Overview

To effectively utilize diaphragm pump rentals, construction managers must prioritize a comprehensive understanding of their applications. Selecting the right equipment based on specific project needs is crucial. Furthermore, adhering to best practices for operation and maintenance is essential. Proper selection and management of diaphragm pumps not only enhance operational efficiency but also bolster safety on construction sites. This article provides valuable insights into the advantages of rentals, key considerations for selection, and effective troubleshooting strategies.

Key Highlights:

- Diaphragm pumps are crucial in construction for efficiently transporting liquids, especially in applications like dewatering, slurry transfer, and chemical handling.

- The demand for diaphragm pumps, particularly for rental options, has increased due to their reliability and effectiveness in dewatering applications.

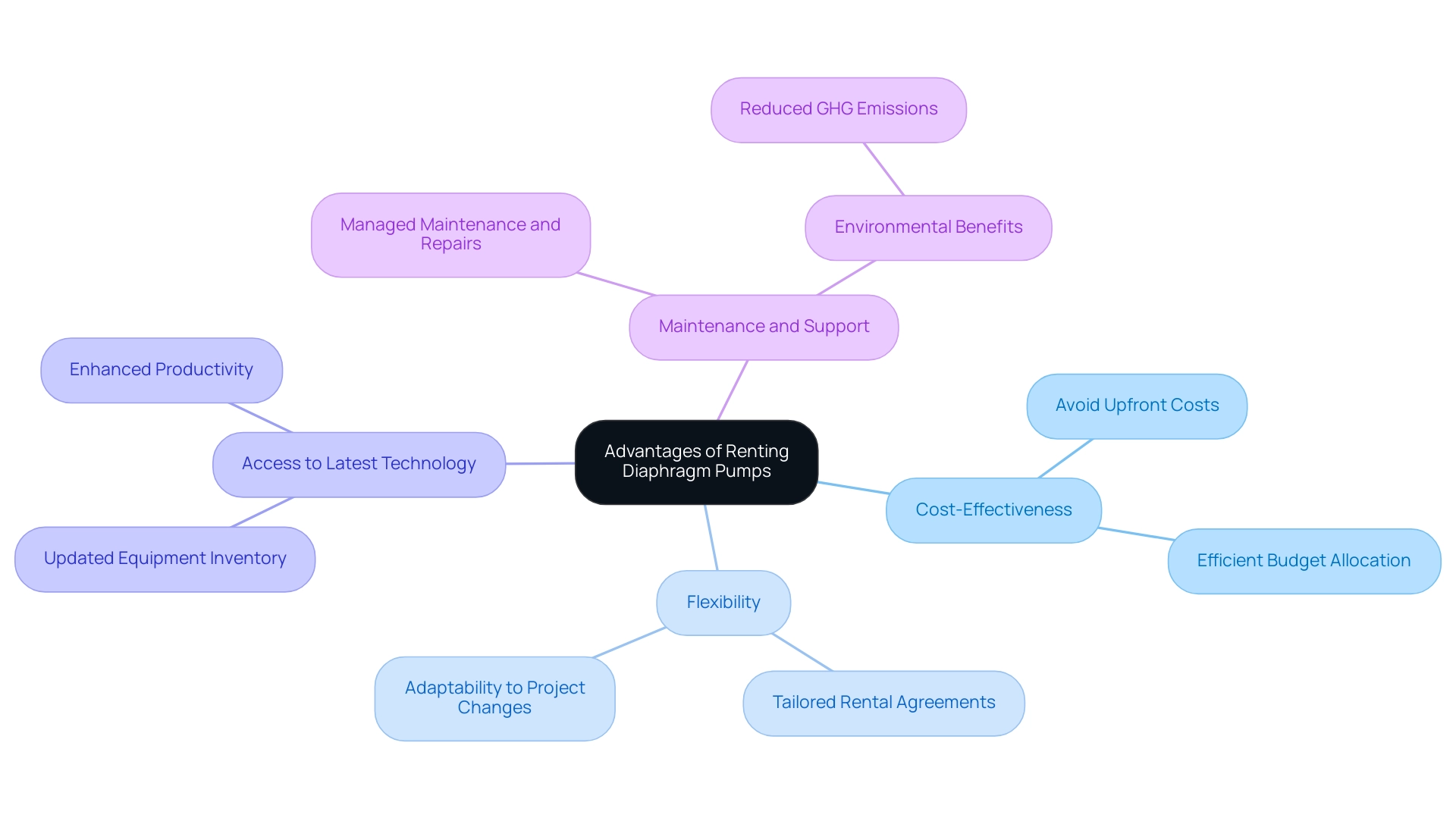

- Key benefits of renting diaphragm pumps include cost-effectiveness, flexibility in rental terms, access to the latest technology, and maintenance support from rental companies.

- Selecting the right diaphragm pump rental involves considering fluid type, flow rate, pump size, and rental terms to ensure compatibility and efficiency.

- Best practices for using diaphragm pumps include regular maintenance, proper setup, performance monitoring, operator training, and established emergency procedures.

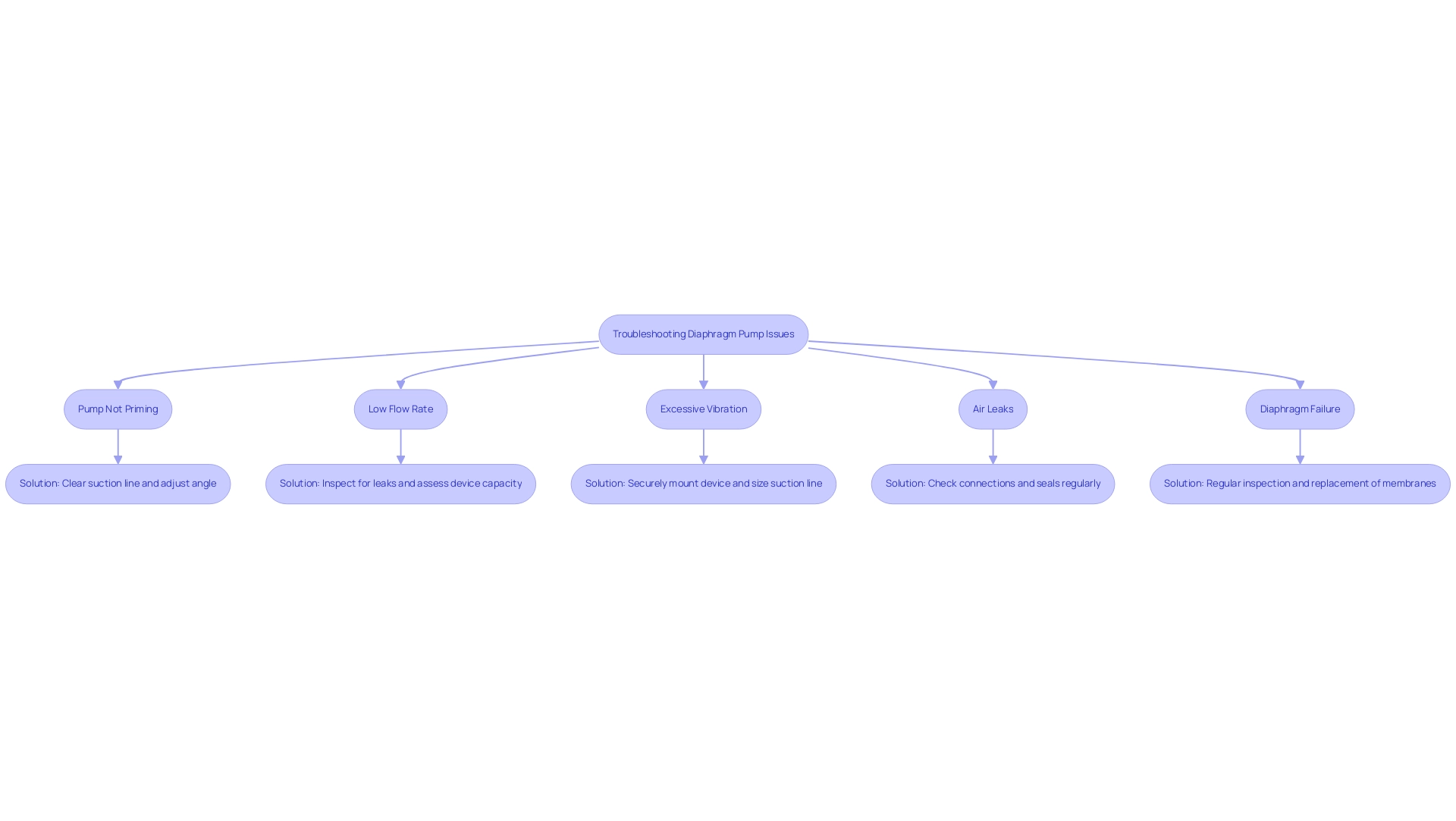

- Common issues with diaphragm pumps include priming failures, low flow rates, excessive vibrations, air leaks, and diaphragm wear, each needing specific troubleshooting strategies.

- Advancements in diaphragm pump technology, such as Graco Inc.'s QUANTM device, enhance efficiency and operational performance in construction projects.

Introduction

In the dynamic landscape of construction, diaphragm pumps have emerged as indispensable tools, facilitating the efficient movement of fluids across various applications. Their unique design allows them to handle everything from dewatering to slurry transfer, making them essential for maintaining operational safety and efficiency on job sites. As construction projects grow in complexity, understanding the importance and versatility of diaphragm pumps becomes paramount.

This article delves into the critical applications of diaphragm pumps, the advantages of renting them, and key considerations for selecting the right pump rental. Additionally, it highlights best practices and troubleshooting tips to ensure seamless operations. With insights into technological advancements and market trends, construction managers are equipped to make informed decisions that enhance project outcomes.

Understanding Diaphragm Pumps: Importance and Applications in Construction

Flexible membrane devices represent a crucial category of positive displacement mechanisms that utilize adaptable membranes for the efficient transportation of liquids, making them indispensable in the building sector. Their versatility enables them to excel across various applications, including dewatering, slurry transfer, and the management of abrasive materials. This adaptability is particularly vital on construction sites, where the ability to handle a diverse range of fluids—especially those with high solids content—ensures operational efficiency and safety.

Key Applications:

- Dewatering: Diaphragm devices play a vital role in removing excess water from excavations, essential for maintaining site integrity and preventing project delays. As of 2025, the demand for efficient dewatering solutions has surged, leading to a preference for diaphragm pump rental options due to their reliability and effectiveness.

- Slurry Transfer: These devices are ideally suited for transporting thick mixtures of solids and liquids, commonly encountered in building processes. Their design facilitates the seamless flow of slurries, minimizing the risk of clogs and ensuring uninterrupted operation.

- Chemical Handling: Diaphragm devices are also adept at securely transferring corrosive or hazardous substances, a necessity in many construction projects. Their ability to manage such materials without leakage enhances safety measures on-site.

The significance of membrane devices in construction projects cannot be overstated. As the industry evolves, reliance on these devices for various applications continues to grow, with current statistics indicating a notable increase in their usage across projects. Recent reports highlight that diaphragm pump rental is increasingly employed in dewatering applications, reflecting a broader trend towards more efficient and effective building practices.

Within the machinery market context, membrane pumps are categorized as positive displacement systems, segmented into . This classification provides insight into their market positioning and the technological advancements influencing their application in construction.

Practical examples further illustrate the importance of these devices. In a recent urban renewal project, dewatering devices were utilized for groundwater removal during foundation work, effectively controlling water levels and preventing site inundation. This scenario underscores the necessity of selecting the right diaphragm pump rental to ensure adherence to timelines and prioritization of safety.

Moreover, advancements in pumping technology, such as Graco Inc.'s introduction of the QUANTM device—featuring an electric motor design that is up to eight times more efficient than traditional pneumatic systems—highlight ongoing innovations in this sector.

Additionally, macroeconomic factors like inflation and interest rates are influencing the demand for membrane pumps in construction, as these financial conditions impact budgets and schedules.

In summary, comprehending the uses and advantages of membrane pumps is essential for managers in the construction industry. Their role in enhancing operational efficiency and safety on building sites, combined with current market dynamics and expert insights, positions them as an indispensable tool within the industry.

The Advantages of Renting Diaphragm Pumps for Construction Projects

Renting diaphragm pumps presents numerous advantages for construction projects, making it a strategic choice for project managers in 2025.

- Cost-Effectiveness is one of the primary benefits. By opting for diaphragm pump rental, construction teams can avoid the substantial upfront costs associated with purchasing diaphragm pumps. This approach allows for more efficient allocation of budget resources, enabling funds to be directed toward other critical needs.

- Flexibility is another significant advantage. Rental agreements can be tailored to match specific timelines, ensuring that equipment is available exactly when needed. This adaptability is especially advantageous in evolving building environments where scopes may change.

- Moreover, Access to Latest Technology is a key benefit of renting. Rental companies frequently update their inventory with the latest models, providing construction managers with access to cutting-edge technology. This ensures that endeavors benefit from the most efficient and reliable equipment available, enhancing overall productivity.

- Additionally, Maintenance and Support are crucial aspects of renting. One of the significant advantages is that rental companies typically manage maintenance and repairs. This relieves the strain on project teams, ensuring that membrane devices are always in optimal condition and prepared for use.

In 2025, the construction rental industry is expected to experience modest growth, with a steady Confidence Index indicating a positive outlook. This trend highlights the growing acknowledgment of the cost-efficiency of equipment rentals, especially for specific types of machinery. For example, case studies have demonstrated that comprehending the specific needs and expenses related to specialty apparatus, such as membrane systems, enables rental providers to more effectively inform clients and enhance pricing strategies.

Notably, specialty equipment often comes with higher rental rates and may require specific training or certifications for operation. Furthermore, expert opinions highlight that the transition to renting equipment not only supports budget management but also aligns with sustainability goals. Coates has reduced its GHG emissions footprint by approximately 30% since 2020, showcasing the environmental benefits of renting equipment. As the sector progresses towards decreasing greenhouse gas emissions, provides a practical solution for initiatives aiming to lessen their environmental footprint while preserving operational efficiency.

Nathan Venables, General Manager of Fleet, notes that "battery, solar, and hybrid power solutions are becoming more accessible, efficient, and cost-effective, making them a viable alternative to traditional diesel-powered generators for many sites." With these benefits, leasing diaphragm pump rental devices appears as a wise option for construction supervisors aiming to improve results in 2025.

Choosing the Right Diaphragm Pump Rental: Key Considerations

When selecting , several critical factors must be taken into account to ensure optimal performance and compatibility with project requirements.

- Fluid Type is paramount; it is essential to verify that the materials are suitable for the fluids being handled. This is especially important for corrosive or abrasive substances, as improper material compatibility can lead to equipment failure and delays.

- Next, accurately determining the Flow Rate and Pressure Requirements is vital. Diaphragm devices are designed to manage different flow rates, and understanding the specific requirements of your task will assist in choosing a device that can effectively meet those needs.

- Additionally, evaluate the Pump Size and Portability. Consider the physical space available at the job site and the need for mobility. Certain initiatives may necessitate regular movement of the device, making portability a crucial aspect in your selection process. Compact and lightweight models can facilitate easier transport and setup.

- The diaphragm pump rental service offers various options tailored to your needs. Rental Terms should be carefully reviewed, paying close attention to the duration of the rental, associated costs, and maintenance responsibilities. Understanding these terms can prevent unexpected expenses and ensure that the equipment remains in optimal condition throughout the rental period.

As the membrane device market continues to develop, with forecasts showing an increase from $6.58 billion in 2024 to $7.13 billion by 2025, it is essential for project managers to remain updated on the latest innovations and choices available. This knowledge not only aids in making informed decisions but also enhances the efficiency and effectiveness of construction projects. Notably, the Asia-Pacific region is recognized as the largest and fastest-growing market for diaphragm devices, which may influence sourcing decisions.

Furthermore, advancements in fluid transfer technology are significant. As noted by Graco Inc., "This innovative device, which boasts a revolutionary new electric motor design, offers efficiency that outperforms conventional pneumatic systems by up to eight times." Grasping these technological advancements is crucial for managers in the building sector when evaluating their options. Additionally, the challenges rental companies face in keeping their fleets updated due to rapid technological advancements should be acknowledged, as this can impact the attractiveness of existing rental offerings.

Step-by-Step Guide to Renting Diaphragm Pumps: From Inquiry to Delivery

To successfully rent a diaphragm pump for your construction project, follow these essential steps:

- Identify Your Needs: Begin by assessing the specific requirements of your project. Consider factors such as the type of fluid you will be pumping, the required flow rate, and the anticipated duration of use. This clarity will assist you in choosing the right device for your needs.

- : Explore rental companies that specialize in diaphragm pump rentals to identify reputable businesses. EZ Equipment Rental stands out for its extensive inventory and commitment to customer satisfaction, making it a reliable choice in the Dallas-Fort Worth area. Their expert guidance ensures you find the right equipment suited to your requirements. Additionally, consider looking for rental software that features a user-friendly online booking system and robust reporting capabilities to streamline your research process.

- Request Quotes: Reach out to multiple rental companies to obtain quotes. This will allow you to compare pricing, rental terms, and any additional services offered, ensuring you make an informed decision. According to industry insights, understanding customer needs is crucial, as highlighted by Kyle's completion of thousands of customer interviews in the equipment rental market.

- Negotiate Terms: Once you have your quotes, engage in discussions with the rental companies. Negotiate terms related to delivery, maintenance, and any potential additional fees. This step is crucial for ensuring that you understand all aspects of the rental agreement.

- Review the Agreement: Before finalizing your rental, carefully read through the rental agreement. Pay close attention to your responsibilities, the company’s policies, and any liability clauses. It is essential to understand payment details and insurance options, as these can prevent misunderstandings later on. As Kevin Forestell, CEO of DOZR, emphasizes, "Effective communication with rental companies is key to ensuring a smooth rental process."

- Schedule Delivery: Finally, arrange for the device to be delivered to your job site. Ensure that all necessary preparations are made for its arrival, including access for delivery personnel and any required setup.

By adhering to these steps, you can simplify the procedure of renting a diaphragm pump, ensuring that you possess the appropriate equipment to fulfill your project’s requirements effectively. With EZ Equipment Rental's customer-centric service and diverse offerings, including diaphragm pump rental and locations throughout the Dallas-Fort Worth area, you can unlock efficiency and elevate your projects. Reach out to EZ Equipment Rental today to begin your rental of the pumping device!

Furthermore, think about referring to user manuals for comprehensive guidance on operating the diaphragm pump efficiently.

Best Practices for Utilizing Diaphragm Pumps on Construction Sites

To ensure optimal performance of diaphragm pumps on construction sites, it is essential to adhere to best practices that enhance reliability and efficiency.

- Regular Maintenance: Implement a routine maintenance schedule to inspect the device's functionality. This includes checking hoses and connections for leaks, which can significantly impact efficiency. Regular maintenance not only extends the lifespan of the device but also reduces the likelihood of unforeseen breakdowns that can disturb project schedules. Notably, pumping systems account for over 40% of industrial energy use, making efficient operation and maintenance crucial for reducing energy consumption.

- Proper Setup: Install the device on a stable, level surface to prevent operational issues. Additionally, keep suction lines as short as possible to reduce resistance and enhance flow efficiency. A properly configured device can function at optimal efficiency, guaranteeing that building activities progress seamlessly.

- Monitor Performance: Actively monitor flow rates and pressure levels during operation. This vigilance allows for the early detection of potential issues, enabling timely interventions that can prevent costly downtime. Statistics indicate that effective performance monitoring can lead to a 20% increase in operational efficiency on construction sites.

- Training Operators: Ensure that all personnel operating the diaphragm device receive comprehensive training. Familiarity with the device's operation and safety protocols is crucial for preventing accidents and ensuring efficient use. Well-trained operators can identify and address issues quickly, maintaining productivity on site. As Leighton Jones, Director of Sales for AODD Devices, states, "Whether an AODD unit is leaking, has inadequate flow, will not prime or will not cycle, managers can use the above checklists to find the root cause."

- Emergency Procedures: Establish clear emergency procedures for addressing malfunctions or unexpected situations. Having a plan in place ensures that all team members know how to respond effectively, minimizing risks and maintaining safety standards. A pertinent case study titled 'Identifying Leaks in AODD Pumps' emphasizes the significance of checking bolt tightness, inspecting manifold O-rings, and ensuring that seals are secure to prevent leaks, which aligns with discussed.

By adhering to these best practices, construction managers can significantly improve the reliability and efficiency of their diaphragm pump rental devices, ultimately aiding the success of their projects.

Troubleshooting Common Issues with Diaphragm Pump Rentals

Common issues encountered with diaphragm devices and their corresponding solutions include:

- Pump Not Priming: This issue often arises from blockages in the suction line or improper positioning of the device. To resolve this, ensure that the suction line is clear and that the device is installed at the correct angle to facilitate fluid movement.

- Low Flow Rate: A low flow rate can indicate leaks within the system or that the device may be undersized for the specific application. Conduct a thorough inspection for any leaks and assess whether the device's capacity meets the demands of the task at hand.

- Excessive Vibration: Vibration can result in premature wear and tear on the device. To mitigate this, ensure that the device is securely mounted and that the suction line is appropriately sized and not excessively long, as restrictive lines can contribute to vibration issues.

- Air Leaks: Air leaks can severely affect the performance of the device. Regularly check all connections and seals for tightness, as even minor leaks can lead to significant operational inefficiencies.

- Diaphragm Failure: Diaphragm wear is a common issue that can lead to operational failures. Establish a regular inspection timetable to assess the state of membranes and substitute them as needed to ensure peak performance.

Membrane systems are extensively employed in diverse sectors, such as agriculture, automotive, chemical processing, food and beverage, and water treatment, underscoring their adaptability and significance in fluid management applications. In 2025, statistics indicate that membrane device failures often arise from these frequent problems, emphasizing the significance of proactive upkeep and diagnostics. For example, a case study on membrane maintenance highlighted that consistent lubrication of moving components greatly prolongs the lifespan of the devices, decreasing the chances of leaks and pressure issues.

As noted in the Machinery Global Market Report 2025, understanding the types of machinery and their applications is crucial for effective equipment management. Furthermore, Graco Inc. introduced , which features a revolutionary electric motor design that is up to 8 times more efficient than traditional pneumatic systems, showcasing advancements in technology. By addressing these common challenges with effective solutions, construction managers can ensure the reliability and efficiency of diaphragm pump rental services in their projects.

Conclusion

Diaphragm pumps are indispensable in modern construction, providing exceptional versatility and efficiency across a range of applications, from dewatering to chemical handling. Their innovative design facilitates the safe and effective transfer of fluids, particularly in demanding environments where managing high solids content is crucial. As the construction industry progresses, the escalating demand for diaphragm pumps underscores their vital role in ensuring operational safety and efficiency on job sites.

Renting diaphragm pumps offers a strategic advantage for construction managers, enabling cost-effective solutions that align with project timelines and technological advancements. The flexibility of rental agreements, along with access to the latest models and reduced maintenance responsibilities, makes renting an appealing option for projects of any scale. Moreover, the environmental benefits associated with equipment rentals highlight the industry's commitment to sustainability, as companies strive to reduce their carbon footprints while sustaining productivity.

Choosing the appropriate diaphragm pump rental requires careful consideration of various factors, such as fluid compatibility, flow rates, and rental terms. By adhering to maintenance and operational best practices, construction teams can optimize the performance and longevity of these pumps, ensuring seamless project execution. Additionally, being proactive in troubleshooting common issues can avert costly downtime and enhance overall project efficiency.

In summary, grasping the essential applications, rental advantages, and operational best practices related to diaphragm pumps equips construction managers to make informed decisions. By leveraging these insights, projects can achieve superior outcomes, reinforcing the significance of diaphragm pumps as a cornerstone of successful construction practices in an increasingly complex industry.

Frequently Asked Questions

What are flexible membrane devices and their significance in construction?

Flexible membrane devices are positive displacement mechanisms that utilize adaptable membranes to efficiently transport liquids. They are crucial in the building sector due to their versatility, enabling applications such as dewatering, slurry transfer, and managing abrasive materials, which are vital for operational efficiency and safety on construction sites.

What are the key applications of diaphragm devices in construction?

The key applications include: Dewatering: Removing excess water from excavations to maintain site integrity and prevent delays. Slurry Transfer: Transporting thick mixtures of solids and liquids, minimizing clogging risks. Chemical Handling: Securely transferring corrosive or hazardous substances, enhancing on-site safety.

Why is there an increasing demand for diaphragm pump rental options in 2025?

The demand for efficient dewatering solutions has surged, leading to a preference for diaphragm pump rentals due to their reliability and effectiveness, especially in construction projects where managing water levels is critical.

How are membrane pumps categorized in the machinery market?

Membrane pumps are categorized as positive displacement systems, segmented into automatic and semi-automatic systems, providing insight into their market positioning and technological advancements.

Can you provide an example of diaphragm devices in action?

In a recent urban renewal project, dewatering devices were used for groundwater removal during foundation work, effectively controlling water levels and preventing site inundation, highlighting the importance of selecting the right diaphragm pump rental.

What technological advancements are influencing membrane pump efficiency?

Recent innovations, such as Graco Inc.'s QUANTM device, feature an electric motor design that is up to eight times more efficient than traditional pneumatic systems, showcasing ongoing improvements in pumping technology.

What are the advantages of renting diaphragm pumps for construction projects?

The advantages include: Cost-Effectiveness: Avoiding substantial upfront costs and allowing better budget allocation. Flexibility: Tailored rental agreements to match specific project timelines. Access to Latest Technology: Rental companies provide updated models, ensuring efficient equipment usage. Maintenance and Support: Rental companies typically handle maintenance and repairs, ensuring optimal equipment condition.

How is the construction rental industry expected to evolve in 2025?

The construction rental industry is expected to experience modest growth, with a positive outlook reflected in a steady Confidence Index, highlighting the growing recognition of the cost-efficiency of equipment rentals.

What sustainability benefits are associated with renting equipment?

Renting equipment can support sustainability goals, as it helps reduce greenhouse gas emissions. For instance, Coates has reduced its GHG emissions footprint by approximately 30% since 2020, showcasing the environmental benefits of the rental model.

What alternative power solutions are becoming more accessible for construction sites?

Battery, solar, and hybrid power solutions are becoming more accessible, efficient, and cost-effective, providing viable alternatives to traditional diesel-powered generators for construction sites.