Introduction

In the realm of surface preparation, dustless blasting has emerged as a revolutionary method that addresses the common challenges associated with traditional blasting techniques. By integrating water with abrasive materials, this innovative approach not only minimizes airborne dust but also protects surfaces from damage, making it an ideal solution for various projects, from automotive restoration to industrial cleaning.

Understanding how to effectively utilize this technology is crucial for anyone looking to enhance their project outcomes. With the right knowledge and equipment, professionals can navigate the complexities of dustless blasting, ensuring safety and efficiency while achieving superior results.

As the demand for this method grows across industries, so too does the need for clear guidance on how to:

- Rent these powerful tools

- Operate them safely

- Maintain them effectively

Understanding Dustless Blasting: What You Need to Know

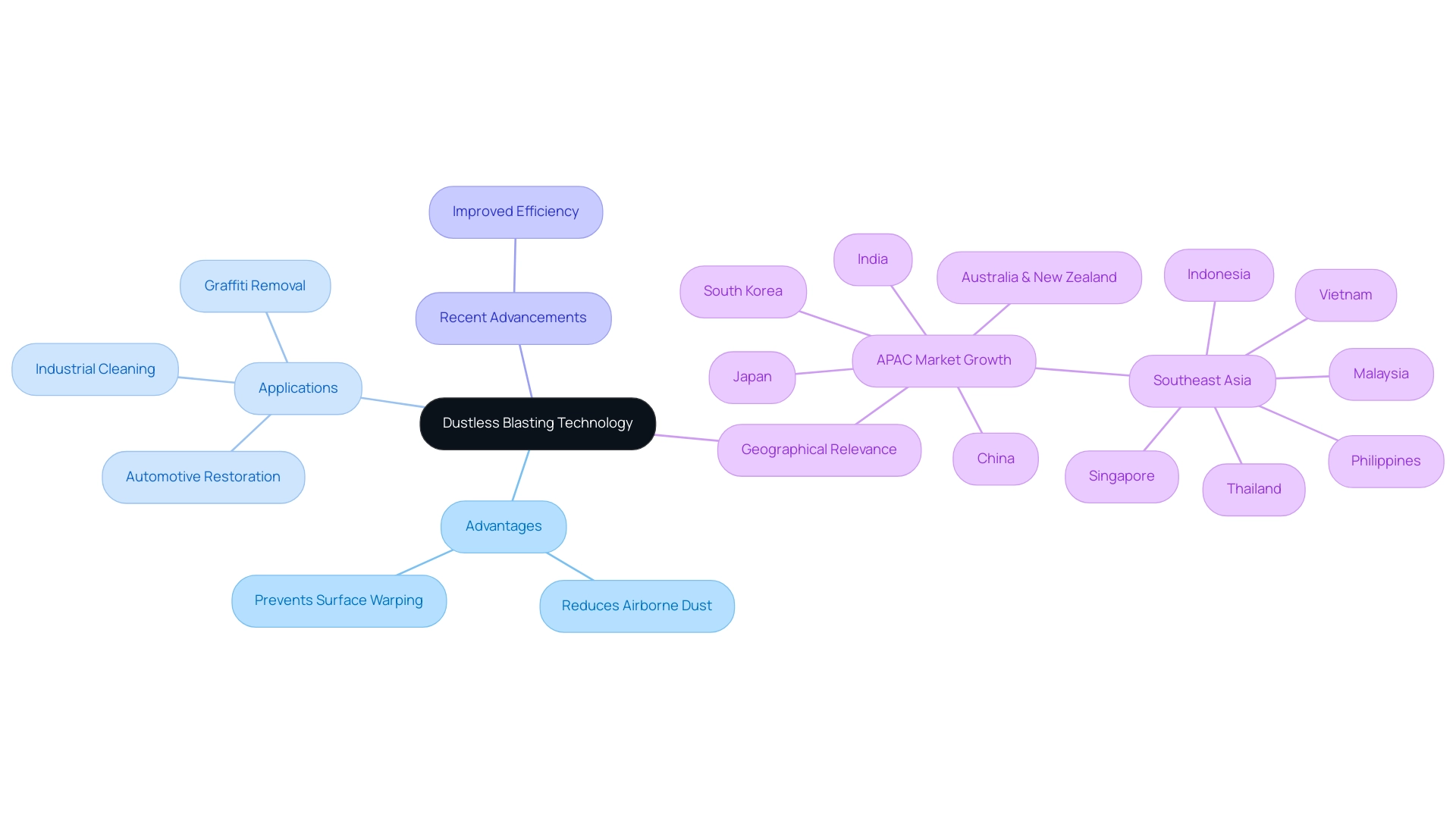

Dustless technology represents a groundbreaking advancement in surface preparation, effectively combining water and abrasive materials to significantly reduce airborne dust and debris. This method is particularly advantageous for a variety of projects, including:

- Surface cleaning

- Paint removal

- Rust eradication

The incorporation of water not only mitigates dust but also cools the surface, thereby preventing warping or damage that can occur during traditional blasting methods.

Grasping the nuances of this technology is essential for selecting the right tools and achieving optimal results. Its applications span across numerous industries, including:

- Automotive restoration

- Industrial cleaning

- Graffiti removal

Familiarizing yourself with these diverse uses will enable you to better evaluate your specific needs when considering a dustless blaster rental near me.

Recent advancements in non-abrasive cleaning technology have further improved its efficiency and effectiveness, making it an increasingly popular choice among project managers aiming to tackle challenging surface preparation tasks. However, it's important to note that while particle-free abrasion significantly reduces airborne particles, it does not eliminate them entirely, as observed in conventional wet abrasion processes where not all sub-particles are encapsulated.

Additionally, keeping your team motivated through project challenges is crucial; employing strategies to break down goals, provide support, and foster positivity can enhance project outcomes in surface preparation tasks.

Furthermore, the technology's relevance is underscored in leading markets such as China, Japan, South Korea, and , where its adoption is on the rise.

Step-by-Step Guide to Finding and Renting a Dustless Blaster

-

Investigate nearby leasing firms to find near me by examining online resources for leasing services in your area, especially in Irving, TX. Utilize keywords like 'dustless blaster rental near me' to pinpoint local options. Pay close attention to customer reviews and ratings, which can provide insights into the reliability and quality of service offered by different companies serving the DFW Metroplex, including popular choices for boom lifts, excavators, and forklifts. Prominent firms consist of [Company Name] at [Contact Information] and [Company Name] at [Contact Information], both recognized for their outstanding service and product diversity.

Evaluate Equipment Options: After identifying , assess the variety of dustless blaster rental near me options available. Ensure that the tools align with the specific requirements of your project, including size, power, and functionality. Opt for well-maintained machines that come with a solid reputation to guarantee performance. Numerous leasing services in the area also provide extra machinery like trailers and other lifting tools to improve your project's efficiency, frequently with promotional deals that can lower expenses.

Contact Leasing Firms: Engage with the selected leasing firms to gather essential information. Ask about the availability of tools, pricing, and any extra fees such as delivery costs or insurance. It’s also crucial to ask about the specifications of the equipment and whether they provide training on its operation, as this can enhance safety and efficiency, especially when using specialized equipment like a dustless blaster rental near me.

Compare Lease Terms: Take the time to scrutinize the terms and conditions offered by each leasing company. Look for adaptable leasing periods, support for maintenance, and transparent policies regarding damage or repairs. Comprehending the lease agreement thoroughly will help you avoid unexpected issues down the line.

Complete Your Lease: After selecting a leasing company that fulfills your requirements, proceed to finalize the lease agreement. Sign the necessary documents and make any required payments. Coordinate a pickup or delivery schedule that fits seamlessly into your project timeline.

Prepare for Use: Before using the blaster, take the time to become acquainted with the tools. Adhere to the manufacturer’s instructions for setup and operation. If training is available through the rental company, seize the opportunity to ensure safe and effective use of the equipment, optimizing your operational efficiency.

In 2024, the average rental costs for blasting machines in the DFW area can vary significantly, ranging from $75 to $300 per hour, depending on factors like surface type and job complexity. Understanding these costs and how they translate to time saved can lead to substantial financial savings in your projects. As you embark on this journey, remember that 'Entrepreneurship is a learning process and a journey of discovery.

You don’t need to know everything to take the first small step.' Referencing a case study on non-dust blasting pricing, it’s important to note that costs can vary based on surface type and job complexity, with vehicle part cleaning ranging from $40 to $990, illustrating how informed choices can lead to better project outcomes.

Safety Considerations When Using a Dustless Blaster

Prioritizing safety is paramount when using a blaster that produces no dust. Consider the following critical guidelines to ensure a secure working environment:

-

Personal Protective Equipment (PPE): Always don appropriate PPE, including safety goggles, gloves, and a reliable respiratory mask. This essential gear shields you from hazards such as flying debris and the inhalation of fine particles, which can lead to serious health issues.

For instance, overexposure to zinc or copper can result in metal fume fever, presenting acute pneumonia-like symptoms. NIOSH recommends that medical examinations for crystalline silica exposure include a chest X-ray and pulmonary function testing, underscoring the importance of monitoring health in this line of work.

-

[Work Area Preparation](https://blog.ezequipmentrental.com/3-essential-tips-for-pneumatic-nail-gun-rental-success): Keep your work area free from obstacles and ensure adequate ventilation. In indoor settings, utilize fans or exhaust systems to effectively direct dust and particles outside, thereby minimizing exposure risks, particularly when using near me.

-

Equipment Inspection: Conduct thorough inspections of the dustless blaster rental near me before use, checking for any signs of wear or damage. Ensure all hoses and connections are secure to prevent leaks that could compromise safety.

-

Follow Manufacturer Guidelines: Adhere strictly to the manufacturer’s operating instructions. This encompasses comprehending pressure settings and the proper mixing of abrasive materials to ensure effective and safe operations.

-

Emergency Procedures: Familiarize yourself with emergency protocols in case of accidents. Keep a first aid kit on hand and be prepared to contact emergency services promptly if necessary. As stated by specialists,

Don’t believe the myth: the process generates dust, regardless of the tools,

emphasizing the significance of these safety precautions. Additionally, it is crucial to implement measures to mitigate heat-related illnesses, particularly in challenging environments where PPE can exacerbate the risk, as highlighted in case studies. Before acquiring abrasive jetting tools, it is advisable to ask for an air quality report from an impartial third party to enhance safety and confirm dust suppression assertions, particularly when looking for a dustless blaster rental near me. By adhering to these guidelines, you can greatly minimize the risk of injuries and guarantee a safer work environment during clean surface preparation operations.

Post-Rental Equipment Care and Maintenance

Proper maintenance of the blasting tools after use is essential to ensure their longevity and functionality for future projects. Here are key maintenance practices to follow:

-

Thorough Cleaning: After each use, it’s crucial to clean the dustless blaster meticulously. This includes removing any residual abrasive materials and debris, which can prevent clogs and potential damage to the machinery.

Neglecting this step may result in expensive repairs or reduced efficiency during later tasks.

-

Damage Inspection: Regularly examine the machinery for any signs of wear or damage that might have occurred during operation. Identifying issues early can save time and resources. If any problems are detected, report them immediately to the leasing company to ensure swift resolution.

-

Torque Settings Check: Check the torque settings on the water pump bolts every 10-20 hours of blasting to maintain optimal performance and prevent mechanical failures.

-

Fuel Filter Replacement: Replace the fuel filter (and pre-filter if present) at the first 50 hours of use, and then every 500 hours thereafter, to ensure proper fuel flow and engine operation.

-

Timely Return: Adhere to the agreed-upon return date to avoid incurring additional fees. When returning the items, ensure they are securely packed to prevent any transit damage. This not only preserves the equipment’s condition but also encourages a positive relationship with the leasing company.

-

Provide Constructive Feedback: Sharing your experiences, whether positive or negative, with the leasing company can lead to enhancements in their services and equipment offerings. As Scott Faust, an owner in the industry, noted,

I am quickly learning that having a mobile blaster on hand is becoming another business of its own. We find ourselves engaging in only exciting jobs which is really nice. Input from clients assists rental firms in comprehending their customers' requirements more effectively.

-

Real-World Example: A notable marine repair shipyard on the Mexican Pacific coast switched to a non-dust method for epoxy removal, leading to a 31.82% rise in coating removal speed. This case illustrates the effectiveness of dustless blasting equipment and emphasizes the importance of proper maintenance to achieve such results, particularly when considering a dustless blaster rental near me. By following , construction project managers can extend the lifespan of dustless blasters and optimize their performance, ensuring readiness for future projects.

Conclusion

Dustless blasting stands out as a transformative method in surface preparation, offering significant advantages over traditional techniques. By effectively combining water and abrasives, it minimizes airborne dust and protects surfaces from damage, making it suitable for various applications such as automotive restoration and industrial cleaning. Understanding the intricacies of this technology, from selecting the right equipment to adhering to safety protocols, is essential for maximizing project outcomes.

Securing a dustless blaster involves a systematic approach, starting with:

- Thorough research on local rental options

- Evaluating equipment types

- Ensuring the alignment of the equipment's capabilities with project requirements

Engaging with rental companies to clarify terms and conditions, as well as familiarizing oneself with the equipment before use, can lead to a smoother operational experience. Moreover, being aware of rental costs and their implications on project budgets allows for informed financial decisions.

Safety cannot be overlooked when operating dustless blasting equipment. Adhering to personal protective equipment guidelines, ensuring proper work area preparation, and following manufacturer instructions are critical steps in mitigating risks. Regular maintenance of the equipment post-use is also vital for its longevity, involving thorough cleaning and inspections to maintain optimal performance.

As the industry increasingly adopts dustless blasting, mastering its use and care not only enhances project efficiency but also contributes to a safer working environment. By prioritizing safety, proper rental practices, and diligent maintenance, professionals can harness the full potential of this innovative technology, leading to superior results in surface preparation tasks. Embracing dustless blasting is not just a choice; it’s a strategic move towards achieving excellence in various projects.

Frequently Asked Questions

What is dustless technology in surface preparation?

Dustless technology is an advanced method that combines water and abrasive materials to significantly reduce airborne dust and debris during surface preparation.

What are the primary applications of dustless technology?

The primary applications include surface cleaning, paint removal, and rust eradication.

How does dustless technology prevent damage to surfaces?

The incorporation of water in dustless technology not only reduces dust but also cools the surface, preventing warping or damage that can occur with traditional blasting methods.

In which industries is dustless technology commonly used?

Dustless technology is commonly used in automotive restoration, industrial cleaning, and graffiti removal.

What recent advancements have been made in non-abrasive cleaning technology?

Recent advancements have improved the efficiency and effectiveness of non-abrasive cleaning technology, making it a popular choice for project managers dealing with challenging surface preparation tasks.

Does dustless technology eliminate airborne particles completely?

No, while dustless technology significantly reduces airborne particles, it does not eliminate them entirely, as some sub-particles may not be encapsulated during the process.

Why is it important to keep a team motivated during surface preparation projects?

Keeping the team motivated is crucial for overcoming project challenges, and employing strategies to break down goals, provide support, and foster positivity can enhance project outcomes.

Where is dustless technology gaining popularity?

Dustless technology is becoming increasingly popular in leading markets such as China, Japan, South Korea, and other APAC countries.