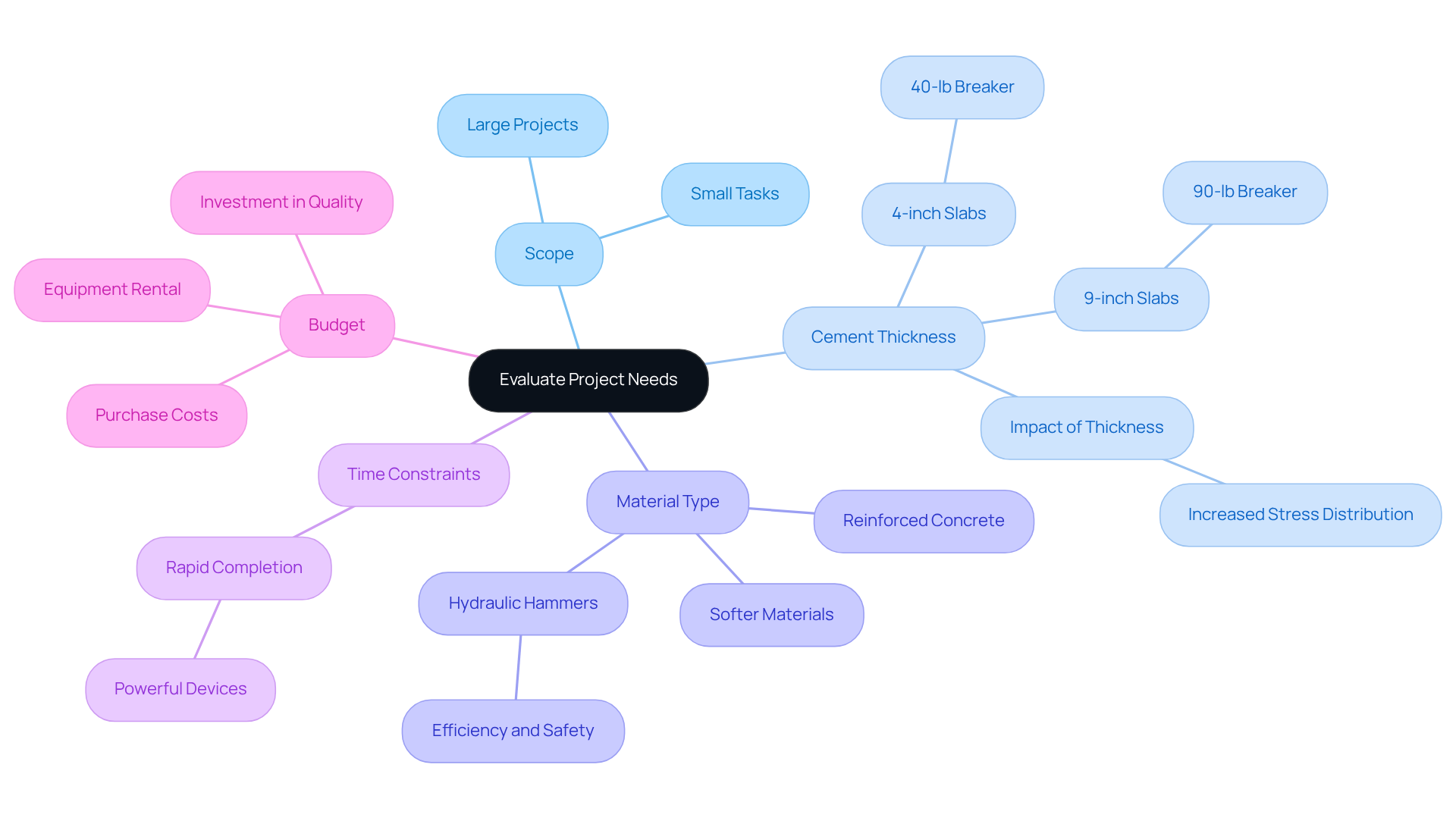

- Evaluating project needs includes assessing scope, cement thickness, material type, time constraints, and budget.

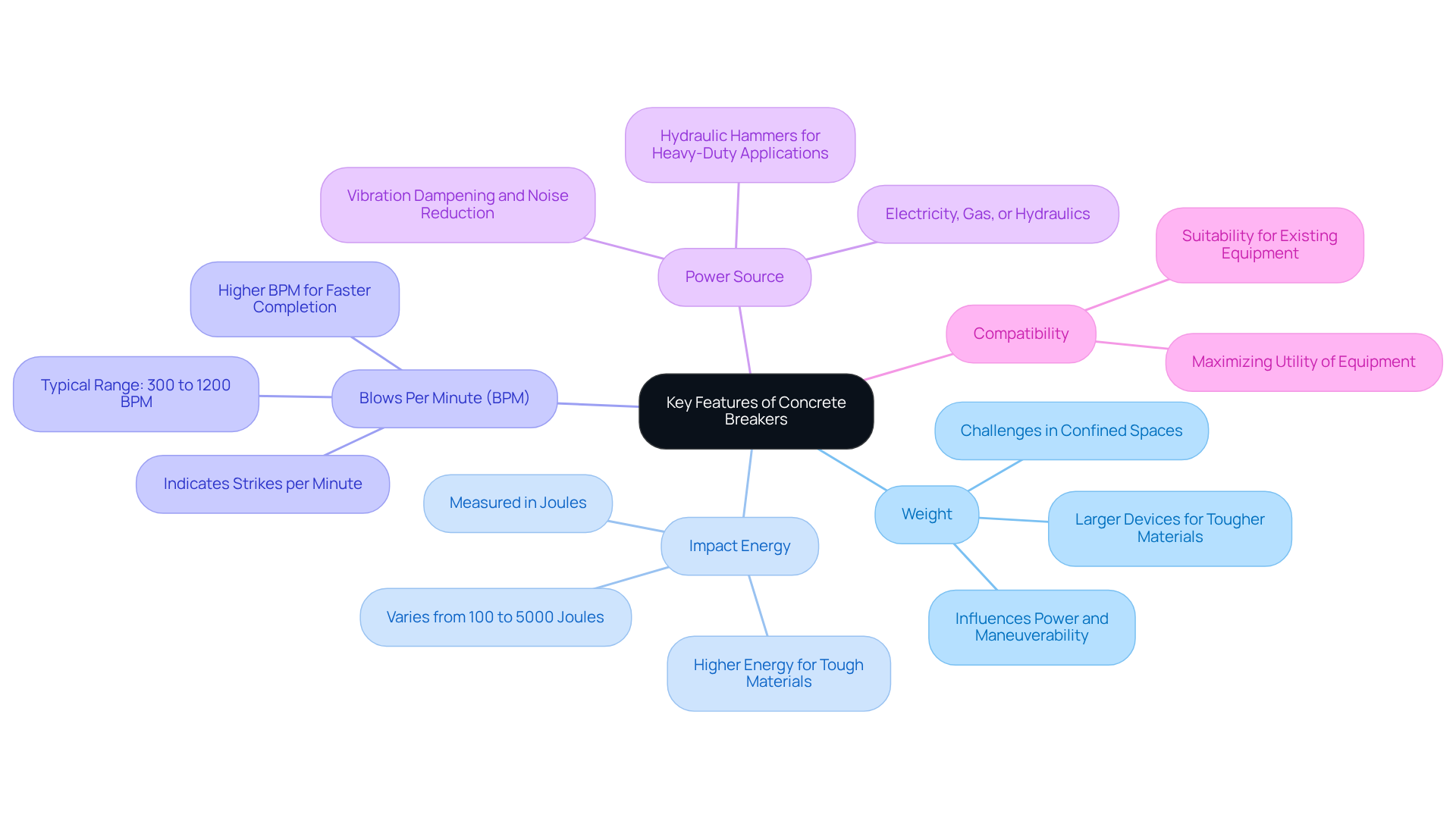

- Key specifications to consider when selecting a concrete breaker include weight, impact energy, blows per minute, power source, and compatibility.

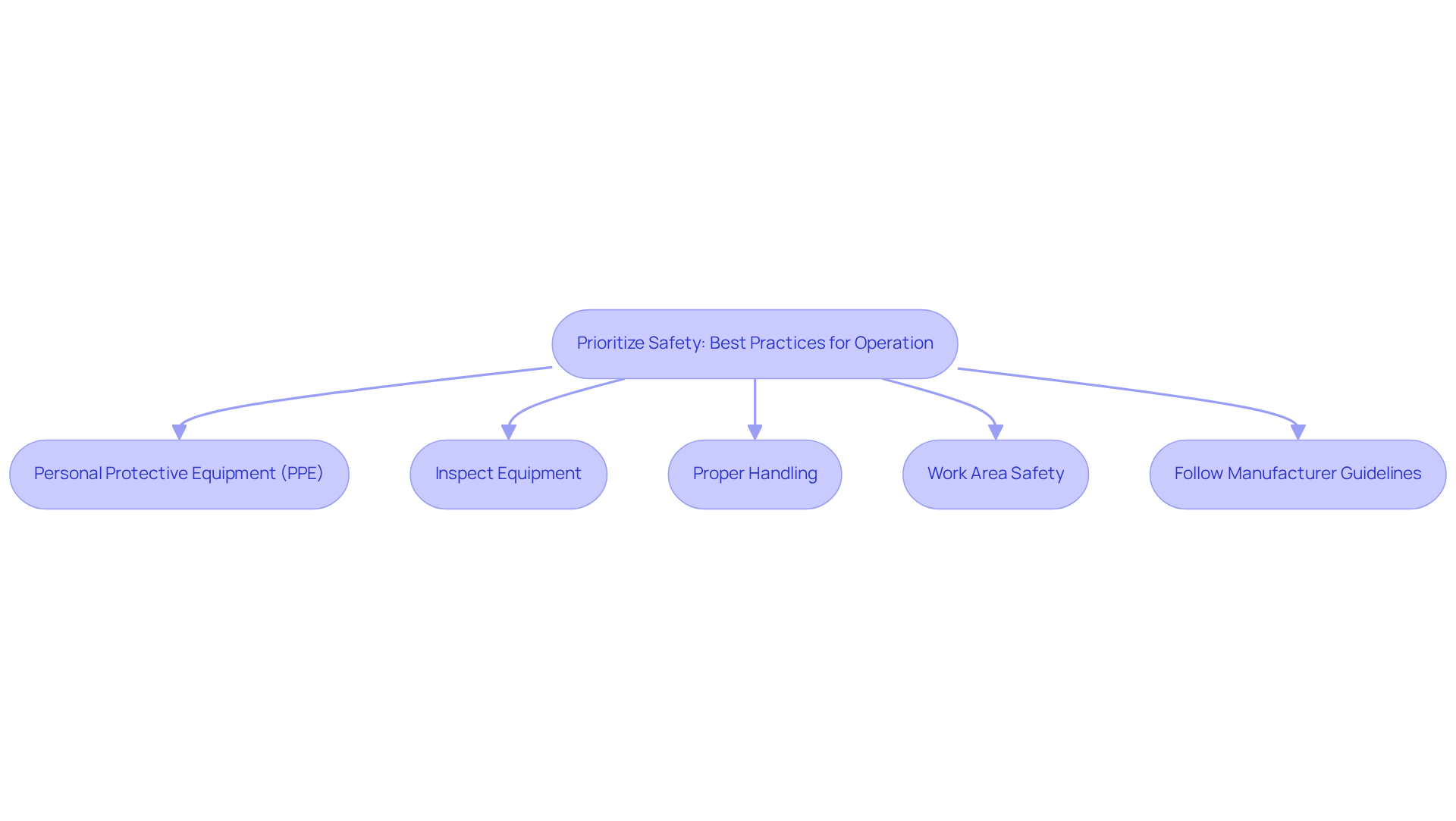

- Safety best practises include wearing PPE, inspecting equipment, proper handling, maintaining a safe work area, and following manufacturer guidelines.

Introduction

Selecting the appropriate concrete breaker is crucial for the success of any construction project, significantly impacting both efficiency and safety. With a range of options available - from lightweight power chisels to robust hydraulic hammers - it's vital to understand their specific functions and applications to achieve optimal performance. Given the multitude of choices, how can one ensure they choose the most suitable tool for their unique project requirements? This guide explores the essential factors to consider, equipping readers with the knowledge to confidently navigate the complexities of concrete breaker selection.

Understand Concrete Breakers: Types and Functions

Concrete breakers are classified into various types, each designed for specific tasks in construction and demolition. Understanding these categories is crucial for selecting the right tool for your project.

-

Power Chisel: Lightweight and easy to handle, power chisels are ideal for light demolition tasks. They excel in smaller jobs, such as removing tiles or breaking up thin cement layers. Construction professionals often rely on power chisels for precise work in residential renovations, where minimal damage to surrounding materials is essential.

-

Rotary Hammer: This versatile tool combines rotation with hammering, making it effective for drilling into and breaking apart masonry. It is well-suited for medium-sized tasks, such as installing anchors or breaking through walls. The market for rotary hammers is projected to grow significantly, reflecting their importance in various construction applications.

-

Demolition Hammer: Designed for heavier applications, demolition hammers deliver powerful impacts, making them suitable for breaking up stone slabs and larger structures. They are essential for significant demolition tasks where efficiency is key. Industry reports indicate that the demand for demolition hammers is anticipated to grow as urban redevelopment initiatives increase.

-

Heavy-Duty Breakers: These robust tools are used for the most demanding jobs, such as breaking through thick concrete or asphalt. Typically mounted on excavators or used as standalone units, they are indispensable for large-scale demolition projects. Leading manufacturers in this segment, such as Atlas Copco and Hilti, are known for their innovative designs and reliability.

-

Hydraulic Hammers: Utilizing hydraulic power, these tools deliver high-impact force, making them efficient for heavy-duty applications. Often used in conjunction with heavy machinery, they are ideal for large construction sites where power and efficiency are paramount. The hydraulic demolition tools market is projected to reach USD 26,500.75 million by 2033, highlighting the growing reliance on these powerful instruments.

Recent advancements in demolition technology, including AI-driven adaptive systems, are enhancing performance and energy efficiency. These innovations enable optimized impact frequency and reduced operational expenses. As the market evolves, understanding the specific roles and uses of each concrete breaker will empower you to make informed choices for your projects.

Evaluate Project Needs: Assess Requirements and Constraints

Selecting the right concrete breaker for your project necessitates a careful evaluation of your specific needs.

Scope: Start by assessing the scale of your initiative. Smaller tasks may only require a lighter breaker, while larger projects typically necessitate heavy-duty equipment to meet increased demands.

Cement Thickness: Next, determine the thickness of the material to be broken. For instance, a 40-lb breaker is generally effective for 4-inch slabs, whereas a 90-lb breaker is more suitable for 9-inch surfaces. It's crucial to recognize that increasing slab thickness can significantly affect stress distribution, as evidenced by studies indicating that thicker slabs lead to heightened stress at the top.

Material Type: Identify the type of cement or material involved. Some devices are optimized for reinforced concrete, while others perform better with softer materials, impacting overall efficiency. Hydraulic hammers, for example, are known to be quicker, safer, and more economical than manual breaking techniques, making them a preferred choice for various materials.

Time Constraints: Consider your timeline for the task. If rapid completion is essential, opting for a more powerful device can greatly enhance productivity and minimize downtime. A concrete breaker is a hydraulic tool that can swiftly break hardened surfaces into manageable fragments, facilitating quicker task completion.

Budget: Finally, evaluate your financial parameters for equipment rental or purchase. Ensure that the selected breaker fits within your budget while still meeting the essential requirements of the task. Remember that investing in a high-quality hydraulic tool can boost efficiency and support sustainable practices in material recycling.

By thoughtfully considering these factors and integrating insights from case studies and external sources, you can make a well-informed decision regarding the most suitable demolition tool for your project, ensuring both efficiency and effectiveness in your operations.

Identify Key Features: Specifications to Consider

When selecting a concrete breaker, several key features warrant careful consideration:

-

Weight: The mass of the device significantly influences its power and maneuverability. Larger devices typically deliver stronger force, making them more efficient for tougher materials. However, they can be more challenging to handle, particularly in confined spaces. For instance, a larger hydraulic hammer can provide enhanced energy, which is crucial for effectively penetrating reinforced cement.

-

Impact Energy: This essential metric, measured in joules, signifies the force exerted by the device. Higher impact energy is vital for a concrete breaker to efficiently break through tougher materials like reinforced concrete. Energy per impact can vary from 100 to 5000 joules, depending on the size and configuration of the device. As noted by Rich Elliott, understanding the internal components and energy output is crucial for making informed decisions.

-

Blows Per Minute (BPM): This metric indicates how many times the device strikes per minute. An increased BPM can lead to faster completion times, as it allows for more frequent impacts on the material. Typical impact frequencies for hydraulic hammers range from 300 to 1200 blows per minute, enhancing productivity on the job site. The increased energy output in hydraulic tools facilitates quicker project completion, making BPM a critical factor in selection.

-

Power Source: A concrete breaker can be powered by electricity, gas, or hydraulics. The choice of power source should align with the project environment and resource availability. Hydraulic hammers, for example, are recognized for their effectiveness and strength, making them suitable for heavy-duty applications. Additionally, modern hydraulic hammers often feature vibration dampening technology and noise reduction capabilities, enhancing operator comfort and safety.

-

Compatibility: Ensure that the switch is suitable for any existing equipment, especially if you plan to use attachments or other machinery. This compatibility is essential for maximizing the utility of your equipment and ensuring seamless operation.

By focusing on these specifications, you can select a demolition tool that not only meets your project requirements but also enhances overall efficiency and effectiveness. Understanding the interplay between weight, impact energy, and operational metrics is vital for making an informed decision. Industry experts emphasize that the kinetic energy transfer during impact is crucial for optimal performance. Furthermore, recognizing the importance of standardized ratings, as highlighted by the AEM testing system, can guide you in selecting the right equipment.

Prioritize Safety: Best Practices for Operation

Safety is paramount when using demolition tools. Adhering to best practices can significantly reduce the risk of accidents and injuries on the job site:

-

Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety goggles, gloves, ear protection, and steel-toed boots. These items are crucial for safeguarding against debris and noise. Incorrect use of demolition tools has been linked to a substantial proportion of construction injuries. The Bureau of Labor Statistics indicates that proper PPE can reduce workplace injuries by up to 60%. As safety professionals emphasize, "The proper use of PPE is critical for maintaining safety across various industries."

-

Inspect Equipment: Conduct a thorough examination of the concrete crushing tool before use. Look for any signs of damage or wear, ensuring that all components are functioning correctly. Regular equipment inspections are vital for preventing accidents, particularly those related to caught-in/between incidents, which account for 5.4% of work-related deaths among contractors.

-

Proper Handling: Operate the switch with both hands and maintain a stable stance. Avoid overreaching or using the tool in awkward positions, as these practices can lead to loss of control and potential injuries.

-

Work Area Safety: Clear the work area of obstacles and ensure that bystanders are at a safe distance. Implement barriers if necessary to keep others away from the work zone. Awareness of struck-by hazards, such as dropped tools and flying debris, is critical for maintaining safety. Notably, 8% of construction deaths in 2021 were due to workers struck by objects, underscoring the importance of vigilance in the work area.

-

Follow Manufacturer Guidelines: Always adhere to the manufacturer's instructions for operation and maintenance. Understanding the specific capabilities and limitations of the device is essential for safe usage.

By implementing these safety practices, you can minimize risks and create a safer working environment when using a concrete breaker. The construction industry recorded 1,008 fatalities in 2021, highlighting the urgent need for prioritizing safety measures and fostering a culture that emphasizes worker well-being.

Conclusion

Selecting the right concrete breaker is crucial for the success of any construction or demolition project. Understanding the different types of concrete breakers and their specific functions enables informed decisions that align with project requirements and constraints.

Key factors such as project scope, material type, and safety practices are essential in the selection process. Evaluating the weight, impact energy, and operational specifications of each tool enhances efficiency and ensures safety on the job site. The importance of personal protective equipment and proper handling cannot be overstated, as these measures significantly mitigate risks associated with demolition work.

Ultimately, choosing the appropriate concrete breaker can lead to improved productivity and safety, supporting successful project outcomes. Prioritizing thorough evaluations and adhering to best practices not only optimizes performance but also fosters a culture of safety that is vital in the construction industry. As technology continues to advance, staying informed about the latest tools and techniques empowers professionals to tackle even the most challenging tasks with confidence.

Frequently Asked Questions

What are concrete breakers and why are they important?

Concrete breakers are tools classified into various types, each designed for specific tasks in construction and demolition. Understanding these categories is crucial for selecting the right tool for your project.

What is a power chisel and what tasks is it best suited for?

A power chisel is a lightweight and easy-to-handle tool ideal for light demolition tasks, such as removing tiles or breaking up thin cement layers. It is commonly used in residential renovations where precision and minimal damage to surrounding materials are essential.

How does a rotary hammer function and what tasks can it perform?

A rotary hammer combines rotation with hammering, making it effective for drilling into and breaking apart masonry. It is well-suited for medium-sized tasks, such as installing anchors or breaking through walls.

What is a demolition hammer and in what scenarios is it used?

A demolition hammer is designed for heavier applications, delivering powerful impacts suitable for breaking up stone slabs and larger structures. It is essential for significant demolition tasks where efficiency is key.

What are heavy-duty breakers and where are they typically used?

Heavy-duty breakers are robust tools used for demanding jobs, such as breaking through thick concrete or asphalt. They are typically mounted on excavators or used as standalone units for large-scale demolition projects.

What are hydraulic hammers and what advantages do they offer?

Hydraulic hammers utilize hydraulic power to deliver high-impact force, making them efficient for heavy-duty applications. They are ideal for large construction sites where power and efficiency are paramount.

What recent advancements are being made in demolition technology?

Recent advancements include AI-driven adaptive systems that enhance performance and energy efficiency by optimizing impact frequency and reducing operational expenses.

Why is it important to understand the specific roles and uses of each concrete breaker?

Understanding the specific roles and uses of each concrete breaker empowers you to make informed choices for your projects, ensuring you select the right tool for the tasks at hand.

List of Sources

- Understand Concrete Breakers: Types and Functions

- Hydraulic Breakers Rental Market | Global Market Analysis Report - 2035 (https://factmr.com/report/hydraulic-breakers-rental-market)

- Concrete Breakers Market Size, Trends, Key Highlights & Industry Review 2033 (https://linkedin.com/pulse/concrete-breakers-market-size-trends-key-highlights-oycse)

- Concrete Breakers Market Size, Share, Growth | CAGR Forecast 2032 (https://futuremarketreport.com/industry-report/concrete-breakers-market)

- Concrete breaker trends 2025: AI, electric & hydraulic advances (https://accio.com/business/concrete-breaker-trends)

- Concrete Breakers Market Report | Global Forecast From 2025 To 2033 (https://dataintelo.com/report/concrete-breakers-market)

- Evaluate Project Needs: Assess Requirements and Constraints

- 14 Essential Questions About Hydraulic Breaker for Concrete Recycling | Beilite Machinery (https://beilite.com/en/blog/info_itemid_13544.html)

- Effect Change Concrete Slab Layer Thickness on Rigid Pavement | Engineering, Technology & Applied Science Research (https://etasr.com/index.php/ETASR/article/view/5283)

- The Effects of Concrete Thickness and Strength on Composite Shear Wall Behavior Coefficient (https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4312596)

- Latest Official Press Release - Rotair Spa (https://rotairspa.com/press-release/getting-the-most-of-hydraulic-breakers-expert-tips-for-construction-and-demolition-projects)

- Methvin | Demolishing Concrete (https://methvin.org/estimating-production-rates/demolition-renovation/demolishing-concrete)

- Identify Key Features: Specifications to Consider

- Top Hydraulic Concrete Breakers of 2025 for Efficient Demolition Projects (https://ytligong.com/blog/top-hydraulic-concrete-breakers-for-efficient-demolition)

- Getting a Handle on Power (https://cdrecycler.com/article/getting-a-handle-on-power)

- Insider's insight: impact energy ratings for hydraulic breakers (https://epiroc.blog/insiders-insight-impact-energy)

- Impact Dynamics in Hydraulic Breaker Applications - Lekatech Oy (https://lekatech.fi/news/impact-dynamics-in-hydraulic-breaker-applications)

- Hydraulic Hammer Attachment Finder | Gorilla Hammers™ (https://gorillahammers.com/hydraulic-hammer-breaker-size-guide)

- Prioritize Safety: Best Practices for Operation

- OSHA’s “Fatal Four” - The leading causes of death in the construction industry (https://tdi.texas.gov/tips/safety/oshafatal4.html)

- Commonly Used Statistics | Occupational Safety and Health Administration (https://osha.gov/data/commonstats)

- Personal Protective Equipment (PPE) Statistics To Know In 2025 (https://oshagear.com/blog/ppe-statistics)

- 5 Alarming Contractor Safety Statistics - Appruv (https://appruv.com/blog/5-alarming-contractor-safety-statistics)

- PPE non-compliance among construction workers: An assessment of contributing factors utilizing fuzzy theory (https://sciencedirect.com/science/article/pii/S0022437523000233)