Overview

To rent a dustless blaster for your construction project, follow a structured process that includes:

- Finding local suppliers

- Checking equipment availability

- Understanding lease conditions

- Ensuring the equipment's proper functioning upon receipt

This process is crucial for a successful rental experience and efficient project execution. Preparation is key; define the project scope and assess site conditions to maximize the effectiveness of the equipment. By taking these steps, you not only ensure the reliability of the tools you rent but also contribute to the overall success of your project.

Key Highlights:

- Dustless blasting combines water and abrasives to reduce dust and environmental impact.

- Key benefits include reduced dust emissions, versatility across different surfaces, increased efficiency, and less cleanup required.

- The rental process involves finding local suppliers, checking availability, understanding lease conditions, making a reservation, and ensuring equipment condition upon receipt.

- Key considerations before renting include defining project scope, assessing site conditions, ensuring proper safety gear, scheduling training, and establishing a budget.

- Common issues during rental include equipment malfunction, insufficient water supply, inadequate training, and unexpected costs, which can be managed with proactive troubleshooting.

Introduction

Dustless blasting has transformed surface preparation in construction, providing a cleaner and more efficient alternative to traditional methods. This innovative technique not only reduces airborne dust but also enhances safety and minimizes cleanup time, establishing itself as a vital asset for any project.

However, navigating the rental landscape for a dustless blaster can present challenges. How can one ensure a seamless experience and fully leverage the advantages of this advanced equipment? Understanding the rental process is crucial to maximizing the benefits of dustless blasting.

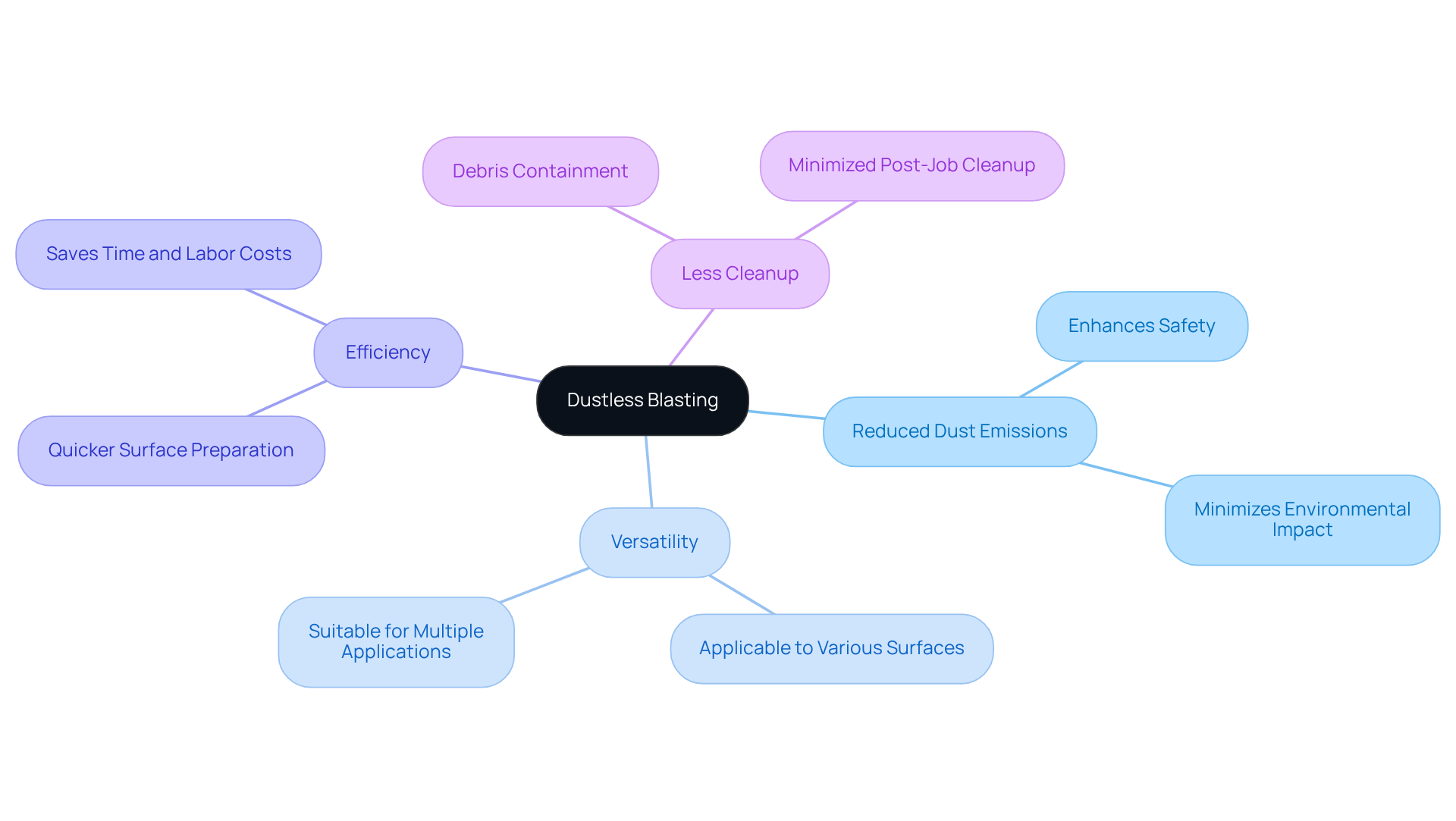

Understand Dustless Blasting: Benefits and Applications

Dustless blasting represents an innovative surface preparation method that effectively combines water and abrasive materials to minimize dust and reduce environmental impact. This technique is especially advantageous for projects that involve paint removal, surface cleaning, or restoration work. The key benefits of dustless blasting are as follows:

- Reduced Dust Emissions: Unlike traditional blasting methods, dustless blasting significantly lowers airborne dust levels, enhancing safety for both workers and the environment.

- Versatility: This method is applicable to a variety of surfaces, including metal, wood, and concrete, making it suitable for a broad range of applications.

- Efficiency: The synergy of water and abrasive materials facilitates quicker surface preparation, ultimately saving time and labor costs.

- Less Cleanup: The water utilized in the process effectively contains debris, thereby minimizing the cleanup required once the job is completed.

Understanding these advantages will empower you to make an informed decision regarding whether a dust-free device is the ideal choice for your construction project.

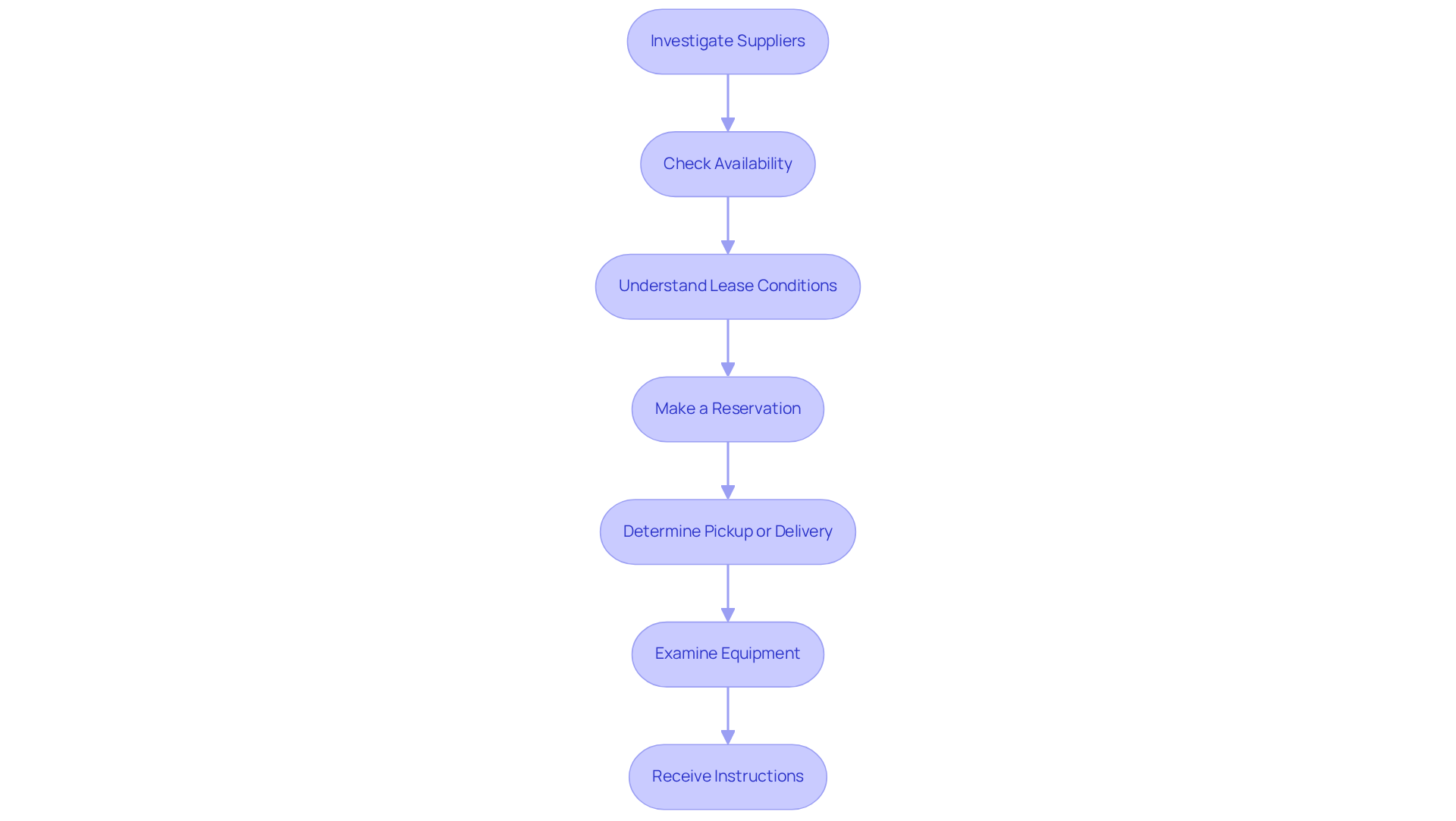

Follow the Rental Process: Step-by-Step Instructions

To rent a dustless blaster, follow these essential steps to ensure a seamless experience:

- Investigate local equipment suppliers that offer dust-free blasting devices. EZ Equipment Rental is a premier choice in the Dallas-Fort Worth area for those who want to rent a dustless blaster, known for its reliability and quality.

- Check availability by contacting the company to confirm if you can rent a dustless blaster for your desired booking dates. This step is crucial to avoid any last-minute surprises.

- Understand the lease conditions, including duration, pricing, and any additional fees such as delivery or insurance, when you rent a dustless blaster. This knowledge will help you budget effectively and avoid unexpected costs.

- Once you have verified availability and terms, make a reservation by supplying necessary details, including your name, contact information, dates of use, and any request to rent a dustless blaster. Securing your ability to rent a dustless blaster early ensures you have the equipment when you need it.

- Determine whether you will pick up the equipment or if the leasing service will deliver it to your job site. Verify the logistics with the leasing company to ensure a smooth process, as this can save you time and hassle.

- Upon receiving the rent dustless blaster, examine it for any damage or missing components. Ensure that the equipment, specifically the rent dustless blaster, is in good working condition before signing any lease agreements, as this protects you from potential issues later.

- Finally, receive instructions by requesting a demonstration or comprehensive guidelines on how to use the rent dustless blaster safely and effectively. This step is vital for maximizing the efficiency of your project.

By following these steps, you can focus on your construction project with confidence, knowing that you have secured the right equipment for the job.

Prepare for Rental: Key Considerations and Requirements

Before you rent a dustless blaster, it is essential to consider several key factors that will ensure the successful execution of your project.

- Project Scope: Begin by clearly defining the project scope. This will allow you to determine the appropriate size and type of dustless blaster required. Understanding the specific tasks at hand is crucial for selecting the right equipment.

- Site Conditions: Next, assess the job site for accessibility and potential hazards that could impact the use of the equipment. Factors such as terrain stability and proximity to sensitive areas must be evaluated to ensure safe operation.

- Safety Gear: Proper safety gear is non-negotiable. Statistics show that the use of appropriate safety gear significantly reduces injury rates on construction sites. Ensure that all operators are equipped with the necessary safety gear, including goggles, gloves, and protective clothing, to safely operate the rent dustless blaster.

- Training: If you or your team lack experience with a rent dustless blaster, consider scheduling training sessions or reviewing instructional materials provided by the leasing firm. Be aware that some leasing companies may charge extra fees for operator training services, so it's important to factor this into your planning. Proper training is vital for the safe and effective use of the equipment.

- Budget: Finally, establish a comprehensive budget for the rent dustless blaster. Account for additional costs such as supplies, safety gear, labor expenses, and potential delivery fees. This proactive approach will help you avoid unexpected expenses and keep the project on track.

By adequately preparing for these factors, you can significantly increase the chances of a successful leasing experience and ensure smooth project execution.

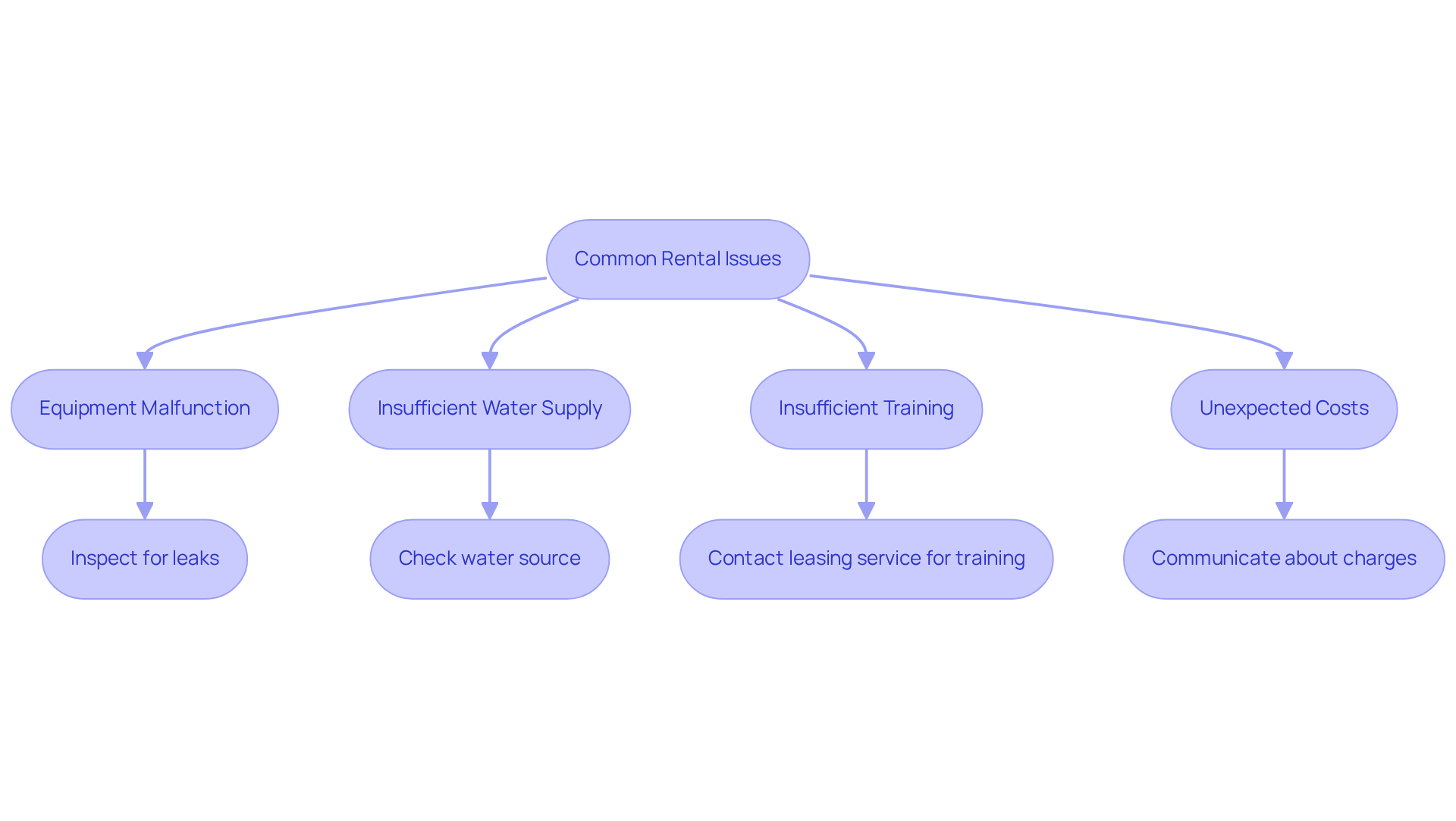

Troubleshoot Common Issues: Ensuring a Successful Rental Experience

Even with careful planning, challenges may arise during the leasing process. Understanding these common problems and knowing how to troubleshoot them is essential for a smooth experience:

- Equipment Malfunction: Should the dustless blaster fail to operate correctly, begin by inspecting for visible issues such as leaks or blockages. Consult the user manual for troubleshooting tips, or reach out to the leasing service for expert assistance.

- Insufficient Water Supply: It's crucial to ensure a reliable water source is available at the job site. An inadequate water supply can significantly impact the performance of the rent dustless blaster.

- Insufficient Training: If you or your team encounter difficulties using the equipment, do not hesitate to contact the leasing service for additional training or resources.

- Unexpected Costs: Stay vigilant regarding any extra charges that may arise during the leasing period. Open communication with the leasing company can clarify any charges and help you avoid surprises.

By proactively addressing these common issues, you can secure a successful rental experience when you rent a dustless blaster and efficiently complete your construction project.

Conclusion

Dustless blasting stands out as a revolutionary method for surface preparation in construction, presenting a cleaner and safer alternative to traditional blasting techniques. By integrating water with abrasive materials, this method not only minimizes dust emissions but also boosts efficiency and reduces cleanup time. Recognizing the advantages of dustless blasting equips project managers and contractors to select the most appropriate equipment for their needs.

This article delineates a thorough rental process for dustless blasters, underscoring the significance of preparation and planning. Essential steps include:

- Researching local suppliers

- Confirming equipment availability

- Comprehending lease terms

- Ensuring proper training and safety measures

Furthermore, anticipating potential challenges—such as equipment malfunctions or unforeseen costs—facilitates a smoother rental experience.

Incorporating dustless blasting into construction projects enhances operational efficiency and showcases a commitment to environmental stewardship. As the construction industry evolves, adopting innovative methods like dustless blasting leads to superior results and a safer working environment. For those contemplating a dustless blaster rental, investing time in adequate preparation and understanding the process will ultimately contribute to the success of their projects.

Frequently Asked Questions

What is dustless blasting?

Dustless blasting is an innovative surface preparation method that combines water and abrasive materials to minimize dust and reduce environmental impact.

What are the main benefits of dustless blasting?

The main benefits include reduced dust emissions, versatility for various surfaces, increased efficiency in surface preparation, and less cleanup required after the job is completed.

How does dustless blasting reduce dust emissions?

Dustless blasting significantly lowers airborne dust levels compared to traditional blasting methods, enhancing safety for both workers and the environment.

What surfaces can dustless blasting be used on?

Dustless blasting is applicable to a variety of surfaces, including metal, wood, and concrete.

Why is dustless blasting considered efficient?

The combination of water and abrasive materials in dustless blasting facilitates quicker surface preparation, ultimately saving time and labor costs.

How does dustless blasting minimize cleanup?

The water used in the dustless blasting process effectively contains debris, thereby reducing the amount of cleanup needed after the job is completed.